ignition PEUGEOT 308 SW BL 2010 Workshop Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2010, Model line: 308 SW BL, Model: PEUGEOT 308 SW BL 2010Pages: 336, PDF Size: 21.2 MB

Page 171 of 336

1

i

169

PRACTICAL INFORMATION

This repair kit is available from

PEUGEOT dealers.

It is designed to repair holes of a

maximum diameter of 6 mm, only

where located on the tyre tread or

shoulder. Avoid removing any for-

eign bodies which have penetrated

the tyre.

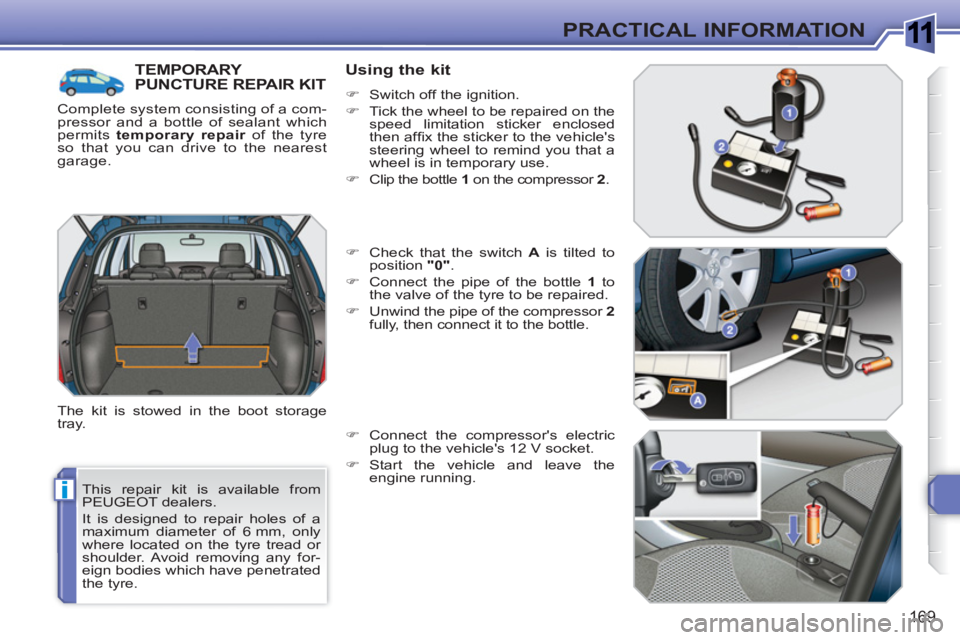

TEMPORARY PUNCTURE REPAIR KIT

Complete system consisting of a com-

pressor and a bottle of sealant which

permits temporary repair

of the tyre

so that you can drive to the nearest

garage.

The kit is stowed in the boot storage

tray.

Using the kit

�)

Switch off the ignition.

�)

Tick the wheel to be repaired on the

speed limitation sticker enclosed

then affi x the sticker to the vehicle's

steering wheel to remind you that a

wheel is in temporary use.

�)

Clip the bottle 1

on the compressor 2

.

�)

Check that the switch A

is tilted to

position "0"

.

�)

Connect the pipe of the bottle 1

to

the valve of the tyre to be repaired.

�)

Unwind the pipe of the compressor 2

fully, then connect it to the bottle.

�)

Connect the compressor's electric

plug to the vehicle's 12 V socket.

�)

Start the vehicle and leave the

engine running.

Page 179 of 336

1

i

177

PRACTICAL INFORMATION

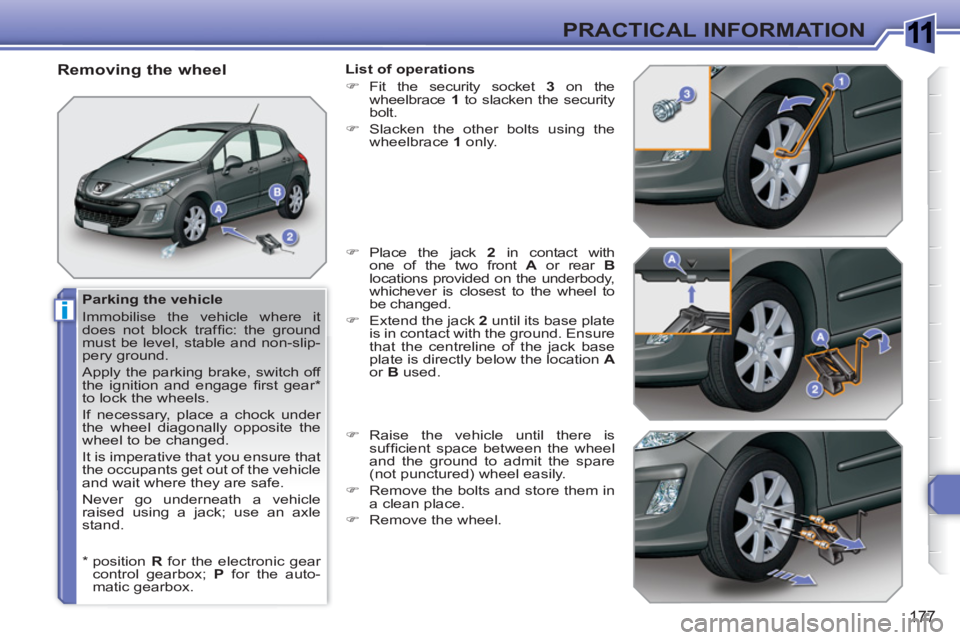

Parking the vehicle

Immobilise the vehicle where it

does not block traffi c: the ground

must be level, stable and non-slip-

pery ground.

Apply the parking brake, switch off

the ignition and engage fi rst gear *

to lock the wheels.

If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

It is imperative that you ensure that

the occupants get out of the vehicle

and wait where they are safe.

Never go underneath a vehicle

raised using a jack; use an axle

stand.

Removing the wheel

List of operations

�)

Fit the security socket 3

on the

wheelbrace 1

to slacken the security

bolt.

�)

Slacken the other bolts using the

wheelbrace 1

only.

�)

Place the jack 2

in contact with

one of the two front A

or rear B

locations provided on the underbody,

whichever is closest to the wheel to

be changed.

�)

Extend the jack 2

until its base plate

is in contact with the ground. Ensure

that the centreline of the jack base

plate is directly below the location A

or B

used.

�)

Raise the vehicle until there is

suffi cient space between the wheel

and the ground to admit the spare

(not punctured) wheel easily.

�)

Remove the bolts and store them in

a clean place.

�)

Remove the wheel.

*

position R

for the electronic gear

control gearbox; P

for the auto-

matic gearbox.

Page 189 of 336

1

187

PRACTICAL INFORMATION

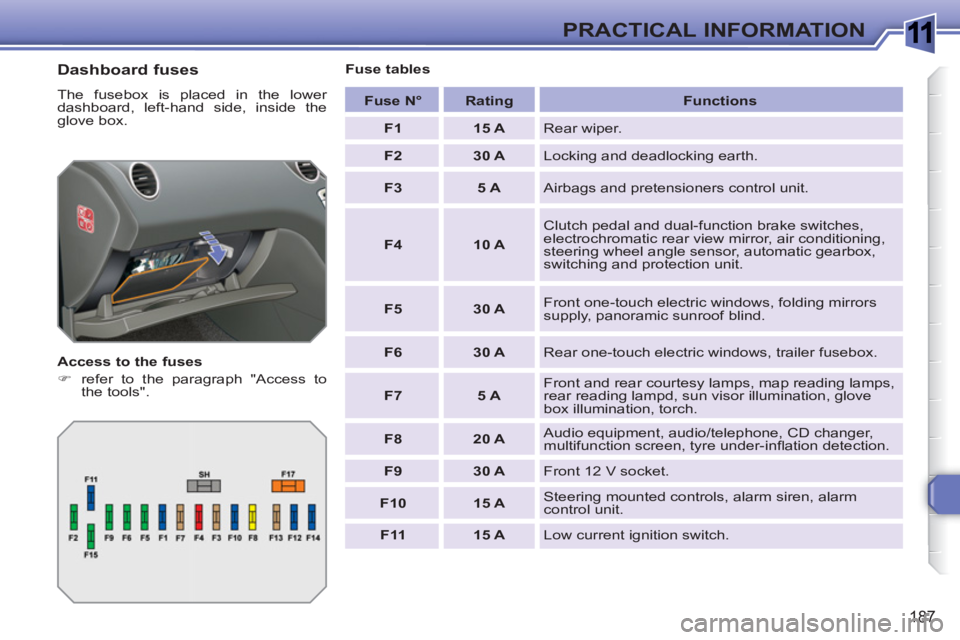

Dashboard fuses

The fusebox is placed in the lower

dashboard, left-hand side, inside the

glove box.

Access to the fuses

�)

refer to the paragraph "Access to

the tools".

Fuse tables

Fuse N°

Rating

Functions

F1

15 A

Rear wiper.

F2

30 A

Locking and deadlocking earth.

F3

5 A

Airbags and pretensioners control unit.

F4

10 A

Clutch pedal and dual-function brake switches,

electrochromatic rear view mirror, air conditioning,

steering wheel angle sensor, automatic gearbox,

switching and protection unit.

F5

30 A

Front one-touch electric windows, folding mirrors

supply, panoramic sunroof blind.

F6

30 A

Rear one-touch electric windows, trailer fusebox.

F7

5 A

Front and rear courtesy lamps, map reading lamps,

rear reading lampd, sun visor illumination, glove

box illumination, torch.

F8

20 A

Audio equipment, audio/telephone, CD changer,

multifunction screen, tyre under-infl ation detection.

F9

30 A

Front 12 V socket.

F10

15 A

Steering mounted controls, alarm siren, alarm

control unit.

F11

15 A

Low current ignition switch.

Page 191 of 336

1

189

PRACTICAL INFORMATION

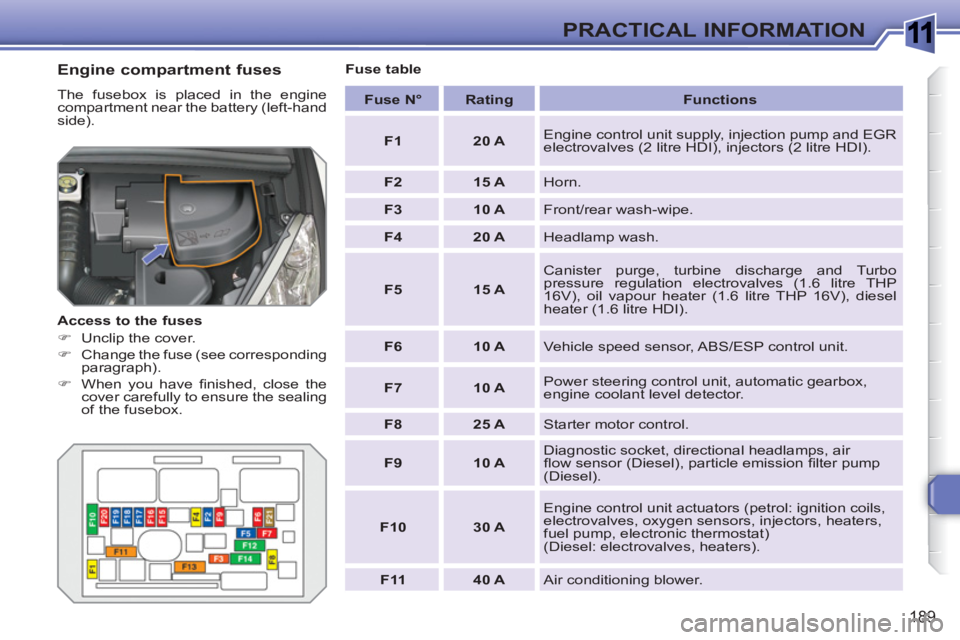

Engine compartment fuses

The fusebox is placed in the engine

compartment near the battery (left-hand

side).

Access to the fuses

�)

Unclip the cover.

�)

Change the fuse (see corresponding

paragraph).

�)

When you have fi nished, close the

cover carefully to ensure the sealing

of the fusebox.

Fuse table

Fuse N°

Rating

Functions

F1

20 A

Engine control unit supply, injection pump and EGR

electrovalves (2 litre HDI), injectors (2 litre HDI).

F2

15 A

Horn.

F3

10 A

Front/rear wash-wipe.

F4

20 A

Headlamp wash.

F5

15 A

Canister purge, turbine discharge and Turbo

pressure regulation electrovalves (1.6 litre THP

16V), oil vapour heater (1.6 litre THP 16V), diesel

heater (1.6 litre HDI).

F6

10 A

Vehicle speed sensor, ABS/ESP control unit.

F7

10 A

Power steering control unit, automatic gearbox,

engine coolant level detector.

F8

25 A

Starter motor control.

F9

10 A

Diagnostic socket, directional headlamps, air

fl ow sensor (Diesel), particle emission fi lter pump

(Diesel).

F10

30 A

Engine control unit actuators (petrol: ignition coils,

electrovalves, oxygen sensors, injectors, heaters,

fuel pump, electronic thermostat)

(Diesel: electrovalves, heaters).

F11

40 A

Air conditioning blower.

Page 192 of 336

1

190

PRACTICAL INFORMATION

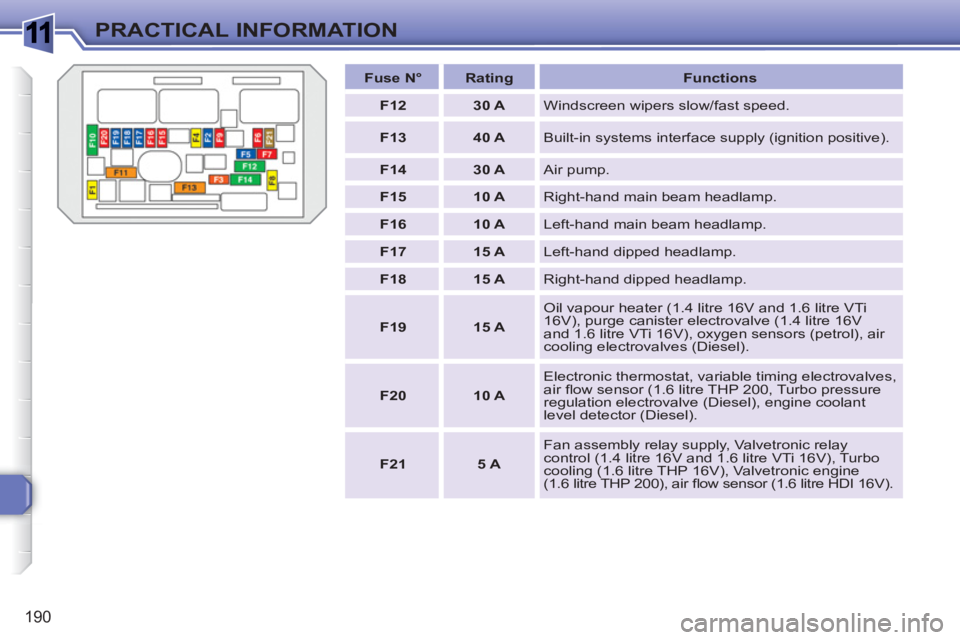

Fuse N°

Rating

Functions

F12

30 A

Windscreen wipers slow/fast speed.

F13

40 A

Built-in systems interface supply (ignition positive).

F14

30 A

Air pump.

F15

10 A

Right-hand main beam headlamp.

F16

10 A

Left-hand main beam headlamp.

F17

15 A

Left-hand dipped headlamp.

F18

15 A

Right-hand dipped headlamp.

F19

15 A

Oil vapour heater (1.4 litre 16V and 1.6 litre VTi

16V), purge canister electrovalve (1.4 litre 16V

and 1.6 litre VTi 16V), oxygen sensors (petrol), air

cooling electrovalves (Diesel).

F20

10 A

Electronic thermostat, variable timing electrovalves,

air fl ow sensor (1.6 litre THP 200, Turbo pressure

regulation electrovalve (Diesel), engine coolant

level detector (Diesel).

F21

5 A

Fan assembly relay supply, Valvetronic relay

control (1.4 litre 16V and 1.6 litre VTi 16V), Turbo

cooling (1.6 litre THP 16V), Valvetronic engine

(1.6 litre THP 200), air fl ow sensor (1.6 litre HDI 16V).

Page 195 of 336

1

!

i

193

PRACTICAL INFORMATION

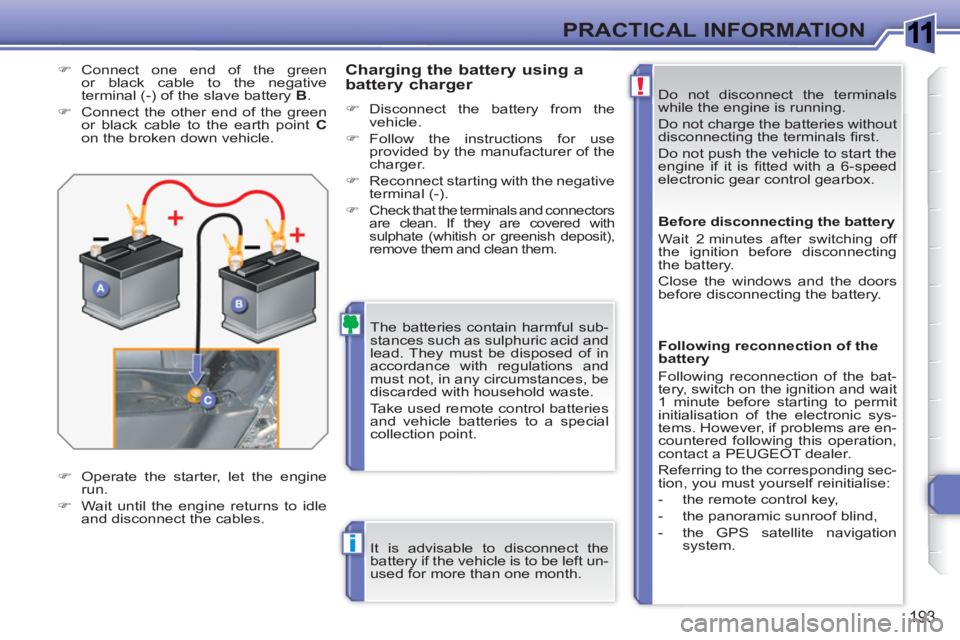

Do not disconnect the terminals

while the engine is running.

Do not charge the batteries without

disconnecting the terminals fi rst.

Do not push the vehicle to start the

engine if it is fi tted with a 6-speed

electronic gear control gearbox.

The batteries contain harmful sub-

stances such as sulphuric acid and

lead. They must be disposed of in

accordance with regulations and

must not, in any circumstances, be

discarded with household waste.

Take used remote control batteries

and vehicle batteries to a special

collection point.

It is advisable to disconnect the

battery if the vehicle is to be left un-

used for more than one month.

Before disconnecting the battery

Wait 2 minutes after switching off

the ignition before disconnecting

the battery.

Close the windows and the doors

before disconnecting the battery.

Following reconnection of the

battery

Following reconnection of the bat-

tery, switch on the ignition and wait

1 minute before starting to permit

initialisation of the electronic sys-

tems. However, if problems are en-

countered following this operation,

contact a PEUGEOT dealer.

Referring to the corresponding sec-

tion, you must yourself reinitialise:

- the remote control key,

- the panoramic sunroof blind,

- the GPS satellite navigation

system.

Charging the battery using a

battery charger

�)

Disconnect the battery from the

vehicle.

�)

Follow the instructions for use

provided by the manufacturer of the

charger.

�)

Reconnect starting with the negative

terminal (-).

�)

Check that the terminals and connectors

are clean. If they are covered with

sulphate (whitish or greenish deposit),

remove them and clean them.

�)

Connect one end of the green

or black cable to the negative

terminal (-) of the slave battery B

.

�)

Connect the other end of the green

or black cable to the earth point C

on the broken down vehicle.

�)

Operate the starter, let the engine

run.

�)

Wait until the engine returns to idle

and disconnect the cables.

Page 196 of 336

1

!

i

194

PRACTICAL INFORMATION

A fl at battery prevents the engine

from starting (refer to the corre-

sponding paragraph). If the telephone is being used at

this time:

- it will be maintained for 10 minutes

with the hands-free kit of your

Peugeot Connect Sound,

-

it will be maintained for 10 minutes

with the Peugeot Connect Navi-

gation or the Peugeot Connect

Media, then it will transfer to your

telephone depending on the tele-

phone model.

System which manages the duration of

use of certain functions to conserve a

suffi cient level of charge in the battery.

After the engine has stopped, you can

still use functions such as the audio and

telematics system, windscreen wip-

ers, dipped beam headlamps, courtesy

lamps, etc. for a maximum combined

duration of thirty minutes.

Exiting economy mode

These functions are reactivated auto-

matically next time the vehicle is driven.

�)

In order to resume the use of these

functions immediately, start the

engine and let it run:

- for less than ten minutes, to use

the equipment for approximately

fi ve minutes,

- for more than ten minutes, to

use the equipment for up to

approximately thirty minutes.

Switching to economy mode

Once the thirty minutes are over, a

message appears on the multi-function

screen indicating that the vehicle has

switched to economy mode and the ac-

tive functions are put on standby.

CHANGING A WIPER BLADE

Removing

�)

Raise the corresponding wiper arm.

�)

Unclip the wiper blade and remove it.

Fitting

�)

Put the corresponding new wiper

blade in place and clip it.

�)

Fold down the wiper arm carefully.

Before removing a front wiper

blade

�)

Within one minute after switching off

the ignition, operate the wiper stalk

to position the wiper blades vertically

on the windscreen.

After fitting a front wiper blade

�)

Switch on the ignition.

�)

Operate the wiper stalk again to

park the wiper blades.

LOAD REDUCTION MODE

System which manages the use of certain

functions according to the level of charge

remaining in the battery.

When the vehicle is being driven, the load

reduction function temporarily deactivates

certain functions, such as the air condition-

ing, the heated rear screen...

The deactivated functions are reactivated

automatically as soon as conditions permit.

Page 232 of 336

230

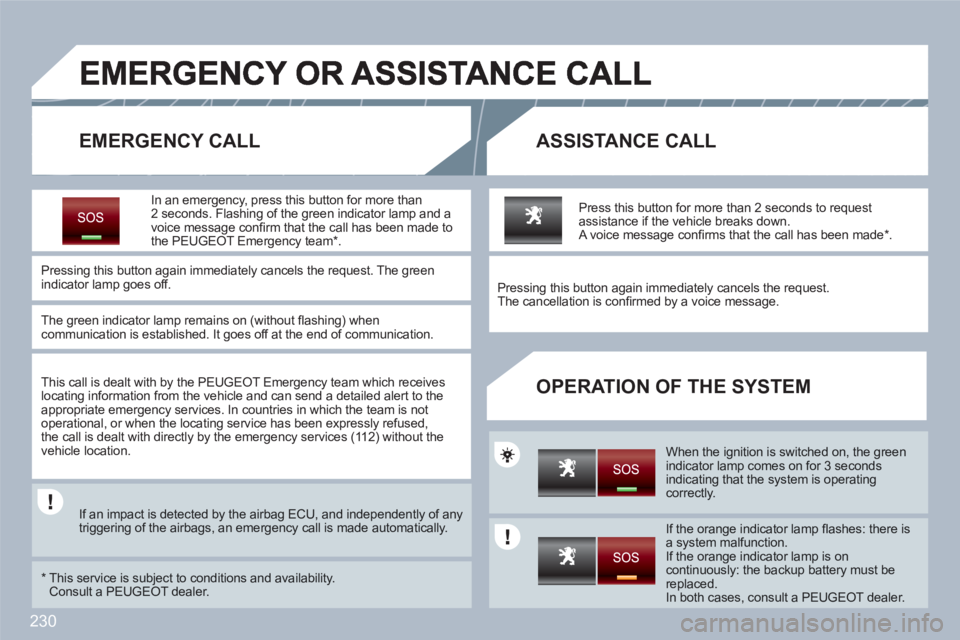

EMERGENCY CALLASSISTANCE CALL

OPERATION OF THE SYSTEM

In an emergency, press this button for more than 2 seconds. Flashing of the green indicator lamp and avoice message confi rm that the call has been made tothe PEUGEOT Emergency team *

.

Pressing this button again immediately cancels the request. The greenindicator lamp goes off.

The green indicator lamp remains on (without fl ashing) when communication is established. It goes off at the end of communication.

This call is dealt with by the PEUGEOT Emergency team which receives locating information from the vehicle and can send a detailed alert to the appropriate emergency services. In countries in which the team is not operational, or when the locating service has been expressly refused,the call is dealt with directly by the emergency services (11 2) without thevehicle location.

If an impact is detected by the airbag ECU, and independently of any triggering of the airbags, an emergency call is made automatically.

*

This service is subject to conditions and availability. Consult a PEUGEOT dealer.

Press this button for more than 2 seconds to requestassistance if the vehicle breaks down. A voice message confi rms that the call has been made * .

Pressing this button again immediately cancels the request.

The cancellation is confi rmed by a voice message.

When the ignition is switched on, the greenindicator lamp comes on for 3 seconds indicating that the system is operating correctly.

If the orange indicator lamp fl ashes: there isa system malfunction.

If the orange indicator lamp is oncontinuously: the backup battery must bereplaced.

In both cases, consult a PEUGEOT dealer.

Page 255 of 336

253

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIO MEDIANAV ESC TRAFFIC

SETUPADDR

BOOK

1

2

3

RADIONAVESCTRAFFICADDRBOOKMEDIAMEDIA

RADIONAVESCTRAFFICADDRBOOKMEDIAMEDIA

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK4

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

5

6

7

8

9

MEDIA

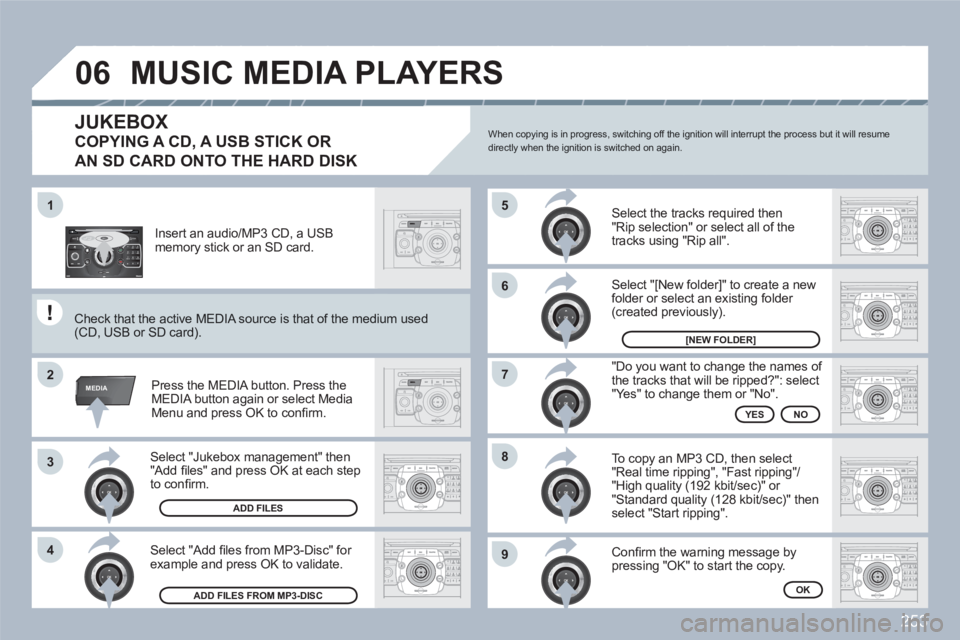

06

Select "Jukebox management" then "Add fi les" and press OK at each step to confi rm.

Press the MEDIA button. Press the MEDIA button again or select Media Menu and press OK to confi rm.

Insert an audio/MP3 CD, a USB memory stick or an SD card.

JUKEBOX

ADD FILES

Check that the active MEDIA source is that of the meddium used (CD, USB or SD card).

Select "Add fi les from MP3-Disc" for example and press OK to validate.

Select the tracks required then"Rip selection" or select all of thetracks using "Rip all".

Select "[New folder]" to create a new folder or select an existing folder (created previously).

ADD FILES FROM MP3-DISC

[NEW FOLDER]

"Do you want to change the names of the tracks that will be ripped?": select"Yes" to change them or "No".

To copy an MP3 CD, then select "Real time ripping", "Fast ripping"/"High quality (192 kbit/sec)" or "Standard quality (128 kbit/sec)" then select "Start ripping".

Confi rm the warning message by pressing "OK" to start the copy.

OK

YESNO

When copying is in progress, switching off the ignition will interrupt the process but it will resumedirectly when the ignition is switched on again.

MUSIC MEDIA PLAYERS

COPYING A CD, A USB STICK OR

AN SD CARD ONTO THE HARD DISK

Page 259 of 336

257

07

1

3

5

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

4

2

12ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

2ABC3DEF5JKL4GHI6MNO8TUV7PQRS9WXYZ0*#

1RADIOMEDIANAVESCTRAFFICSETUPADDRBOOK

*

The services available via the telephone depend on the network, the SIM card and the compatibilityof the Bluetooth equipment used. Refer to your telephone's manual and your operator to checkwhich services you have access to. A list of mobile telephones which offer the best range of servicesis available from dealers.

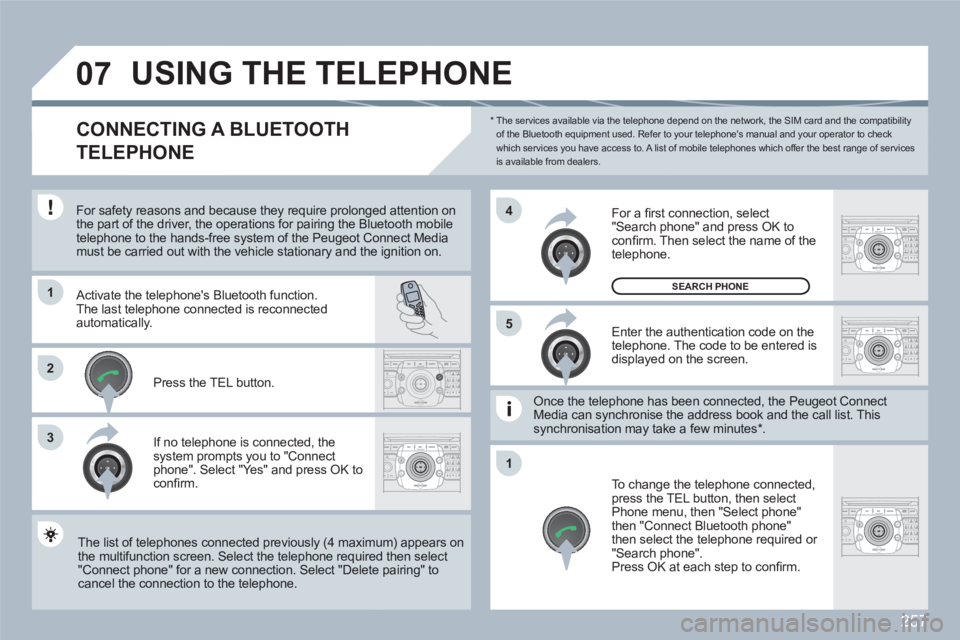

USING THE TELEPHONE

CONNECTING A BLUETOOTH

TELEPHONE

For safety reasons and because they require prolongeed attention onthe part of the driver, the operations for pairing the Bluuetooth mobiletelephone to the hands-free system of the Peugeot Coonnect Media must be carried out with the vehicle stationary and thee ignition on.

Activate the telephone's Bluetooth function.

The last telephone connected is reconnected automatically.

If no telephone is connected, thesystem prompts you to "Connect phone". Select "Yes" and press OK to confi rm.

Enter the authentication code on thetelephone. The code to be entered is displayed on the screen.

To change the telephone connected,press the TEL button, then selectPhone menu, then "Select phone" then "Connect Bluetooth phone"then select the telephone required or "Search phone".

Press OK at each step to confi rm.

Once the telephone has been connected, the Peugeott Connect Media can synchronise the address book and the call list. This synchronisation may take a few minutes * .

The list of telephones connected previously (4 maximum) appears onthe multifunction screen. Select the telephone requireed then select "Connect phone" for a new connection. Select "Deletee pairing" tocancel the connection to the telephone.

Press the TEL button.

For a fi rst connection, select"Search phone" and press OK to confi rm. Then select the name of the telephone.

SEARCH PHONE