Tyre change PEUGEOT 308 2024 Owners Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2024, Model line: 308, Model: PEUGEOT 308 2024Pages: 280, PDF Size: 8.13 MB

Page 11 of 280

9

Eco-driving

Eco-driving

Eco-driving refers to a range of everyday

practices that allow the motorist to optimise

the vehicle's energy consumption (fuel and/or

electricity) and CO

2 emissions.

Optimise your use of the gearbox

With a manual gearbox, move off gently and

change up promptly. While accelerating, change

up early.

With an automatic gearbox, favour automatic

mode. Do not depress the accelerator pedal

heavily or suddenly.

The gear shift indicator prompts you to engage

the most suitable gear. Whenever this indication

is displayed on the instrument panel, follow it

straight away.

With an automatic gearbox, this indicator

appears only in manual mode.

Drive smoothly

Maintain a safe distance between vehicles, use

engine braking rather than the brake pedal and

press the accelerator gradually. These practices

help to save on energy consumption, reduce

CO

2 emissions and decrease general traffic

noise.

With a hybrid engine, engine braking is more

efficient. Anticipate slowing down as much as

you can and, if possible, favour deceleration with

engine braking in order to charge the traction

battery, to increase all-electric driving and to

reduce fuel consumption. With an EAT8 gearbox, with the gear selector in

mode

D, and except in Sport mode, favour "free-

wheeling" by gradually lifting your foot fully off

the accelerator pedal in order to save fuel.

When the traffic is flowing smoothly, select the

cruise control.

Control the use of electrical equipment

Before moving off, if the passenger compartment

is too warm, ventilate it by opening the windows

and air vents before using the air conditioning.

At speeds above 31

mph (50 km/h), close the

windows and leave the air vents open.

Consider using equipment that can help keep

the temperature in the passenger compartment

down.

Unless automatically regulated, switch off the air

conditioning as soon as the desired temperature

has been reached.

Switch off the demisting and defrosting functions,

if they are not managed automatically.

Switch off the heated seat and heated steering

wheel as soon as possible.

Adapt your use of the headlamps and/or

foglamps to the level of visibility, in accordance

with current legislation in the country in which

you are driving.

Avoid running the engine before moving off,

particularly in winter (other than in severe wintry

conditions: temperature below -23°C). The

vehicle will warm up much faster while driving. As a passenger, avoid connecting your

multimedia devices (e.g.

film, music, video

game) to help reduce the consumption of energy.

Disconnect all portable devices before leaving

the vehicle.

Limit the causes of excess consumption

Spread loads throughout the vehicle. Place the

heaviest items in the boot as close as possible to

the rear seats.

Limit the loads carried in the vehicle and

minimise wind resistance (e.g.

roof bars, roof

rack, bicycle carrier, trailer). Preferably, use a

roof box.

Remove roof bars and roof racks after use.

At the end of winter, remove snow tyres and refit

summer tyres.

Comply with the servicing instructions

Check tyre pressures regularly, with the tyres

cold, referring to the label in the door aperture on

the driver's side.

Carry out this check in particular:

–

before a long journey

.

–

at each change of season.

–

after a long period out of use.

Do not forget the spare wheel and, where

applicable, the tyres on your trailer or caravan.

Have your vehicle serviced regularly (e.g.

engine

oil, oil filter, air filter, passenger compartment

filter, etc.). Observe the schedule of operations in

the manufacturer's service schedule.

With a BlueHDi Diesel engine, if the SCR system

has a fault, your vehicle will emit pollution. Visit

Page 120 of 280

11 8

Driving

The display of a message on the instrument

panel confirms the change of state.

Function deactivated, this indicator lights

up in the instrument panel.

If high traction is required, the driver can

deactivate the e-Auto mode using the

touch screen application.

Tyre under-inflation detection

This system alerts the driver if one or more tyres

suffer a drop in pressure.

The alert is raised when the vehicle is moving,

not when stationary.

It compares the information given by the wheel

speed sensors with reference values, which

must be reinitialised every time the tyre

pressures are adjusted or a wheel changed.

It takes into account the last values stored

during the reinitialisation request. It is therefore

essential that the tyre pressure is correct during

the operation. This operation is the driver’s

responsibility.

The tyre under-inflation detection cannot, in any circumstances, replace the need

for vigilance on the part of the driver.

This system does not avoid the need to

regularly check the tyre pressures (including

the spare wheel), especially before a long

journey.

Driving with under-inflated tyres, particularly

in adverse conditions (heavy load, high

speed, long journey):

–

worsens road-holding.

–

lengthens braking distances.

–

causes premature wear of the tyres.

–

increases energy consumption.

The inflation pressures defined for the vehicle can be found on the tyre pressure

label.

For more information on the Identification

markings, refer to the corresponding section.

Checking tyre pressures

This check should be done monthly

when the tyres are "cold" (vehicle stopped for

1

hour or after a journey of less than 6 miles

(10

km) at moderate speeds).

Otherwise, add 0.3

bar to the pressures

shown on the label.

Snow chains

The system does not have to be

reinitialised after fitting or removing snow

chains.

Under-inflation alert

This is signalled by the fixed illumination of this warning lamp, accompanied by an

audible signal and, depending on equipment, the

display of a message.

►

Reduce speed immediately

, avoid excessive

steering movements and avoid sudden braking.

►

Stop the vehicle as soon as it is safe to do

so.

The loss of pressure detected may not always cause visible deformation of the

tyre.

Do not rely on just a visual check.

►

Using a compressor

, such as the one in

the temporary puncture repair kit, check the

pressures of all four tyres when cold.

►

If it is not possible to carry out this check

immediately

, drive carefully at reduced speed.

►

In the event of a puncture, use the

temporary puncture repair kit or the spare wheel

(depending on equipment).

Driving too slowly may not ensure

optimum monitoring.

The alert is not immediately triggered in the

event of a sudden loss of pressure or tyre

blow-out. This is because analysis of the

values read by the wheel's speed sensors

can take several minutes.

The alert may be delayed at speeds below

25

mph (40 km/h), or when adopting a sporty

driving mode.

The alert is kept active until the system is reinitialised.

Page 202 of 280

200

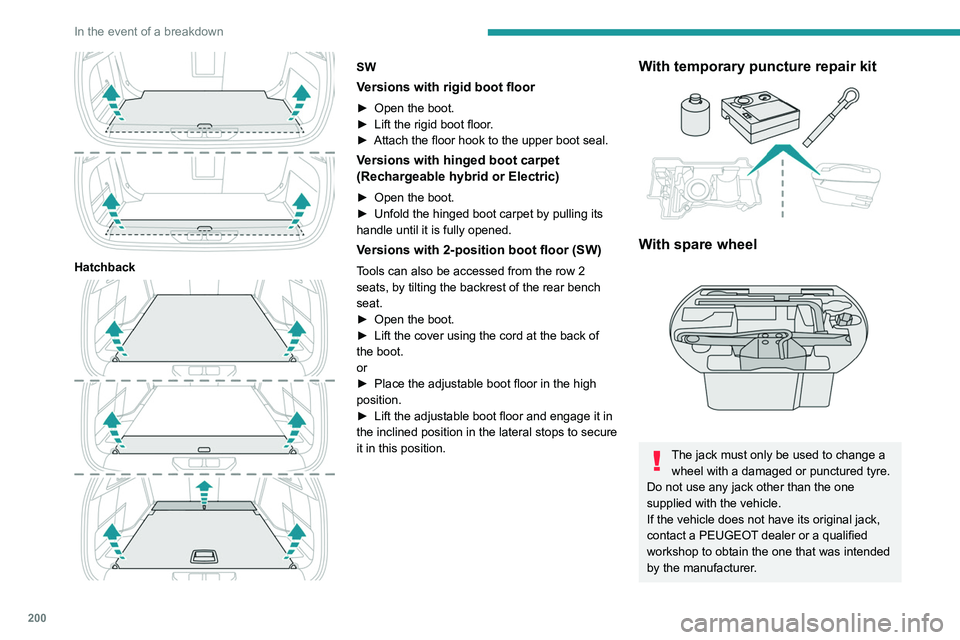

In the event of a breakdown

Hatchback

SW

Versions with rigid boot floor

► Open the boot.

► Lift the rigid boot floor .

►

Attach the floor hook to the upper boot seal.

Versions with hinged boot carpet

(Rechargeable hybrid or Electric)

► Open the boot.

► Unfold the hinged boot carpet by pulling its

handle until it is fully opened.

Versions with 2-position boot floor (SW)

Tools can also be accessed from the row 2

seats, by tilting the backrest of the rear bench

seat.

►

Open the boot.

►

Lift the cover using the cord at the back of

the boot.

or

►

Place the adjustable boot floor in the high

position.

►

Lift the adjustable boot floor and engage it in

the inclined position in the lateral stops to secure

it in this position.

With temporary puncture repair kit

With spare wheel

The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a PEUGEOT dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

Page 205 of 280

203

In the event of a breakdown

8If after approximately 7 minutes, the

pressure of 2 bar is not reached, this

indicates that the tyre is not repairable;

contact a PEUGEOT dealer or a qualified

workshop for assistance.

►

Move the switch to position

"O".

►

Disconnect the compressor's electric plug

from the vehicle's 12

V socket.

►

Remove the kit.

►

Refit the cap on the valve.

►

Remove and store the bottle of sealant.

The sealant product is harmful if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of children.

The use-by date of the fluid is marked on the

bottle.

After use, do not discard the bottle into the

environment; take it to a PEUGEOT dealer or

an authorised waste disposal site.

Do not forget to obtain a new bottle of

sealant, available from a PEUGEOT dealer or

a qualified workshop.

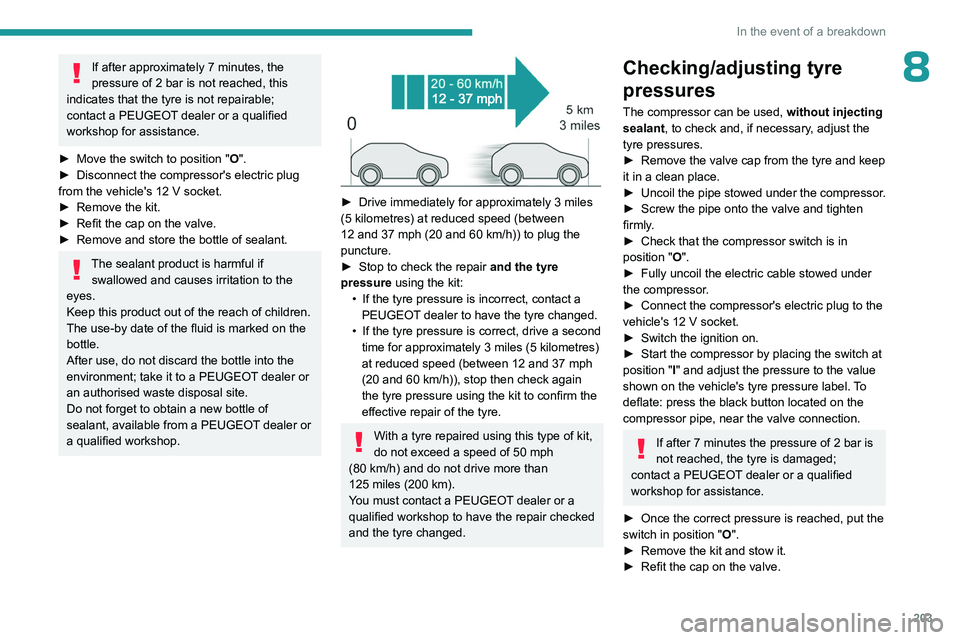

► Drive immediately for approximately 3 miles

(5 kilometres) at reduced speed (between

12 and 37

mph (20 and 60 km/h)) to plug the

puncture.

►

Stop to check the repair

and the tyre

pressure using the kit:

•

If the tyre pressure is incorrect, contact a

PEUGEOT

dealer to have the tyre changed.

•

If the tyre pressure is correct, drive a second

time for approximately 3

miles (5 kilometres)

at reduced speed (between 12 and 37

mph

(20 and 60

km/h)), stop then check again

the tyre pressure using the kit to confirm the

effective repair of the tyre.

With a tyre repaired using this type of kit,

do not exceed a speed of 50 mph

(80

km/h) and do not drive more than

125

miles (200 km).

You must contact a PEUGEOT dealer or a

qualified workshop to have the repair checked

and the tyre changed.

Checking/adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

►

Remove the valve cap from the tyre and keep

it in a clean place.

►

Uncoil

the pipe stowed under the compressor.

►

Screw the pipe onto the valve and tighten

firmly

.

►

Check that the compressor switch is in

position

"O".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect the compressor's electric plug to the

vehicle's 12

V socket.

►

Switch the ignition on.

►

Start the compressor by placing the switch at

position

"I" and adjust the pressure to the value

shown on the vehicle's tyre pressure label. To

deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bar is

not reached, the tyre is damaged;

contact a PEUGEOT

dealer or a qualified

workshop for assistance.

►

Once the correct pressure is reached, put the

switch in position

"O".

►

Remove the kit and stow it.

►

Refit the cap on the valve.

Page 230 of 280

228

Technical data

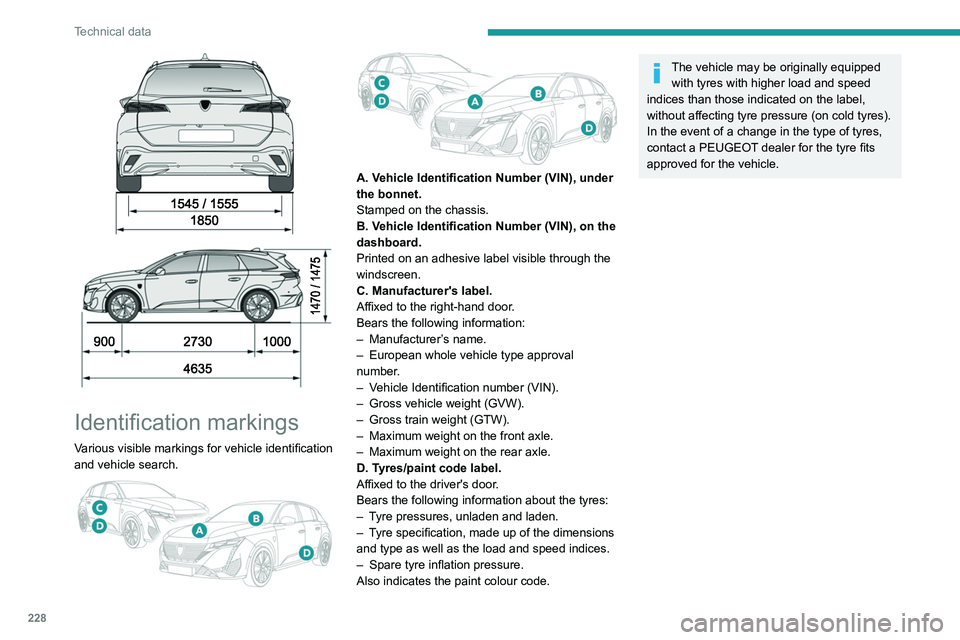

Identification markings

Various visible markings for vehicle identification

and vehicle search.

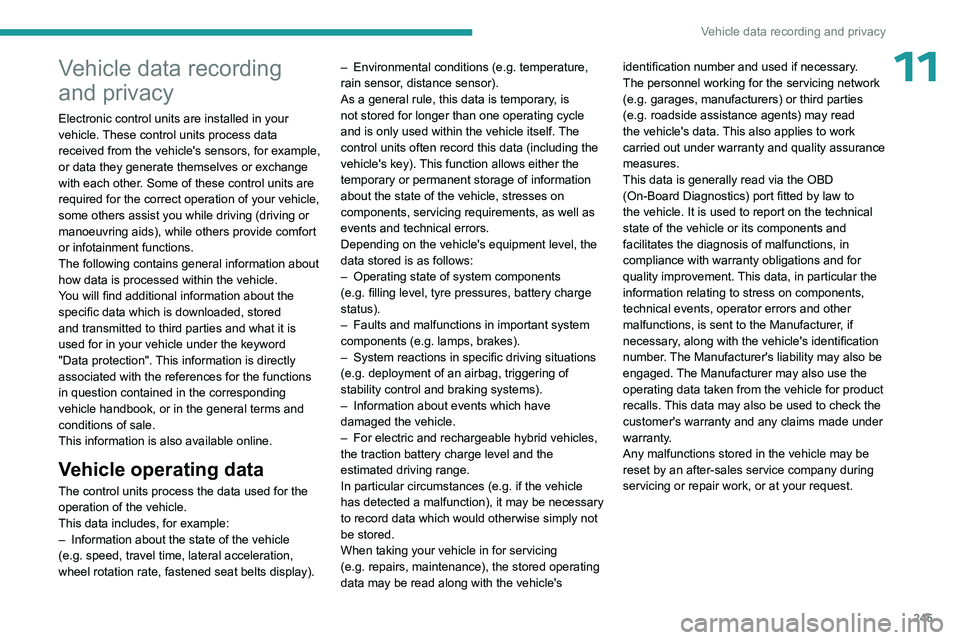

A. Vehicle Identification Number (VIN), under

the bonnet.

Stamped on the chassis.

B. Vehicle Identification Number (VIN), on the

dashboard.

Printed on an adhesive label visible through the

windscreen.

C. Manufacturer's label.

Affixed to the right-hand door.

Bears the following information:

–

Manufacturer

’s name.

–

European whole vehicle type approval

number

.

–

V

ehicle Identification number (VIN).

–

Gross vehicle weight (GVW).

–

Gross train weight (GTW).

–

Maximum weight on the front axle.

–

Maximum weight on the rear axle.

D. T

yres/paint code label.

Affixed to the driver's door.

Bears the following information about the tyres:

–

T

yre pressures, unladen and laden.

–

T

yre specification, made up of the dimensions

and type as well as the load and speed indices.

–

Spare tyre inflation pressure.

Also indicates the paint colour code.

The vehicle may be originally equipped with tyres with higher load and speed

indices than those indicated on the label,

without affecting tyre pressure (on cold tyres).

In the event of a change in the type of tyres,

contact a PEUGEOT dealer for the tyre fits

approved for the vehicle.

Page 247 of 280

245

Vehicle data recording and privacy

11Vehicle data recording

and privacy

Electronic control units are installed in your

vehicle. These control units process data

received from the vehicle's sensors, for example,

or data they generate themselves or exchange

with each other. Some of these control units are

required for the correct operation of your vehicle,

some others assist you while driving (driving or

manoeuvring aids), while others provide comfort

or infotainment functions.

The following contains general information about

how data is processed within the vehicle.

You will find additional information about the

specific data which is downloaded, stored

and transmitted to third parties and what it is

used for in your vehicle under the keyword

"Data protection". This information is directly

associated with the references for the functions

in question contained in the corresponding

vehicle handbook, or in the general terms and

conditions of sale.

This information is also available online.

Vehicle operating data

The control units process the data used for the

operation of the vehicle.

This data includes, for example:

–

Information about the state of the vehicle

(e.g.

speed, travel time, lateral acceleration,

wheel rotation rate, fastened seat belts display). –

Environmental conditions (e.g.

temperature,

rain sensor, distance sensor).

As a general rule, this data is temporary, is

not stored for longer than one operating cycle

and is only used within the vehicle itself. The

control units often record this data (including the

vehicle's key). This function allows either the

temporary or permanent storage of information

about the state of the vehicle, stresses on

components, servicing requirements, as well as

events and technical errors.

Depending on the vehicle's equipment level, the

data stored is as follows:

–

Operating state of system components

(e.g.

filling level, tyre pressures, battery charge

status).

–

Faults and malfunctions in important system

components (e.g.

lamps, brakes).

–

System reactions in specific driving situations

(e.g.

deployment of an airbag, triggering of

stability control and braking systems).

–

Information about events which have

damaged the vehicle.

–

For electric and rechargeable hybrid vehicles,

the traction battery charge level and the

estimated driving range.

In particular circumstances (e.g.

if the vehicle

has detected a malfunction), it may be necessary

to record data which would otherwise simply not

be stored.

When taking your vehicle in for servicing

(e.g.

repairs, maintenance), the stored operating

data may be read along with the vehicle's identification number and used if necessary.

The personnel working for the servicing network

(e.g.

garages, manufacturers) or third parties

(e.g. roadside assistance agents) may read

the vehicle's data. This also applies to work

carried out under warranty and quality assurance

measures.

This data is generally read via the OBD

(On-Board Diagnostics) port fitted by law to

the vehicle. It is used to report on the technical

state of the vehicle or its components and

facilitates the diagnosis of malfunctions, in

compliance with warranty obligations and for

quality improvement. This data, in particular the

information relating to stress on components,

technical events, operator errors and other

malfunctions, is sent to the Manufacturer, if

necessary, along with the vehicle's identification

number. The Manufacturer's liability may also be

engaged. The Manufacturer may also use the

operating data taken from the vehicle for product

recalls. This data may also be used to check the

customer's warranty and any claims made under

warranty.

Any malfunctions stored in the vehicle may be

reset by an after-sales service company during

servicing or repair work, or at your request.

Page 254 of 280

252

Alphabetical index

Motor, electric 101, 114, 163, 167,

189, 224, 226

Motorised tailgate

37–38, 40

Mountings, ISOFIX

93, 95–96

N

Net, high load retaining 67

Net, luggage retaining

66

Normal mode

113–114

O

Obstacle detection 151

Oil change

190

Oil consumption

190

Oil, engine

190

On-board tools

68, 199–201

Opening the bonnet

188–189

Opening the boot

32, 37

Opening the doors

32, 37

P

Pads, brake 193

Paint

197, 228

Paint colour code

228

Parking brake, electric

102–104, 193

Parking (sensors)

151

Parking sensors, audible and visual 151

Parking sensors, front

152

Parking sensors, rear

151

Passenger compartment temperature pre-

conditioning (Rechargeable hybrid)

29, 59

Pedestrian horn (Electric)

99

Personalisation

12, 29

Plates, identification

228

Port, USB

61, 64

Post Collision Safety Brake

84

Power

22

Power indicator (Rechargeable hybrid)

22

Pressures, tyres

193, 202, 228

Pre-tensioning (seat belts)

87

Priming the fuel system

199

Profiles

230

Protecting children

89–94

Proximity Keyless Entry and Start

32

Public fast charging station

175, 178

Puncture

201–202, 204

R

Radar (warnings) 119

Radio

240

Range

10

Range, AdBlue®

21, 191

Reading lamps

64

Rear bench seat

53

Rear cross traffic alert

157

Rear screen (demisting)

59

Rechargeable hybrid engine 28, 218, 224

Rechargeable hybrid system

6, 28, 100, 114, 167

Recharging the battery

210–211, 213, 215

Recharging the traction battery

165

Recharging the traction battery

(Electric)

173, 177, 179–180

Recharging the traction battery

(Rechargeable hybrid)

167, 170, 172–173

Recirculation, air

58

Recorder, trip distance

25

Reduction of electrical load (mode)

188

Regeneration of the particle filter

192

Regenerative braking (deceleration

by engine braking)

110, 112

Reinitialising the remote control

36

Reinitialising the under-inflation detection

system

119

Reminder, lighting on

69

Remote control

30–33, 35

Remote functions

172, 178

Remotely operable functions (Rechargeable

hybrid)

29, 59

Removing a wheel

205–206

Removing the mat

63

Replacing bulbs

207–209

Replacing fuses

209

Replacing the air filter

192

Replacing the oil filter

192

Replacing the passenger compartment

filter

192

Reservoir, screenwash

191