lock PEUGEOT 3008 2020 Repair Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: 3008, Model: PEUGEOT 3008 2020Pages: 308, PDF Size: 10.1 MB

Page 182 of 308

180

Practical information

8.Engine oil filler cap

9. Engine oil dipstick

10. Priming pump*

11 . Degassing screw*

The Diesel fuel system operates under

very high pressure.

All work on this circuit must be carried out

only by a PEUGEOT dealer or a qualified

workshop.

Checking levels

Check all of the following levels regularly in

accordance with the manufacturer's service

schedule. Top them up if required, unless

otherwise indicated.

If a level drops significantly, have the

corresponding system checked by a PEUGEOT

dealer or a qualified workshop.

The fluids must comply with the manufacturer's requirements and with

the vehicle's engine.

Take care when working under the bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and the

cooling fan could start at any time (even with

the ignition off).

* Depending on engine.

Take care with objects or clothing that

could be caught in the blades of the fan!

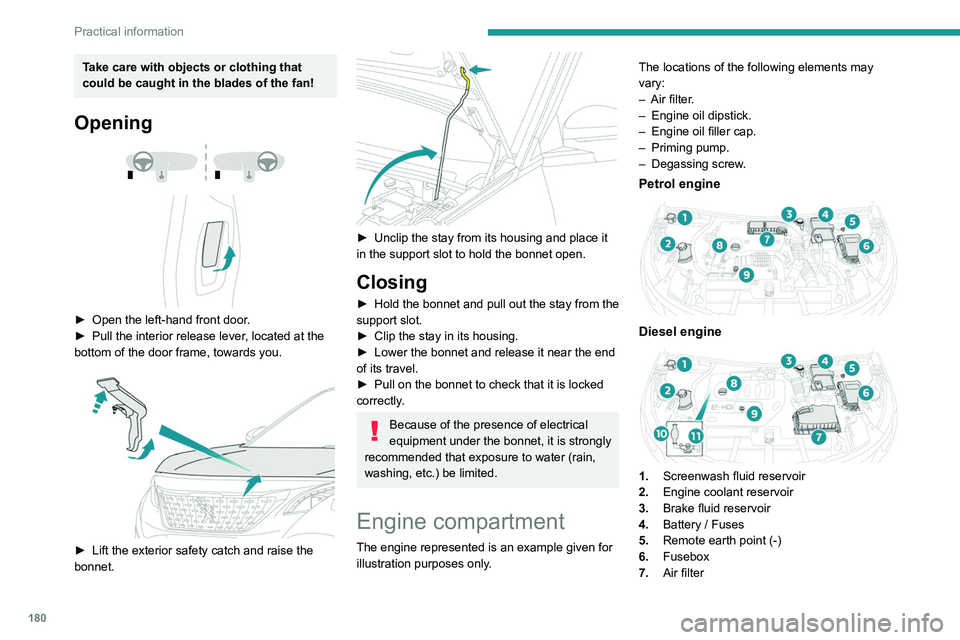

Opening

► Open the left-hand front door .

► Pull the interior release lever , located at the

bottom of the door frame, towards you.

► Lift the exterior safety catch and raise the

bonnet.

► Unclip the stay from its housing and place it

in the support slot to hold the bonnet open.

Closing

► Hold the bonnet and pull out the stay from the

support slot.

►

Clip the stay in its housing.

►

Lower the bonnet and release it near the end

of its travel.

►

Pull on the bonnet to check that it is locked

correctly

.

Because of the presence of electrical

equipment under the bonnet, it is strongly

recommended that exposure to water (rain,

washing, etc.) be limited.

Engine compartment

The engine represented is an example given for

illustration purposes only. The locations of the following elements may

vary:

–

Air filter

.

–

Engine oil dipstick.

–

Engine oil filler cap.

–

Priming pump.

–

Degassing screw

.

Petrol engine

Diesel engine

1.

Screenwash fluid reservoir

2. Engine coolant reservoir

3. Brake fluid reservoir

4. Battery / Fuses

5. Remote earth point (-)

6. Fusebox

7. Air filter

Page 188 of 308

186

Practical information

The system only registers AdBlue® top-ups of

5 litres or more.

If the AdBlue® tank is completely empty

– which is confirmed by the message

"Top up AdBlue: Starting impossible" – it is

essential to add at least 5 litres.

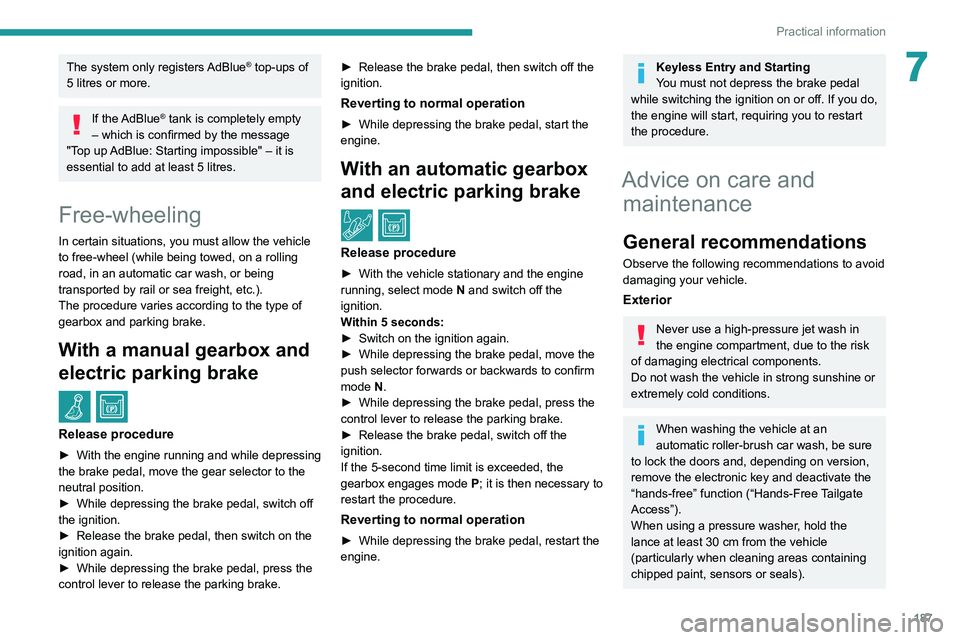

Free-wheeling

In certain situations, you must allow the vehicle

to free-wheel (while being towed, on a rolling

road, in an automatic car wash, or being

transported by rail or sea freight, etc.).

The procedure varies according to the type of

gearbox and parking brake.

With a manual gearbox and

electric parking brake

/

Release procedure

► With the engine running and while depressing

the brake pedal, move the gear selector to the

neutral position.

► While depressing the brake pedal, switch off

the ignition.

► Release the brake pedal, then switch on the

ignition again.

► While depressing the brake pedal, press the

control lever to release the parking brake.

Precautions for use

AdBlue® is a urea-based solution. This fluid is

non-flammable, colourless and odourless (when

kept in a cool place).

In the event of contact with the skin, wash the

affected area with soap and running water. In the

event of contact with the eyes, immediately rinse

the eyes with large amounts of water or with an

eye wash solution for at least 15 minutes. Seek

medical attention if you feel a persistent burning

sensation or irritation.

If swallowed, immediately wash out the mouth

with clean water and then drink plenty of water.

In certain conditions (high temperature, for

example), the risk of release of ammonia cannot

be excluded: do not inhale the fluid. Ammonia

vapours have an irritant effect on mucous

membranes (eyes, nose and throat).

Store AdBlue® out of the reach of

children, in its original container.

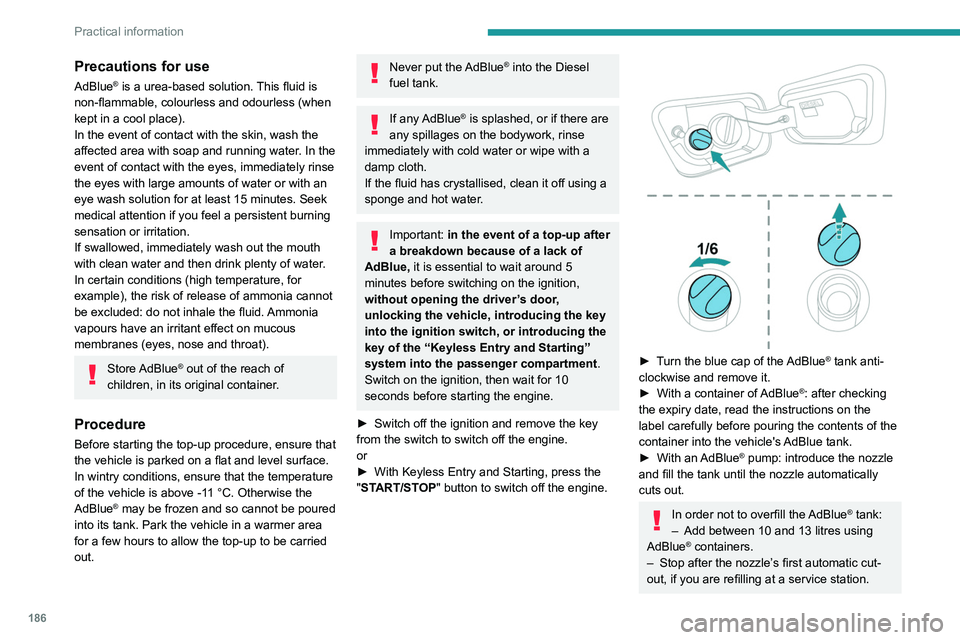

Procedure

Before starting the top-up procedure, ensure that

the vehicle is parked on a flat and level surface.

In wintry conditions, ensure that the temperature

of the vehicle is above -11

°C. Otherwise the

AdBlue

® may be frozen and so cannot be poured

into its tank. Park the vehicle in a warmer area

for a few hours to allow the top-up to be carried

out.

Never put the AdBlue® into the Diesel

fuel tank.

If any AdBlue® is splashed, or if there are

any spillages on the bodywork, rinse

immediately with cold water or wipe with a

damp cloth.

If the fluid has crystallised, clean it off using a

sponge and hot water.

Important: in the event of a top-up after

a breakdown because of a lack of

AdBlue, it is essential to wait around 5

minutes before switching on the ignition,

without opening the driver’s door,

unlocking the vehicle, introducing the key

into the ignition switch, or introducing the

key of the “Keyless Entry and Starting

”

system into the passenger compartment

.

Switch on the ignition, then wait for 10

seconds before starting the engine.

►

Switch off the ignition and remove the key

from the switch to switch off the engine.

or

►

With Keyless Entry and Starting, press the

"

START/STOP" button to switch off the engine.

► Turn the blue cap of the AdBlue® tank anti-

clockwise and remove it.

►

With a container of

AdBlue

®: after checking

the expiry date, read the instructions on the

label carefully before pouring the contents of the

container

into the vehicle's AdBlue tank.

►

With an

AdBlue® pump: introduce the nozzle

and fill the tank until the nozzle automatically

cuts out.

In order not to overfill the AdBlue® tank:

–

Add between 10 and 13 litres using

AdBlue® containers.

–

Stop after the nozzle’ s first automatic cut-

out, if you are refilling at a service station.

Page 189 of 308

187

Practical information

7The system only registers AdBlue® top-ups of

5

litres or more.

If the AdBlue® tank is completely empty

– which is confirmed by the message

"Top up

AdBlue: Starting impossible" – it is

essential to add at least 5 litres.

Free-wheeling

In certain situations, you must allow the vehicle

to free-wheel (while being towed, on a rolling

road, in an automatic car wash, or being

transported by rail or sea freight, etc.).

The procedure varies according to the type of

gearbox and parking brake.

With a manual gearbox and

electric parking brake

/

Release procedure

► With the engine running and while depressing

the brake pedal, move the gear selector to the

neutral position.

►

While depressing the brake pedal, switch off

the ignition.

►

Release the brake pedal, then switch on the

ignition again.

►

While depressing the brake pedal, press the

control lever to release the parking brake. ►

Release the brake pedal, then switch off the

ignition.

Reverting to normal operation

► While depressing the brake pedal, start the

engine.

With an automatic gearbox

and electric parking brake

/

Release procedure

► With the vehicle stationary and the engine

running, select mode N and switch off the

ignition.

Within 5

seconds:

►

Switch on the ignition again.

►

While depressing the brake pedal, move the

push selector forwards or backwards to confirm

mode

N.

►

While depressing the brake pedal, press the

control lever to release the parking brake.

►

Release the brake pedal, switch off the

ignition.

If the 5-second time limit is exceeded, the

gearbox engages mode P

; it is then necessary to

restart the procedure.

Reverting to normal operation

► While depressing the brake pedal, restart the

engine.

Keyless Entry and Starting

You must not depress the brake pedal

while switching the ignition on or off. If you do,

the engine will start, requiring you to restart

the procedure.

Advice on care and maintenance

General recommendations

Observe the following recommendations to avoid

damaging your vehicle.

Exterior

Never use a high-pressure jet wash in

the engine compartment, due to the risk

of damaging electrical components.

Do not wash the vehicle in strong sunshine or

extremely cold conditions.

When washing the vehicle at an

automatic roller-brush car wash, be sure

to lock the doors and, depending on version,

remove the electronic key and deactivate the

“hands-free” function (“Hands-Free Tailgate

Access”).

When using a pressure washer, hold the

lance at least 30 cm from the vehicle

(particularly when cleaning areas containing

chipped paint, sensors or seals).

Page 194 of 308

192

In the event of a breakdown

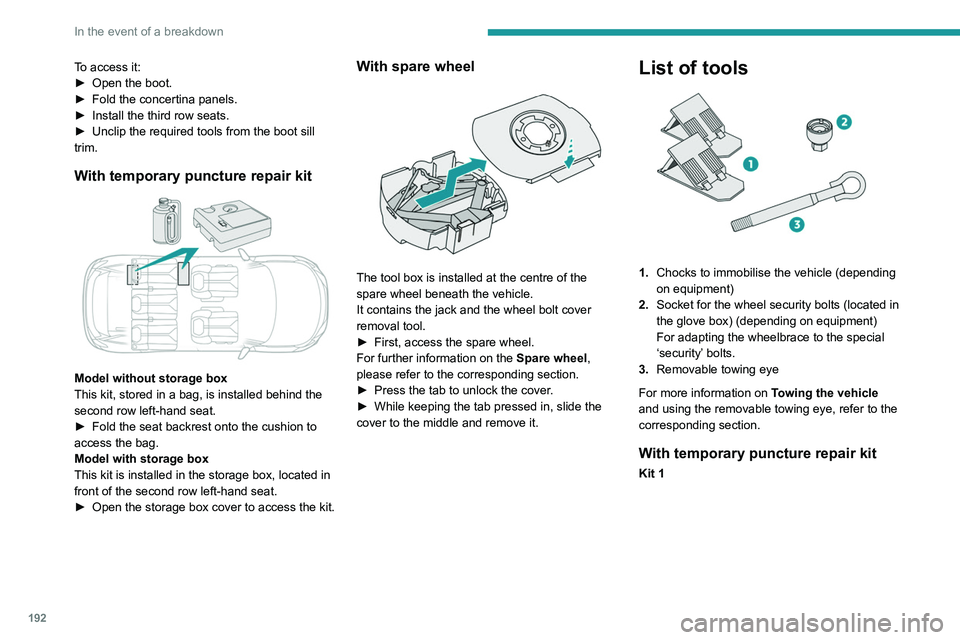

To access it:

► Open the boot.

►

Fold the concertina panels.

►

Install the third row seats.

►

Unclip the required tools from the boot sill

trim.

With temporary puncture repair kit

Model without storage box

This kit, stored in a bag, is installed behind the

second row left-hand seat.

►

Fold the seat backrest onto the cushion to

access the bag.

Model with storage box

This kit is installed in the storage box, located in

front of the second row left-hand seat.

►

Open the storage box cover to access the kit.

With spare wheel

The tool box is installed at the centre of the

spare wheel beneath the vehicle.

It contains the jack and the wheel bolt cover

removal tool.

►

First, access the spare wheel.

For further information on the

Spare wheel,

please refer to the corresponding section.

►

Press the tab to unlock the cover

.

►

While keeping the tab pressed in, slide the

cover to the middle and remove it.

List of tools

1. Chocks to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

For adapting the wheelbrace to the special

‘security’ bolts.

3. Removable towing eye

For more information on Towing the vehicle

and using the removable towing eye, refer to the

corresponding section.

With temporary puncture repair kit

Kit 1

Page 201 of 308

199

In the event of a breakdown

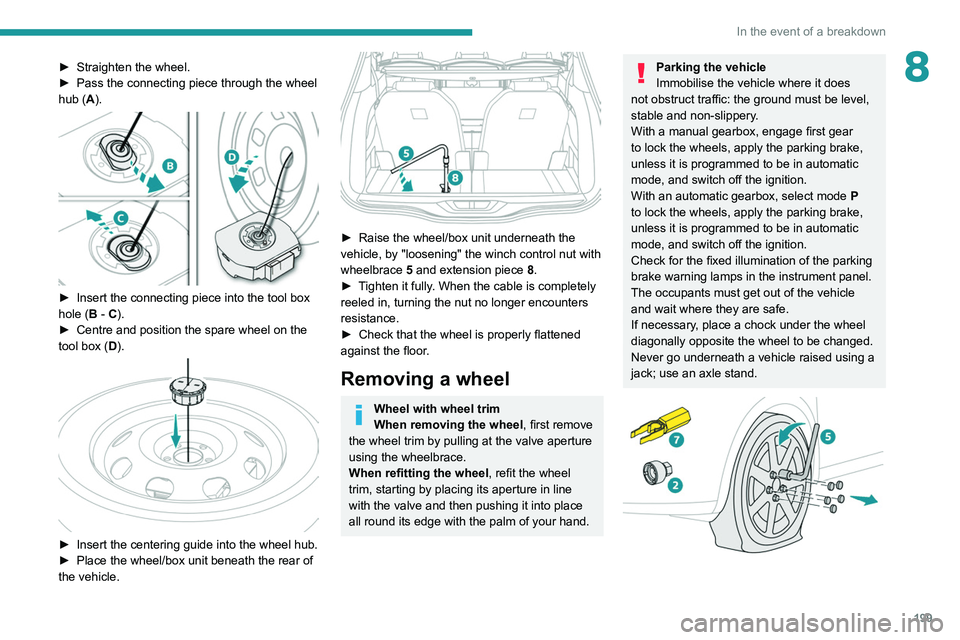

8► Straighten the wheel.

► Pass the connecting piece through the wheel

hub (

A).

► Insert the connecting piece into the tool box

hole ( B - C).

►

Centre and position the spare wheel on the

tool box (

D).

► Insert the centering guide into the wheel hub.

► Place the wheel/box unit beneath the rear of

the vehicle.

► Raise the wheel/box unit underneath the

vehicle, by "loosening" the winch control nut with

wheelbrace 5

and extension piece 8.

►

T

ighten it fully. When the cable is completely

reeled in, turning the nut no longer encounters

resistance.

►

Check that the wheel is properly flattened

against the floor

.

Removing a wheel

Wheel with wheel trim

When removing the wheel , first remove

the wheel trim by pulling at the valve aperture

using the wheelbrace.

When refitting the wheel , refit the wheel

trim, starting by placing its aperture in line

with the valve and then pushing it into place

all round its edge with the palm of your hand.

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

to lock the wheels, apply the parking brake,

unless it is programmed to be in automatic

mode, and switch off the ignition.

With an automatic gearbox, select mode

P

to lock the wheels, apply the parking brake,

unless it is programmed to be in automatic

mode, and switch off the ignition.

Check for the fixed illumination of the parking

brake warning lamps in the instrument panel.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the wheel

diagonally opposite the wheel to be changed.

Never go underneath a vehicle raised using a

jack; use an axle stand.

Page 204 of 308

202

In the event of a breakdown

Always replace a failed bulb with a new bulb

of the same type and specification. To avoid

lighting imbalance, replace the bulbs in pairs.

Refitting the lamp units

Perform the operations in the reverse

order to dismantling.

Light-emitting diode (LED)

headlamps and lamps

Depending on version, the affected types of

headlamps / lamps are:

–

Full LED technology headlamps.

–

Direction indicator side repeaters.

–

Side spotlamps.

–

Third brake lamp.

For the replacement of this type of bulb,

you must contact a PEUGEOT dealer or

a qualified workshop.

Do not touch the "Full LED" technology

headlamps - risk of electrocution!

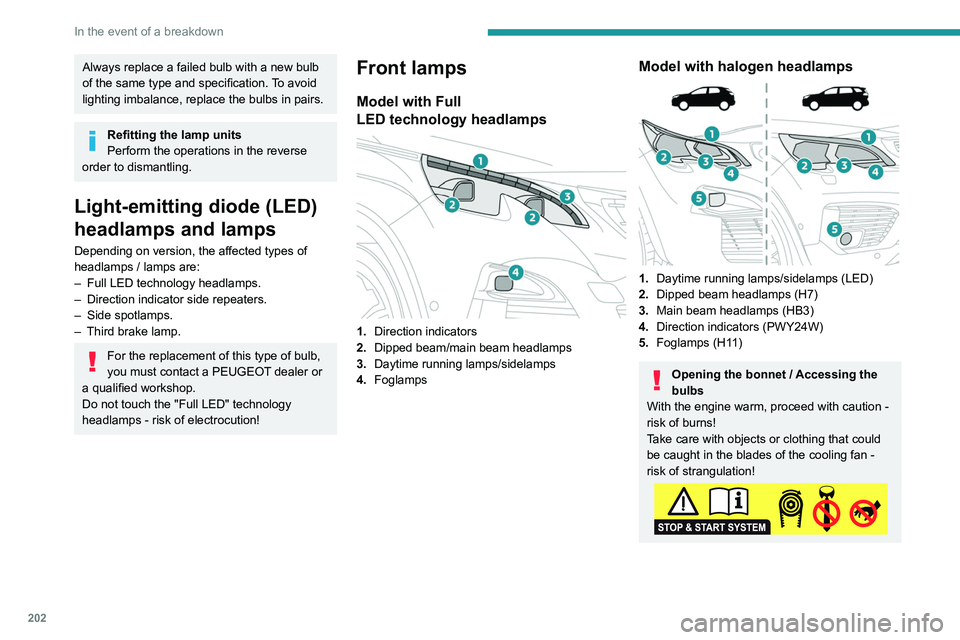

Front lamps

Model with Full

LED technology headlamps

1.Direction indicators

2. Dipped beam/main beam headlamps

3. Daytime running lamps/sidelamps

4. Foglamps

Model with halogen headlamps

1.Daytime running lamps/sidelamps (LED)

2. Dipped beam headlamps (H7)

3. Main beam headlamps (HB3)

4. Direction indicators (PWY24W)

5. Foglamps (H11)

Opening the bonnet / Accessing the

bulbs

With the engine warm, proceed with caution -

risk of burns!

Take care with objects or clothing that could

be caught in the blades of the cooling fan -

risk of strangulation!

Halogen bulbs (Hx)

To ensure good quality lighting, check

that the bulb is correctly positioned in its

housing.

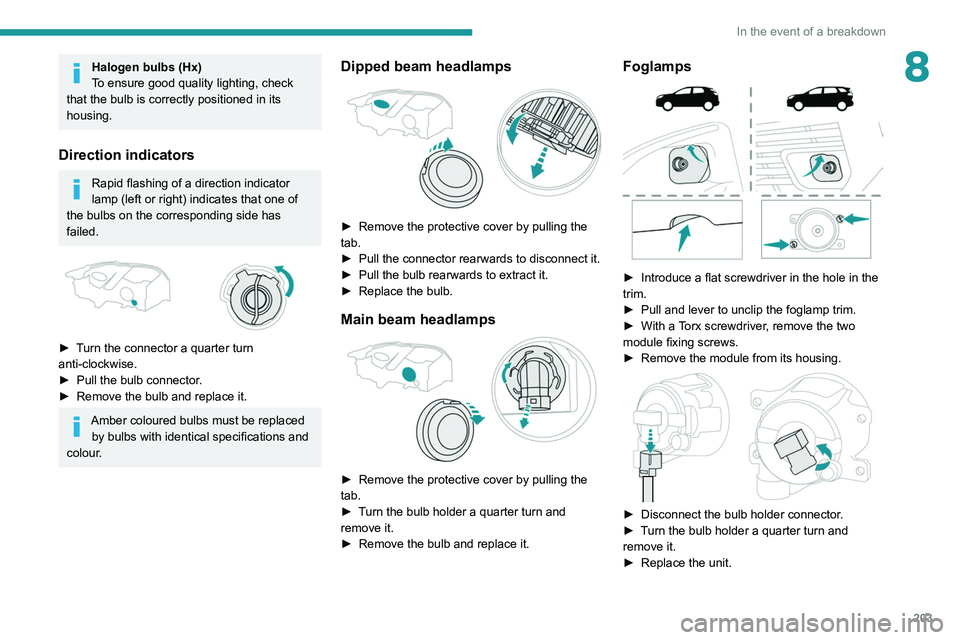

Direction indicators

Rapid flashing of a direction indicator

lamp (left or right) indicates that one of

the bulbs on the corresponding side has

failed.

► Turn the connector a quarter turn

anti-clockwise.

► Pull the bulb connector.

► Remove the bulb and replace it.

Amber coloured bulbs must be replaced

by bulbs with identical specifications and

colour.

Page 205 of 308

203

In the event of a breakdown

8Halogen bulbs (Hx)

To ensure good quality lighting, check

that the bulb is correctly positioned in its

housing.

Direction indicators

Rapid flashing of a direction indicator

lamp (left or right) indicates that one of

the bulbs on the corresponding side has

failed.

► Turn the connector a quarter turn

anti-clockwise.

►

Pull the bulb connector

.

►

Remove the bulb and replace it.

Amber coloured bulbs must be replaced by bulbs with identical specifications and

colour.

Dipped beam headlamps

► Remove the protective cover by pulling the

tab.

►

Pull the connector rearwards to disconnect it.

►

Pull the bulb rearwards to extract it.

►

Replace the bulb.

Main beam headlamps

► Remove the protective cover by pulling the

tab.

►

T

urn the bulb holder a quarter turn and

remove it.

►

Remove the bulb and replace it.

Foglamps

► Introduce a flat screwdriver in the hole in the

trim.

►

Pull and lever to unclip the foglamp trim.

►

With a

Torx screwdriver, remove the two

module fixing screws.

►

Remove the module from its housing.

► Disconnect the bulb holder connector .

► T urn the bulb holder a quarter turn and

remove it.

►

Replace the unit.

Page 206 of 308

204

In the event of a breakdown

To replace this type of bulb, you can also contact a PEUGEOT dealer or a qualified

workshop.

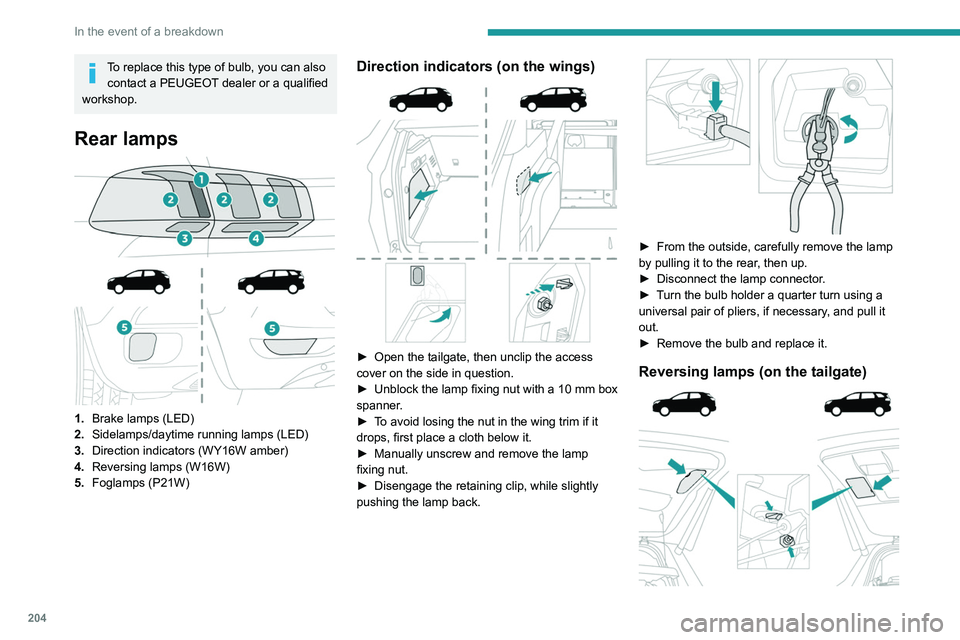

Rear lamps

1. Brake lamps (LED)

2. Sidelamps/daytime running lamps (LED)

3. Direction indicators (WY16W amber)

4. Reversing lamps (W16W)

5. Foglamps (P21W)

Direction indicators (on the wings)

► Open the tailgate, then unclip the access

cover on the side in question.

►

Unblock the lamp fixing nut with a 10

mm box

spanner.

►

T

o avoid losing the nut in the wing trim if it

drops, first place a cloth below it.

►

Manually unscrew and remove the lamp

fixing nut.

►

Disengage the retaining clip, while slightly

pushing the lamp back.

► From the outside, carefully remove the lamp

by pulling it to the rear , then up.

►

Disconnect the lamp connector

.

►

T

urn the bulb holder a quarter turn using a

universal pair of pliers, if necessary, and pull it

out.

►

Remove the bulb and replace it.

Reversing lamps (on the tailgate)

Page 207 of 308

205

In the event of a breakdown

8► Open the tailgate, then insert a flat

screwdriver into the cut-out to unclip the access

cover on the side in question.

►

Unblock the lamp fixing nut with a 10

mm box

spanner.

►

Manually unscrew and remove the lamp

fixing nut.

►

Disengage the retaining clip, while slightly

pushing the lamp back.

► From the outside, carefully remove the lamp

by pulling it to the rear .

►

Disconnect the lamp connector by pressing

on each side.

►

T

urn the bulb holder a quarter turn and

remove it.

►

Remove the bulb and replace it.

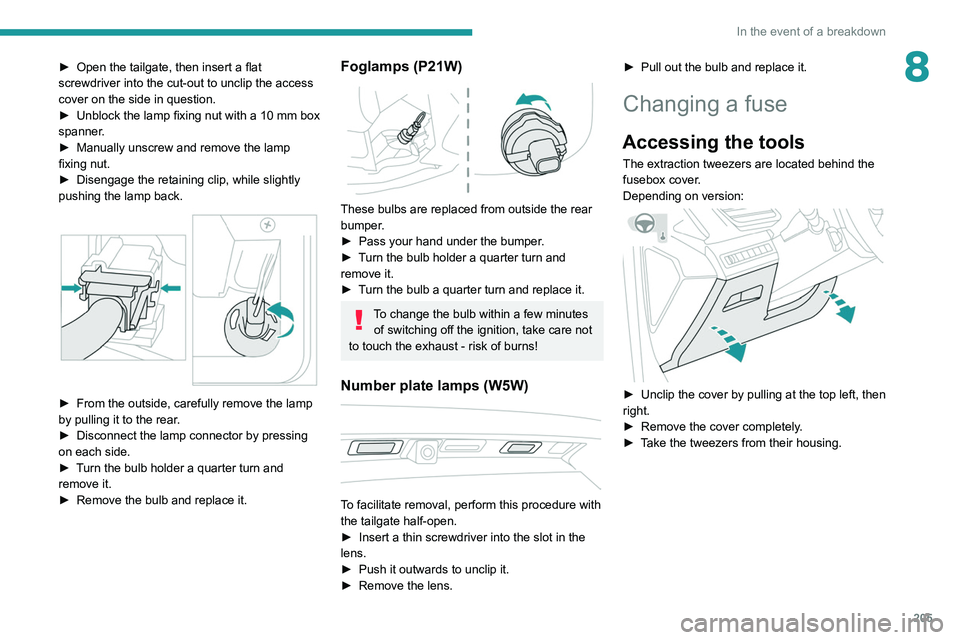

Foglamps (P21W)

These bulbs are replaced from outside the rear

bumper.

►

Pass your hand under the bumper

.

►

T

urn the bulb holder a quarter turn and

remove it.

►

T

urn the bulb a quarter turn and replace it.

To change the bulb within a few minutes of switching off the ignition, take care not

to touch the exhaust - risk of burns!

Number plate lamps (W5W)

To facilitate removal, perform this procedure with

the tailgate half-open.

►

Insert a thin screwdriver into the slot in the

lens.

►

Push it outwards to unclip it.

►

Remove the lens. ►

Pull out the bulb and replace it.

Changing a fuse

Accessing the tools

The extraction tweezers are located behind the

fusebox cover.

Depending on version:

► Unclip the cover by pulling at the top left, then

right.

►

Remove the cover completely

.

►

T

ake the tweezers from their housing.

Page 208 of 308

206

In the event of a breakdown

► Open the glove box.

► Press on the central handle of the fusebox

cover

.

►

Lower the cover completely

.

►

T

ake the tweezers from their housing.

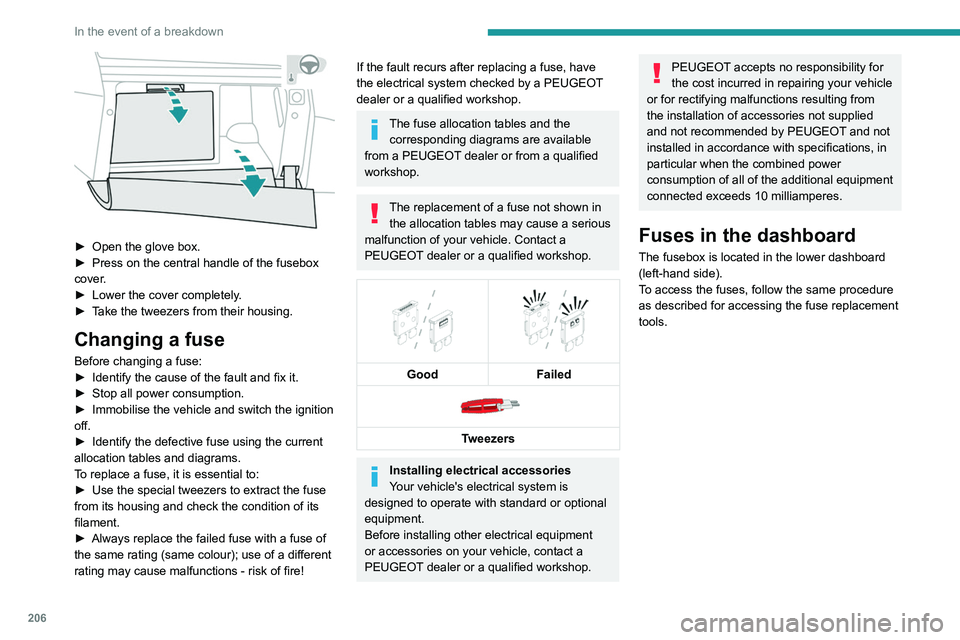

Changing a fuse

Before changing a fuse:

► Identify the cause of the fault and fix it.

►

Stop all power consumption.

►

Immobilise the vehicle and switch the ignition

off.

►

Identify the defective fuse using the current

allocation tables and diagrams.

T

o replace a fuse, it is essential to:

►

Use the special tweezers to extract the fuse

from its housing and check the condition of its

filament.

►

Always replace the failed fuse with a fuse of

the same rating (same colour); use of a different

rating may cause malfunctions - risk of fire!

If the fault recurs after replacing a fuse, have

the electrical system checked by a PEUGEOT

dealer or a qualified workshop.

The fuse allocation tables and the corresponding diagrams are available

from a PEUGEOT dealer or from a qualified

workshop.

The replacement of a fuse not shown in the allocation tables may cause a serious

malfunction of your vehicle. Contact a

PEUGEOT dealer or a qualified workshop.

Good

Failed

Tweezers

Installing electrical accessories

Your vehicle's electrical system is

designed to operate with standard or optional

equipment.

Before installing other electrical equipment

or accessories on your vehicle, contact a

PEUGEOT dealer or a qualified workshop.

PEUGEOT accepts no responsibility for

the cost incurred in repairing your vehicle

or for rectifying malfunctions resulting from

the installation of accessories not supplied

and not recommended by PEUGEOT and not

installed in accordance with specifications, in

particular when the combined power

consumption of all of the additional equipment

connected exceeds 10 milliamperes.

Fuses in the dashboard

The fusebox is located in the lower dashboard

(left-hand side).

To access the fuses, follow the same procedure

as described for accessing the fuse replacement

tools.

Version 1 (Full)

Box 1

Fuse N° Rating (A)Functions

F1 3 AKeyless Entry and Starting.

F2 5 AMultifunction screen.

F5 5 AReversing camera - Parking sensors.

F7 10 AHi-Fi amplifier.

F8 20 ARear wiper.

F10 30 ALocks.

F 11 30 ALocks.

F17 10 ABoot 12 V accessory socket.

F18 5 AEmergency and assistance calls.

F22 3 AGlove box lighting.

F26 3 ASeat belts not fastened warning lamps display.

F27 3 ARain/sunshine sensor.

F31 5 AAirbags.

F33 15 AFront 12 V accessory socket.

F35 5 AInstrument panel.

F36 20 AAudio system - Touch screen - CD player - Audio/navigation system.

Box 2 Fuse N° Rating (A)Functions

F17 10 AMemorising driving positions.