Changing wheel Peugeot Partner Tepee 2016 User Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2016, Model line: Partner Tepee, Model: Peugeot Partner Tepee 2016Pages: 296, PDF Size: 10.76 MB

Page 173 of 296

171

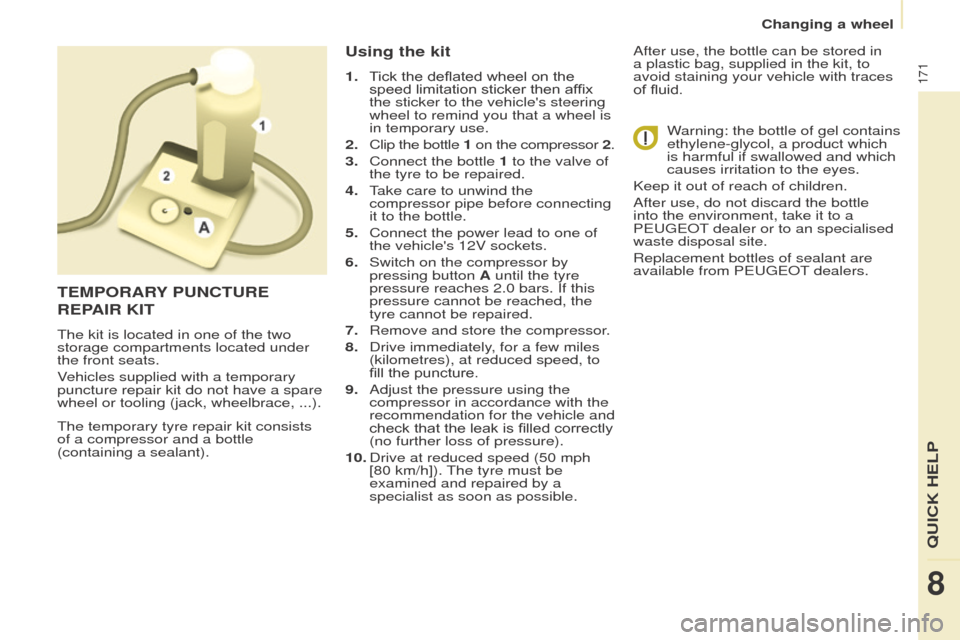

The temporary tyre repair kit consists

of a compressor and a bottle

(containing a sealant).

using the kit

1. Tick the deflated wheel on the speed limitation sticker then affix

the sticker to the vehicle's steering

wheel to remind you that a wheel is

in temporary use.

2.

Clip the bottle

1 on the compressor

2.

3.

Connect the bottle

1 to the valve of

the tyre to be repaired.

4.

T

ake care to unwind the

compressor pipe before connecting

it to the bottle.

5.

Connect the power lead to one of

the vehicle's 12V sockets.

6.

Switch on the compressor by

pressing button

A until the tyre

pressure reaches 2.0 bars. If this

pressure cannot be reached, the

tyre cannot be repaired.

7.

Remove and store the compressor

.

8.

Drive immediately

, for a few miles

(kilometres), at reduced speed, to

fill the puncture.

9.

Adjust the pressure using the

compressor in accordance with the

recommendation for the vehicle and

check that the leak is filled correctly

(no further loss of pressure).

10.

Drive at reduced speed (50

mph

[80 km/h]). The tyre must be

examined and repaired by a

specialist as soon as possible. After use, the bottle can be stored in

a plastic bag, supplied in the kit, to

avoid staining your vehicle with traces

of fluid.

Warning: the bottle of gel contains

ethylene-glycol, a product which

is harmful if swallowed and which

causes irritation to the eyes.

Keep it out of reach of children.

After use, do not discard the bottle

into the environment, take it to a

P

eugeo T dealer or to an specialised

waste disposal site.

Replacement bottles of sealant are

available from P

eugeo T dealers.

teMPoRARY P u NC tu R e

R

e PAIR KI t

The kit is located in one of the two

storage compartments located under

the front seats.

Vehicles supplied with a temporary

puncture repair kit do not have a spare

wheel or tooling (jack, wheelbrace, ...).

8

QuICK HeLP

Changing a wheel

Page 174 of 296

172

1. Parking the vehicle

- The occupants must get out of the

vehicle and wait in a safe location.

-

If possible, park the vehicle on level,

stable and non-slippery ground.

-

Apply the parking brake, switch

of

f the ignition and engage first or

reverse gear. -

Place a chock under the wheel

diagonally opposite the one to be

changed.

CHANgINg A WH

ee L

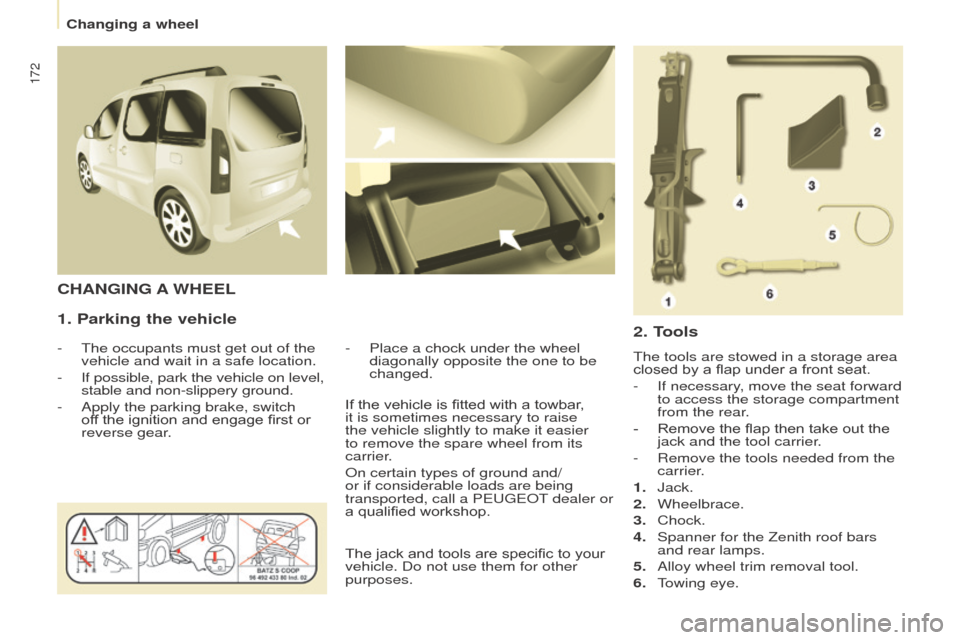

2.

t

ools

The tools are stowed in a storage area

closed by a flap under a front seat.

-

If necessary

, move the seat forward

to access the storage compartment

from the rear.

-

Remove the flap then take out the

jack and the tool carrier

.

-

Remove the tools needed from the

carrier

.

1.

Jack.

2.

Wheelbrace.

3.

Chock.

4.

Spanner for the Zenith roof bars

and rear lamps.

5.

Alloy wheel trim removal tool.

6.

T

owing eye.

If the vehicle is fitted with a towbar,

it is sometimes necessary to raise

the vehicle slightly to make it easier

to remove the spare wheel from its

carrier.

o

n certain types of ground and/

or if considerable loads are being

transported, call a P

eugeo

T dealer or

a qualified workshop.

The jack and tools are specific to your

vehicle. Do not use them for other

purposes.

Changing a wheel

Page 175 of 296

173

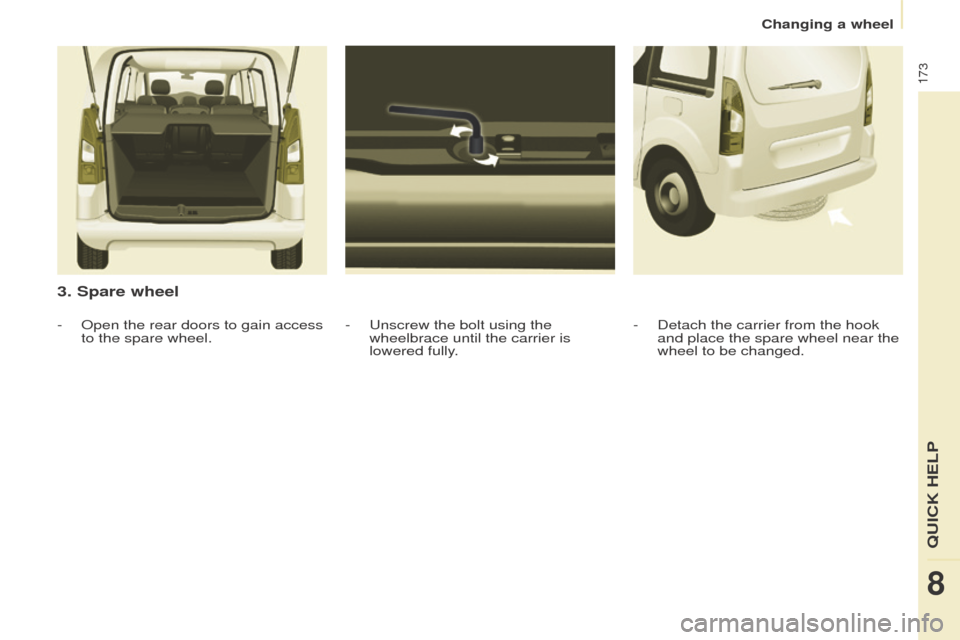

3. Spare wheel

- unscrew the bolt using the

wheelbrace until the carrier is

lowered fully

.

-

o

pen the rear doors to gain access

to the spare wheel. -

Detach the carrier from the hook

and place the spare wheel near the

wheel to be changed.

8

QuICK HeLP

Changing a wheel

Page 176 of 296

174

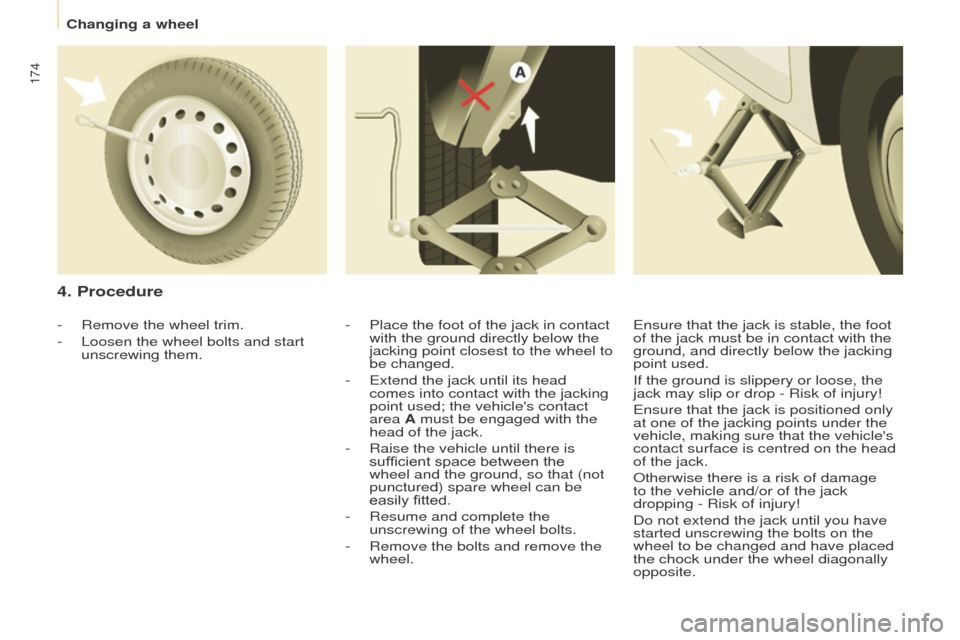

4. Procedure

- Place the foot of the jack in contact

with the ground directly below the

jacking point closest to the wheel to

be changed.

-

e xtend the jack until its head

comes into contact with the jacking

point used; the vehicle's contact

area A must be engaged with the

head of the jack.

-

Raise the vehicle until there is

sufficient space between the

wheel and the ground, so that (not

punctured) spare wheel can be

easily fitted.

-

Resume and complete the

unscrewing of the wheel bolts.

-

Remove the bolts and remove the

wheel.

-

Remove the wheel trim.

-

Loosen the wheel bolts and start

unscrewing them.

e nsure that the jack is stable, the foot

of the jack must be in contact with the

ground, and directly below the jacking

point used.

If the ground is slippery or loose, the

jack may slip or drop - Risk of injury!

e

nsure that the jack is positioned only

at one of the jacking points under the

vehicle, making sure that the vehicle's

contact surface is centred on the head

of the jack.

o

therwise there is a risk of damage

to the vehicle and/or of the jack

dropping

- Risk of injury!

Do not extend the jack until you have

started unscrewing the bolts on the

wheel to be changed and have placed

the chock under the wheel diagonally

opposite.

Changing a wheel

Page 177 of 296

175

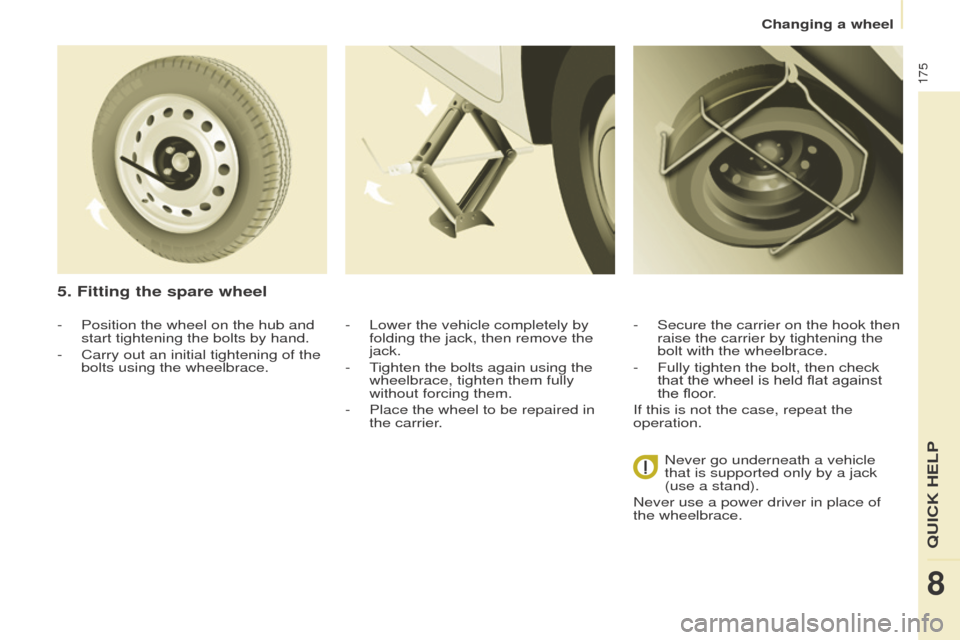

- Position the wheel on the hub and

start tightening the bolts by hand.

-

Carry out an initial tightening of the

bolts using the wheelbrace.

5. Fitting the spare wheel

- Lower the vehicle completely by

folding the jack, then remove the

jack.

-

T

ighten the bolts again using the

wheelbrace, tighten them fully

without forcing them.

-

Place the wheel to be repaired in

the carrier

. -

Secure the carrier on the hook then

raise the carrier by tightening the

bolt with the wheelbrace.

-

Fully tighten the bolt, then check

that the wheel is held flat against

the floor

.

If this is not the case, repeat the

operation.

Never go underneath a vehicle

that is supported only by a jack

(use a stand).

Never use a power driver in place of

the wheelbrace.

8

QuICK HeLP

Changing a wheel

Page 178 of 296

176

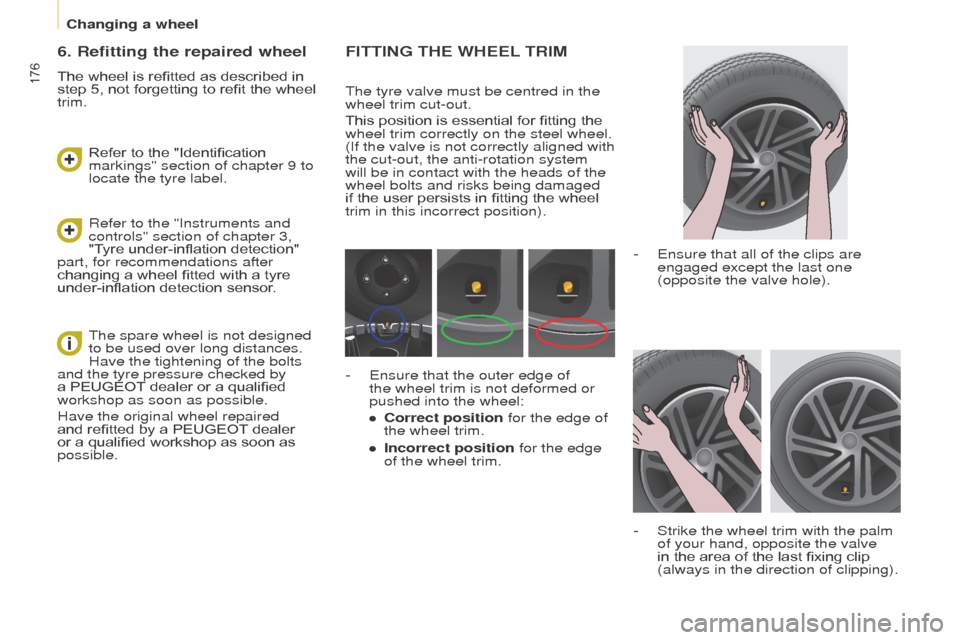

FIttINg tHe WHeeL tRIM

The tyre valve must be centred in the

wheel trim cut-out.

This position is essential for fitting the

wheel trim correctly on the steel wheel.

(If the valve is not correctly aligned with

the cut-out, the anti-rotation system

will be in contact with the heads of the

wheel bolts and risks being damaged

if the user persists in fitting the wheel

trim in this incorrect position).

-

e nsure that all of the clips are

engaged except the last one

(opposite the valve hole).

-

Strike the wheel trim with the palm

of your hand, opposite the valve

in the area of the last fixing clip

(always in the direction of clipping).

-

e nsure that the outer edge of

the wheel trim is not deformed or

pushed into the wheel:

●

Correct position

for the edge of

the wheel trim.

●

Incorrect position

for the edge

of the wheel trim.

6. Refitting the repaired wheel

The wheel is refitted as described in

step 5, not forgetting to refit the wheel

trim.

Refer to the "Instruments and

controls" section of chapter 3,

"Tyre under-inflation detection"

part, for recommendations after

changing a wheel fitted with a tyre

under-inflation detection sensor. Refer to the "Identification

markings" section of chapter 9 to

locate the tyre label.

The spare wheel is not designed

to be used over long distances.

Have the tightening of the bolts

and the tyre pressure checked by

a PEUGEOT dealer or a qualified

workshop as soon as possible.

Have the original wheel repaired

and refitted by a PEUGEOT dealer

or a qualified workshop as soon as

possible.

Changing a wheel

Page 179 of 296

177

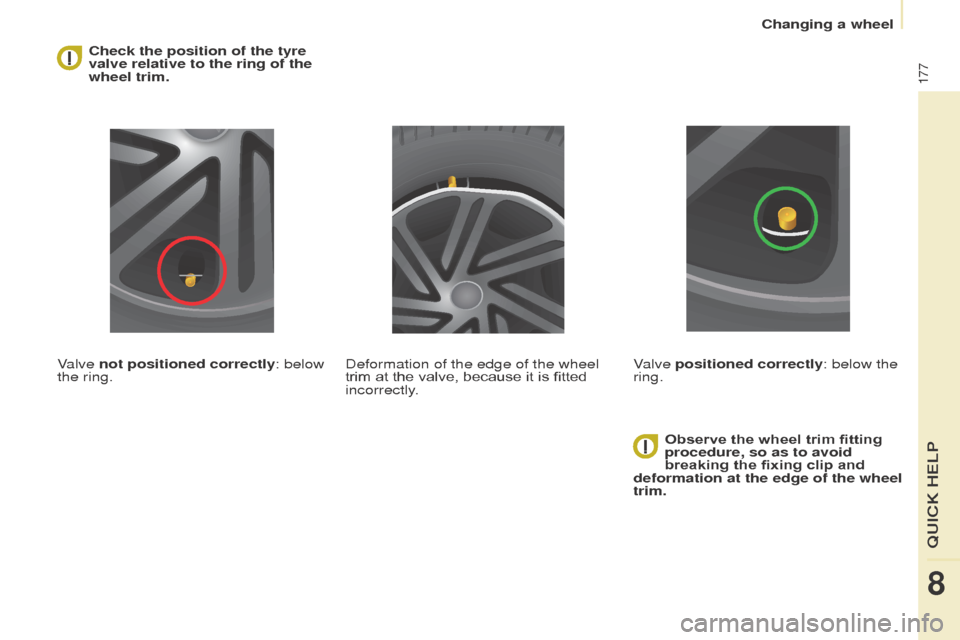

Check the position of the tyre

valve relative to the ring of the

wheel trim.

Valve not positioned correctly: below

the ring. Observe the wheel trim fitting

procedure, so as to avoid

breaking the fixing clip and

deformation at the edge of the wheel

trim.

Deformation of the edge of the wheel

trim at the valve, because it is fitted

incorrectly.

Valve positioned correctly: below the

ring.

8

QuICK HeLP

Changing a wheel

Page 184 of 296

182

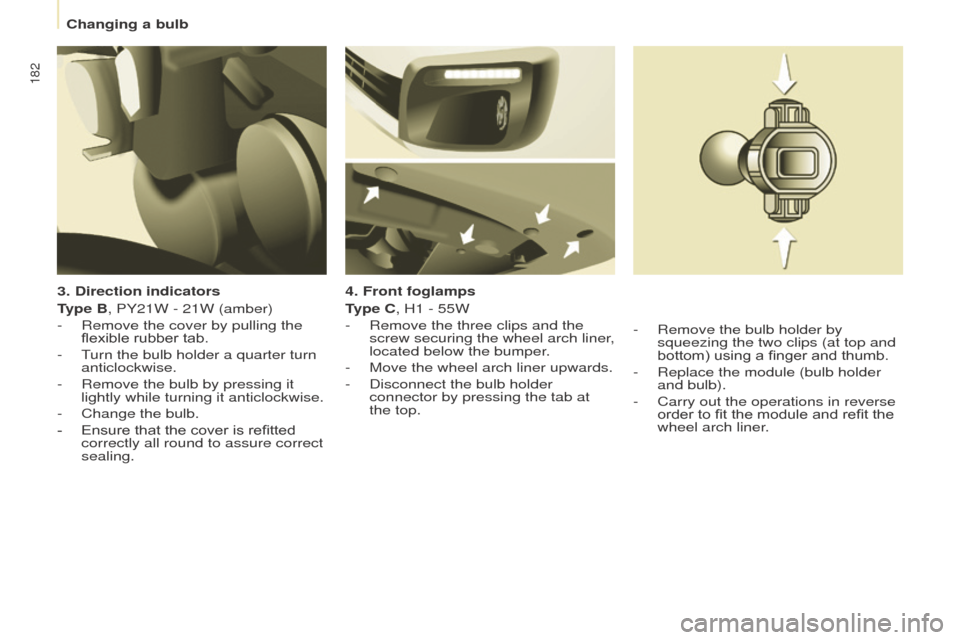

3. Direction indicators

type B

, PY21W - 21W (amber)

-

Remove the cover by pullin

g the

flexible rubber tab.

-

T

urn the bulb holder a quarter turn

anticlockwise.

-

Remove the bulb by pressing it

lightly while turning it anticlockwise.

-

Change the bulb.

-

Ensure that the cover is refitted

correctly all round to assure correct

sealing. 4.

Front foglamps

type C

, H1 - 55W

-

Remove the three clips and the

screw securing the wheel arch liner

,

located below the bumper.

-

Move the wheel arch liner upwards.

-

Disconnect the bulb holder

connector by pressing the tab at

the top.-

Remove the bulb holder by

squeezing the two clips (at top and

bottom) using a finger and thumb.

-

Replace the module (bulb holder

and bulb).

-

Carry out the operations in reverse

order to fit the module and refit the

wheel arch liner

.

Changing a bulb

Page 186 of 296

184

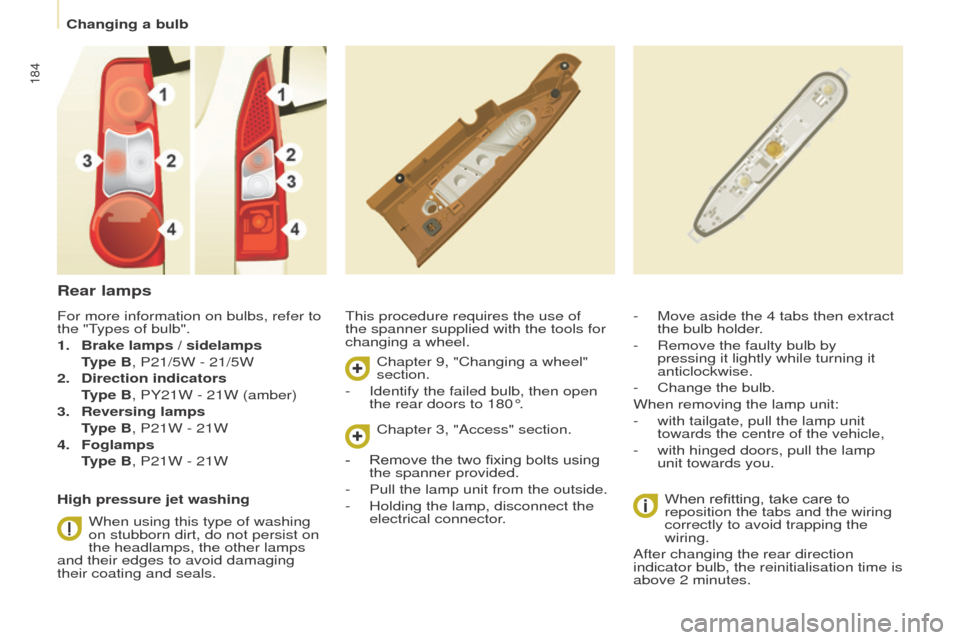

Rear lamps

This procedure requires the use of

the spanner supplied with the tools for

changing a wheel.When refitting, take care to

reposition the tabs and the wiring

correctly to avoid trapping the

wiring.

After changing the rear direction

indicator bulb, the reinitialisation time is

above 2 minutes. - Move aside the 4 tabs then extract

the bulb holder

.

-

Remove the faulty bulb by

pressing it lightly while turning it

anticlockwise.

-

Change the bulb.

When removing the lamp unit:

-

with tailgate, pull the lamp unit

towards the centre of the vehicle,

-

with hinged doors, pull the lamp

unit towards you.

For more information on bulbs, refer to

the "T

ypes of bulb".

1.

Brake lamps / sidelamps

type B

, P21/5W - 21/5W

2.

Direction indicators

type B

, PY21W - 21W (amber)

3.

Reversing lamps

type B

, P21W - 21W

4.

Foglamps

type B

, P21W - 21W

High pressure jet washing When using this type of washing

on stubborn dirt, do not persist on

the headlamps, the other lamps

and their edges to avoid damaging

their coating and seals. Chapter 9, "Changing a wheel"

section.

-

Identify the failed bulb, then open

the rear doors to 180°. Chapter 3, "Access" section.

-

Remove the two fixing bolts using

the spanner provided.

-

Pull the lamp unit from the outside.

-

Holding the lamp, disconnect the

electrical connector

.

Changing a bulb

Page 191 of 296

189

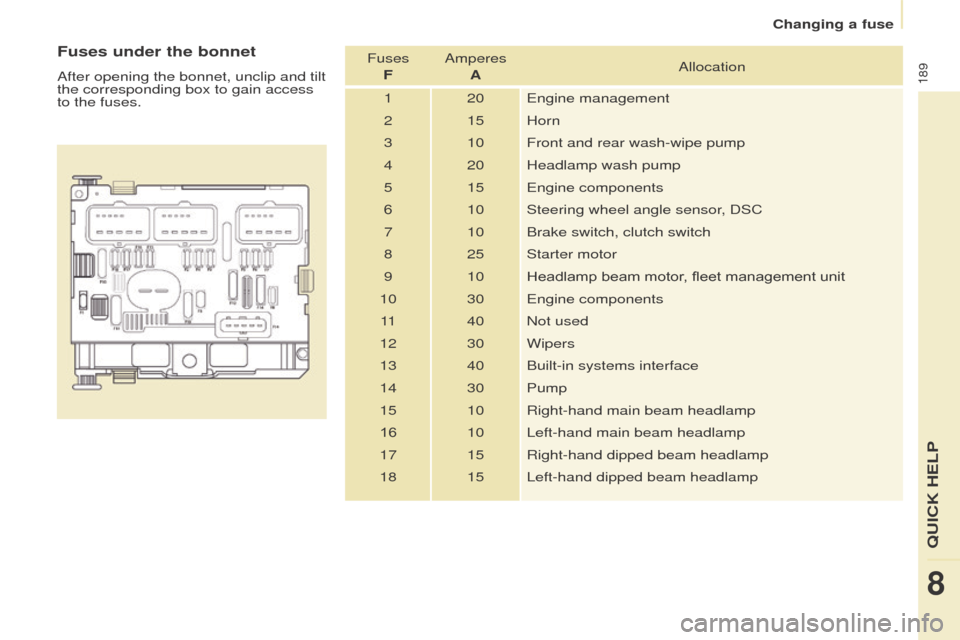

Fuses under the bonnet

After opening the bonnet, unclip and tilt

the corresponding box to gain access

to the fuses.Fuses

F Amperes

A Allocation

1 20

e

ngine management

2 15 Horn

3 10 Front and rear wash-wipe pump

4 20 Headlamp wash pump

5 15

e

ngine components

6 10 Steering wheel angle sensor, DSC

7 10 Brake switch, clutch switch

8 25 Starter motor

9 10 Headlamp beam motor, fleet management unit

10 30

e

ngine components

11 40 Not used

12 30 Wipers

13 40 Built-in systems interface

14 30 Pump

15 10 Right-hand main beam headlamp

16 10 Left-hand main beam headlamp

17 15 Right-hand dipped beam headlamp

18 15 Left-hand dipped beam headlamp

8

QuICK HeLP

Changing a fuse