Peugeot 308 2015.5 Owner's Manual - RHD (UK, Australia)

Manufacturer: PEUGEOT, Model Year: 2015.5, Model line: 308, Model: Peugeot 308 2015.5Pages: 396, PDF Size: 10.06 MB

Page 251 of 396

249

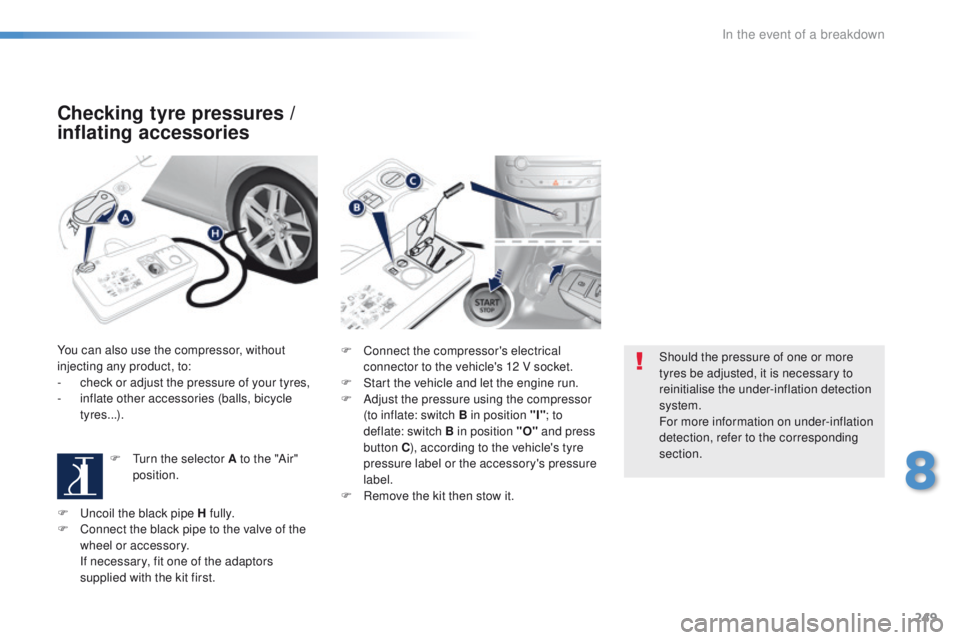

Checking tyre pressures /

inflating accessories

You can also use the compressor, without

injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

t

u

rn the selector A to the "Air"

position. F

C onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label or the accessory's pressure

label.

F

R

emove the kit then stow it.Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on under-inflation

detection, refer to the corresponding

section.

F

u

n

coil the black pipe H fully.

F

C

onnect the black pipe to the valve of the

wheel or accessory.

I

f necessary, fit one of the adaptors

supplied with the kit first.

8

In the event of a breakdown

Page 252 of 396

250

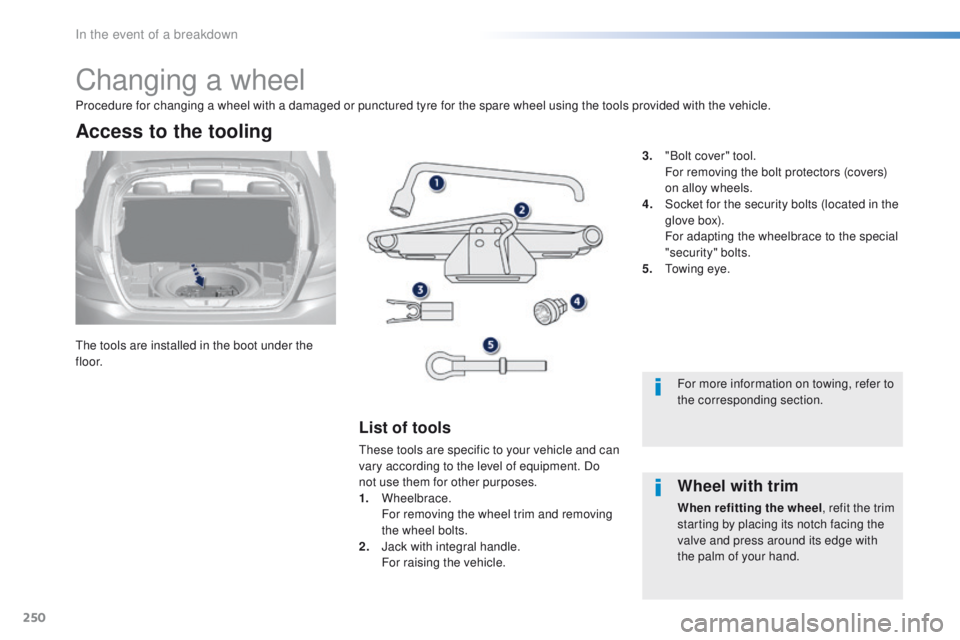

Changing a wheel

the tools are installed in the boot under the

f l o o r.

Access to the tooling

List of tools

these tools are specific to your vehicle and can

vary according to the level of equipment. Do

not use them for other purposes.

1.

Wheelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle. 3.

"

Bolt cover" tool.

F

or removing the bolt protectors (covers)

on alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

5.

t

o

wing eye.

Procedure for changing a wheel with a damaged or punctured tyre for the spare wheel using the tools provided with the vehicle.

For more information on towing, refer to

the corresponding section.

Wheel with trim

When refitting the wheel, refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

In the event of a breakdown

Page 253 of 396

251

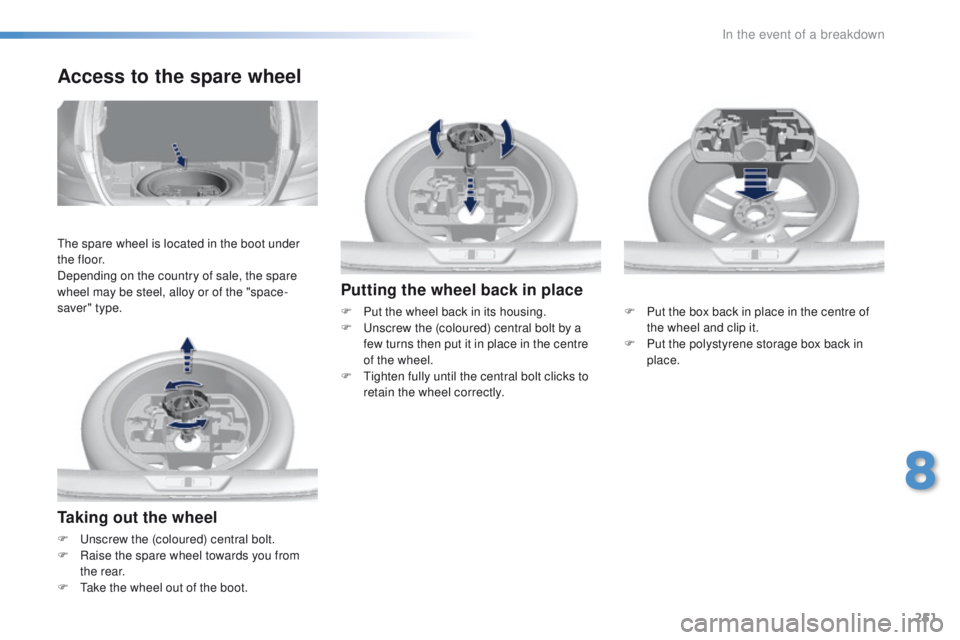

Taking out the wheel

F unscrew the (coloured) central bolt.

F R aise the spare wheel towards you from

the rear.

F

t

a

ke the wheel out of the boot.

Access to the spare wheel

the spare wheel is located in the boot under

t h e f l o o r.

Depending on the country of sale, the spare

wheel may be steel, alloy or of the "space-

saver" type.

Putting the wheel back in place

F Put the wheel back in its housing.

F un screw the (coloured) central bolt by a

few turns then put it in place in the centre

of the wheel.

F

t

i

ghten fully until the central bolt clicks to

retain the wheel correctly. F

P ut the box back in place in the centre of

the wheel and clip it.

F

P

ut the polystyrene storage box back in

place.

8

In the event of a breakdown

Page 254 of 396

252

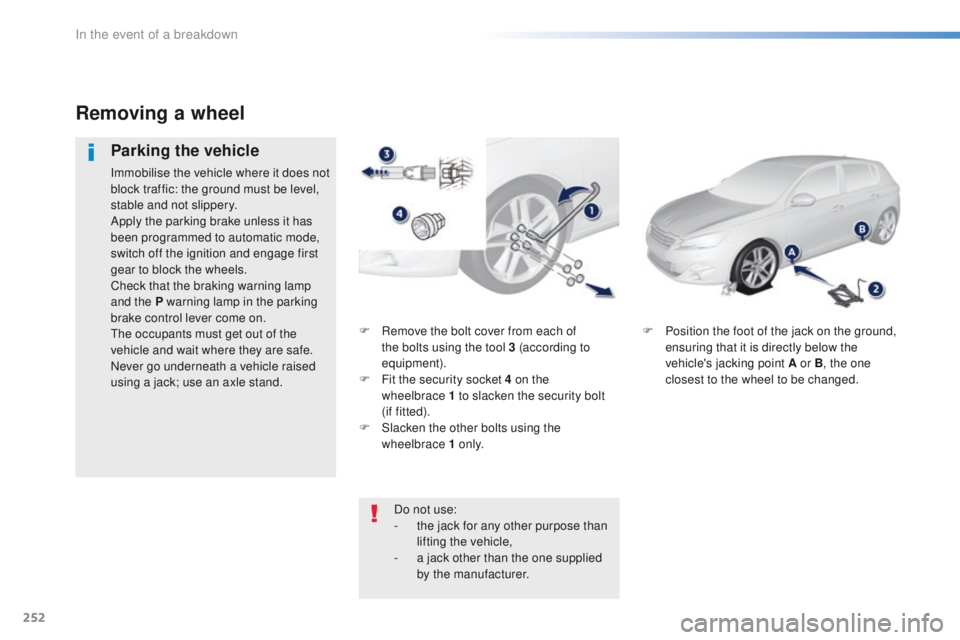

F Remove the bolt cover from each of the bolts using the tool 3 (according to

equipment).

F

F

it the security socket 4 on the

wheelbrace

1 to slacken the security bolt

(if

fitted).

F

S

lacken the other bolts using the

wheelbrace 1 o n l y. F

P osition the foot of the jack on the ground,

ensuring that it is directly below the

vehicle's jacking point A or B , the one

closest to the wheel to be changed.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Apply the parking brake unless it has

been programmed to automatic mode,

switch off the ignition and engage first

gear to block the wheels.

Check that the braking warning lamp

and the P warning lamp in the parking

brake control lever come on.

th

e occupants must get out of the

vehicle and wait where they are safe.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Do not use:

-

t

he jack for any other purpose than

lifting the vehicle,

-

a j

ack other than the one supplied

by the manufacturer.

In the event of a breakdown

Page 255 of 396

253

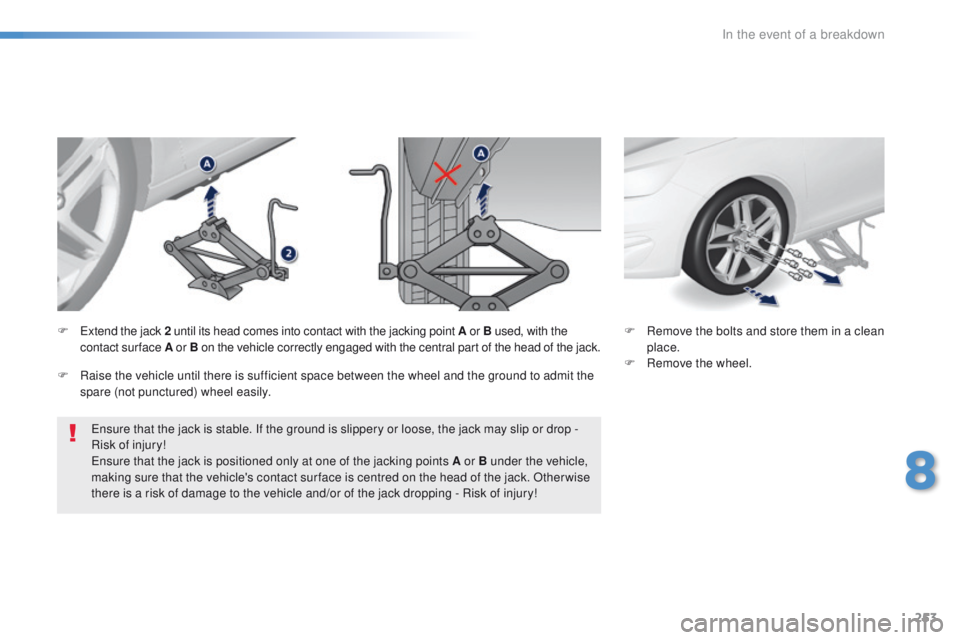

ensure that the jack is stable. If the ground is slippery or loose, the jack may slip or drop -

Risk of injury!

en

sure that the jack is positioned only at one of the jacking points A or B under the vehicle,

making sure that the vehicle's contact sur face is centred on the head of the jack. Other wise

there is a risk of damage to the vehicle and/or of the jack dropping - Risk of injury! F

R

emove the bolts and store them in a clean

place.

F

R

emove the wheel.

F

e

x

tend the jack 2

until its head comes into contact with the jacking point A or B used, with the

contact sur face A or B on the vehicle correctly engaged with the central part of the head of the jack.

F

Ra

ise the vehicle until there is sufficient space between the wheel and the ground to admit the

spare (not punctured) wheel easily.

8

In the event of a breakdown

Page 256 of 396

254

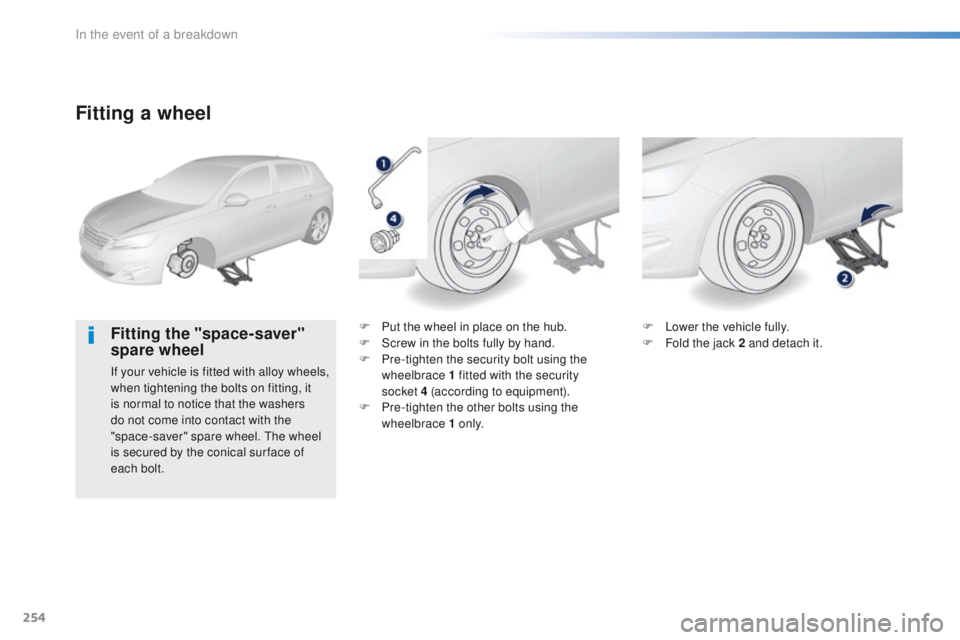

Fitting a wheel

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it

is normal to notice that the washers

do not come into contact with the

"space-saver" spare wheel. t

h

e wheel

is secured by the conical sur face of

each bolt. F

P

ut the wheel in place on the hub.

F

S

crew in the bolts fully by hand.

F P re-tighten the security bolt using the

wheelbrace 1 fitted with the security

socket 4 (according to equipment).

F

P

re-tighten the other bolts using the

wheelbrace 1 o n l y. F

L

ower the vehicle fully.

F

F

old the jack 2 and detach it.

In the event of a breakdown

Page 257 of 396

255

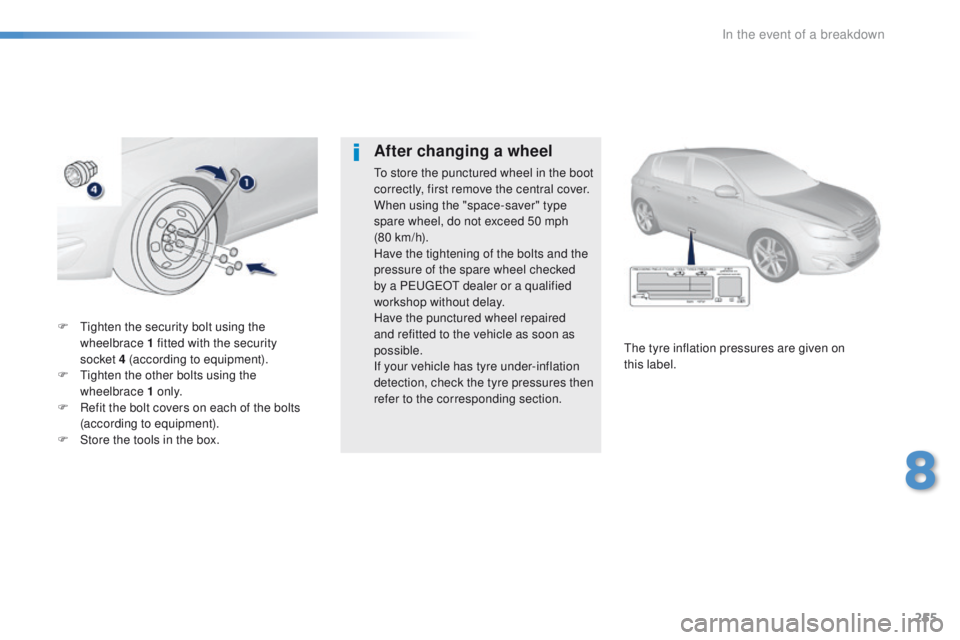

F tighten the security bolt using the wheelbrace 1 fitted with the security

socket

4 (according to equipment).

F

t

i

ghten the other bolts using the

wheelbrace 1 o n l y.

F

R

efit the bolt covers on each of the bolts

(according to equipment).

F

S

tore the tools in the box.

th

e tyre inflation pressures are given on

this

label.

After changing a wheel

to store the punctured wheel in the boot

correctly, first remove the central cover.

When using the "space-saver" type

spare wheel, do not exceed 50 mph

(80

km/h).

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a P

e

uge

Ot

dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures then

refer to the corresponding section.

8

In the event of a breakdown

Page 258 of 396

256

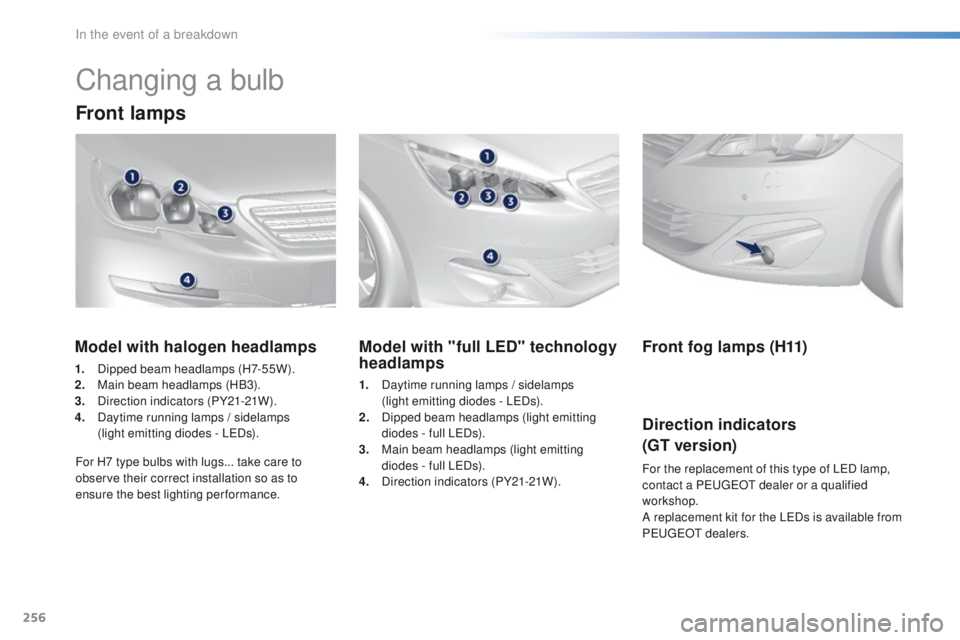

Changing a bulb

Front lamps

Model with "full LED" technology

headlamps

1. Daytime running lamps / sidelamps (light emitting diodes - LeD s).

2.

D

ipped beam headlamps (light emitting

diodes - full L

eD

s).

3.

M

ain beam headlamps (light emitting

diodes - full L

eD

s).

4.

D

irection indicators (PY21-21W).

Model with halogen headlamps

1. Dipped beam headlamps (H7-55W).

2. M ain beam headlamps (HB3).

3.

D

irection indicators (PY21-21W).

4.

D

aytime running lamps / sidelamps

(light emitting diodes - L

eD

s).

For H7 type bulbs with lugs... take care to

observe their correct installation so as to

ensure the best lighting performance.

Front fog lamps (H11)

Direction indicators

(GT version)

For the replacement of this type of LeD l amp,

contact a Pe ugeOt dealer or a qualified

workshop.

A replacement kit for the L

eD

s is available from

P

e

uge

Ot d

ealers.

In the event of a breakdown

Page 259 of 396

257

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal sur face of the

glass of the headlamps and rear lamps

is normal; it disappears after the lamps

have been on for a few minutes.th

e headlamps are fitted with

polycarbonate glass with a protective

coating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

u

se a sponge and soapy water or a

pH neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals.

Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

D

o not touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (

uV

) type bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

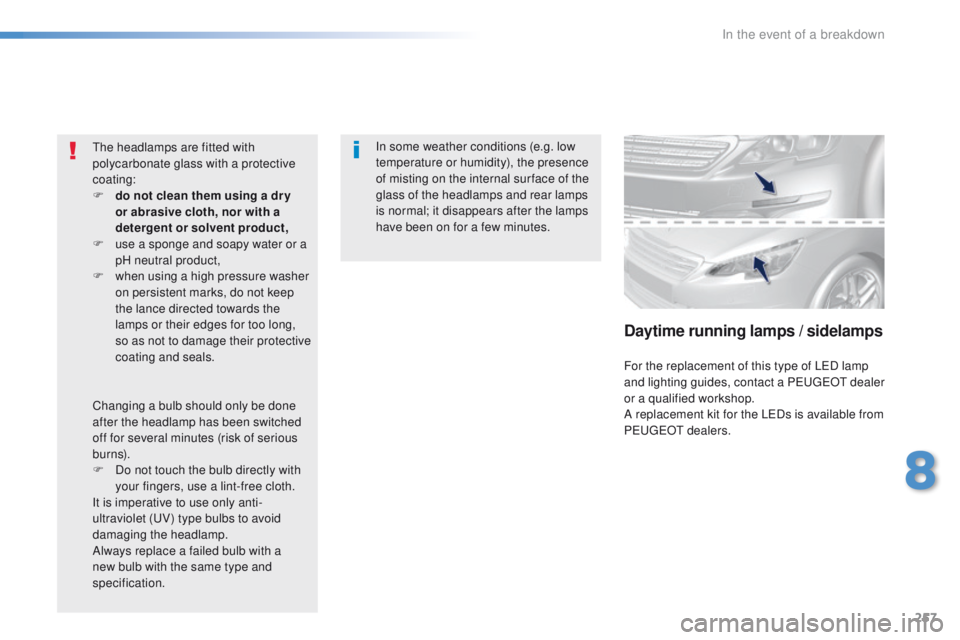

Daytime running lamps / sidelamps

For the replacement of this type of LeD l amp

and lighting guides, contact a Pe ugeOt dealer

or a qualified workshop.

A replacement kit for the L

eD

s is available from

P

e

uge

Ot d

ealers.

8

In the event of a breakdown

Page 260 of 396

258

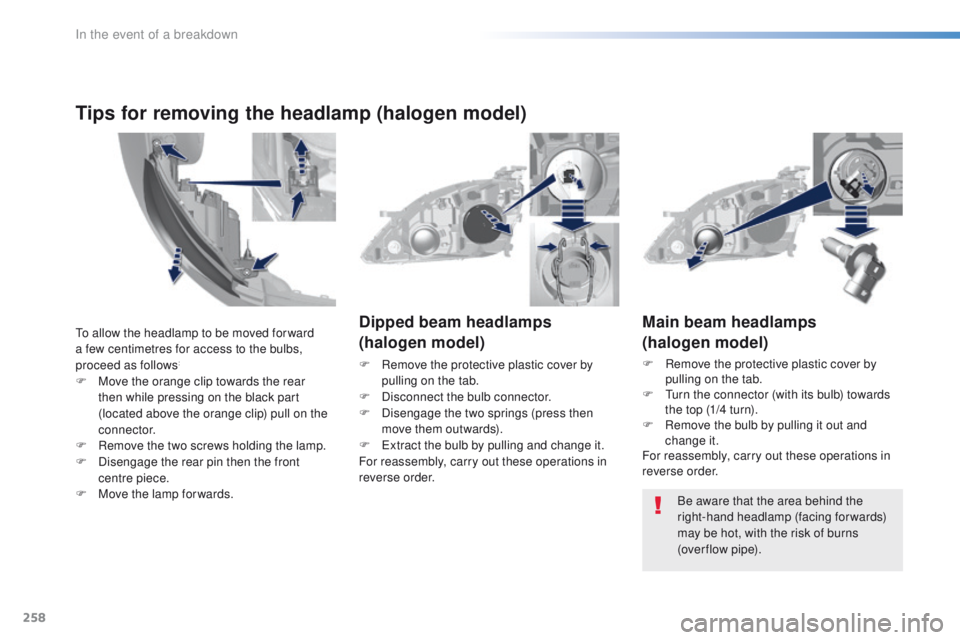

Main beam headlamps

(halogen model)

F Remove the protective plastic cover by pulling on the tab.

F

t

u

rn the connector (with its bulb) towards

the top (1/4 turn).

F

R

emove the bulb by pulling it out and

change it.

For reassembly, carry out these operations in

reverse order.

Dipped beam headlamps

(halogen model)

F Remove the protective plastic cover by

pulling on the tab.

F

D

isconnect the bulb connector.

F

D

isengage the two springs (press then

move them outwards).

F

e

x

tract the bulb by pulling and change it.

For reassembly, carry out these operations in

reverse order.

Be aware that the area behind the

right-hand headlamp (facing forwards)

may be hot, with the risk of burns

(over flow

pipe).

to a

llow the headlamp to be moved for ward

a few centimetres for access to the bulbs,

proceed as follows:

F Move the orange clip towards the rear then while pressing on the black part

(located above the orange clip) pull on the

connector.

F

R

emove the two screws holding the lamp.

F

D

isengage the rear pin then the front

centre piece.

F

M

ove the lamp for wards.

Tips for removing the headlamp (halogen model)

In the event of a breakdown