recommended oil PONTIAC FIERO 1988 Service Owner's Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 938 of 1825

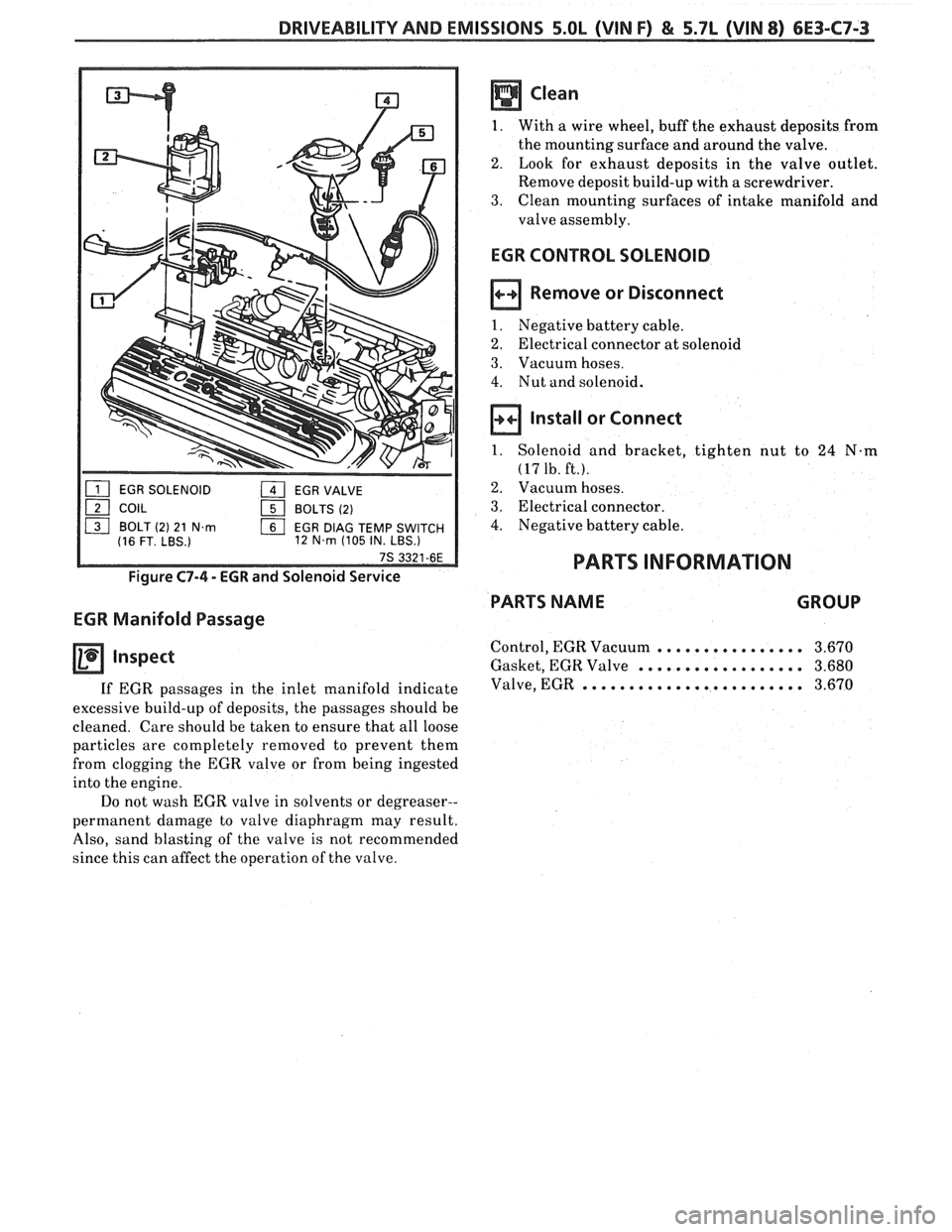

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C7-3

1. With a wire wheel, buff the exhaust deposits from

the mounting surface and around the valve.

2. Look for exhaust deposits in the valve outlet.

Remove deposit build-up with a screwdriver.

3. Clean mounting surfaces of intake manifold and

valve assembly.

EGR SOLENOID 1 EGR VALVE

121 COIL 151 BOLTS (2)

ls] BOLT (2) 21 N.m EGR DlAG TEMP SWITCH

(16 FT. LBS.) 12 N.m (105

IN. LBS.)

Figure C7-4 - EGR and Solenoid Service

EGR Manifold Passage

Inspect

If EGR passages in the inlet manifold indicate

excessive build-up of deposits, the passages should be

cleaned. Care should be taken to ensure that all loose

particles are completely removed to prevent them

from clogging the EGR valve or from being ingested

into the engine.

Do not wash EGR valve in solvents or degreaser--

permanent damage to valve diaphragm may result.

Also, sand blasting of the valve is not recommended

since this can affect the operation of the valve.

EGR CONTROL SOLENOID

Remove or Disconnect

1. Negative battery cable.

2. Electrical connector at solenoid

3. Vacuum hoses.

4. Nut and solenoid.

Install or Connect

1. Solenoid and bracket, tighten nut to 24 N-m

(17 1b. ft.).

2. Vacuum hoses.

3. Electrical connector.

4. Negative battery cable.

PARTS INFORMATION

PARTS NAME GROUP

Control, EGR Vacuum ................ 3.670

Gasket, EGR Valve .................. 3.680

Valve, EGR ........................ 3.670

Page 1108 of 1825

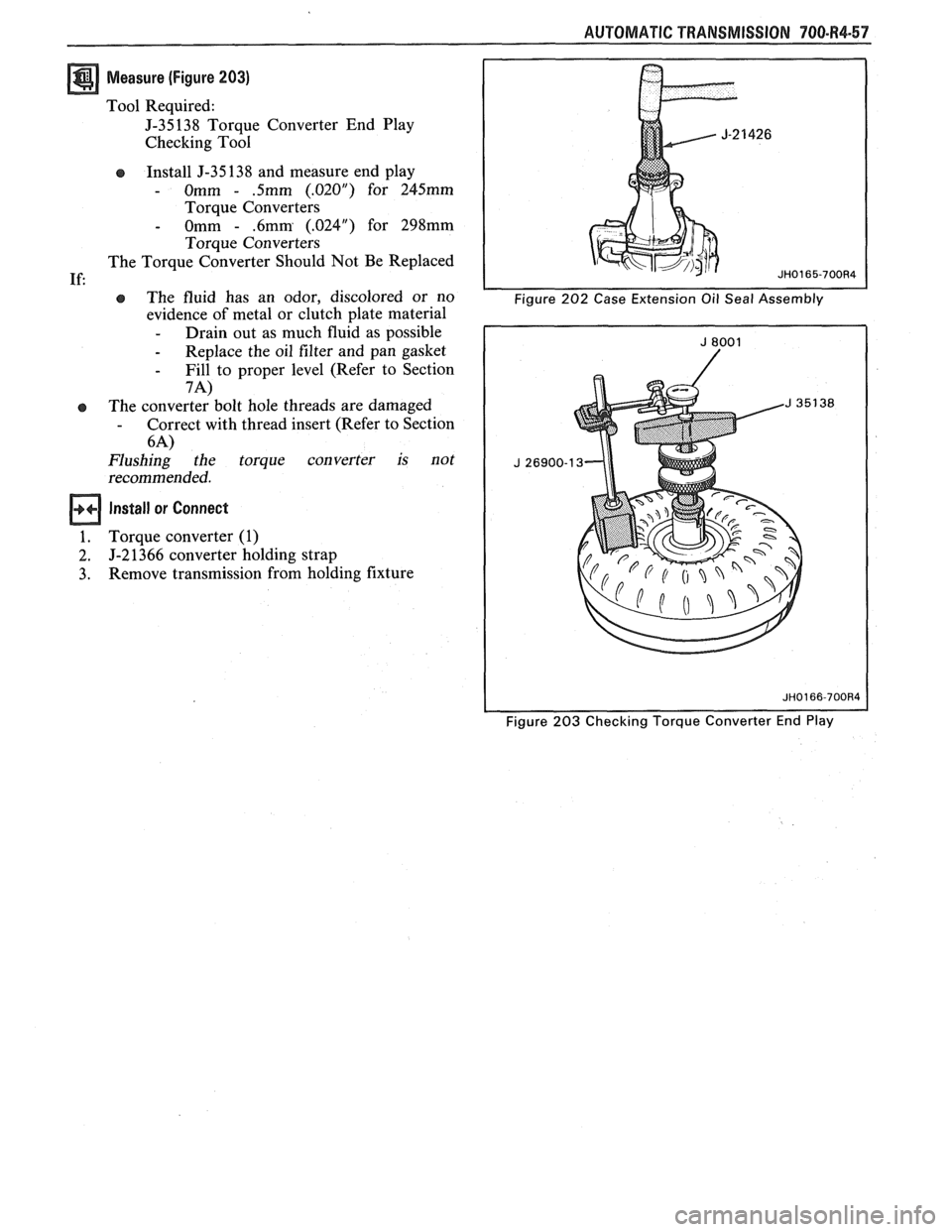

AUTOMATIC TRANSMISSION 700-R4-57

If:

e

Measure (Figure 203)

Tool Required:

J-35138 Torque Converter End Play

Checking Tool

Install J-35 138 and measure end play

- Omm - .5mm (.02OU) for 245mm

Torque Converters

- Omm - .6mm (.024") for 298mm

Torque Converters

The Torque Converter Should Not Be Replaced

e The fluid has an odor, discolored or no

evidence of metal or clutch plate material

- Drain out as much fluid as possible

- Replace the oil filter and pan gasket

- Fill to proper level (Refer to Section

7A)

The converter bolt hole threads are damaged - Correct with thread insert (Refer to Section

6-4)

Flushing the torque converter is not

recommended.

Install or Connect

Torque converter (1)

J-2 1366 converter holding strap

Remove transmission from holding fixture

Figure 203 Checking Torque Converter End Play

Page 1665 of 1825

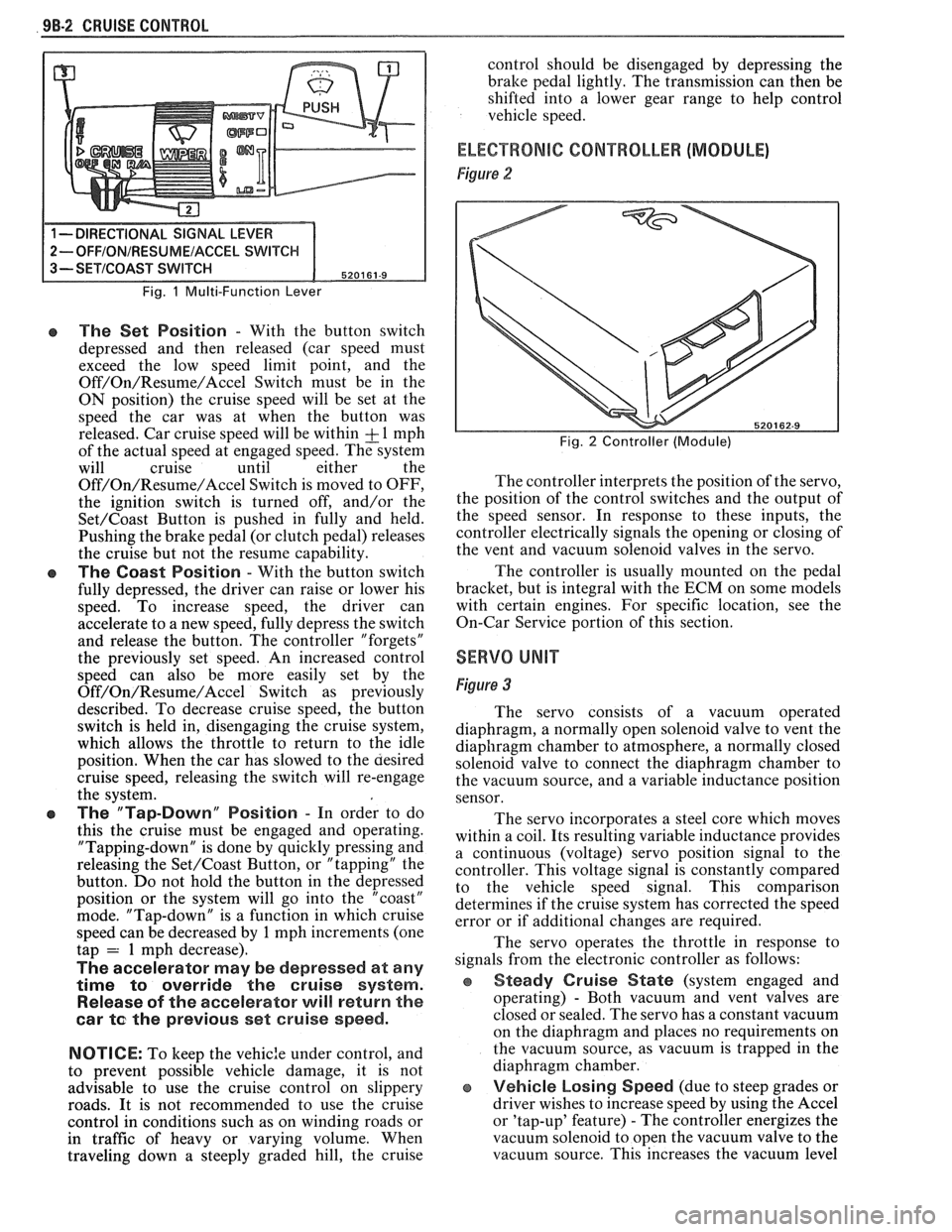

98-2 CRUISE CONTROL

Fig. 1 Multi-Function Lever

e The Set Position - With the button switch

depressed and then released (car speed must

exceed the low speed limit point, and the

Off/On/Resume/Accel Switch must be in the

ON position) the cruise speed will be set at the

speed the car was at when the button was

released. Car cruise speed will be within

& 1 mph

of the actual speed at engaged speed. The system

will cruise until either the

Off/On/Resume/Accel Switch is moved to OFF,

the ignition switch is turned off, and/or the

Set/Coast Button is pushed in fully and held.

Pushing the brake pedal (or clutch pedal) releases

the cruise but not the resume capability.

The Coast Position - With the button switch

fully depressed, the driver can raise or lower his

speed. To increase speed, the driver can

accelerate to a new speed, fully depress the switch

and release the button. The controller "forgets"

the previously set speed. An increased control

speed can also be more easily set by the

Off/On/Resume/Accel Switch as previously

described. To decrease cruise speed, the button

switch is held in, disengaging the cruise system,

which allows the throttle to return to the idle

position. When the car has slowed to the aesired

cruise speed, releasing the switch will re-engage

the system.

e The "Tap-Down" Position - In order to do

this the cruise must be engaged and operating.

"Tapping-down" is done by quickly pressing and

releasing the

Set/Coast Button, or "tapping" the

button. Do not hold the button in the depressed

position or the system will go into the "coast"

mode. "Tap-down" is a function in which cruise

speed can be decreased by

1 mph increments (one

tap = 1 mph decrease).

The accelerator may be depressed at any

time

to override the cruise system.

Release of the accelerator will return the

car

te the previous set cruise speed.

NOTICE:

To keep the vehic:e under control, and

to prevent possible vehicle damage, it is not

advisable to use the cruise control on slippery

roads. It is not recommended to use the cruise

control in conditions such as on winding roads or

in traffic of heavy or varying volume. When

traveling down

a steeply graded hill, the cruise control

should be disengaged by depressing the

bralte pedal lightly. The transmission can then be

shifted into a lower gear range to help control

vehicle speed.

ELECTRONIC CONTROLLER (MODULE)

Figure 2

Fig. 2 Controller (Module)

The controller interprets the position of the servo,

the position of the control switches and the output of

the speed sensor. In response to these inputs, the

controller electrically signals the opening or closing of

the vent and vacuum solenoid valves in the servo.

The controller is usually mounted on the pedal

bracket, but is integral with the ECM on some models

with certain engines. For specific location, see the

On-Car Service portion of this section.

SERVO UNIT

Figure 3

The servo consists of a vacuum operated

diaphragm, a normally open solenoid valve to vent the

diaphragm chamber to atmosphere, a normally closed

solenoid valve to connect the diaphragm chamber to

the vacuum source, and a variable inductance position

sensor.

The servo incorporates a steel core which moves

within a coil. Its resulting variable inductance provides

a continuous (voltage) servo position signal to the

controller. This voltage signal is constantly compared

to the vehicle speed signal. This comparison

determines if the cruise system has corrected the speed

error or if additional changes are required.

The servo operates the throttle in response to

signals from the electronic controller as follows:

Steady Cruise State (system engaged and

operating)

- Both vacuum and vent valves are

closed or sealed. The servo has a constant vacuum

on the diaphragm and places no requirements on

the vacuum source, as vacuum is trapped in the

diaphragm chamber.

e Vehicle Losing Speed (due to steep grades or

driver wishes to increase speed by using the Accel

or 'tap-up' feature)

- The controller energizes the

vacuum solenoid to open the vacuum valve to the

vacuum source. This increases the vacuum level

Page 1683 of 1825

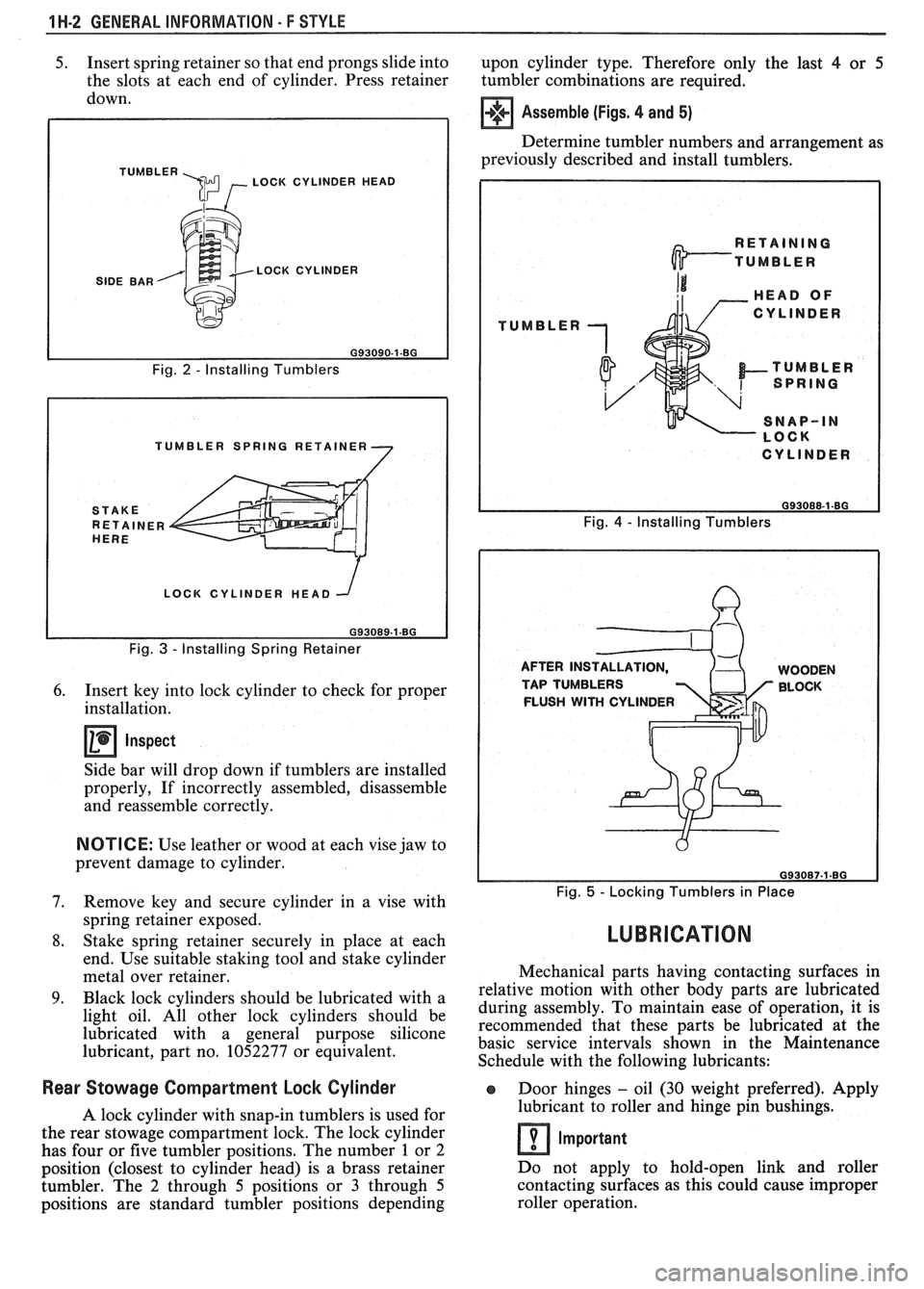

1 H-2 GENERAL INFORMATION - F STYLE

5. Insert spring retainer so that end prongs slide into

upon cylinder type. Therefore only the last 4 or 5

the slots at each end of cylinder. Press retainer

tumbler combinations are required.

down.

TUMBLER \m , LOCK CYLINDER HEAD

SIDE BAR LOCK CYLINDER

Fig.

2 - Installing Tumblers

TUMBLER SPRING RETAINER

LOCK CYLINDER HEAD

Fig.

3 - Installing Spring Retainer

6. Insert key into lock cylinder to check for proper

installation.

Inspect

Side bar will drop down if tumblers are installed

properly, If incorrectly assembled, disassemble

and reassemble correctly.

NOTICE: Use leather or wood at each vise jaw to

prevent damage to cylinder.

7. Remove key and secure cylinder in a vise with

spring retainer exposed.

8. Stake spring retainer securely in place at each

end. Use suitable staking tool and stake cylinder

metal over retainer.

9. Black lock cylinders should be lubricated with a

light oil. All other lock cylinders should be

lubricated with a general purpose silicone

lubricant, part no. 1052277 or equivalent.

Assemble (Figs. 4 and 5)

Determine tumbler numbers and arrangement as

previously described and install tumblers,

TUMBLER

I CYLINDER I

Fig. 4 - Installing Tumblers

AFTER INS WOODEN

TAP TUMBLERS BLOCK

FLUSH

WITH CYLINDER

Fig. 5 - Locking Tumblers in Place

LUBRICATION

Mechanical parts having contacting surfaces in

relative motion with other body parts are lubricated

during assembly. To maintain ease of operation, it is

recommended that these parts be lubricated at the

basic service intervals shown in the Maintenance

Schedule with the following lubricants:

Rear Stowage Compartment Lock Cylinder Door hinges - oil (30 weight preferred). Apply

A lock cylinder with snap-in tumblers is used for lubricant

to roller and hinge pin bushings.

the rear stowage compartment lock. The lock cylinder

Important has four or five tumbler positions. The number 1 or 2

position (closest to cylinder head) is a brass retainer Do

not apply to hold-open link and roller

tumbler. The

2 through 5 positions or 3 through 5 contacting

surfaces as this could cause improper

positions are standard tumbler positions depending roller operation.

Page 1745 of 1825

71.1-2 REAR END - F STYLE

dampened slightly with oil-free naphtha;

then remove tape strips.

COMPARTMENT LIFT WINDOW MOLDING

Refinishing

1. Mask off area(s) adjacent to molding(s).

2. Clean with Ditzler's DX-440 wax and grease

removing solvent or equivalent.

3. Sand with

#400 grit wet or dry sandpaper.

4. Clean

with wax and grease removing solvent.

5. Prime with Ditzler's

epoxy chromate primer DP

40/40 1 or equivalent.

6. Sand with

#500 grit wet or dry sandpaper.

7. Clean with wax and grease removing solvent.

8. Top

coat with flat black acrylic lacquer.

9. Remove masking tape.

When using any of the listed materials, follow the

manufacturer's label directions for application

procedures and drying time.

Removal

CAUTION: When working with glass

assemblies, the use of personal

protection items such as safety

glasses and work gloves is

recommended to minimize the chance

of personal injury should the glass

break.

1. Remove compartment lift window from body, as

described later in this section, and with the aid of

a helper, place upside down on a protected work

surface.

2. Remove upper hinges.

3. Remove screws retaining moldings to panel.

CAUTION: Perform the urethane

burn-out operation in a well ventilated

area and avoid direct inhalation of the

fumes being emitted as these fumes

may be hazardous.

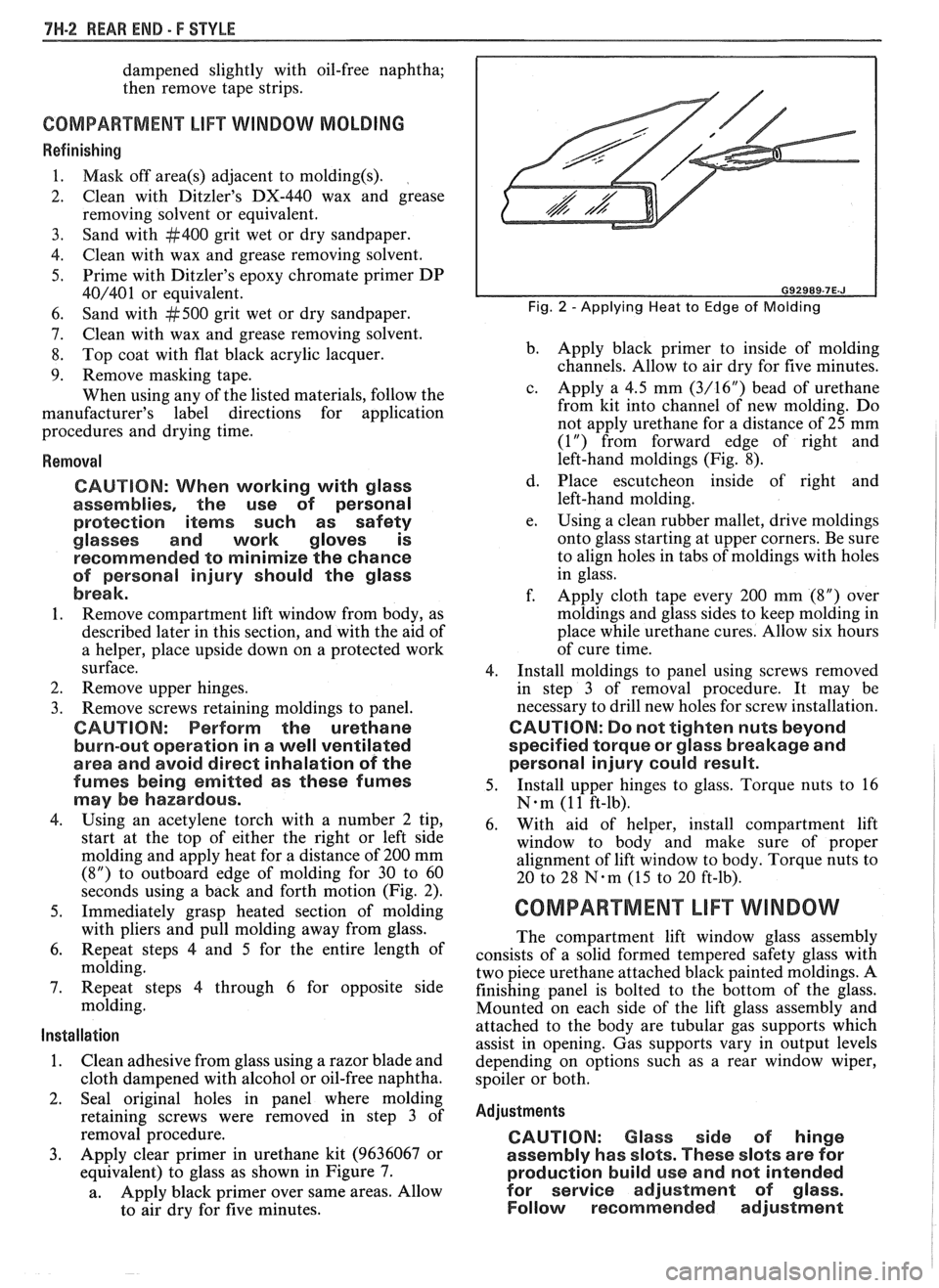

4. Using an acetylene torch with a number 2 tip,

start at the top of either the right or left side

molding and apply heat for a distance of 200 mm

(8") to outboard edge of molding for 30 to 60

seconds using a back and forth motion (Fig. 2).

5. Immediately grasp heated section of molding

with pliers and pull molding away from glass.

6. Repeat steps

4 and 5 for the entire length of

molding.

7. Repeat steps 4 through 6 for opposite side

molding.

Installation

1. Clean adhesive from glass using a razor blade and

cloth dampened with alcohol or oil-free naphtha.

2. Seal original holes in panel where molding

retaining screws were removed in step 3 of

removal procedure.

3. Apply clear primer in urethane kit (9636067 or

equivalent) to glass as shown in Figure 7.

a. Apply

black primer over same areas. Allow

to air dry for five minutes.

Fig. 2 -Applying Heat to Edge of Molding

b. Apply

black primer to inside of molding

channels. Allow to air dry for five minutes.

c. Apply a 4.5 mm

(3/16") bead of urethane

from kit into channel of new molding. Do

not apply urethane for a distance of

25 mm

(1") from forward edge of right and

left-hand moldings (Fig. 8).

d. Place escutcheon inside of right and

left-hand molding.

e. Using a

clean rubber mallet, drive moldings

onto glass starting at upper corners. Be sure

to align holes in tabs of moldings with holes

in glass.

f. Apply cloth tape every 200 mm (8") over

moldings and glass sides to keep molding in

place while urethane cures. Allow six hours

of cure time.

4. Install moldings to panel using screws removed

in step 3 of removal procedure. It may be

necessary to drill new holes for screw installation.

CAUTION: Do not tighten nuts beyond

specified torque or glass breakage and

personal injury could result.

5. Install

upper hinges to glass. Torque nuts to 16

N-m (1 1 ft-lb).

6. With aid of helper, install compartment lift

window to body and make sure of proper

alignment of lift window to body. Torque nuts to

20 to 28

N-m (15 to 20 ft-lb).

COMPARTMENT LIFT WINDOW

The compartment lift window glass assembly

consists of a solid formed tempered safety glass with

two piece urethane attached black painted moldings. A

finishing panel is bolted to the bottom of the glass.

Mounted on each side of the lift glass assembly and

attached to the body are tubular gas supports which

assist in opening. Gas supports vary in output levels

depending on options such as a rear window wiper,

spoiler or both.

Adjustments

CAUTION: Glass side of hinge

assembly has slots. These slots are for

production build use and not intended

for service adjustment of

glass.

Follow recommended adjustment

Page 1758 of 1825

WEAR END - F STYLE 7H-15

A

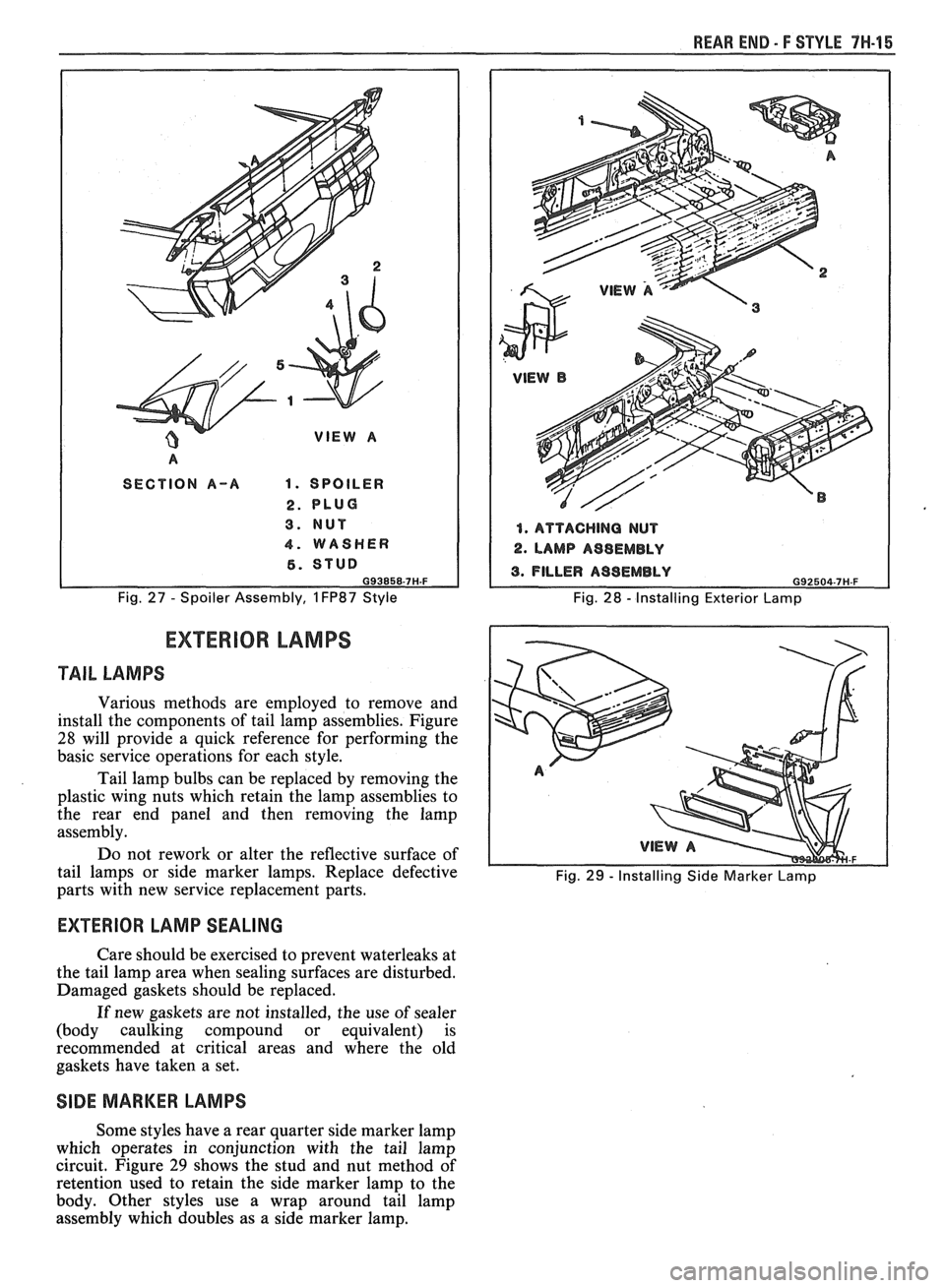

SECTION A-A 1. SPOILER

2. PLUG

3. NUT

4. WASHER

6. STUD 093858-7H.F

Fig. 27 - Spoiler Assembly, 1 FP87 Style

1. ATTACHING NUT

2. LAMP A98EMBLY

Fig. 28 - Installing Exterior Lamp

EXTERIOR LAMPS

TAIL LAMPS

Various methods are employed to remove and

install the components of tail lamp assemblies. Figure

28 will provide a quick reference for performing the

basic service operations for each style.

Tail lamp bulbs can be replaced by removing the

plastic wing nuts which retain the lamp assemblies to

the rear end panel and then removing the lamp

assembly.

Do not rework or alter the reflective surface of

tail lamps or side marker lamps. Replace defective

Fig. 29 - Installing Side Marker Lamp parts with new service replacement parts.

EXTERIOR LAMP SEALING

Care should be exercised to prevent waterleaks at

the tail lamp area when sealing surfaces are disturbed.

Damaged gaskets should be replaced.

If new gaskets are not installed, the use

of sealer

(body caulking compound or equivalent) is

recommended at critical areas and where the old

gaskets have taken a set.

SIDE MARKER LAMPS

Some styles have a rear quarter side marker lamp

which operates in conjunction with the tail lamp

circuit. Figure

29 shows the stud and nut method of

retention used to retain the side marker lamp to the

body. Other styles use a wrap around tail lamp

assembly which doubles as a side marker lamp.