cruise control PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 2 of 1825

1988

SER

This manual applies to the 1988 Pontiac Firebird Models.

It contains the latest product information available at the

time of publication approval. lnformation pertaining to

the operation of the vehicle is contained in the Owner's

Manual which accompanies each vehicle. The right is

reserved to make changes at any time without notice.

Any references to brand names in this manual is intended

merely as an example of the types of

lubricant% tools,

materials, etc, recommended for use in servicing 1988

Pontiac Models. In all cases, an equivalent may be used.

PONTIAC DIVISION

GENERAL

MOTORS CORPORATION

PONTIAC, MICHIGAN 48053

1987 General Motors Corp. All Rights Reserved.

No part of this publication may be reproduced, stored in any

retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical,

photocopying, recording or otherwise, without the prior written

permission of General Motors Corp. This includes all text,

illustrations, tables and charts.

S-881 OF 9-87 Printed in Canada

TABLE OF CONTENTS

SECTION NAME

GENERAL INFORMATION

OA. General lnformation

OB. Maintenance & Lubrication

1 SECT.

HEATING AND AIR CONDITIONING

1A. Heating and Ventilation

1 B. Air Conditioning

1D1. R-4 AIC Com~ressor Overhaul

FRAME AND BUMPERS

2B. Bumpers 2C. Chassis Sheet Metal

STEERING, SUSPENSION, WHEELS

AND TIRES

3. Diagnosis

3A. Wheel Alignment

3B5. Steering Wheels and Columns 3B6. Steering Linkage 3B7. Power Steering Gear and Pump

3C. Front Suspension

3D. Rear Suspension

3E. Tires and Wheels

FINAL DRIVE

4A. Propeller Shaft

4B. Rear Axle

4B1. Bora-Warner Axle

BRAKES 5. Brakes 5A3. Comoosite Master Cvlinder 5B1. Disc r rake Caliper ~ssembly - 300013100 Series 5B6. Disc Brake Caliper Assembly - 3548

Series

5C3. Direct Torque Drum Brake Assembly 5D2. Power Head Assembly - Tandem Diaohraam 5F. ~~ecifications and Special Tools

ENGINE 6. Engine General lnformation 6A2. 2.8L 6A3. 5.OL & 5.7L 6B. Engine Cooling

6C. En~ine Fuel

6D. ~ngine Electrical 6D1. Battery 6D2. Cranking System 6D3. Charging System 6D4. Ignition System 6D5. Engine Wiring

6E. Driveabilitv and Emissions

6E2. ~missions' 6E3. Emissions - PFI

6F. Engine Exhaust

TRANSMISSION 7A. Automatic Transmission - General

lnformation

7A1. Automatic Transmission - On-Car

Service

700R4. Automatic Transmission Hydraulic Diagnosis

700R4. Automatic Transmission Unit Repair

76. 5-Speed Manual Transmission

7C. Clutch

CHASSIS ELECTRICAL 8A. Electrical Diagnosis

8B. Lighting and Horns

8C. Instrument

Panel, Gages

& Console

8E. Windshield Wiper &Washer System

ACCESSORIES 9A. Radio Systems and Antennas 9B. Cruise Control 9G. Miscellaneous Accessories

I BODY SERVICE MANUAL END

OF

MANUAL

Page 173 of 1825

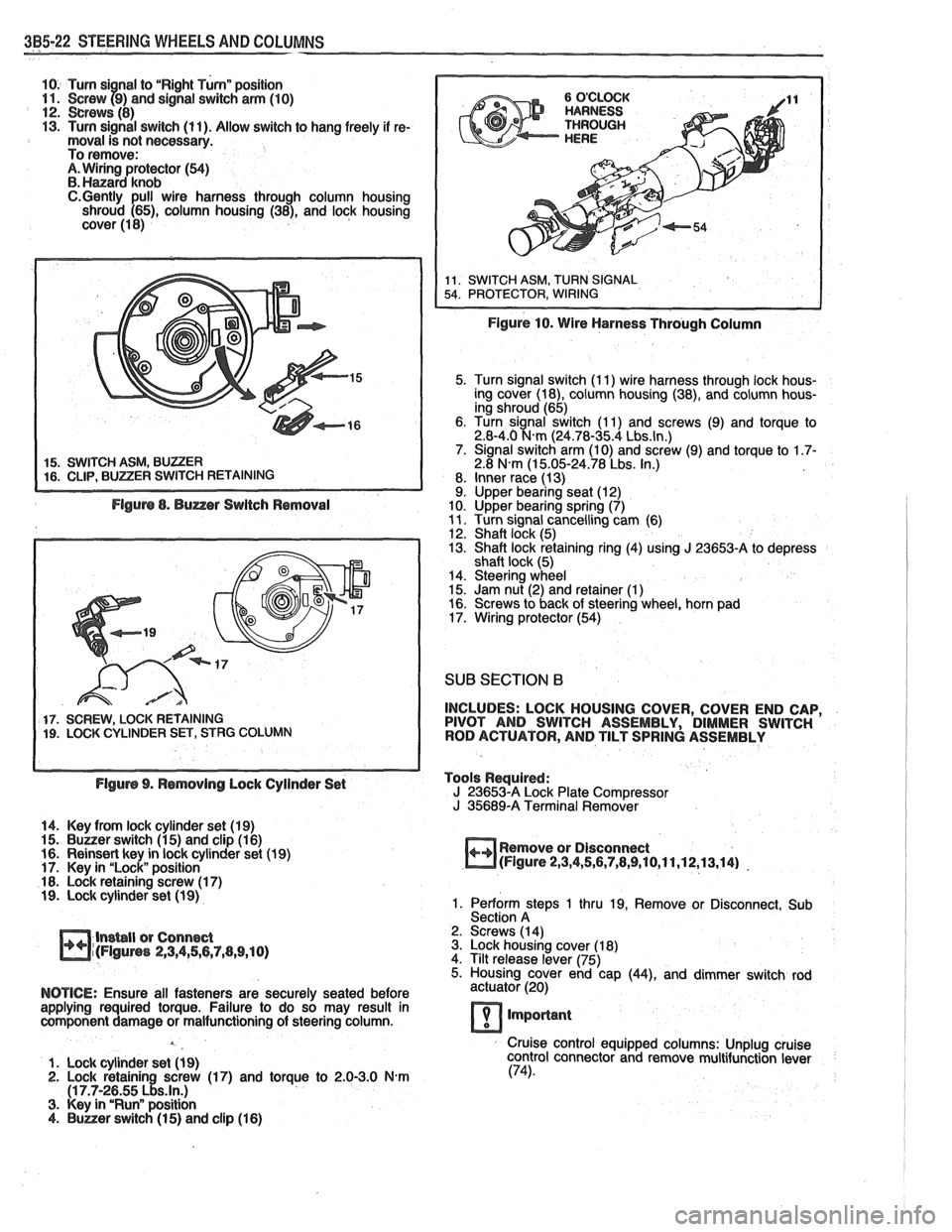

385-22 STEERING WHEELS AND COLUMNS

10. Turn si nal to "Right Turnn position 11. Screw f9) and signal switch arm (10) 12. crews (8) 13. Turn signal switch (11). Allow switch to hang freely if re- moval is not necessary.

To remove:

A. Wiring protector (54) B. Hanard knob C.Gently pull wire harness through column housing

shroud (65), column housing (38), and lock housing

cover (1 8)

5. Turn signal switch (I 1) wire harness through lock hous-

ing cover (18), column housing (38), and column hous-

ing shroud (65)

6. Turn signal switch (1 1) and screws (9) and torque to

2.8-4.0

N.m (24.78-35.4 Lbs.ln.) 7. Signal switch arm (10) and screw (9) and torque to 1.7- 2.8 N.m (1 5.05-24.78 Lbs. In.)

8. Inner race (13)

9. Upper bearing seat (12)

10. Upper bearing spring (7)

11. Turn signal cancelling cam (6)

12. Shaft lock (5)

13. Shaft lock retaining ring (4) using J 23653-A to depress

shaft lock (5)

14. Steering wheel

15. Jam nut (2) and retainer

(1) 16. Screws to back of steering wheel, horn pad

17. Wiring protector (54)

SUB SECTION 6

17. SCREW, LOCK RETAINING INCLUDES:

LOCK HOUSING COVER, COVER END CAP, 19. LOCK CYLINDER SET, STRG COLUMN PIVOT

AND SWITCH ASSEMBLY, DIMMER SWITCH

ROD ACTUATOR, AND TILT SPRING ASSEMBLY

Flgurs 9. Rsmovlng Lock Cylinder Set Tools

Required:

J 23653-A Lock Plate Compressor

J 35689-A Terminal Remover

14. Key from lock cylinder set (19)

15.

Buuer switch (1 5) and clip (1 6)

16. Reinsert key in lock cylinder set (1 9) Remove

or Disconnect

17. Key in "Lock" position

m(Flgure 2,3,4,5,6,7,8,9,10,11,12,13,14) -

18. Lock retaining screw (1 7) 19. Lock cylinder set (1 9) 1. Perform steps 1 thru 19, Remove or Disconnect, Sub

Section A

lnsbll or Connect 2.

Screws (14)

m~(FIguns 2,3,4,56,7,(1,9,10) 3. Lock housing cover (1 8)

4. Tilt release lever (75)

5. Housing cover end cap

(44), and dimmer switch rod

NOTICE: Ensure all fasteners are securely seated before actuator (20)

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

lmporlant

Cruise control equipped columns: Unplug cruise

1. Lock cylinder set

(1 9) control

connector and remove multifunction lever 2. Lock retainin screw (17) and torque to 2.0-3.0 N-m (74).

(1 7.7-2~55 ~!s.ln.) 3. Key in "Runn position 4. Buner switch (1 5) and clip (1 6)

Page 174 of 1825

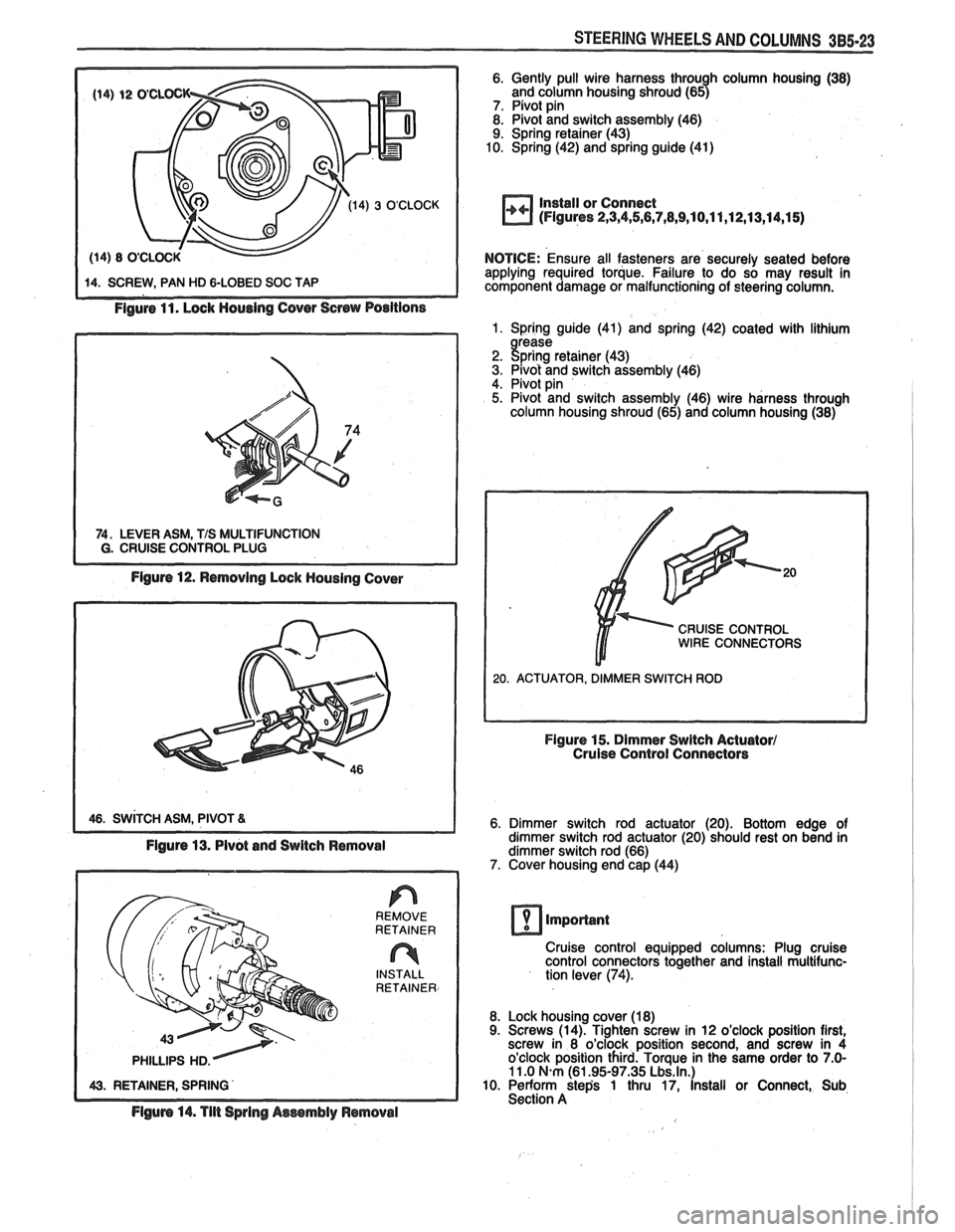

STEERING WHEELS AND COLUMNS 385.23

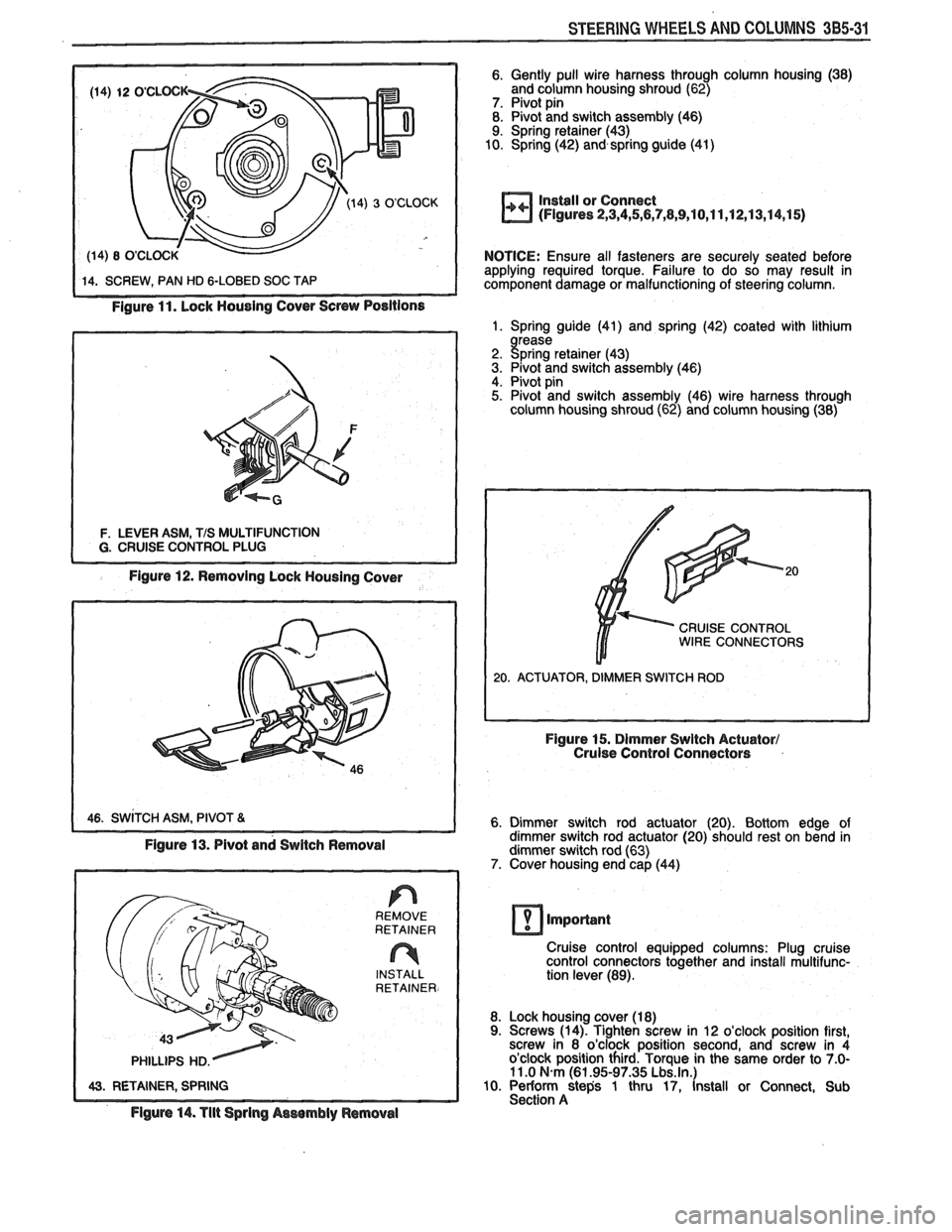

Figure 11. Lock Housing Cover Screw Positions

74. LEVER ASM, TIS MULTIFUNCTION I G. CRUISE CONTROL PLUG

Figure 12. Removing Lock Housing Cover

1 46. SWITCH ASM, PIVOT 81

Figure 13. Pivot and Switch Removal

REMOVE

RETAINER

n INSTALL

RETAINER

Flgum 14. Tilt Spring Aessmbly Removal

6. Gently pull wire harness throu h column housing (38)

and column housing shroud (657 7. Pivot pin 8. Pivot and switch assembly (46)

9. Spring retainer (43)

10. Spring (42) and spring guide (41)

Install or Connect

(Figures 2,3,4,5,6,7,8,9,10,11 ,12,13,14,1 5)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Spring guide (41) and spring (42) coated with lithium

2. !$;rK: retainer (43) 3. Pivot and switch assembly (46)

4. Pivot pin

5. Pivot and switch assembly (46) wire harness through

column housing shroud (65) and column housing (38)

CRUISE CONTROL WIRE CONNECTORS

Figure 15. Dimmer Switch Actuator1 Cruise Control Connectors

6. Dimmer switch rod actuator (20). Bottom edge of

dimmer switch rod actuator (20) should rest on bend in

dimmer switch rod (66)

7. Cover housing end cap (44)

important

Cruise control equipped columns: Plug cruise

control connectors together and install multifunc-

tion lever

(74).

8. Lock housing cover (18)

9. Screws (14). Tighten screw in 12 o'clock position first,

screw in 8 o'clock position second, and screw in 4

o'clock position third. Torque in the same order to

7.0- 11 .O N.m (61.95-97.35 Lbs.ln.) 10. Perform step's 1 thru 17, install or Connect, Sub

Section A

Page 181 of 1825

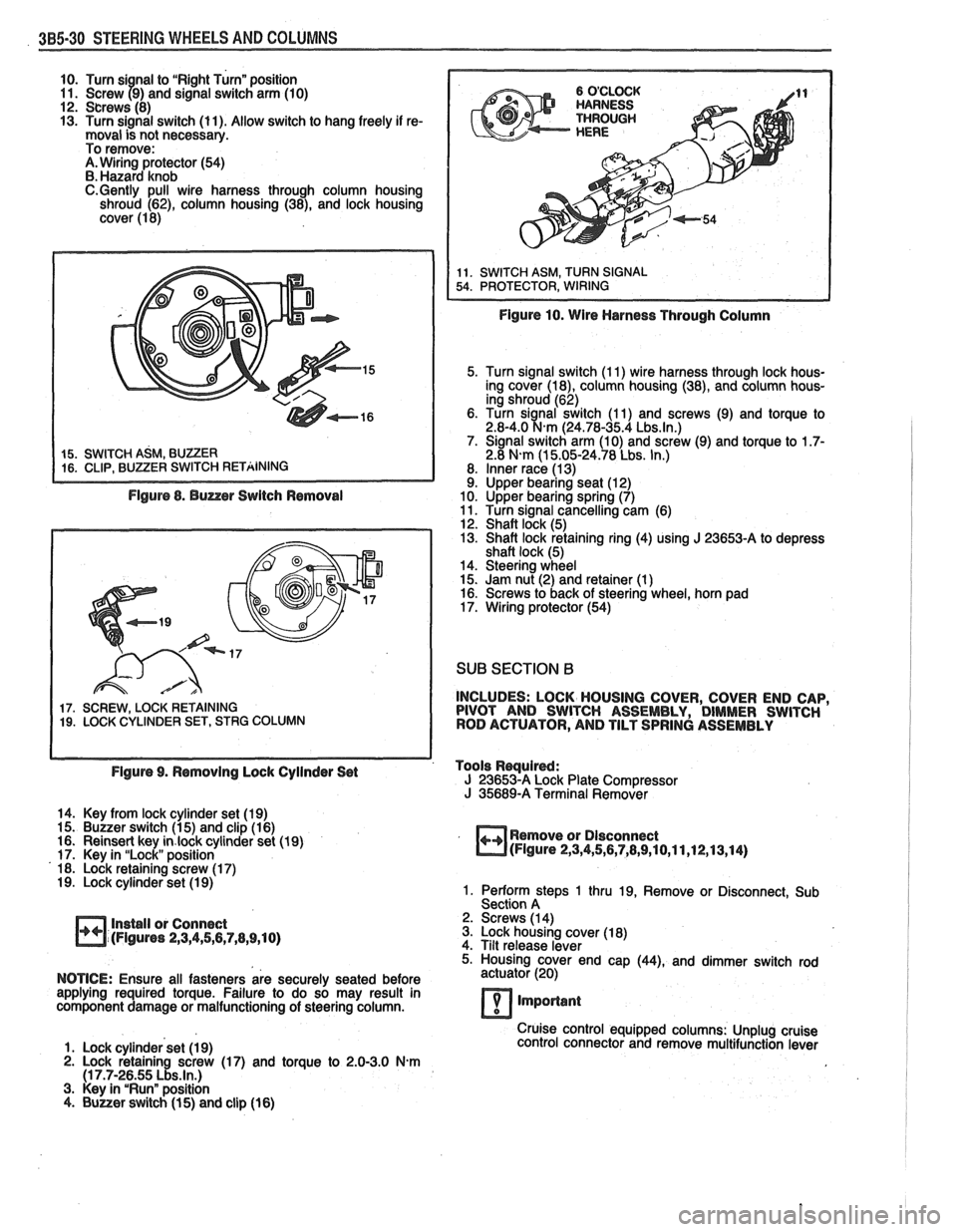

385-30 STEERING WHEELS AND COLUMNS

10. Turn si nal to "Right Turn" position

11. Screw 79) and signal switch arm (10)

12. Screws (8)

13. Turn signal switch (11). Allow switch to hang freely if re-

moval is not necessary.

To remove:

A. Wiring protector (54)

B. Hazard knob

C.Gently pull wire harness through column housing

shroud (62), column housing (38), and lock housing

cover (1 8)

Figure 8. Buzzer Switch Removal

17. SCREW, LOCK RETAINING 19. LOCK CYLINDER SET, STRG COLUMN

Figure 10. Wire Harness Through Column

5. Turn signal switch (1 1) wire harness through lock hous-

ing cover

(la), column housing (38), and column hous-

ing shroud (62)

6. Turn

sianal switch (1 1) and screws (9) and torque to 2.8-4.0 %km (24.78-35.4 Lbs.ln.) 7. Signal switch arm (10) and screw (9) and torque to 1.7- 2.8 N-m (1 5.05-24.78 Lbs. In.)

8. Inner race (1 3) 9. Upper bearing seat (1 2)

10. Upper bearing spring (7)

11. Turn signal cancelling cam (6)

12. Shaft lock (5)

13. Shaft lock retaining ring (4) using

J 23653-A to depress

shaft lock (5)

14. Steering wheel

15. Jam nut (2) and retainer (1

) 16. Screws to back of steering wheel, horn pad

17. Wiring protector (54)

SUB SECTION B

INCLUDES: LOCK HOUSING COVER, COVER END CAP,

PIVOT AND SWITCH ASSEMBLY, DIMMER SWITCH

ROD ACTUATOR, AND TILT SPRING ASSEMBLY

Figure 9. Removing Lock Cyilnder Set Tools

Rwuired: J 23653-A Lock

Plate Compressor J 35689-A Terminal Remover

14. Key from lock cylinder set (19)

15. Buzzer switch (1 5) and clip (1 6)

16. Reinsert key

in.lock cylinder set (19)

17. Key in "Lock" position

18. Lock retaining screw (1 7)

19. Lock cylinder set (1 9)

Install or Connect

(Figures

2,3,4,5,6,7,8,9,10)

Remove or Dlsconnect (Figure 2,3,4,5,6,7,8,9,10,11,12,13,14)

1. Perform steps 1 thru 19, Remove or Disconnect, Sub

Section A

2. Screws (1 4)

3. Lock housing cover (1 8)

4. Tilt release lever

5. Housing cover end cap

(44), and dimmer switch rod

NOTICE: Ensure all fasteners are securely seated before actuator

(20)

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

7 important

Cruise control equipped columns: Unplug cruise

1. Lock cylinder set (1 9) control

connector and remove multifunction lever

2. Lock retaining screw (17) and torque to 2.0-3.0 N.m (1 7.7-26.55 Lbs.ln.) 3. Key in "Run" position

4. Buuer switch (1 5) and clip (16)

Page 182 of 1825

STEERING WHEELS AND COLUMNS 385-31

Figure 11. Lock Housing Cover Screw Positions

F. LEVER ASM, TIS MULTIFUNCTION

Figure 12. Removing Lock Housing Cover

6. Gently pull wire harness through column housing (38)

and column housing shroud (62)

7. Pivot pin

8. Pivot and switch assembly (46)

9. Spring retainer (43)

10. Spring (42) and spring guide

(41)

Install or Connect

(Figures 2,3,4,5,6,7,8,9,10,11,12,13,14,15)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Spring guide (41) and spring (42) coated with lithium

rease

2. gpring retainer (43)

3. Pivot and switch assembly (46) 4. Pivot pin 5. Pivot and switch assembly (46) wire harness through

column housing shroud (62) and column housing (38)

CRUISE CONTROL WIRE CONNECTORS

6. Dimmer switch rod actuator (20). Bottom edge of

dimmer switch rod actuator (20) should rest on bend in

dimmer switch rod (63)

7. Cover housing end cap (44)

1 43. RETAINER, SPRING REMOVE

RETAINER

INSTALL

RETAINER.

Figure 14. Tlit Sprlng Aswmbly ~emovel

Cruise control equipped columns: Plug cruise

control connectors together and install multifunc-

tion lever (89).

8. Lock housing cover (1

8) 9. Screws (14). Tighten screw in 12 o'clock position first,

screw in 8 o'clock position second, and screw in 4

o'clock position third. Torque in the same order to

7.0- 11 .O N.m (61.95-97.35 Lbs.ln.) 10. Periorrn steps 1 thru 17, Install or Connect, Sub

Section A

Page 301 of 1825

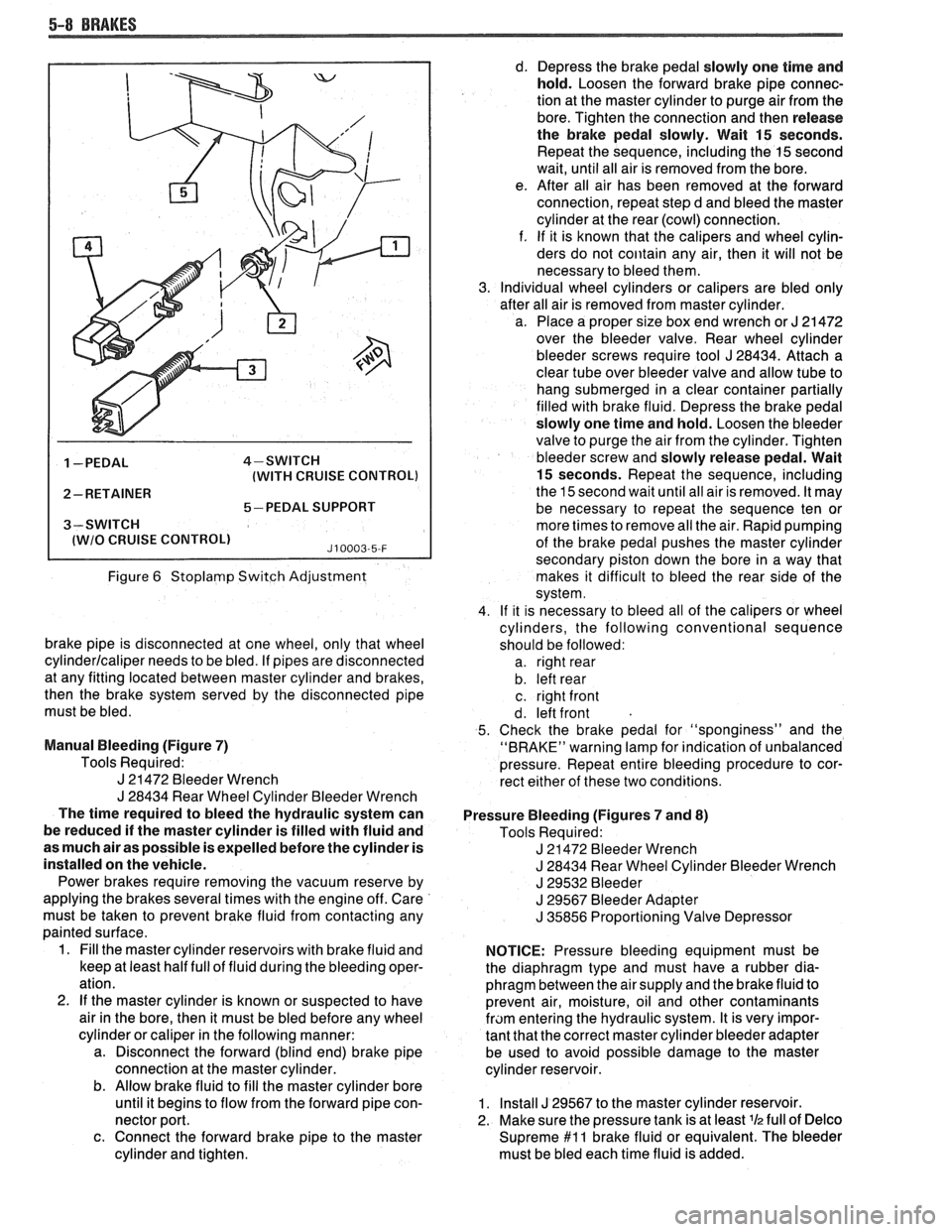

5-8 BRAKES

1 -PEDAL 4-SWITCH

(WITH CRUISE CONTROL)

2- RETAINER

5-PEDAL SUPPORT

3-SWITCH

I lWlO CRUISE CONTROLl J10003-5-F

Figure 6 Stoplamp Switch Adjustment

brake pipe is disconnected at one wheel, only that wheel

cylinderlcaliper needs to be bled. If pipes are disconnected

at any fitting located between master cylinder and brakes,

then the brake system served by the disconnected pipe

must be bled.

Manual Bleeding (Figure

7)

Tools Required:

J 21472 Bleeder Wrench

J 28434 Rear Wheel Cylinder Bleeder Wrench

The time required to bleed the hydraulic system can

be reduced if the master cylinder is filled with fluid and

as much air as possible is expelled before the cylinder is

installed on the vehicle.

Power brakes require removing the vacuum reserve by

applying the brakes several times with the engine off. Care

must be taken to prevent brake fluid from contacting any

painted surface.

1. Fill the master cylinder reservoirs with brake fluid and

keep at least half full of fluid during the bleeding oper-

ation.

2.

If the master cylinder is known or suspected to have

air in the bore, then it must be bled before any wheel

cylinder or caliper in the following manner:

a. Disconnect the forward (blind end) brake pipe

connection at the master cylinder.

b. Allow brake fluid to fill the master cylinder bore

until it begins to flow from the forward pipe con-

nector port.

c. Connect the forward brake pipe to the master

cylinder and tighten. d.

Depress the brake pedal slowly one time and

hold. Loosen the forward brake pipe connec-

tion at the master cylinder to purge air from the

bore. Tighten the connection and then release

the brake pedal slowly. Wait

15 seconds.

Repeat the sequence, including the

15 second

wait, until all air is removed from the bore.

e. After all air has been removed at the forward

connection, repeat step d and bleed the master

cylinder at the rear (cowl) connection.

f. If it is known that the calipers and wheel cylin-

ders do not

coiitain any air, then it will not be

necessary to bleed them.

Individual wheel cylinders or calipers are bled only

after all air is removed from master cylinder.

a. Place a proper size box end wrench or

J 21 472

over the bleeder valve. Rear wheel cylinder

bleeder screws require tool

J 28434. Attach a

clear tube over bleeder valve and allow tube to

hang submerged in a clear container partially

filled with brake fluid. Depress the brake pedal

slowly one time and hold. Loosen the bleeder

valve to purge the air from the cylinder. Tighten

bleeder screw and slowly release pedal. Wait

15 seconds. Repeat the sequence, including

the 15 second wait until all air is removed. It may

be necessary to repeat the sequence ten or

more times to remove all the air. Rapid pumping

of the brake pedal pushes the master cylinder

secondary piston down the bore in a way that

makes it difficult to bleed the rear side of the

system.

If it is necessary to bleed all of the calipers or wheel

cylinders, the following conventional sequence

should be followed: a. right rear

b. left rear

c. right front

d. left front

Check the brake pedal for "sponginess" and the

"BRAKE" warning lamp for indication of unbalanced

pressure. Repeat entire bleeding procedure to cor-

rect either of these two conditions.

Pressure Bleeding (Figures

7 and 8)

Tools Required:

J 21472 Bleeder Wrench

J 28434 Rear Wheel Cylinder Bleeder Wrench

J 29532 Bleeder

J 29567 Bleeder Adapter

J 35856 Proportioning Valve Depressor

NOTICE: Pressure bleeding equipment must be

the diaphragm type and must have a rubber dia-

phragm between the air supply and the brake fluid to

prevent air, moisture, oil and other contaminants

fram entering the hydraulic system. It is very impor-

tant that the correct master cylinder bleeder adapter

be used to avoid possible damage to the master

cylinder reservoir.

1. Install J 29567 to the master cylinder reservoir.

2. Make sure the pressure tank is at least

lh full of Delco

Supreme $1 1 brake fluid or equivalent. The bleeder

must be bled each time fluid is added.

Page 376 of 1825

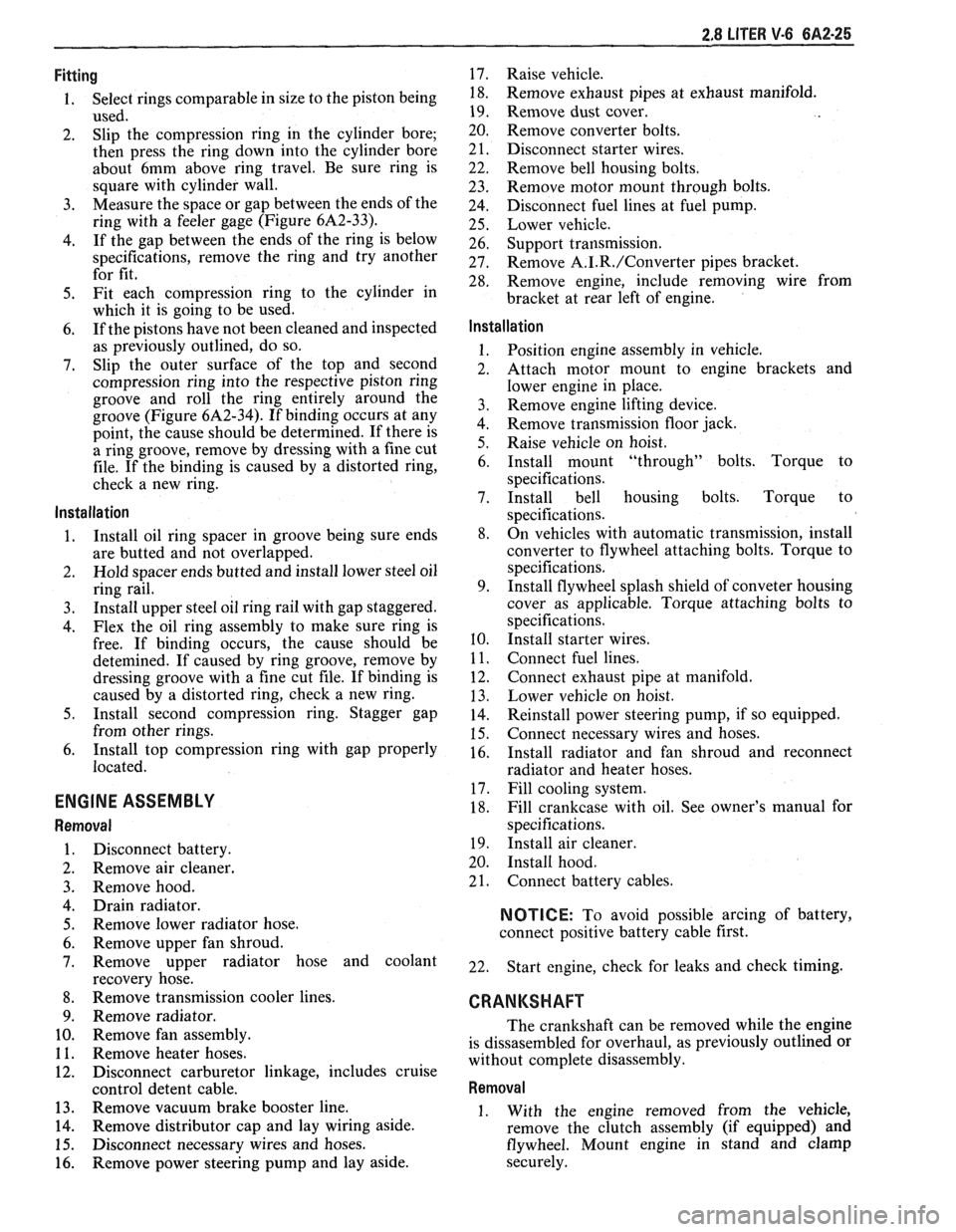

2.8 LITER V-6 6A2-25

Fitting

1. Select rings comparable in size to the piston being

used.

2. Slip

the compression ring in the cylinder bore;

then press the ring down into the cylinder bore

about 6mm above ring travel. Be sure ring is

square with cylinder wall.

3. Measure the space or gap between the ends of the

ring with a feeler gage (Figure

6A2-33).

4. If

the gap between the ends of the ring is below

specifications, remove the ring and try another

for fit.

5. Fit each compression ring to the cylinder in

which it is going to be used.

6. If the pistons have not been cleaned and inspected

as previously outlined, do so.

7. Slip the outer surface of the top and second

compression ring into the respective piston ring

groove and roll the ring entirely around the

groove (Figure

6A2-34). If binding occurs at any

point, the cause should be determined. If there is

a ring groove, remove by dressing with a fine cut

file. If the binding is caused by a distorted ring,

check a new ring.

Installation

1. Install oil ring spacer in groove being sure ends

are butted and not overlapped.

2. Hold

spacer ends butted and install lower steel oil

ring rail.

3. Install upper

steel oil ring rail with gap staggered.

4. Flex

the oil ring assembly to make sure ring is

free. If binding occurs, the cause should be

detemined. If caused by ring groove, remove by

dressing groove with a fine cut file. If binding is

caused by a distorted ring, check a new ring.

5. Install second compression ring. Stagger gap

from other rings.

6. Install top compression ring with gap properly

located.

ENGINE ASSEMBLY

Removal

Disconnect battery.

Remove air cleaner.

Remove hood. Drain radiator.

Remove lower radiator hose.

Remove upper fan shroud.

Remove upper radiator hose and coolant

recovery hose.

Remove transmission cooler lines. Remove radiator.

Remove fan assembly.

Remove heater hoses.

Disconnect carburetor linkage, includes cruise

control detent cable.

Remove vacuum brake booster line.

Remove distributor cap and lay wiring aside.

Disconnect necessary wires and hoses.

Remove power steering pump and lay aside. Raise

vehicle.

Remove exhaust pipes at exhaust manifold.

Remove dust cover.

Remove converter bolts.

Disconnect starter wires.

Remove bell housing bolts.

Remove motor mount through bolts.

Disconnect fuel lines at fuel pump.

Lower vehicle. Support transmission.

Remove

A.I.R./Converter pipes bracket.

Remove engine, include removing wire from

bracket at rear left of engine.

Installation

Position engine assembly in vehicle.

Attach motor mount to engine brackets and

lower engine in place.

Remove engine lifting device.

Remove transmission floor jack.

Raise vehicle on hoist.

Install mount "through" bolts. Torque to

specifications.

Install bell housing bolts. Torque to

specifications.

On vehicles with automatic transmission, install

converter to flywheel attaching bolts. Torque to

specifications.

Install flywheel splash shield of conveter housing

cover as applicable. Torque attaching bolts to

specifications.

Install starter wires.

Connect fuel lines.

Connect exhaust pipe at manifold.

Lower vehicle on hoist.

Reinstall power steering pump, if so equipped.

Connect necessary wires and hoses.

Install radiator and fan shroud and reconnect

radiator and heater hoses.

Fill cooling system.

Fill crankcase with oil. See owner's manual for

specifications.

Install air cleaner.

Install hood.

Connect battery cables.

NOTICE: To avoid possible arcing of battery,

connect positive battery cable first.

22. Start engine, check for leaks and check timing.

CRANKSHAFT

The crankshaft can be removed while the engine

is dissasembled for overhaul, as previously outlined or

without complete disassembly.

Removal

1. With the engine removed from the vehicle,

remove the clutch assembly (if equipped) and

flywheel. Mount engine in stand and clamp

securely.

Page 385 of 1825

6A3-6 V-8 ENGINE

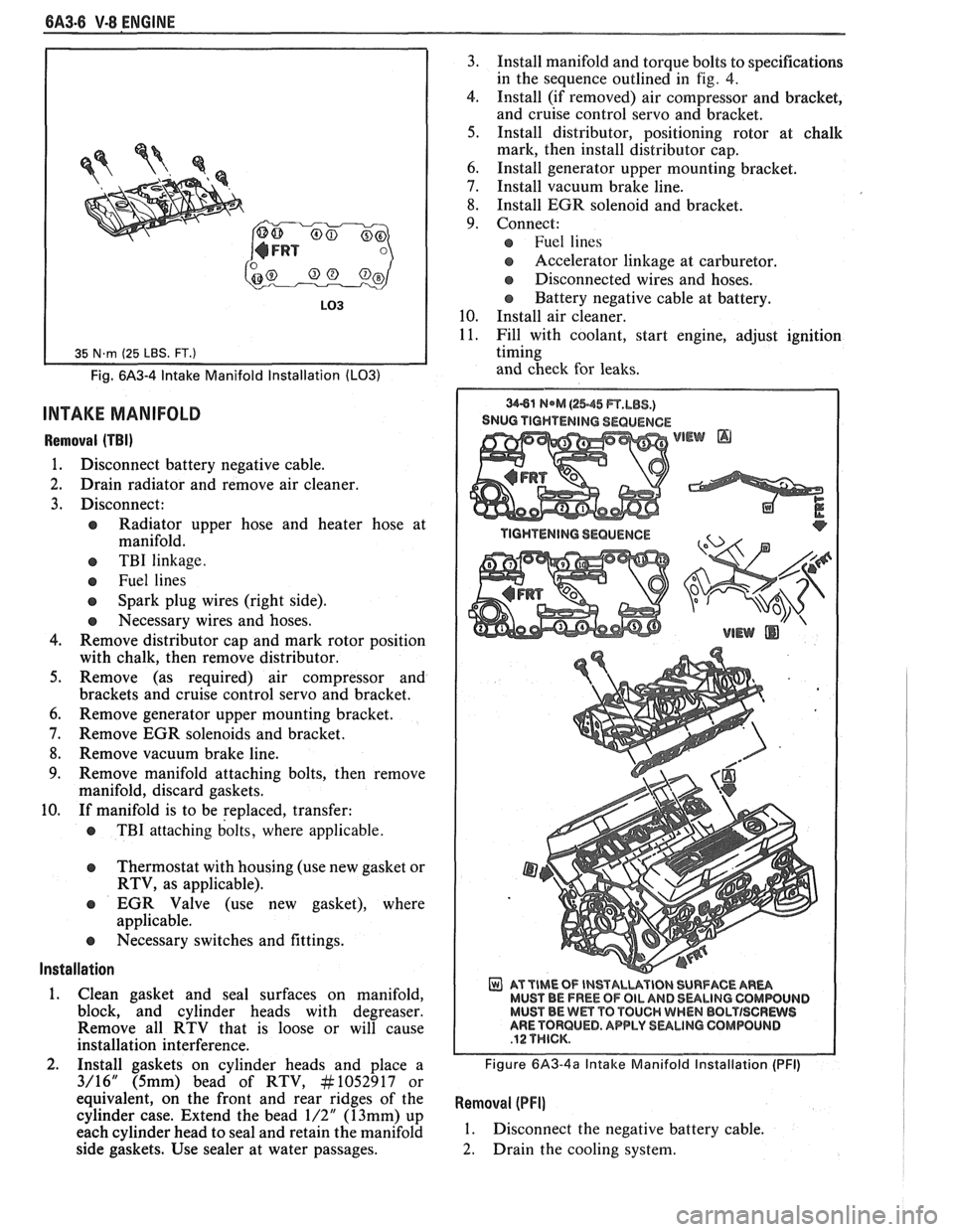

Fig. 6A3-4 Intake Manifold Installation (LO31

INTAKE MANIFOLD

Removal (TBI)

1. Disconnect battery negative cable.

2. Drain radiator and remove air cleaner.

3. Disconnect:

e Radiator upper hose and heater hose at

manifold.

e TBI linkage.

e Fuel lines

Spark plug wires (right side).

e Necessary wires and hoses.

4. Remove distributor cap and mark rotor position

with chalk, then remove distributor.

5. Remove (as required) air compressor and

brackets and cruise control servo and bracket.

6. Remove generator upper mounting bracket.

7. Remove EGR solenoids and bracket.

8. Remove vacuum brake line.

9. Remove manifold attaching bolts, then remove

manifold, discard gaskets.

10. If manifold is to be replaced, transfer:

e TBI attaching bolts, where applicable.

Thermostat with housing (use new gasket or

RTV, as applicable).

EGR Valve (use new gasket), where

applicable.

e Necessary switches and fittings.

lnstallation

1. Clean gasket and seal surfaces on manifold,

block, and cylinder heads with degreaser.

Remove all RTV that is loose or will cause

installation interference.

2. Install gaskets on cylinder heads and place a

3/16" (5mm) bead of RTV, At1052917 or

equivalent, on the front and rear ridges of the

cylinder case. Extend the bead

1/2" (13mm) up

each cylinder head to seal and retain the manifold

side gaskets. Use sealer at water passages. 3.

Install manifold and torque bolts to specifications

in the sequence outlined in

fig. 4.

4. Install (if removed) air compressor and bracket,

and cruise control servo and bracket.

5. Install distributor, positioning rotor at chalk

mark, then install distributor cap.

6. Install generator upper mounting bracket.

7. Install vacuum brake line.

8. Install EGR solenoid and bracket.

9. Connect:

Fuel lines

s Accelerator linkage at carburetor.

@ Disconnected wires and hoses.

Battery negative cable at battery.

10. Install air cleaner.

11. Fill with coolant, start engine, adjust ignition

timing

and check for leaks.

SNUG TIGHTENING SEQUENCE

WEW @

AT TIME OF INSTALUVIBN SURFACE AR- MUST BE FREE OF OIL AND 8ULlNG CQMWUIJD MUST BE Wm TO TOUCH WHEN BBLTISCRWS ARE TORQUED. APPLY SULINO GOMPOLINB

Figure 6A3-4a Intake Manifold Installation (PFI)

Removal (PFI]

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Page 406 of 1825

V-8 ENGINE 6A3-27

3. When finish honing

a cylinder bore to fit a piston,

the hone should be moved up and down at a

sufficient speed to obtain very fine uniform

surface finish marks in a cross-hatch pattern of

approximately

45" to 65" included angle. The

finish marks should be clean but not sharp, free

from imbedded particles and torn or folded

metal.

4. Permanently mark

the piston for the cylinder to

which it has been fitted and proceed to hone

cylinders and fit the remaining pistons.

NOTICE: Handle the pistons with care and do not

attempt to force them through the cylinder until

the cylinder has been honed to correct size as this

type piston can be distorted through careless

handling.

5. Thoroughly

clean the bores with hot water and

detergent. Scrub well with a stiff bristle brush and

rinse thoroughly with hot water. It is extremely

essential that a good cleaning operation be

performed. If any of the abrasive material is

allowed to remain in the cylinder bores, it will

rapidly wear the new rings and cylinder bores in

addition to the bearings lubricated by the

contaminated oil, the bores should be swabbed

and then wiped with a clean dry cloth. Cylinder

should not be cleaned with kerosene or gasoline.

Clean the remainder of the cylinder block to

remove the excess material spread during the

honing operation.

Piston Selection

1. Check USED piston to cylinder bore clearance as

follows:

a. Measure

the "Cylinder Bore Diameter"

with a telescope gage

"2-1/2" (64mm) from

top of cylinder bore").

b. Measure

the

"Piston Diameter" (at skirt

across center line of piston pin).

c. Subtract

piston diameter from cylinder bore

diameter to determine "Piston to Bore

Clearance".

d. Determine if piston to bore clearance is in

the acceptable range.

2. If

used piston is not acceptable, check Piston Size

Chart and determine if a new piston can be

selected to fit cylinder bore within the acceptable

range.

3. If

cylinder bore must be reconditioned, measure

new piston diameter (across center line of piston

pin) then hone cylinder bore to correct clearance

(preferable range).

4. Mark the piston to identify the cylinder for which

it was fitted.

OIL FILTER BYPASS VALVE

Inspection and Replacement

With the oil filter removed, check the spring and

fibre valve for operation. Inspect for a cracked or

broken valve. If replacement is necessary, the oil filter

adapter and bypass valve assembly must be replaced as an

assembly. Clean valve chamber in cylinder block

thoroughly. Torque retaining screws to specifications.

ENGINE ASSEMBLY

Removal

1. Disconnect battery.

2. Remove air cleaner.

3. Remove hood.

4. Drain radiator.

5. Remove lower radiator hose.

6. Remove upper fan shroud.

7. Remove upper radiator hose and coolant

recovery hose.

8. Remove transmission cooler lines.

9. Remove radiator.

10. Remove fan assembly.

1 1. Remove heater hoses.

12. Disconnect

carburetor linkage, includes cruise

control detent cable.

13. Remove vacuum brake booster line.

14. Remove

distributor cap and lay wiring aside.

15. Disconnect necessary wires and hoses.

16. Remove power steering

pump and lay aside.

17. Raise vehicle.

18. Remove exhaust

pipes at exhaust manifold.

19. Remove dust cover.

20. Remove converter bolts.

2 1. Disconnect starter wires.

22. Remove bell housing bolts.

23. Remove

motor mount through bolts.

24. Disconnect fuel lines

at fuel pump.

25. Lower vehicle.

26. Support transmission.

27. Remove

A.I.R./Converter pipe bracket.

28. Remove engine, include removing wire

from

bracket at rear left of engine.

Installation

1. Position engine

assembly in vehicle.

2. Attach

motor mount to engine brackets and

lower engine in place.

3. Remove engine lifting device.

4. Remove transmission floor jack.

5. Raise vehicle on hoist.

6. Install mount "through" bolts. Torque to

specifications.

7. Install bell housing bolts. Torque to

specifications.

8. On vehicles with automatic transmissions, install

I

converter to flywheel attaching bolts. Torque to

specifications.

9. Install flywheel splash shield of converter

housing cover as applicable. Torque attaching

bolts to specifications.

I

10. Install starter wires.

1 1. Connect fuel lines.

12. Connect exhaust pipe at manifold.

13. Lower vehicle on hoist.

14. Reinstall power steering pump, if so equipped.

15. Connect necessary wires and hoses.

Page 550 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN E) 6E2-B-3

SURGES AND/OR CHUGGLE

Definition: Engine power variation, under steady

throttle or cruise. Feels like the car speeds up and slows

down, with no change in the accelerator pedal.

@ Use a "Scan" tool to make sure reading of VSS

matches vehicle speedometer. See "Special

Information", Section

"6E".

e CHECK:

- For intermittent EGR at idle. See appropriate

CHART C-7.

- Ignition timing. See Emission Control

Information label.

- Inline fuel filter for dirt or restriction.

- Fuel pressure. See CHART A-7.

- Generator output voltage. Repair if less than 9,

or more than

16 volts.

- TCC Operation. CHART C-8A.

@ Inspect oxygen sensor for silicon contamination

from fuel, or use of improper RTV sealant. The

sensor may have a white, powdery

coabing and

result in a high but false signal voltage (rich

exhaust indication). The ECM will then reduce

the amount of fuel delivered to the engine,

causing a severe driveability problem.

@ Remove spark plugs. Check for cracks, wear,

improper gap, burned electrodes, or heavy

deposits. Also, check condition of the rest of the

ignition system.

LACK OF BOWER, SLUGGISH, OR SPONGY

Definition: Engine delivers less than expected power. Little or no

increase in speed, when accelerator pedal is pushed down part way.

@ Compare customer's car to similar unit. Make - For restricted fuel filter, contaminated fuel or

sure the customer's car has an actual problem. improper fuel pressure. See CHART A-7.

@ Remove air cleaner and check air filter for dirt, - ECM Grounds.

or for being plugged. Replace as necessary.

- EGR operation for being open, or partly open, all

If there is spray from only one injector, then, the time

- CHART C-7.

there is a malfunction in the injector assembly,

- Generator output voltage. Repair if less than 9, or

or in the signal to the injector assembly.

'I'he more than 16 volts.

malfunction can be isolated, by switching the

- Engine valve timing and compression.

injector connectors.

If the problem remains with - Engine, for proper or worn camshaft. See Section

the original injector, after switching the

"6A".

connector, then the injector is defective. Replace - Transmission torque converter operation. See

the injector. If the problem moves with the

Sectionw7A".

injector connector, then the problem is an - Secondary ignition voltage.

improper signal in the injector circuits, see

- Proper operation or ESC. See Section "C5".

CHART A-3. @ Check exhaust system for restriction. See

@ CHECK: CHART B- 1.

- Ignition timing. See Emission Control

Information label.