Peugeot 508 Hybrid 2016 Owner's Manual

Manufacturer: PEUGEOT, Model Year: 2016, Model line: 508 Hybrid, Model: Peugeot 508 Hybrid 2016Pages: 424, PDF Size: 13.29 MB

Page 231 of 424

229

508_en_Chap08_en-cas-de-pannes_ed01-2016

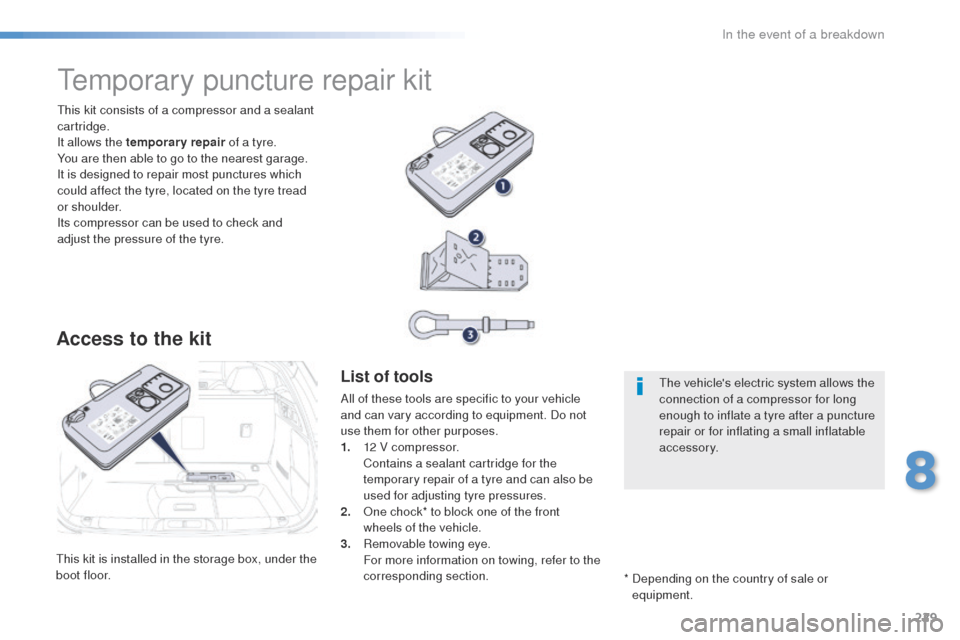

this kit is installed in the storage box, under the

boot floor.

th

is kit consists of a compressor and a sealant

cartridge.

It allows the temporary repair of a tyre.

You are then able to go to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Its compressor can be used to check and

adjust the pressure of the tyre.

temporary puncture repair kit

Access to the kit

List of tools

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

use them for other purposes.

1.

1

2 V compressor.

C

ontains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2.

O

ne chock* to block one of the front

wheels of the vehicle.

3.

R

emovable towing eye.

F

or more information on towing, refer to the

corresponding section. *

D

epending on the country of sale or

equipment.th e vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

8

In the event of a breakdown

Page 232 of 424

230

508_en_Chap08_en-cas-de-pannes_ed01-2016

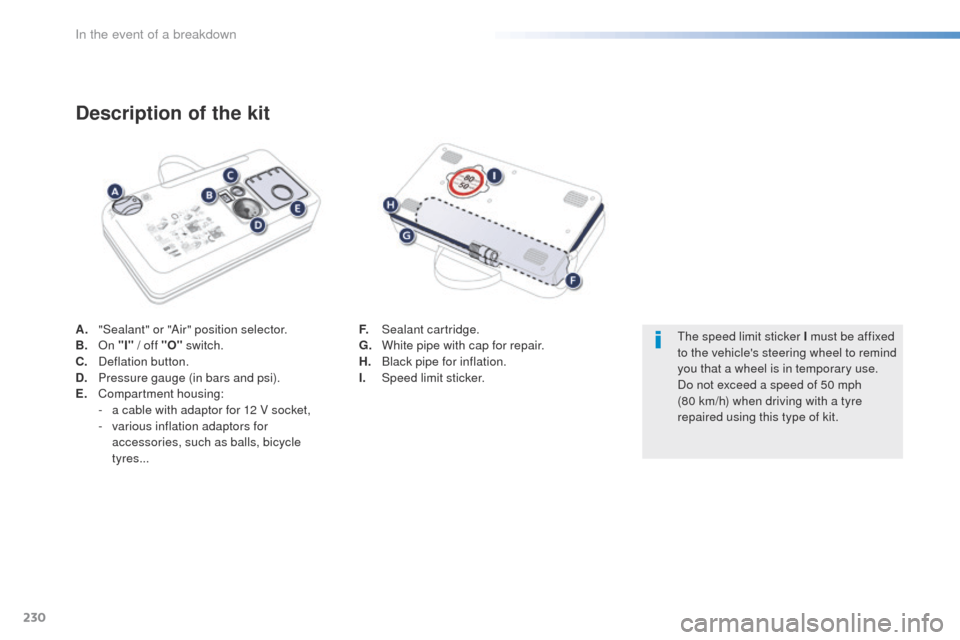

A. "Sealant" or "Air" position selector.

B. On "I" / off "O" switch.

C.

D

eflation button.

D.

P

ressure gauge (in bars and psi).

E.

C

ompartment housing:

-

a c

able with adaptor for 12 V socket,

-

v

arious inflation adaptors for

accessories, such as balls, bicycle

tyres...

Description of the kit

F. Sealant cartridge.

G. W hite pipe with cap for repair.

H.

B

lack pipe for inflation.

I.

Spe

ed limit sticker.th e speed limit sticker I must be affixed

to the vehicle's steering wheel to remind

you that a wheel is in temporary use.

Do not exceed a speed of 50 mph

(80

km/h) when driving with a tyre

repaired using this type of kit.

In the event of a breakdown

Page 233 of 424

231

508_en_Chap08_en-cas-de-pannes_ed01-2016

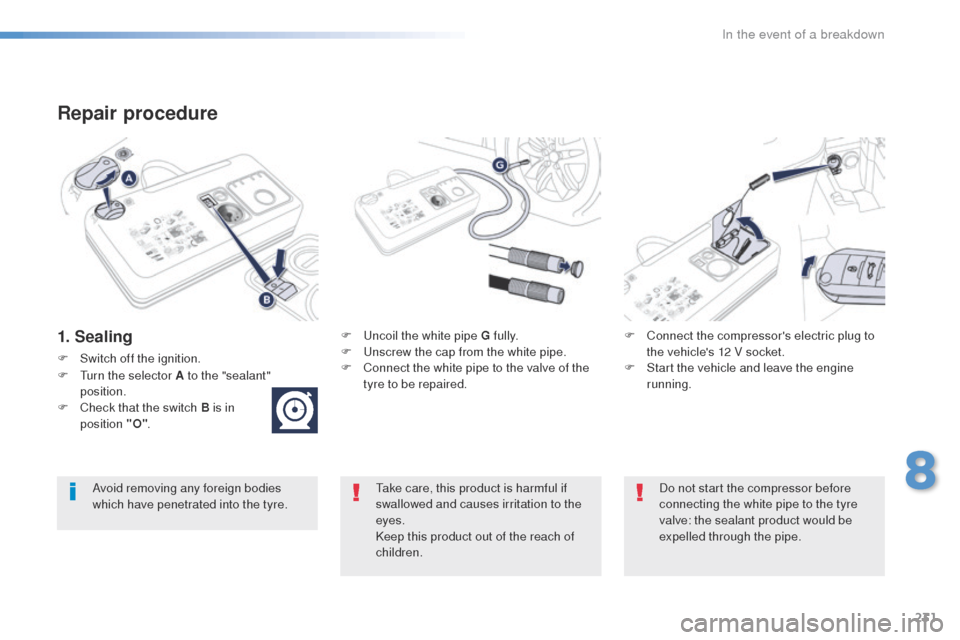

Repair procedure

1. SealingF uncoil the white pipe G fully.

F un screw the cap from the white pipe.

F

C

onnect the white pipe to the valve of the

tyre to be repaired. F

C onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

tart the vehicle and leave the engine

running.

ta

ke care, this product is harmful if

swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

Avoid removing any foreign bodies

which have penetrated into the tyre.

Do not start the compressor before

connecting the white pipe to the tyre

valve: the sealant product would be

expelled through the pipe.

F

S

witch off the ignition.

F

t

u

rn the selector A to the "sealant"

position.

F

C

heck that the switch B is in

position "O" .

8

In the event of a breakdown

Page 234 of 424

232

508_en_Chap08_en-cas-de-pannes_ed01-2016

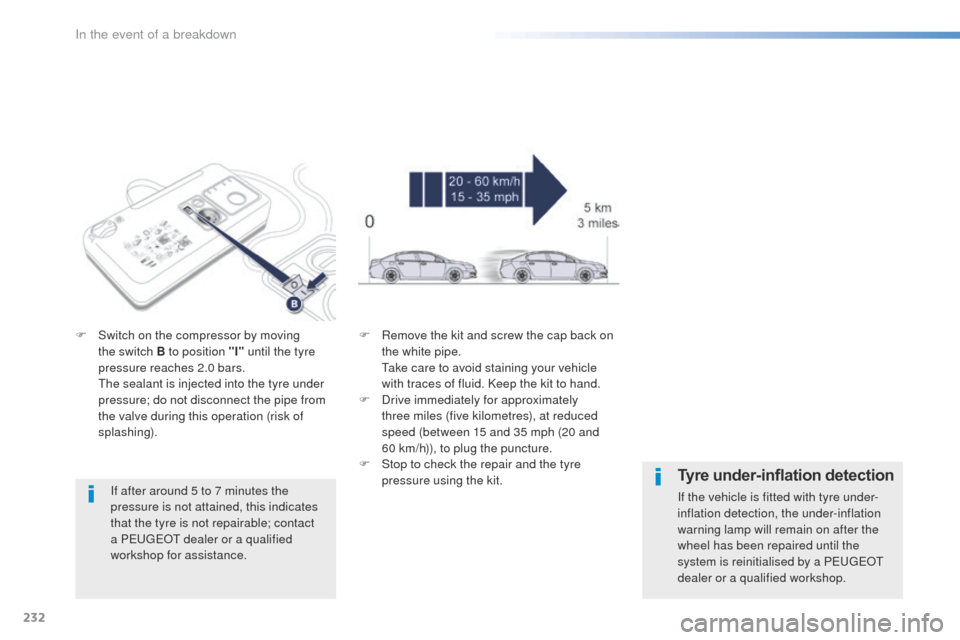

If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a P

e

uge

Ot

dealer or a qualified

workshop for assistance.

F

S

witch on the compressor by moving

the switch B to position "I" until the tyre

pressure reaches 2.0 bars.

t

h

e sealant is injected into the tyre under

pressure; do not disconnect the pipe from

the valve during this operation (risk of

splashing). F

R

emove the kit and screw the cap back on

the white pipe.

t

a

ke care to avoid staining your vehicle

with traces of fluid. Keep the kit to hand.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60 km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.Tyre under-inflation detection

If the vehicle is fitted with tyre under-

inflation detection, the under-inflation

warning lamp will remain on after the

wheel has been repaired until the

system is reinitialised by a P

e

uge

Ot

dealer or a qualified workshop.

In the event of a breakdown

Page 235 of 424

233

508_en_Chap08_en-cas-de-pannes_ed01-2016

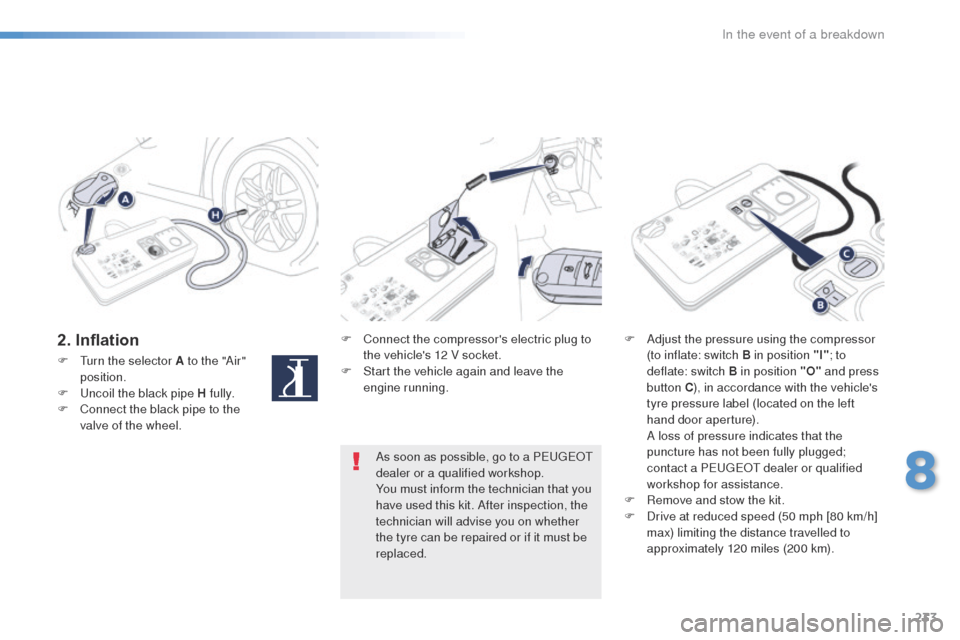

2. InflationF Connect the compressor's electric plug to the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running. F

A djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B

in position "O" and press

button C ), in accordance with the vehicle's

tyre pressure label (located on the left

hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a P

e

uge

Ot

dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph [80 km/h]

max) limiting the distance travelled to

approximately 120 miles (200 km).

As soon as possible, go to a P

e

uge

Ot

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

F

t

u

rn the selector A to the "Air"

position.

F

u

n

coil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel.

8

In the event of a breakdown

Page 236 of 424

234

508_en_Chap08_en-cas-de-pannes_ed01-2016

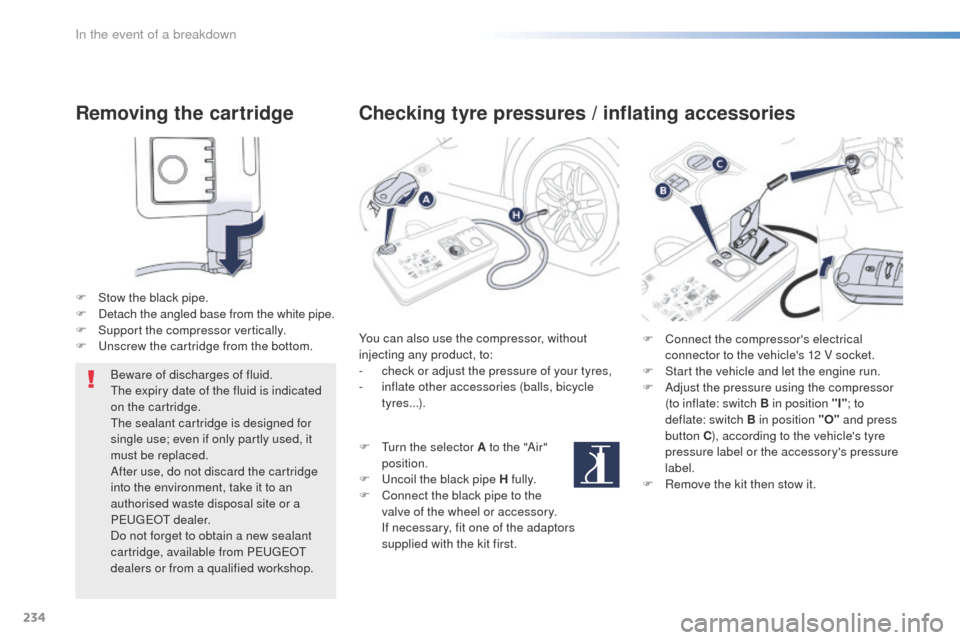

Removing the cartridge

F Stow the black pipe.

F D etach the angled base from the white pipe.

F

S

upport the compressor vertically.

F

u

n

screw the cartridge from the bottom.

Beware of discharges of fluid.

th

e expiry date of the fluid is indicated

on the cartridge.

th

e sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

P

e

uge

Ot d

ealer.

Do not forget to obtain a new sealant

cartridge, available from P

e

uge

Ot

dealers or from a qualified workshop.

Checking tyre pressures / inflating accessories

You can also use the compressor, without

injecting any product, to:

-

c

heck or adjust the pressure of your tyres,

-

i

nflate other accessories (balls, bicycle

tyres...).

F

t

u

rn the selector A to the "Air"

position.

F

u

n

coil the black pipe H fully.

F

C

onnect the black pipe to the

valve of the wheel or accessory.

I

f necessary, fit one of the adaptors

supplied with the kit first. F

C onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ; to

deflate: switch B in position "O" and press

button C ), according to the vehicle's tyre

pressure label or the accessory's pressure

label.

F

R

emove the kit then stow it.

In the event of a breakdown

Page 237 of 424

235

508_en_Chap08_en-cas-de-pannes_ed01-2016

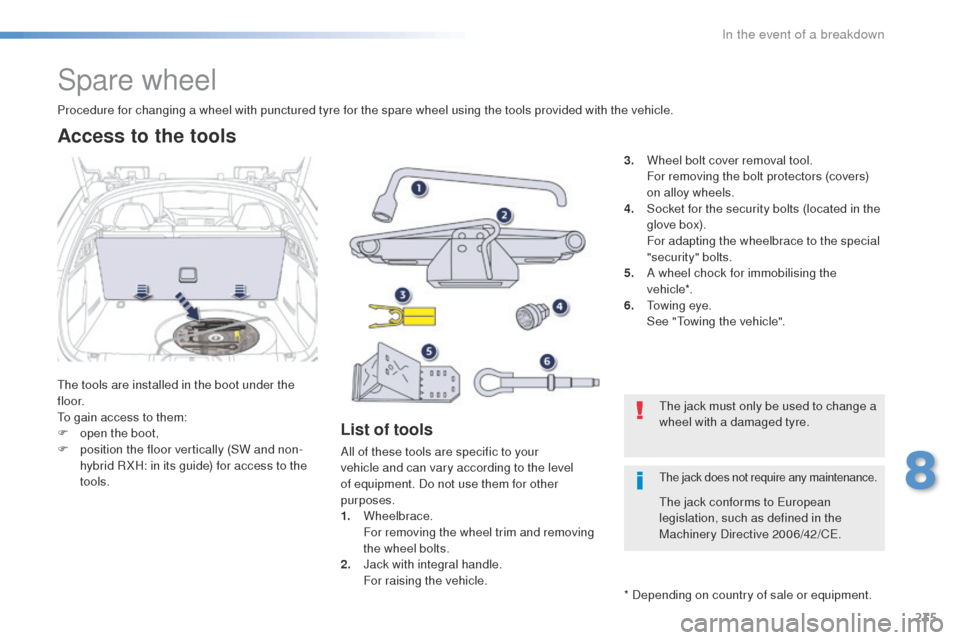

Spare wheel

the tools are installed in the boot under the

f l o o r.

to g

ain access to them:

F

o

pen the boot,

F

p

osition the floor vertically (SW and non-

hybrid R XH: in its guide) for access to the

tools.

Procedure for changing a wheel with punctured tyre for the spare wheel using the tools provided with the vehicle.

List of tools

All of these tools are specific to your

vehicle and can vary according to the level

of equipment. Do not use them for other

purposes.

1.

Wheelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle. 3.

W

heel bolt cover removal tool.

F

or removing the bolt protectors (covers)

on alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts.

5.

A w

heel chock for immobilising the

vehicle*.

6.

t

o

wing eye.

S

ee "

to

wing the vehicle".

Access to the tools

* Depending on country of sale or equipment.

th

e jack must only be used to change a

wheel with a damaged tyre.

th

e jack conforms to e

u

ropean

legislation, such as defined in the

Machinery Directive 2006/42/C

e.

the jack does not require any maintenance.

8

In the event of a breakdown

Page 238 of 424

236

508_en_Chap08_en-cas-de-pannes_ed01-2016

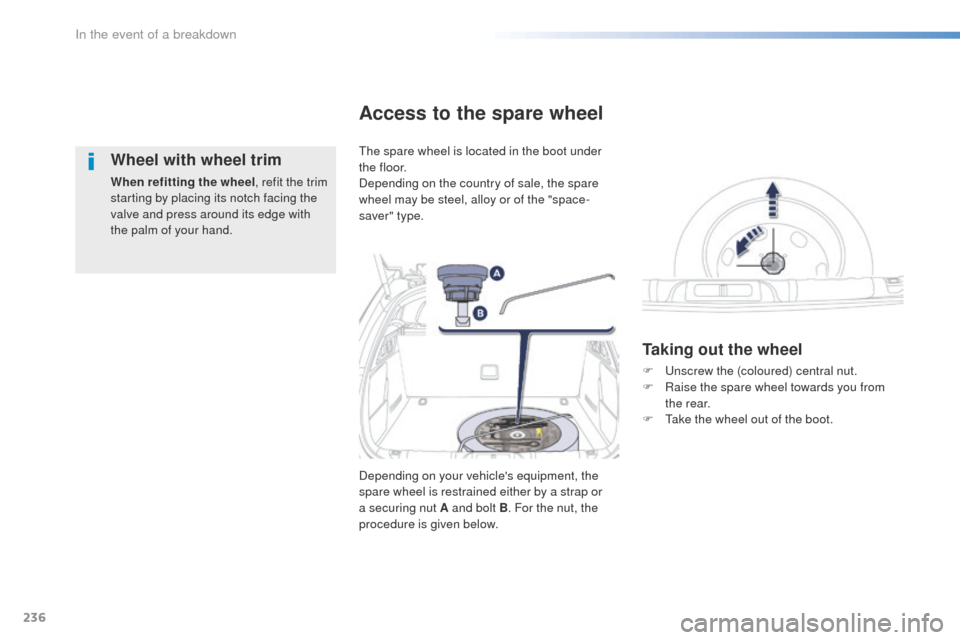

Wheel with wheel trim

When refitting the wheel, refit the trim

starting by placing its notch facing the

valve and press around its edge with

the palm of your hand.

th

e spare wheel is located in the boot under

t h e f l o o r.

Depending on the country of sale, the spare

wheel may be steel, alloy or of the "space-

saver" type.

Access to the spare wheel

Taking out the wheel

Depending on your vehicle's equipment, the

spare wheel is restrained either by a strap or

a securing nut A and bolt B . For the nut, the

procedure is given below. F

u

n

screw the (coloured) central nut.

F

R

aise the spare wheel towards you from

the rear.

F t

a

ke the wheel out of the boot.

In the event of a breakdown

Page 239 of 424

237

508_en_Chap08_en-cas-de-pannes_ed01-2016

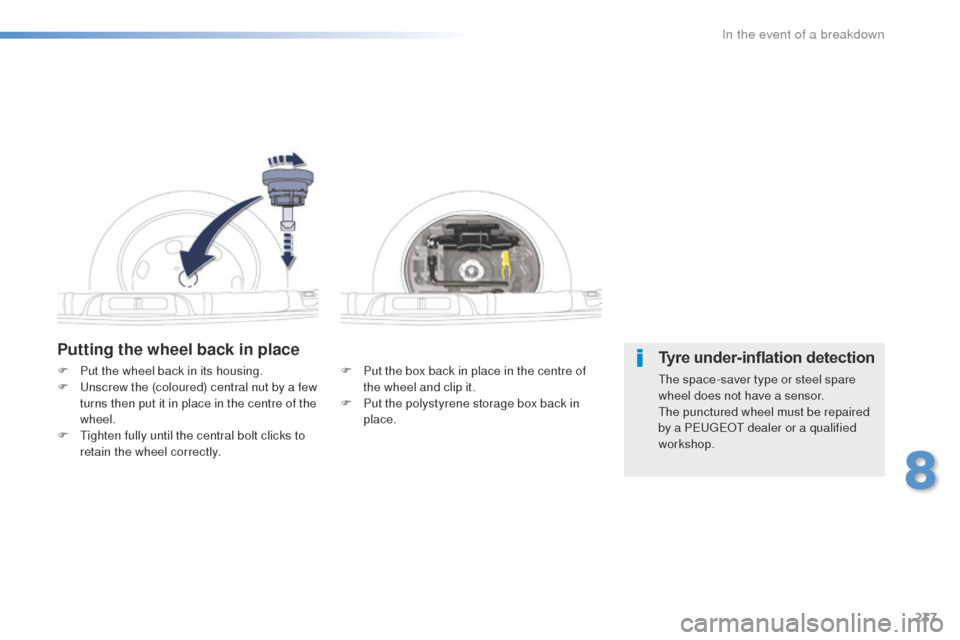

Putting the wheel back in place

F Put the box back in place in the centre of the wheel and clip it.

F

P

ut the polystyrene storage box back in

place.

F

P

ut the wheel back in its housing.

F

un

screw the (coloured) central nut by a few

turns then put it in place in the centre of the

wheel.

F

t

i

ghten fully until the central bolt clicks to

retain the wheel correctly.Tyre under-inflation detection

the space-saver type or steel spare

wheel does not have a sensor.

th

e punctured wheel must be repaired

by a P

e

uge

Ot

dealer or a qualified

workshop.

8

In the event of a breakdown

Page 240 of 424

238

508_en_Chap08_en-cas-de-pannes_ed01-2016

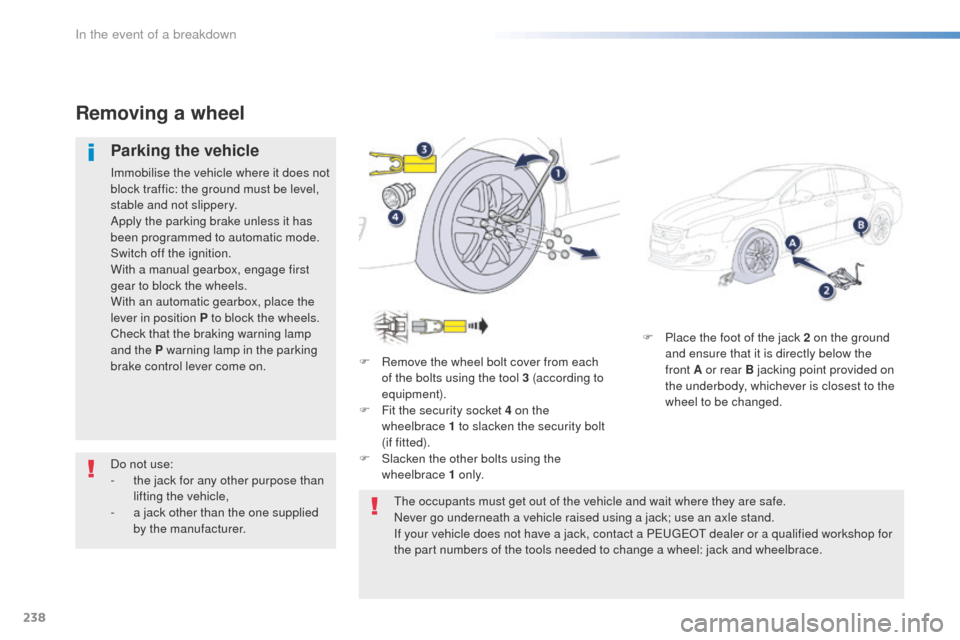

F Place the foot of the jack 2 on the ground and ensure that it is directly below the

front

A or rear B jacking point provided on

the underbody, whichever is closest to the

wheel to be changed.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Apply the parking brake unless it has

been programmed to automatic mode.

Switch off the ignition.

With a manual gearbox, engage first

gear to block the wheels.

With an automatic gearbox, place the

lever in position P to block the wheels.

Check that the braking warning lamp

and the P warning lamp in the parking

brake control lever come on. F

R

emove the wheel bolt cover from each

of the bolts using the tool 3 (according to

equipment).

F

F

it the security socket 4 on the

wheelbrace

1 to slacken the security bolt

(if

fitted).

F

S

lacken the other bolts using the

wheelbrace 1 o n l y.

th

e occupants must get out of the vehicle and wait where they are safe.

Never go underneath a vehicle raised using a jack; use an axle stand.

If your vehicle does not have a jack, contact a P

e

uge

Ot

dealer or a qualified workshop for

the part numbers of the tools needed to change a wheel: jack and wheelbrace.

Do not use:

-

t

he jack for any other purpose than

lifting the vehicle,

-

a j

ack other than the one supplied

by the manufacturer.

In the event of a breakdown