ignition PEUGEOT PARTNER TEPEE 2020 Service Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2020, Model line: PARTNER TEPEE, Model: PEUGEOT PARTNER TEPEE 2020Pages: 216, PDF Size: 8.46 MB

Page 123 of 216

121

Operation

When your vehicle is too close to or

approaches the vehicle ahead too quickly, the

system automatically applies the brakes to

avoid a collision.

You are then warned by the display of a

message.

Your vehicle's brake lamps come on to warn

other road users.The collision can be avoided if the speed

difference between your vehicle and

the one ahead is not more than 9

mph

(15

km/h).

Above this threshold, the system will do

what is possible to avoid or reduce the

accident by lowering the speed of impact.

The automatic braking can bring the vehicle to

a complete stop if the situation requires it.

In this case, the vehicle is held stationary

temporarily (for about 1.5

seconds) to allow

the driver to take back control by pressing the

brake pedal.

Unless the driver presses the clutch

quickly enough during automatic braking,

triggering of the system may cause the

engine to stall. During automatic braking, the driver can

always obtain a higher rate of deceleration

than that controlled by the system, by

pressing firmly on the brake pedal.

After an impact, the system is

automatically put out of ser vice: it no

longer operates.

You must go to a PEUGEOT dealer or a

qualified workshop to have the system

made operational again.

Operating limits

The system only detects vehicles that are

stationary or moving in the same direction as

your vehicle.

It does not detect small vehicles (bicycles,

motorcycles), pedestrians or animals, nor

non-reflective stationary objects.

This system will not trigger or will be interrupted

if the driver:

-

a

ccelerates hard

-

o

r turns the steering wheel sharply

(avoidance manoeuvre). When weather conditions are difficult

(extremely heavy rain, snow, fog, hail,

etc.), braking distances increase, which

may reduce the system’s ability to avoid a

collision.

The driver must therefore remain

particularly cautious.

Never let snow build up on the bonnet

or any object beyond the bonnet or the

front of the roof: this could enter the

field of vision of the sensor and obstruct

detection.Deactivation

The system is deactivated in the vehicle

configuration menu, accessible with the ignition

on.

Its status is stored when the ignition is switched off.

When the system is deactivated, a

message is displayed every time the

ignition is switched on, to warn you.

6

Driving

Page 129 of 216

127

Fuel system cut-off

In the event of a severe collision, a device

automatically cuts off the fuel supply to the

engine.The flashing of this warning lamp is

accompanied by a message on the

screen.

Verify the absence of any odour and fuel leaks

outside the vehicle and restore the supply:

F

s

witch off the ignition (STOP position),

F

r

emove the key from the ignition,

F

r

einsert the key in the ignition,

F

s

witch on the ignition and start.

7

Practical information

Page 132 of 216

130

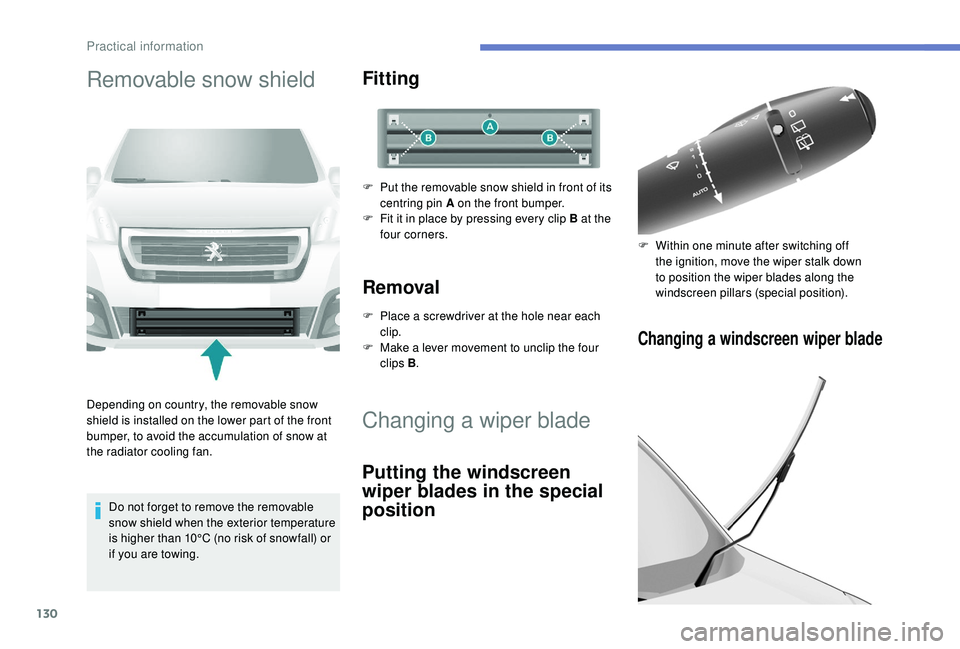

Removable snow shield

Depending on country, the removable snow

shield is installed on the lower part of the front

bumper, to avoid the accumulation of snow at

the radiator cooling fan.Do not forget to remove the removable

snow shield when the exterior temperature

is higher than 10°C (no risk of snowfall) or

if you are towing.

Fitting

F Put the removable snow shield in front of its centring pin A on the front bumper.

F

F

it it in place by pressing every clip B at the

four corners.

Removal

F Place a screwdriver at the hole near each clip.

F

M

ake a lever movement to unclip the four

clips B .

Changing a wiper blade

Putting the windscreen

wiper blades in the special

position

Changing a windscreen wiper blade

F Within one minute after switching off

the ignition, move the wiper stalk down

to position the wiper blades along the

windscreen pillars (special position).

Practical information

Page 133 of 216

131

To return the wiper blades to their normal

position, switch on the ignition and operate the

wiper stalk again.

Changing the rear wiper blade

F Raise the wiper arm.

F U nclip the wiper blade and remove it.

F

I

nstall the new blade.

F

F

old the arm down.

F

L

ift the arm, then unclip the blade and

remove it.

F

I

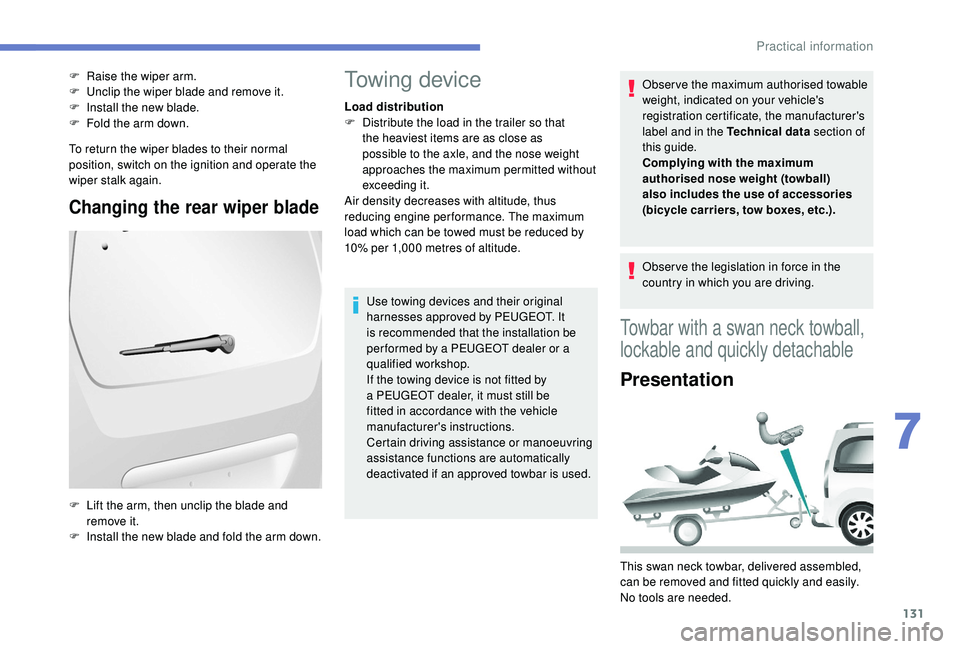

nstall the new blade and fold the arm down.Towing device

Load distribution

F D istribute the load in the trailer so that

the heaviest items are as close as

possible to the axle, and the nose weight

approaches the maximum permitted without

exceeding

it.

Air density decreases with altitude, thus

reducing engine performance. The maximum

load which can be towed must be reduced by

10% per 1,000

metres of altitude.

Use towing devices and their original

harnesses approved by PEUGEOT. It

is recommended that the installation be

per formed by a PEUGEOT dealer or a

qualified workshop.

If the towing device is not fitted by

a PEUGEOT dealer, it must still be

fitted in accordance with the vehicle

manufacturer's instructions.

Certain driving assistance or manoeuvring

assistance functions are automatically

deactivated if an approved towbar is used. Obser ve the maximum authorised towable

weight, indicated on your vehicle's

registration certificate, the manufacturer's

label and in the Technical data

section of

this guide.

Complying with the maximum

authorised nose weight (towball)

also includes the use of accessories

(bicycle carriers, tow boxes, etc.).

Obser ve the legislation in force in the

country in which you are driving.

Towbar with a swan neck towball,

lockable and quickly detachable

Presentation

This swan neck towbar, delivered assembled,

can be removed and fitted quickly and easily.

No tools are needed.

7

Practical information

Page 139 of 216

137

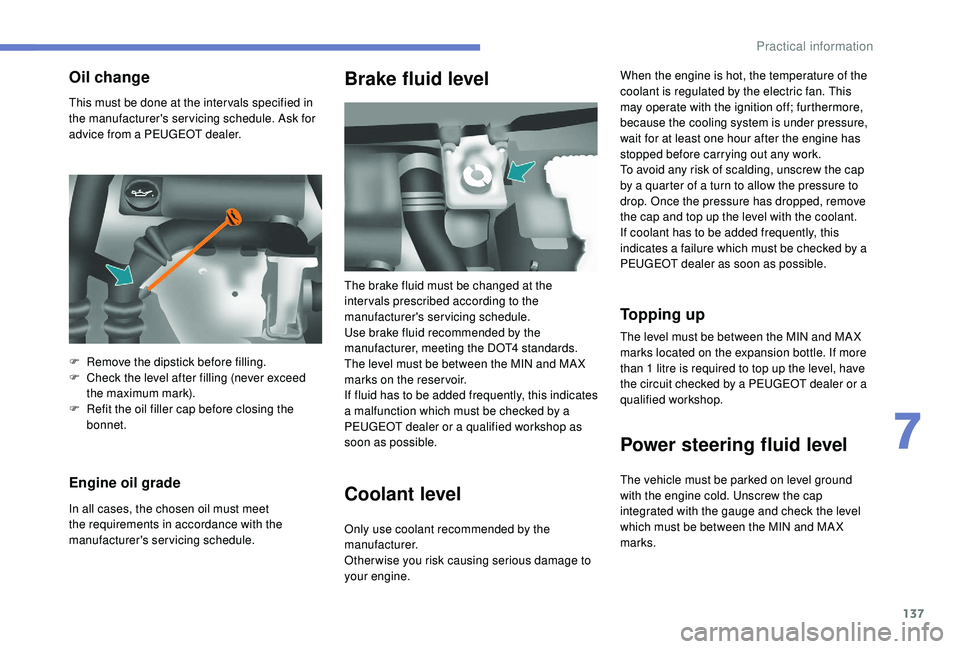

This must be done at the inter vals specified in

the manufacturer's servicing schedule. Ask for

advice from a PEUGEOT dealer.

Engine oil grade

In all cases, the chosen oil must meet

the requirements in accordance with the

manufacturer's servicing schedule.

Brake fluid level

Coolant levelWhen the engine is hot, the temperature of the

coolant is regulated by the electric fan. This

may operate with the ignition off; furthermore,

because the cooling system is under pressure,

wait for at least one hour after the engine has

stopped before carrying out any work.

To avoid any risk of scalding, unscrew the cap

by a quarter of a turn to allow the pressure to

drop. Once the pressure has dropped, remove

the cap and top up the level with the coolant.

If coolant has to be added frequently, this

indicates a failure which must be checked by a

PEUGEOT dealer as soon as possible.

To p p i n g u p

Oil change

The brake fluid must be changed at the

inter vals prescribed according to the

manufacturer's servicing schedule.

Use brake fluid recommended by the

manufacturer, meeting the DOT4 standards.

The level must be between the MIN and MA X

marks on the reservoir.

If fluid has to be added frequently, this indicates

a malfunction which must be checked by a

PEUGEOT dealer or a qualified workshop as

soon as possible.

Only use coolant recommended by the

manufacturer.

Otherwise you risk causing serious damage to

your engine.

F

R

emove the dipstick before filling.

F

C

heck the level after filling (never exceed

the maximum mark).

F

R

efit the oil filler cap before closing the

bonnet. The level must be between the MIN and MA X

marks located on the expansion bottle. If more

than 1

litre is required to top up the level, have

the circuit checked by a PEUGEOT dealer or a

qualified workshop.

Power steering fluid level

The vehicle must be parked on level ground

with the engine cold. Unscrew the cap

integrated with the gauge and check the level

which must be between the MIN and MA X

marks.

7

Practical information

Page 144 of 216

142

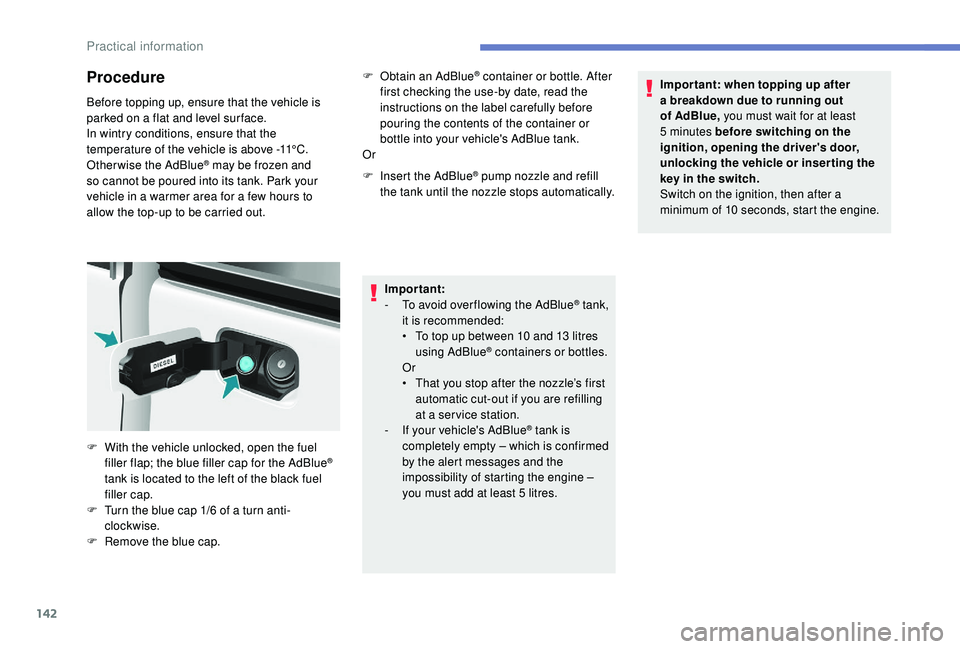

Procedure

Before topping up, ensure that the vehicle is

parked on a flat and level sur face.

In wintry conditions, ensure that the

temperature of the vehicle is above -11°C.

Otherwise the AdBlue

® may be frozen and

so cannot be poured into its tank. Park your

vehicle in a warmer area for a few hours to

allow the top-up to be carried out. F

O

btain an AdBlue

® container or bottle. After

first checking the use-by date, read the

instructions on the label carefully before

pouring the contents of the container or

bottle into your vehicle's AdBlue tank.

Or

F

I

nsert the AdBlue

® pump nozzle and refill

the tank until the nozzle stops automatically.

Important:

-

T

o avoid over flowing the AdBlue

® tank,

i

t is recommended:

•

T

o top up between 10 and 13

litres

using AdBlue

® containers or bottles.

Or

•

T

hat you stop after the nozzle’s first

automatic cut-out if you are refilling

at a ser vice station.

-

I

f your vehicle's AdBlue

® tank is

completely empty – which is confirmed

by the alert messages and the

impossibility of starting the engine –

you must add at least 5

litres. Impor tant: when topping up after

a breakdown due to running out

of AdBlue,

you must wait for at least

5 minutes before switching on the

ignition, opening the driver's door,

unlocking the vehicle or inser ting the

key in the switch.

Switch on the ignition, then after a

minimum of 10 seconds, start the engine.

F

W

ith the vehicle unlocked, open the fuel

filler flap; the blue filler cap for the AdBlue

®

tank is located to the left of the black fuel

filler cap.

F

T

urn the blue cap 1/6 of a turn anti-

clockwise.

F

R

emove the blue cap.

Practical information

Page 145 of 216

143

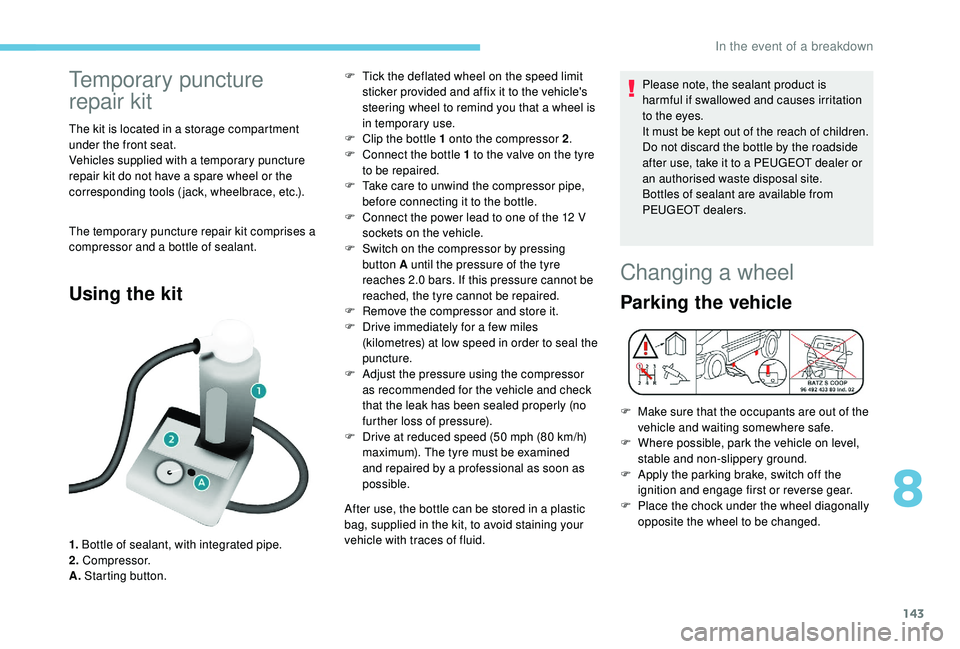

Temporary puncture

repair kit

The kit is located in a storage compartment

under the front seat.

Vehicles supplied with a temporary puncture

repair kit do not have a spare wheel or the

corresponding tools ( jack, wheelbrace, etc.).

The temporary puncture repair kit comprises a

compressor and a bottle of sealant.

Using the kit

1. Bottle of sealant, with integrated pipe.

2. Compressor.

A. Starting button. F

T

ick the deflated wheel on the speed limit

sticker provided and affix it to the vehicle's

steering wheel to remind you that a wheel is

in temporary use.

F

C

lip the bottle 1 onto the compressor 2

.

F

C

onnect the bottle 1 to the valve on the tyre

to be repaired.

F

T

ake care to unwind the compressor pipe,

before connecting it to the bottle.

F

C

onnect the power lead to one of the 12 V

sockets on the vehicle.

F

S

witch on the compressor by pressing

button A until the pressure of the tyre

reaches 2.0 bars. If this pressure cannot be

reached, the tyre cannot be repaired.

F

R

emove the compressor and store it.

F

D

rive immediately for a few miles

(kilometres) at low speed in order to seal the

puncture.

F

A

djust the pressure using the compressor

as recommended for the vehicle and check

that the leak has been sealed properly (no

further loss of pressure).

F

D

rive at reduced speed (50 mph (80 km/h)

maximum). The tyre must be examined

and repaired by a professional as soon as

possible.

After use, the bottle can be stored in a plastic

bag, supplied in the kit, to avoid staining your

vehicle with traces of fluid. Please note, the sealant product is

harmful if swallowed and causes irritation

to the eyes.

It must be kept out of the reach of children.

Do not discard the bottle by the roadside

after use, take it to a PEUGEOT dealer or

an authorised waste disposal site.

Bottles of sealant are available from

PEUGEOT dealers.

Changing a wheel

Parking the vehicle

F Make sure that the occupants are out of the

vehicle and waiting somewhere safe.

F

W

here possible, park the vehicle on level,

stable and non-slippery ground.

F

A

pply the parking brake, switch off the

ignition and engage first or reverse gear.

F

P

lace the chock under the wheel diagonally

opposite the wheel to be changed.

8

In the event of a breakdown

Page 152 of 216

150

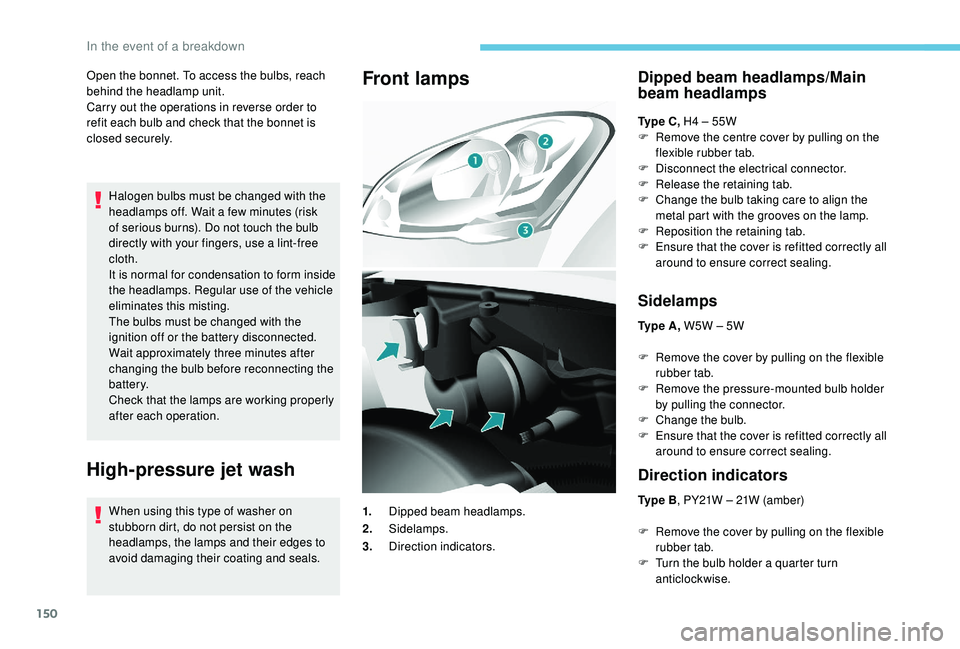

Open the bonnet. To access the bulbs, reach

behind the headlamp unit.

Carry out the operations in reverse order to

refit each bulb and check that the bonnet is

closed securely.Halogen bulbs must be changed with the

headlamps off. Wait a few minutes (risk

of serious burns). Do not touch the bulb

directly with your fingers, use a lint-free

cloth.

It is normal for condensation to form inside

the headlamps. Regular use of the vehicle

eliminates this misting.

The bulbs must be changed with the

ignition off or the battery disconnected.

Wait approximately three minutes after

changing the bulb before reconnecting the

battery.

Check that the lamps are working properly

after each operation.

High-pressure jet wash

When using this type of washer on

stubborn dirt, do not persist on the

headlamps, the lamps and their edges to

avoid damaging their coating and seals.

Front lampsDipped beam headlamps/Main

beam headlamps

Ty p e C , H4 – 55W

F R emove the centre cover by pulling on the

flexible rubber tab.

F

D

isconnect the electrical connector.

F

R

elease the retaining tab.

F

C

hange the bulb taking care to align the

metal part with the grooves on the lamp.

F

R

eposition the retaining tab.

F

E

nsure that the cover is refitted correctly all

around to ensure correct sealing.

Sidelamps

Ty p e A , W5W – 5W

F

R

emove the cover by pulling on the flexible

rubber tab.

F

R

emove the pressure-mounted bulb holder

by pulling the connector.

F

C

hange the bulb.

F

E

nsure that the cover is refitted correctly all

around to ensure correct sealing.

Direction indicators

Ty p e B , PY21W – 21W (amber)

F

R

emove the cover by pulling on the flexible

rubber tab.

F

T

urn the bulb holder a quarter turn

anticlockwise.

1.

Dipped beam headlamps.

2. Sidelamps.

3. Direction indicators.

In the event of a breakdown

Page 158 of 216

156

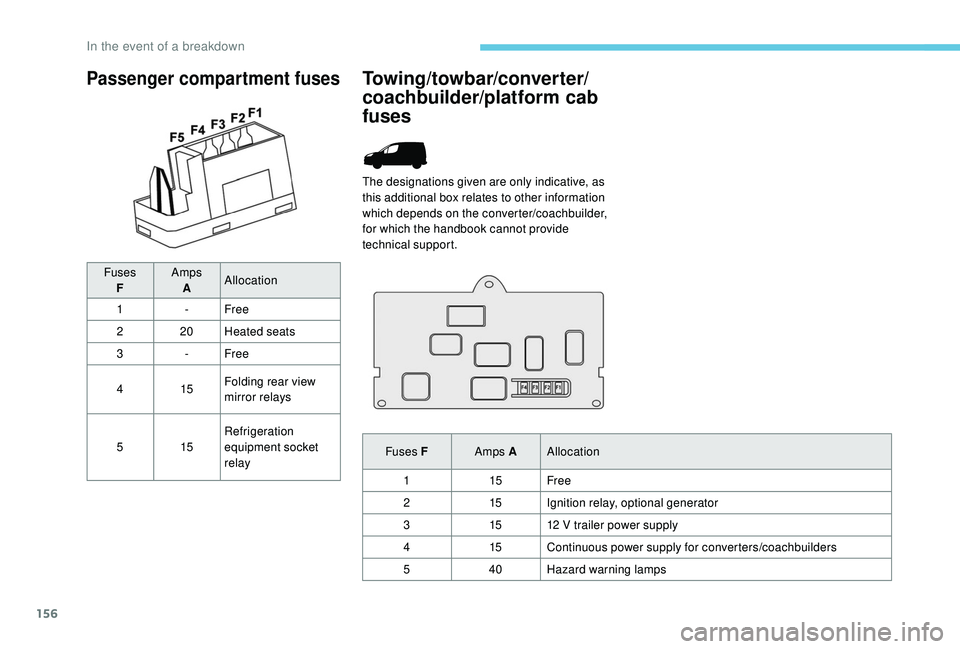

Passenger compartment fuses

FusesF Amps

A Allocation

1 -Free

2 20Heated seats

3 -Free

4 15Folding rear view

mirror relays

5 15Refrigeration

equipment socket

relay

Towing/towbar/converter/

coachbuilder/platform cab

fuses

The designations given are only indicative, as

this additional box relates to other information

which depends on the converter/coachbuilder,

for which the handbook cannot provide

technical support.

Fuses F Amps AAllocation

1 15Free

2 15Ignition relay, optional generator

3 1512

V trailer power supply

4 15Continuous power supply for converters/coachbuilders

5 40Hazard warning lamps

In the event of a breakdown

Page 160 of 216

158

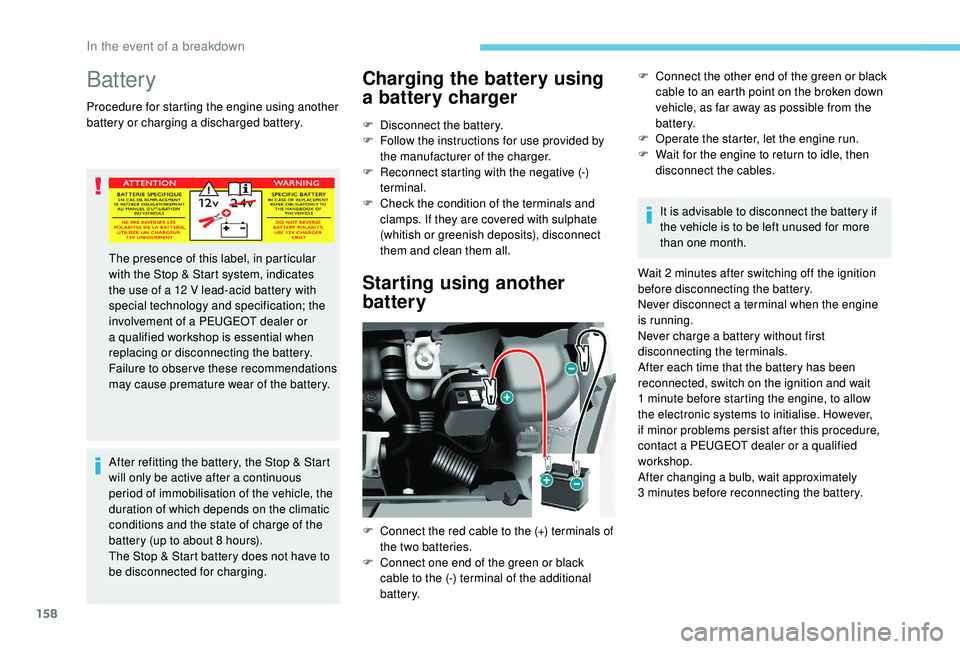

Battery

Procedure for starting the engine using another

battery or charging a discharged battery.After refitting the battery, the Stop & Start

will only be active after a continuous

period of immobilisation of the vehicle, the

duration of which depends on the climatic

conditions and the state of charge of the

battery (up to about 8

hours).

The Stop & Start battery does not have to

be disconnected for charging.

Charging the battery using

a battery charger

F Disconnect the battery.

F F ollow the instructions for use provided by

the manufacturer of the charger.

F

R

econnect starting with the negative (-)

terminal.

F

C

heck the condition of the terminals and

clamps. If they are covered with sulphate

(whitish or greenish deposits), disconnect

them and clean them all.

Starting using another

battery

F Connect the other end of the green or black cable to an earth point on the broken down

vehicle, as far away as possible from the

battery.

F

O

perate the starter, let the engine run.

F

W

ait for the engine to return to idle, then

disconnect the cables.

It is advisable to disconnect the battery if

the vehicle is to be left unused for more

than one month.

Wait 2

minutes after switching off the ignition

before disconnecting the battery.

Never disconnect a terminal when the engine

is running.

Never charge a battery without first

disconnecting the terminals.

After each time that the battery has been

reconnected, switch on the ignition and wait

1

minute before starting the engine, to allow

the electronic systems to initialise. However,

if minor problems persist after this procedure,

contact a PEUGEOT dealer or a qualified

workshop.

After changing a bulb, wait approximately

3

minutes before reconnecting the battery.

The presence of this label, in particular

with the Stop & Start system, indicates

the use of a 12

V lead-acid battery with

special technology and specification; the

involvement of a PEUGEOT dealer or

a qualified workshop is essential when

replacing or disconnecting the battery.

Failure to observe these recommendations

may cause premature wear of the battery.

F

C

onnect the red cable to the (+) terminals of

the two batteries.

F

C

onnect one end of the green or black

cable to the (-) terminal of the additional

battery.

In the event of a breakdown