head bolt Peugeot Boxer 2018 Owner's Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2018, Model line: Boxer, Model: Peugeot Boxer 2018Pages: 232, PDF Size: 9.09 MB

Page 145 of 232

143

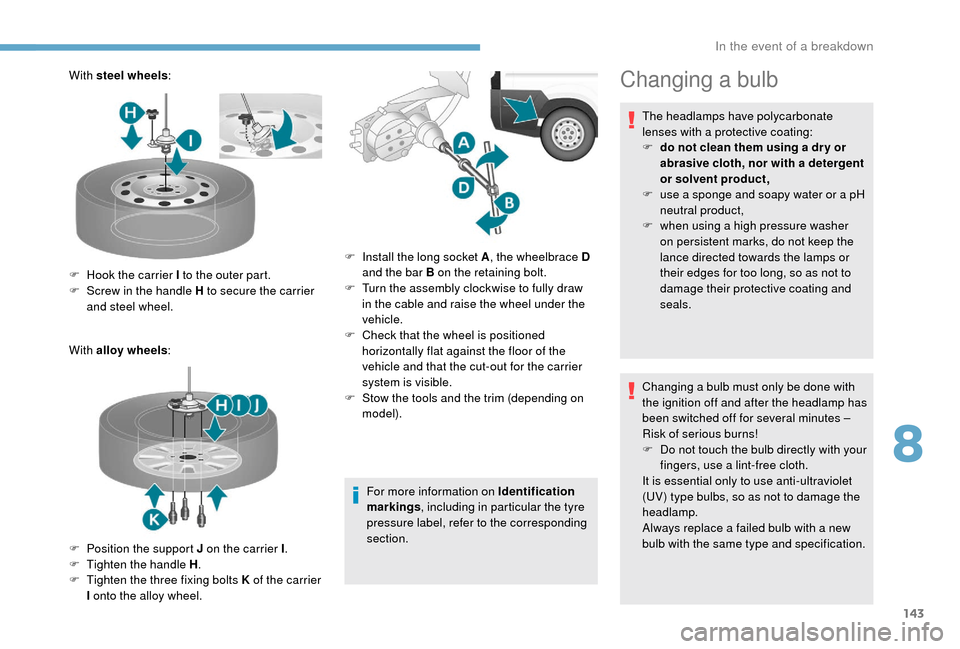

With steel wheels:

With alloy wheels :

For more information on Identification

markings, including in particular the tyre

pressure label, refer to the corresponding

section.

F

H

ook the carrier I to the outer part.

F

S

crew in the handle H to secure the carrier

and steel wheel.

F

P

osition the support J on the carrier I .

F

T

ighten the handle H .

F

T

ighten the three fixing bolts K of the carrier

I onto the alloy wheel. F

I

nstall the long socket A, the wheelbrace D

and the bar B on the retaining bolt.

F

T

urn the assembly clockwise to fully draw

in the cable and raise the wheel under the

vehicle.

F

C

heck that the wheel is positioned

horizontally flat against the floor of the

vehicle and that the cut-out for the carrier

system is visible.

F

S

tow the tools and the trim (depending on

model).Changing a bulb

The headlamps have polycarbonate

lenses with a

protective coating:

F

d

o not clean them using a dr y or

abrasive cloth, nor with a

detergent

or solvent product,

F

u

se a sponge and soapy water or a pH

neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep the

lance directed towards the lamps or

their edges for too long, so as not to

damage their protective coating and

seals.

Changing a

bulb must only be done with

the ignition off and after the headlamp has

been switched off for several minutes –

Risk of serious burns!

F

D

o not touch the bulb directly with your

fingers, use a

lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a

failed bulb with a new

bulb with the same type and specification.

8

In the event of a breakdown

Page 152 of 232

150

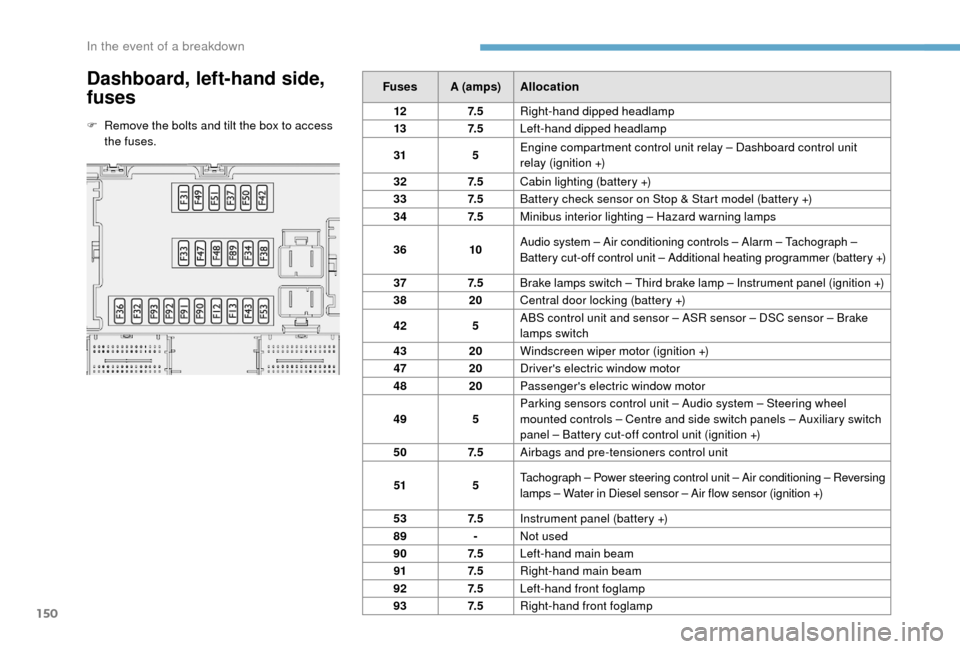

Dashboard, left-hand side,

fuses

F Remove the bolts and tilt the box to access the fuses. Fuses A (amps)

Allocation

12 7. 5Right-hand dipped headlamp

13 7. 5Left-hand dipped headlamp

31 5Engine compartment control unit relay – Dashboard control unit

relay (ignition +)

32 7. 5Cabin lighting (battery +)

33 7. 5Battery check sensor on Stop & Start model (battery +)

34 7. 5Minibus interior lighting – Hazard warning lamps

36 10Audio system – Air conditioning controls – Alarm – Tachograph –

Battery cut-off control unit – Additional heating programmer (battery +)

37 7. 5

Brake lamps switch – Third brake lamp – Instrument panel (ignition +)

38 20Central door locking (battery +)

42 5ABS control unit and sensor – ASR sensor – DSC sensor – Brake

lamps switch

43 20Windscreen wiper motor (ignition +)

47 20Driver's electric window motor

48 20Passenger's electric window motor

49 5Parking sensors control unit – Audio system – Steering wheel

mounted controls – Centre and side switch panels – Auxiliary switch

panel – Battery cut-off control unit (ignition +)

50 7. 5Airbags and pre-tensioners control unit

51 5Tachograph – Power steering control unit – Air conditioning – Reversing

lamps – Water in Diesel sensor – Air flow sensor (ignition +)

53 7. 5Instrument panel (battery +)

89 -Not used

90 7. 5Left-hand main beam

91 7. 5Right-hand main beam

92 7. 5Left-hand front foglamp

93 7. 5Right-hand front foglamp

In the event of a breakdown

Page 183 of 232

181

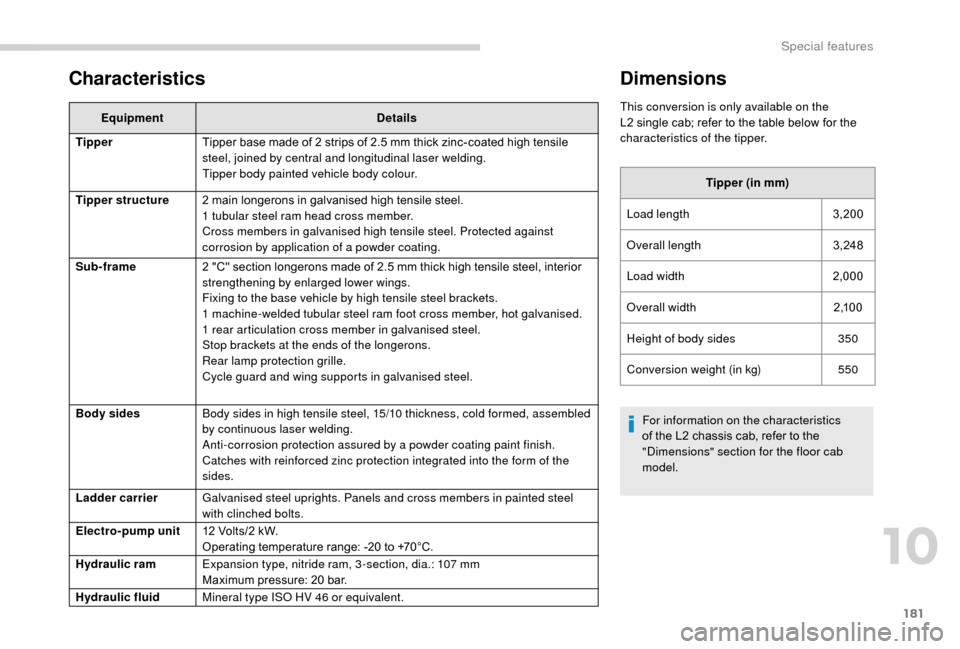

Characteristics

EquipmentDetails

Tipper Tipper base made of 2

strips of 2.5 mm thick zinc-coated high tensile

steel, joined by central and longitudinal laser welding.

Tipper body painted vehicle body colour.

Tipper structure 2

main longerons in galvanised high tensile steel.

1

tubular steel ram head cross member.

Cross members in galvanised high tensile steel. Protected against

corrosion by application of a

powder coating.

Sub-frame 2 "C" section longerons made of 2.5

mm thick high tensile steel, interior

strengthening by enlarged lower wings.

Fixing to the base vehicle by high tensile steel brackets.

1

machine-welded tubular steel ram foot cross member, hot galvanised.

1

rear articulation cross member in galvanised steel.

Stop brackets at the ends of the longerons.

Rear lamp protection grille.

Cycle guard and wing supports in galvanised steel.

Body sides Body sides in high tensile steel, 15/10

thickness, cold formed, assembled

by continuous laser welding.

Anti-corrosion protection assured by a

powder coating paint finish.

Catches with reinforced zinc protection integrated into the form of the

sides.

Ladder carrier Galvanised steel uprights. Panels and cross members in painted steel

with clinched bolts.

Electro-pump unit 12

Volts/2 kW.

Operating temperature range: -20

to +70°C.

Hydraulic ram Expansion type, nitride ram, 3 -section, dia.: 107

mm

Maximum pressure: 20

bar.

Hydraulic fluid Mineral type ISO HV 46

or equivalent.

Dimensions

This conversion is only available on the

L2 single cab; refer to the table below for the

characteristics of the tipper.

Tipper (in mm)

Load length 3,200

Overall length 3,248

Load width 2,000

Overall width 2 ,1 0 0

Height of body sides 350

Conversion weight (in kg) 550

For information on the characteristics

of the L2

chassis cab, refer to the

"Dimensions" section for the floor cab

model.

10

Special features