PEUGEOT 308 SW BL 2012 Owners Manual

Manufacturer: PEUGEOT, Model Year: 2012, Model line: 308 SW BL, Model: PEUGEOT 308 SW BL 2012Pages: 382, PDF Size: 17.71 MB

Page 191 of 382

11

189

PRACTICAL INFORMATION

CHANGING A WHEEL

Procedure for changing a

faulty wheel for the spare

wheel using the tools pro-

vided with the vehicle.

The wheelbrace 1

is stowed in the boot

left-hand side trim; for access to it:

�)

open the boot,

�)

open the access fl ap in the left-hand

side trim,

�)

unclip the wheelbrace from its support,

The tools 2

and 3

are stowed in a box

fi tted under the spare wheel; the as-

sembly is installed underneath the rear

of the vehicle (refer to the section "Ac-

cess to the spare wheel" on the follow-

ing page for instructions on how to get

them out).

Access to the tools

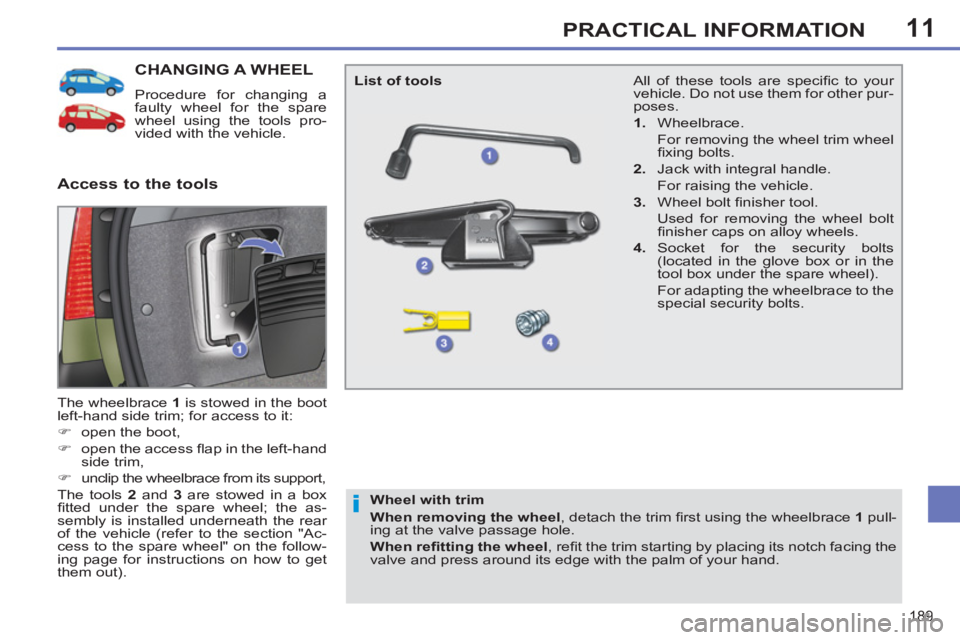

List of tools

Wheel with trim

When removing the wheel

, detach the trim fi rst using the wheelbrace 1

pull-

ing at the valve passage hole.

When refi tting the wheel

, refi t the trim starting by placing its notch facing the

valve and press around its edge with the palm of your hand.

All of these tools are specifi c to your

vehicle. Do not use them for other pur-

poses.

1.

Wheelbrace.

For removing the wheel trim wheel

fi xing bolts.

2.

Jack with integral handle.

For raising the vehicle.

3.

Wheel bolt fi nisher tool.

Used for removing the wheel bolt

fi nisher caps on alloy wheels.

4.

Socket for the security bolts

(located in the glove box or in the

tool box under the spare wheel).

For adapting the wheelbrace to the

special security bolts.

Page 192 of 382

11

190

PRACTICAL INFORMATION

Fitting a steel or "space-saver"

type spare wheel

If your vehicle is fi tted with alloy

wheels, it is normal to notice, when

tightening the bolts on fi tting, that

the washers do not come into con-

tact with the steel or "space-saver"

type spare wheel. The wheel is

secured by the conical contact of

each bolt.

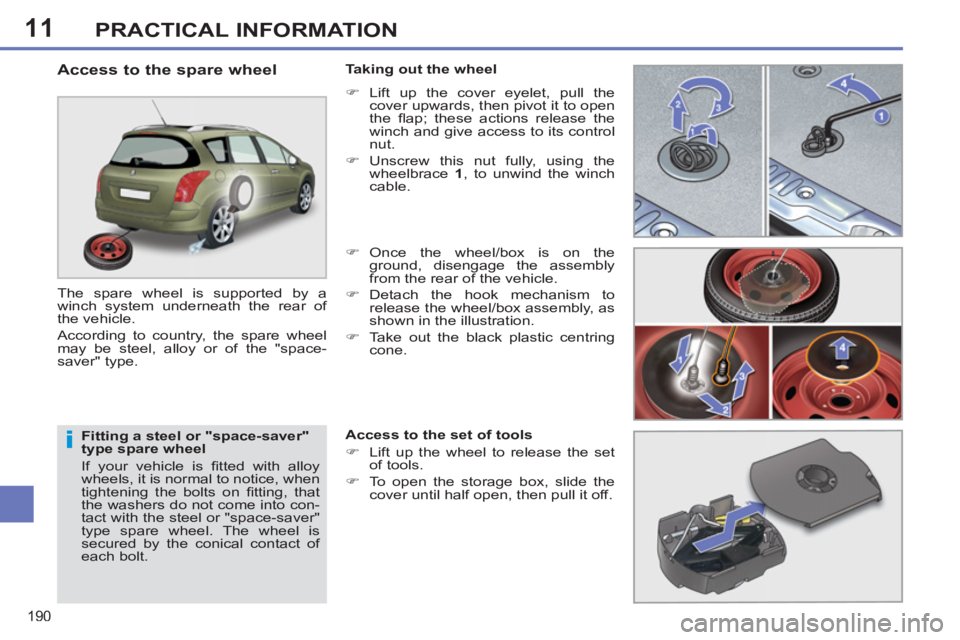

Access to the spare wheel

The spare wheel is supported by a

winch system underneath the rear of

the vehicle.

According to country, the spare wheel

may be steel, alloy or of the "space-

saver" type.

Taking out the wheel

�)

Lift up the cover eyelet, pull the

cover upwards, then pivot it to open

the fl ap; these actions release the

winch and give access to its control

nut.

�)

Unscrew this nut fully, using the

wheelbrace 1

, to unwind the winch

cable.

�)

Once the wheel/box is on the

ground, disengage the assembly

from the rear of the vehicle.

�)

Detach the hook mechanism to

release the wheel/box assembly, as

shown in the illustration.

�)

Take out the black plastic centring

cone.

Access to the set of tools

�)

Lift up the wheel to release the set

of tools.

�)

To open the storage box, slide the

cover until half open, then pull it off.

Page 193 of 382

11

191

PRACTICAL INFORMATION

Tyre under-infl ation detection

The spare wheel is not fi tted with a

sensor. The punctured wheel must

be repaired by a PEUGEOT dealer

or a qualifi ed workshop.

Putting the wheel back in place

�)

Store tools 2

and 3

in the box and

close the cover.

�)

Position the box on the ground.

�)

Place the spare wheel on the box.

�)

Fit the black plastic centring cone in

the centre of the wheel (on steel or

"space-saver" type wheels only).

�)

Pass the hooking device through

the cone and the wheel to secure it

to the box cover.

�)

Raise the wheel/box assembly

underneath the rear of the vehicle

by tightening the winch control nut

using the wheelbrace 1

.

�)

Fully tighten the nut.

�)

Close the fl ap with the eyelet and

cover to secure the winch.

�)

Check that the wheel is located

squarely against the fl oor.

If not, repeat the operation.

If you purchase a wheel of standard

size to replace the "space-saver"

type spare wheel, the spacer, lo-

cated underneath the vehicle, must

be removed. Contact a PEUGEOT

dealer or a qualifi ed workshop.

Page 194 of 382

11

192

PRACTICAL INFORMATION

Parking the vehicle

Immobilise the vehicle where it

does not block traffi c: the ground

must be level, stable and non-slip-

pery ground.

Apply the parking brake, switch off

the ignition and engage fi rst gear *

to lock the wheels.

If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

It is imperative that you ensure that

the occupants get out of the vehicle

and wait where they are safe.

Never go underneath a vehicle

raised using a jack; use an axle

stand.

Removing the wheel

List of operations

�)

Remove the fi nisher cap from each

wheel bolt using tool 3

.

�)

Fit the security socket 4

on the

wheelbrace 1

to slacken the security

bolt.

�)

Slacken the other bolts using the

wheelbrace 1

only.

�)

Place the jack 2

in contact with one

of the two front A

or rear B

locations

provided on the underbody,

whichever is closest to the wheel to

be changed.

�)

Extend the jack 2

until its base plate

is in contact with the ground. Ensure

that the centreline of the jack base

plate is directly below the location A

or B

used.

�)

Raise the vehicle until there is

suffi cient space between the wheel

and the ground to admit the spare

(not punctured) wheel easily.

�)

Remove the bolts and store them in

a clean place.

�)

Remove the wheel.

*

position R

for the electronic

gear control gearbox; P

for the

automatic gearbox.

Page 195 of 382

11

193

PRACTICAL INFORMATION

After changing a wheel

To store the punctured wheel in the

boot correctly, fi rst remove the cen-

tral cover.

When using the "space-saver" type

spare wheel, do not exceed 50 mph

(80 km/h).

Have the tightening of the bolts and

the pressure of the spare wheel

checked by a PEUGEOT dealer or

a qualifi ed workshop without delay.

Have the punctured wheel repaired

and replace it on the vehicle as

soon as possible.

Fitting the wheel

List of operations

�)

Put the wheel in place on the hub.

�)

Screw in the bolts by hand to the

stop.

�)

Pre-tighten the security bolt using

the wheelbrace 1

fi tted with the

security socket 4

.

�)

Pre-tighten the other bolts using the

wheelbrace 1

only.

�)

Lower the vehicle fully.

�)

Fold the jack 2

and detach it.

�)

Tighten the security bolt using the

wheelbrace 1

fi tted with the security

socket 4

.

�)

Tighten the other bolts using the

wheelbrace 1

only.

�)

Refi t the fi nisher caps on each wheel

bolt.

�)

Store the tools in the box.

Page 196 of 382

11

194

PRACTICAL INFORMATION

Risk of electrocution

Xenon bulbs (D1S-35W) must be

replaced by a PEUGEOT dealer or

a qualifi ed workshop.

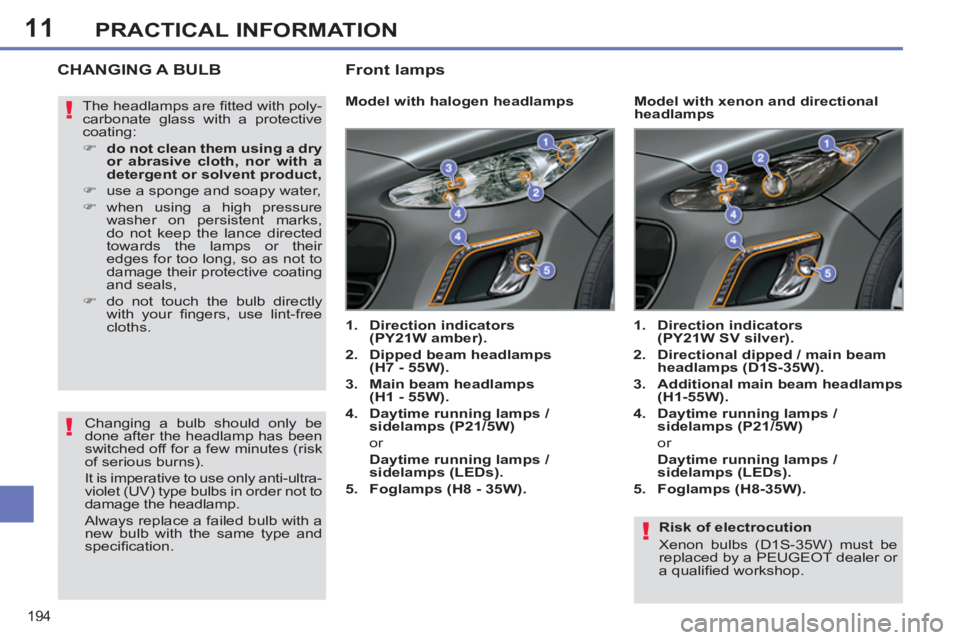

CHANGING A BULB

Model with halogen headlamps

1.

Direction indicators

(PY21W amber).

2.

Dipped beam headlamps

(H7 - 55W).

3.

Main beam headlamps

(H1 - 55W).

4.

Daytime running lamps /

sidelamps (P21/5W)

or

Daytime running lamps /

sidelamps (LEDs).

5.

Foglamps (H8 - 35W).

1.

Direction indicators

(PY21W SV silver).

2.

Directional dipped / main beam

headlamps (D1S-35W).

3.

Additional main beam headlamps

(H1-55W).

4.

Daytime running lamps /

sidelamps

(P21/5W)

or

Daytime running lamps /

sidelamps (LEDs).

5.

Foglamps (H8-35W).

Model with xenon and directional

headlamps The headlamps are fi tted with poly-

carbonate glass with a protective

coating:

�)

do not clean them using a dry

or abrasive cloth, nor with a

detergent or solvent product,

�)

use a sponge and soapy water,

�)

when using a high pressure

washer on persistent marks,

do not keep the lance directed

towards the lamps or their

edges for too long, so as not to

damage their protective coating

and seals,

�)

do not touch the bulb directly

with your fi

ngers, use lint-free

cloths.

Changing a bulb should only be

done after the headlamp has been

switched off for a few minutes (risk

of serious burns).

It is imperative to use only anti-ultra-

violet (UV) type bulbs in order not to

damage the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specifi cation.

Front lamps

Page 197 of 382

11

195

PRACTICAL INFORMATION

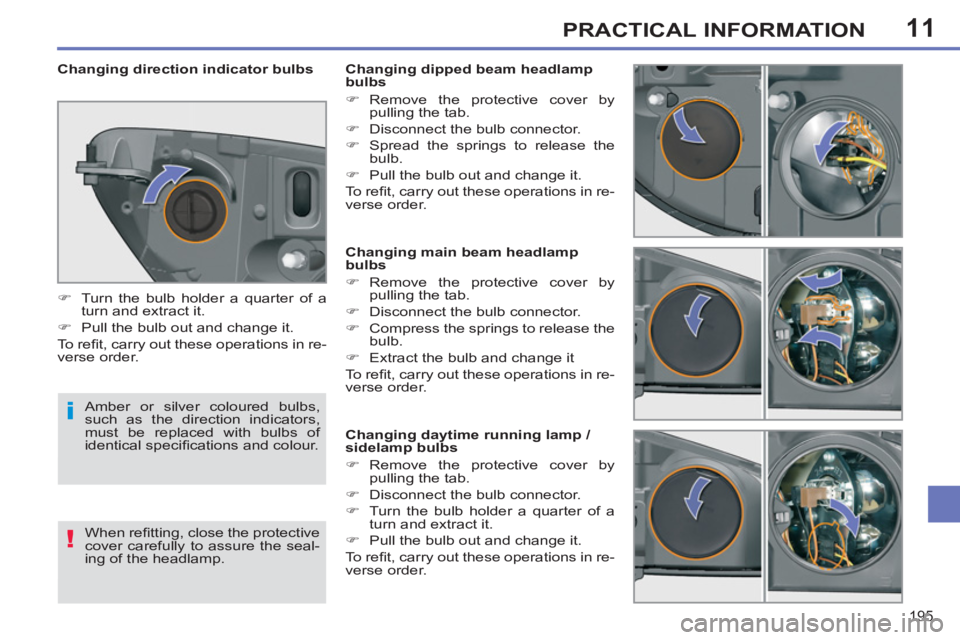

Changing main beam headlamp

bulbs

�)

Remove the protective cover by

pulling the tab.

�)

Disconnect the bulb connector.

�)

Compress the springs to release the

bulb.

�)

Extract the bulb and change it

To r efi t, carry out these operations in re-

verse order.

Changing daytime running lamp /

sidelamp bulbs

�)

Remove the protective cover by

pulling the tab.

�)

Disconnect the bulb connector.

�)

Turn the bulb holder a quarter of a

turn and extract it.

�)

Pull the bulb out and change it.

To r efi t, carry out these operations in re-

verse order.

Changing dipped beam headlamp

bulbs

�)

Remove the protective cover by

pulling the tab.

�)

Disconnect the bulb connector.

�)

Spread the springs to release the

bulb.

�)

Pull the bulb out and change it.

To r efi t, carry out these operations in re-

verse order.

Changing direction indicator bulbs

�)

Turn the bulb holder a quarter of a

turn and extract it.

�)

Pull the bulb out and change it.

To r efi t, carry out these operations in re-

verse order.

Amber or silver coloured bulbs,

such as the direction indicators,

must be replaced with bulbs of

identical specifi cations and colour.

When refi tting, close the protective

cover carefully to assure the seal-

ing of the headlamp.

Page 198 of 382

11PRACTICAL INFORMATION

Changing front foglamp bulbs

�)

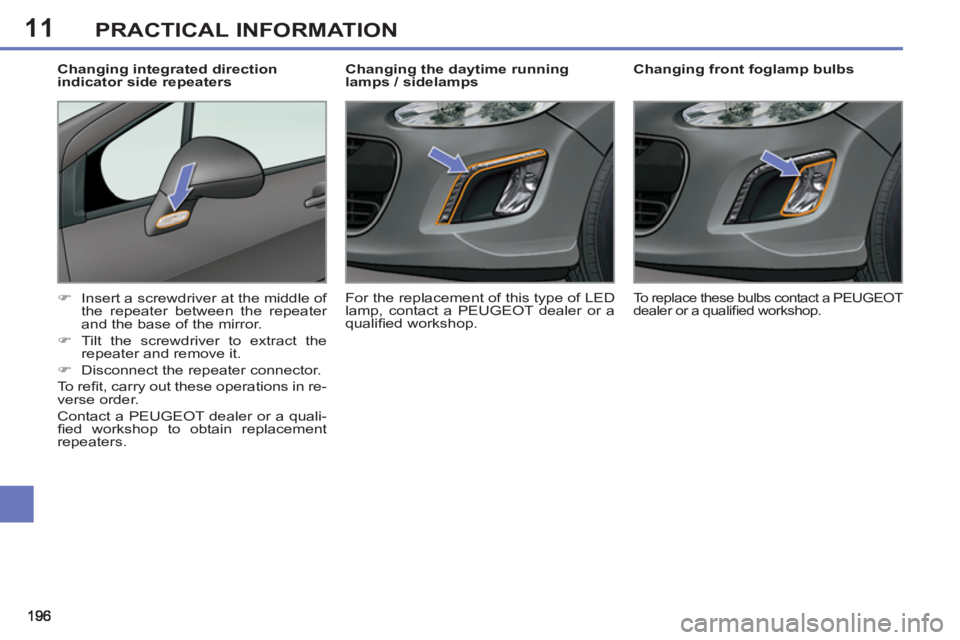

Insert a screwdriver at the middle of

the repeater between the repeater

and the base of the mirror.

�)

Tilt the screwdriver to extract the

repeater and remove it.

�)

Disconnect the repeater connector.

To r efi t, carry out these operations in re-

verse order.

Contact a PEUGEOT dealer or a quali-

fi ed workshop to obtain replacement

repeaters.

Changing integrated direction

indicator side repeaters

To replace these bulbs contact a PEUGEOT

dealer or a qualifi ed workshop.

Changing the daytime running

lamps / sidelamps

For the replacement of this type of LED

lamp, contact a PEUGEOT dealer or a

qualifi ed workshop.

Page 199 of 382

11

197

PRACTICAL INFORMATION

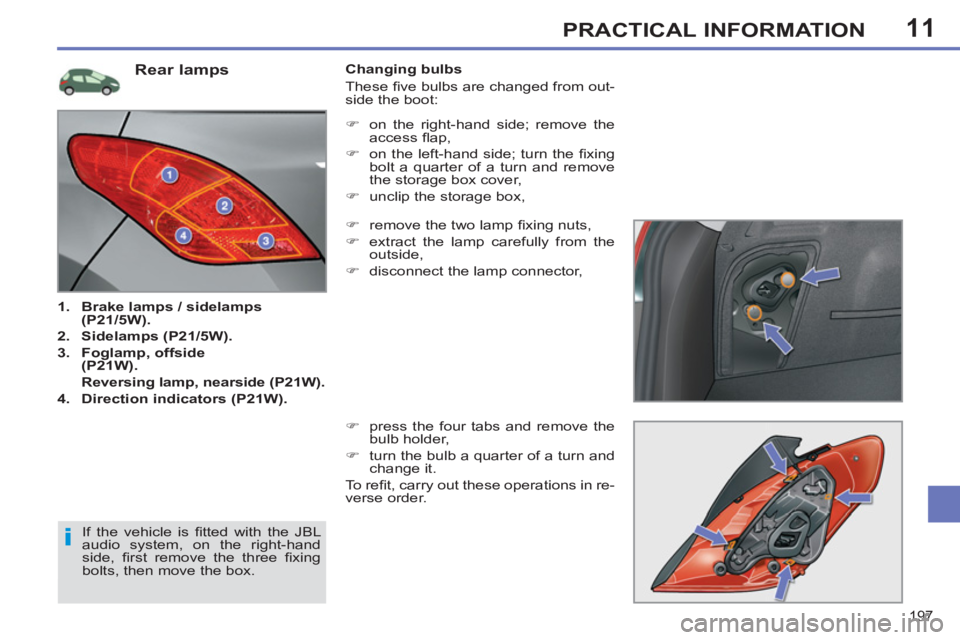

Rear lamps

1.

Brake lamps / sidelamps

(P21/5W).

2.

Sidelamps (P21/5W).

3.

Foglamp, offside

(P21W).

Reversing lamp, nearside (P21W).

4.

Direction indicators (P21W).

Changing bulbs

These fi ve bulbs are changed from out-

side the boot:

�)

remove the two lamp fi xing nuts,

�)

extract the lamp carefully from the

outside,

�)

disconnect the lamp connector,

�)

press the four tabs and remove the

bulb holder,

�)

turn the bulb a quarter of a turn and

change it.

To r efi t, carry out these operations in re-

verse order.

If the vehicle is fi tted with the JBL

audio system, on the right-hand

side, fi rst remove the three fi xing

bolts, then move the box.

�)

on the right-hand side; remove the

access fl ap,

�)

on the left-hand side; turn the fi xing

bolt a quarter of a turn and remove

the storage box cover,

�)

unclip the storage box,

Page 200 of 382

11

198

PRACTICAL INFORMATION

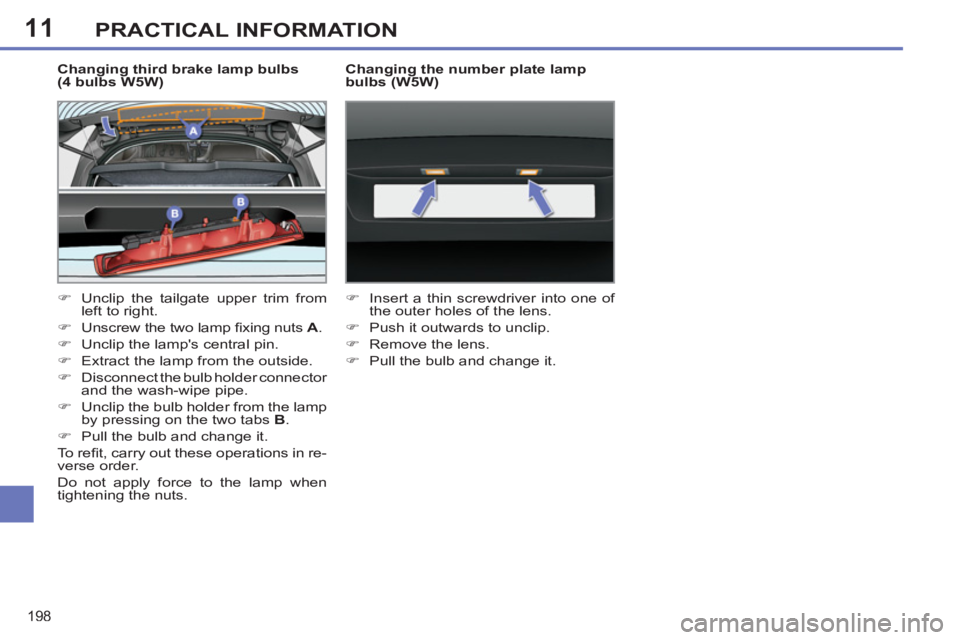

Changing third brake lamp bulbs

(4 bulbs W5W)

�)

Unclip the tailgate upper trim from

left to right.

�)

Unscrew the two lamp fi xing nuts A

.

�)

Unclip the lamp's central pin.

�)

Extract the lamp from the outside.

�)

Disconnect the bulb holder connector

and the wash-wipe pipe.

�)

Unclip the bulb holder from the lamp

by pressing on the two tabs B

.

�)

Pull the bulb and change it.

To r efi t, carry out these operations in re-

verse order.

Do not apply force to the lamp when

tightening the nuts.

Changing the number plate lamp

bulbs (W5W)

�)

Insert a thin screwdriver into one of

the outer holes of the lens.

�)

Push it outwards to unclip.

�)

Remove the lens.

�)

Pull the bulb and change it.