air filter PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 20 of 1825

F CARLINE

ITEM 10

TransmissionRransaxle Service

The manual transmission or transaxle fluid does not

require changing. (Corvette only.) Change fluid in over-

drive unit every 30,000 miles (50 000 km).

For automatic transmissions or transaxles, change

both the fluid and filter every 15,000 miles (25 000 km) if

the car is mainly driven under one or more of these

conditions:

@ In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

@ In hilly or mountainous terrain.

@ Frequent trailer pulling.

@ Uses such as found in taxi, police car or delivery

service.

If you do not use your car under any of these condi-

tions, change both the fluid and filter every 100,000 miles

(160 000 km). See you Owner's Manual for further

details.

ITEM 11

Spark Plug Service*

Replace spark plugs with type listed in your Owner's

Manual.

ITEM 12

Spark Plug Wire Inspection*

Clean wires and inspect for burns, cracks or other dam-

age. Check the wire boot fit at distributor and at spark plugs.

Replace wires as needed.

ITEM 13

Positive Crankcase Ventilation (PCV) Valve

Inspection*

Inspect valve for proper function. Replace valve if

necessary as well as any worn, plugged or collapsed

hoses.

ITEM 14

EGR System Service*

Conduct EGR System Service as referenced in the

EGR System Chart shown in the appropriate 6E Section.

Also, refer to your GM maintenance schedule booklet for

specific applications.

ITEM 15

Air Cleaner and PCV Filter Replacement*

On 1.6 and 2.0 liter engines, replace every 50,000

miles (80 000 km). On all other engines, replace every

30,000 miles (50 000 km). Replace more often under

dusty conditions. Ask your dealer for the proper replace-

ment interval for your driving conditions.

MAINTENANCE AND LUBRICATION 08-3

ITEM 16

Engine Timing Check*

Adjust timing to underhood label specifications. If

no specifications are shown, no adjustment is needed.

ITEM 17

Fuel Tank, Cap and Lines Inspection*

Inspect fuel tank, cap and lines (including fuel rails

and injection assembly, if so equipped) for damage or

leaks. Inspect fuel cap gasket for an even filler neck

imprint or any damage. Replace parts as needed.

ITEM 18

Thermostatically Controlled Air Cleaner

Inspection*

If your car is equipped, inspect all hoses and ducts

for proper hookup. Make sure valve works properly.

OWNER INSPECTIONS AND SERVICES

Listed below are inspections and services which

should be made by either you or a qualified technician at

the intervals shown to help ensure proper safety, emission

performance and dependability of your car. Take any

problems promptly to your dealer or another qualified

technician for service advice. Whenever repairs are neces-

sary, have them completed at once. For your safety and

that of others, any safety-related parts that could have

been damaged in an accident should be inspected and all

needed repairs should be done before operating your car.

Be sure to use the proper fluids and lubricants as shown in

Figure OB-2.

WHILE OPERATING YOUR VEHICLE

Automatic transmissionltransaxle shift indi-

cator operation - Make sure the indicator points to the

gear chosen.

Horn operation - Blow the horn occasionally to

make sure it works. Check all button locations.

I

Brake system operation -- Be alert to abnormal

sounds, increased brake pedal travel or repeated pulling to

one side when braking. Also, if a brake warning light

comes on or flashes, or the anti-lock warning light (if

equipped) comes on or remains on, something may be

wrong with part of the brake system. Have it inspected and

repaired at once.

Exhaust system operation - Be alert to any

changes in the sound of the system or any smell of fumes.

These are signs the system may be leaking or overheating.

.

Have it inspected and repaired at once. Also see "Engine

Exhaust Gas Caution (Carbon Monoxide)" and "Catalytic

Converter" in your Owner's Manual.

*An Emission Control Service

Page 44 of 1825

AIR CONDITIONING 1B-1

SECTION 1B

R COND

When performing air conditioning diagnosis on vehicles equipped with a catalytic converter, it will be necessary to

WARM the engine to a NORMAL operating temperature BEFORE attempting to idle the engine for periods greater

than five

(5) minutes. Once the engine attains normal idle, diagnosis and adjustments can be made.

CONTENTS

.................. General Description .................................. 1B-1 Accumulator Assembly Service .1B-19

.......................... C.C.O.T. A!C System ................................ 1B-1 On-Vehicle Sewice ..... 1B-20

....................................... System Components - Functional ................. 1B-2 Blower Motor .1B-20

..................................... System Components - Control ..................... 1B-3 Hi-Blower Relay 1B-20

...................................... Relays and Switches ................................... 1B-3 Blower Resistor 1B-20

Diagnosis ................................................. 1B-5 Controller, Blower Switch or Vacuum

................................................ Testing the Refrigerant System ...................... 1B-5 Valve .lB-20

Insufficient Cooling "Quick-Check Temperature Control Cable ....................... .1B-20

.................................... Procedure.. ............................................. 1B-5 Vacuum

Harness .lB-20

C.C.O.T. A/C System Diagnostic Control Wiring Harness ........................... .1B-20

..... ................................. Procedure.. ............................................. 1B-8 Heater

Core .. .lB-21

................................ Leak Testing ........................................... 1B-12 Lower Heater Outlet 1B-21

............................... Service Procedures ................................. .1B-12 Heater Module Case .lB-21

.......................... O-Ring Replacement ................................ .1B- 12 Pressure Cycling Switch .1B-21

....................................... Handling Refrigerant- 12 ............................ .1B- 13 Vacuum Tank .lB-21

Discharging, Adding Oil, Evacuating Liquid Line .......................................... .1B-23

and

Charging Procedures - AIC Accumulator ......................................... .1B-23

.................................... Systems .............................................. .1B-14 Evaporator Core .1B-24

In-Line Air Conditioning Evaporator Case .................................... .1B-24

.......................................... Filter

Installation.. .................................. .1B- 18 Compressor .lB-24

.............................................

................ Expansion Tube (Orifice) Service .1 B- 19 Condenser IB-24

GENERAL DESCRIPTION

All engines are equipped with a fixed displace- evaporator temperature. The pressure cycling switch

ment (R-4) air conditioning compressor. This

com- is the freeze protection device in the system and

pressor may cycle on and off under normal air

senses refrigerant pressure on the suction side of the

conditioning demand. system. This switch is located on a standard

Schrader- -

All air conditioning systems that use the fixed

displacement R-4 compressor are referred to as

C. C.O.T. (Cycling Clutch, Orifice Tube) type sys-

tems. This is the same system that has been used on

all General Motors vehicles in the past several years.

The C.C.O.T. NG System

The Cycling Clutch Orifice Tube (C.C.O.T.)

refrigeration system is designed to cycle a compressor

on and off to maintain desired cooling and to prevent

evaporator freeze. Passenger compartment comfort is

maintained by the temperature lever on the controller.

Control of the refrigeration cycle (on and off

operation of the compressor) is done with a switch

which senses low-side pressure as an indicator of type

valve low-side fitting. During air temperatures

over 10°C

(50°F), the equalized pressures within the

charged

A/C system will close the contacts of the

pressure switch. When an air conditioning mode

(max, norm, bi-level, defrost) is selected, electrical

energy is supplied to the compressor clutch coil. AS

the compressor reduces the evaporator pressure

to

approximately 175 kPa (25 psi), the pressure switch

will open, de-energizing the compressor clutch.

As

the system equalizes and the pressure reaches approxl-

mately 315 kPa (46 psi), the pressure switch contacts

close, re-energizing the clutch coil. This cycling

coy

tinues and maintains average evaporator discharge air

temperature at approximately 1°C (33°F). Because of

this cycling, some slight increases and decreases of

engine speedlpower may be noticed under certain con-

ditions. This is normal as the system is designed

to

cycle to maintain desired cooling, thus preventing

evaporator freeze-up.

Page 45 of 1825

18-2 AIR CONDITIONING

SYSTEM GONIPONENE - FFUNCnIONAL

Compressor

All compressors are belt driven from the engine

crankshaft through the compressor clutch pulley. The

compressor pulley rotates without driving the com-

pressor shaft until an electromagnetic clutch coil is

energized. When voltage is applied to energize the

clutch coil, the clutch plate and hub assembly is

drawn rearward toward the pulley. The magnetic

force locks the clutch plate and pulley together as one

unit to drive the compressor shaft.

As the compressor shaft is driven, it compresses

the low-pressure refrigerant vapor from the evaporator

into a high-pressure, high-temperature vapor. Carried

with the refrigerant is the refrigerant oil which is used

to lubricate the compressor. Complete compressor

overhaul procedures can be found in Section

ID of the

General Service Manual.

Pressure Relief Valve

The compressor is equipped with a pressure

relief valve which is placed in the system as a safety

factor. Under certain conditions, the refrigerant on the

discharge side may exceed the designed operating

pressure. To prevent system damage, the valve is

designed to open automatically at approximately

3036

kPa (440 psi). Conditions that might cause this valve

to open (defective high pressure cut-off switch, inop-

erative electric cooling fan, etc.) should be corrected,

and the refrigerant oil and refrigerant should be

replaced as necessary.

A muffler is used on some refrigerant systems to

reduce compressor noises from high or low pressure

vibrations.

Condenser Gore

The condenser assembly in front of the radiator

is made up of coils which carry the refrigerant TO

cooling fins to provide rapid transfer of heat. The air

passing through the condenser cools the high-pressure

refrigerant vapor causing it to condense to a liquid.

Expansion (Orifice) Tube

The plastic expansion tube, with its mesh screen

and orifice, is located in the evaporator inlet pipe at

the liquid line connection. It provides a restriction to

the high-pressure liquid refrigerant in the liquid line,

metering the flow of refrigerant to the evaporator as a

low-pressure liquid. The expansion tube and orifice

are protected from contamination by filter screens on

both inlet and outlet sides. The tube is serviced only

as a replacement assembly.

When the engine is turned "OFF" with the

A/C

system operating, the refrigerant in the system will

flow from the high-pressure side of the expansion tube (orifice) to the low-pressure side until the pressure

is

equalized. This may be detected as a faint sound of

liquid flowing (hissing) for 30 to

60 seconds and is a

normal condition.

Evaporator Gore

The evaporator is a device which cools and

dehumidifies the air before it enters the car. High-

pressure liquid refrigerant flows through the expan-

sion tube (orifice) into the low-pressure area of the

evaporator. The heat in the air passing through the

evaporator core is transferred to the cooler surface of

the core, thereby cooling the air. As the process of

heat transfer from the air to the evaporator core sur-

face is taking place, any moisture (humidity) in the air

condenses on the outside surface of the evaporator

core and is drained off as water.

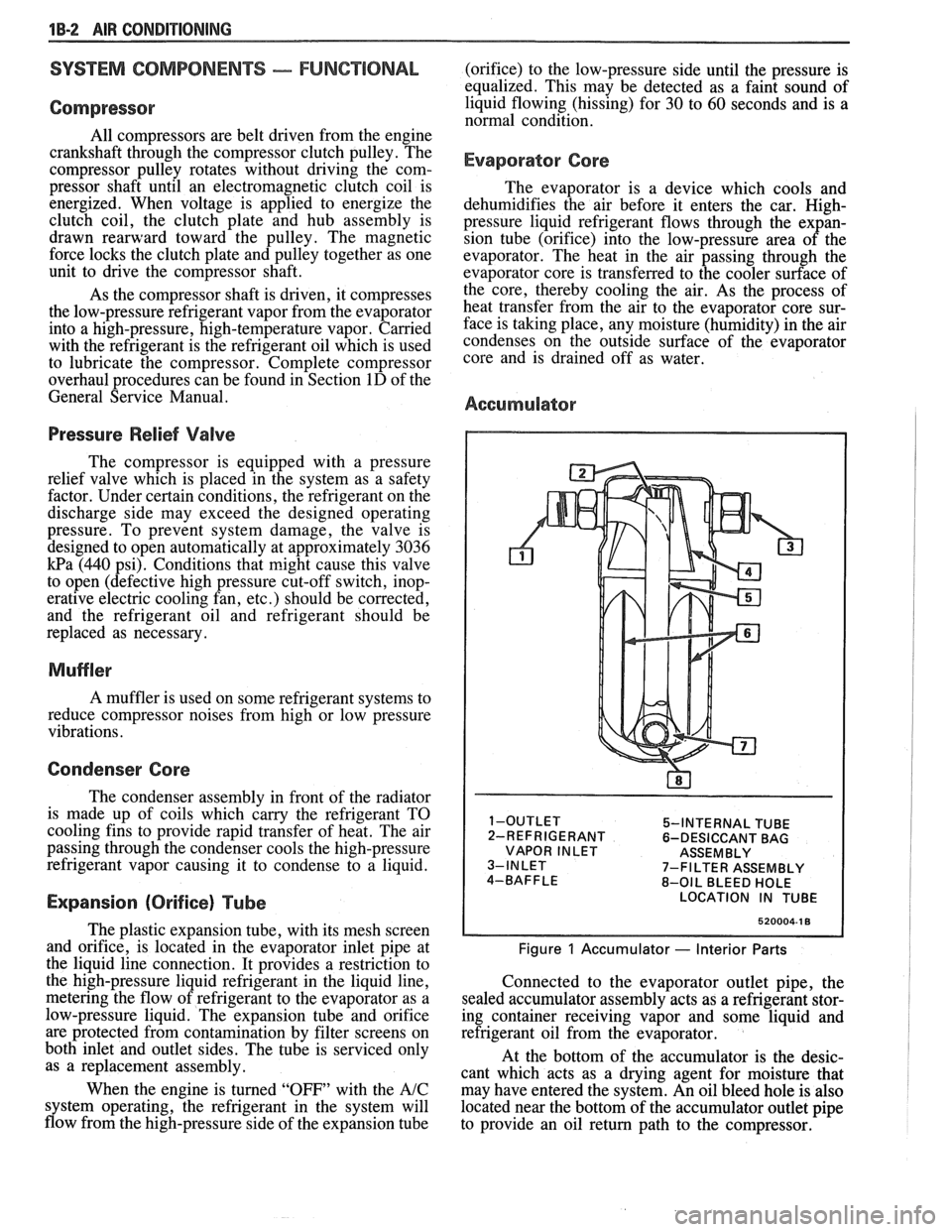

Accumulator

5-INTERNAL TUBE

2-REFRIGERANT 6-DESICCANT BAG

VAPOR INLET ASSEMBLY

7-FILTER ASSEMBLY

8-OIL BLEED HOLE

LOCATION IN TUBE

520004-1 8

Figure 1 Accumulator - Interior Parts

Connected to the evaporator outlet pipe, the

sealed accumulator assembly acts as a refrigerant stor-

ing container receiving vapor and some liquid and

refrigerant oil from the evaporator.

At the bottom of the accumulator is the desic-

cant which acts as a drying agent for moisture that

may have entered the system. An oil bleed hole is also

located near the bottom of the accumulator outlet pipe

to provide an oil return path to the compressor.

Page 294 of 1825

BRAKES

NOTICE: All brake attaching fasteners are important attaching parts in that they could affect the performance of vital parts

and systems.

andlor could result in major repair expense . They must be replaced with one of the same part number or with an

equivalent part if replacement becomes necessary

. Do not use a replacement part of lesser quality or substitute design .

Torque values must be used as specified during reassembly to assure proper retention of parts .

CAUTION: When servicing brake parts. do not create dust by grinding. sanding brake linings. or by cleaning brake

parts with a dry brush or with compressed air

. Many brake parts contain asbestos fibers which can become airborne if

dust is created during servicing

. Breathing dust containing asbestos fibers may cause serious bodily harm . A water

dampened cloth or water based solution should be used to remove any dust on brake parts

. Equipment is commer-

cially available to perform this washing function

. These wet methods will prevent asbestos fibers from becoming

airborne

.

CONTENTS

......................... General Description 5.2

Composite Master Cylinder

.................. 5.2

Brake Fluid Level

lndicatgr ................... 5.2

Operation of Disc Brake

..................... 5.2

Operation of Drum Brake

.................... 5.2

Operation of Combination Valve

............... 5.2

Brake Pressure Differential

.......................... Warning Switch 5.2

Diagnosis and Inspection ..................... 5.3

Brake System Testing

....................... 5.3

External Conditions That Affect Brake Performance

.................... -5-3

Warning Lamp Operation .................... 5.3

Brake Fluid Leaks

.......................... 5.3

Master Cylinder Check

...................... 5.3

Substandard or Contaminated

BrakeFluid ............................. 5-3

............................. On-Car Service 5.7

Brake Pedal Replacement

................... 5.7

Stoplamp Switch Adjustment ................. 5-7

Filling Master Cylinder Reservoirs

............. 5-7

Bleeding Brake Hydraulic System

............. 5.7

Manual Bleeding

......................... 5.8

Pressure Bleeding

........................ 5.8

Flushing Brake Hydraulic System

............. 5.9

Brake Pipe Replacement

.................... 5.9

............................. I.S.O. Flare 5.9

Brake Hose Inspection

...................... 5.9

Brake Hose Replacement

.................... 5.11

Front Brake Hose

........................ 5.11

....................... Center Brake Hose 5.12

..................... Rear Disc Brake Hose 5.12

ParkingBrake ............................. 5-13

Parking Brake Control Assembly

.............. 5.13 Parking Brake Cables

....................... 5.14

Parking Brake Front Cable

................. 5.14

Parking Brake Rear Cable (Drum Brakes)

..... 5.14

Parking Brake Rear Cable (Disc Brakes)

...... 5.15

Brake Lining Inspection

..................... 5.15

............. Inspecting and Refinishing Rotors 5-15

Thickness

Variat~on Check ................. 5.15

Lateral

Runout Check ..................... 5.15

Rotor Tolerance and Surface Finish

.......... 5.16

Refinishing Brake Rotors

.................. 5-16

lnspecting and Refinishing Brake

Drums

................................. 5-16

Cracked Scored, or Grooved Drum

.......... 5.16

Out-of-Round or Tapered Drum

............. 5.16

Refinishing Brake Drums

.................. 5.16

Brake Drum Balance

..................... -5-16

Combination Valve ......................... 5.17

Testing Combination Valve Electrical

............................... Circuit 5.17

Testing Combination Valve Warning

.......................... Lamp Switch 5.17

.......... Combination Valve Replacement 5.17

............ Power Brake Vacuum Hose Filter 5.17

Unit Repair

................ Composite Master Cylinder .5A 3.1

Disc Brake Caliper Assembly

....................... 300013100 Series 581 -1

Disc Brake Caliper Assembly

3548 Series

........................... .5B 6.1

........ Direct Torque Drum Brake Assembly .5C 3.1

Power Head Assembly

-

.................... Tandem Diaphragm .5D 2.1

.............. Specifications and Special Tools 5F-1

Page 299 of 1825

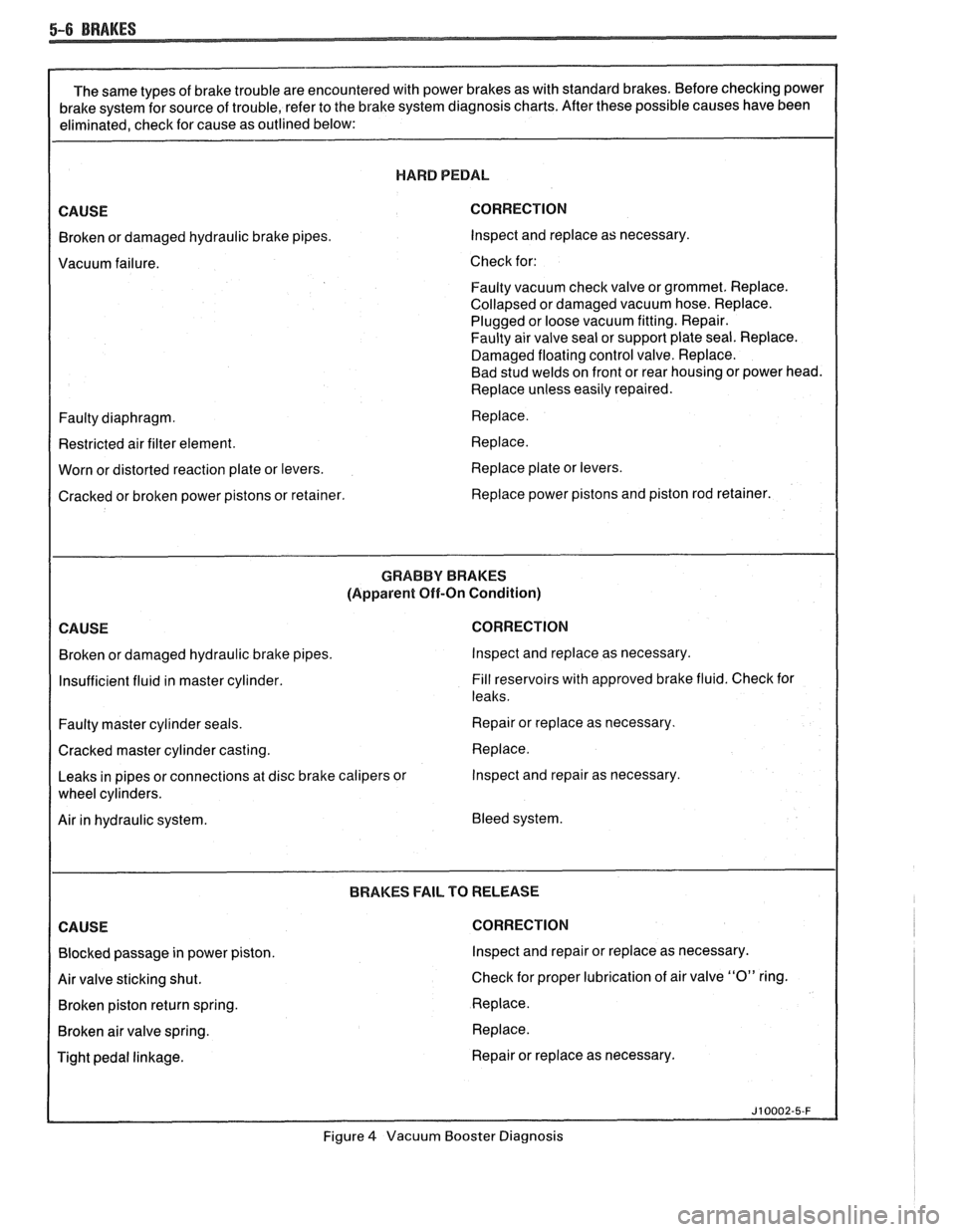

HARD PEDAL

CORRECTION

Broken or damaged hydraulic brake pipes. Inspect and replace

as necessary.

Vacuum failure. Check for:

Faulty vacuum check valve or grommet. Replace.

Collapsed or damaged vacuum hose. Replace.

Plugged or loose vacuum fitting. Repair.

Faulty air valve seal or support plate seal. Replace.

Damaged floating control valve. Replace.

Bad stud welds on front or rear housing or power head.

Replace unless easily repaired.

Faulty diaphragm. Replace.

Restricted air filter element. Replace.

Worn or distorted reaction plate or levers. Replace

plate or levers.

Cracked or broken power pistons or retainer. Replace power pistons and piston

rod retainer.

GRABBV BRAKES

(Apparent Off-On Condition)

CORRECTION

Broken or damaged hydraulic brake pipes. Inspect and replace

as necessary.

Insufficient fluid in master cylinder. Fill

reservoirs with approved brake fluid. Check for

leaks.

Faulty master cylinder seals. Repair or replace

as necessary.

Cracked master cylinder casting. Replace.

Leaks in pipes or connections at disc brake calipers or Inspect and repair

as necessary.

Air in hydraulic system. Bleed system.

BRAKES

FAIL TO RELEASE CORRECTION

Blocked passage in power piston. Inspect and repair or replace

as necessary.

Air valve sticking shut. Check

for proper lubrication of air valve

"0" ring.

Broken piston return spring. Replace.

Broken air valve spring. Replace.

Tight pedal linkage. Repair or replace

as necessary.

Figure

4 Vacuum Booster Diagnosis

Page 310 of 1825

BRAKES 5-17

maintaining proper wheel balance, brake drums should be

checked for balance. Brake drums may be checked for

balance on most off-the-car balancers.

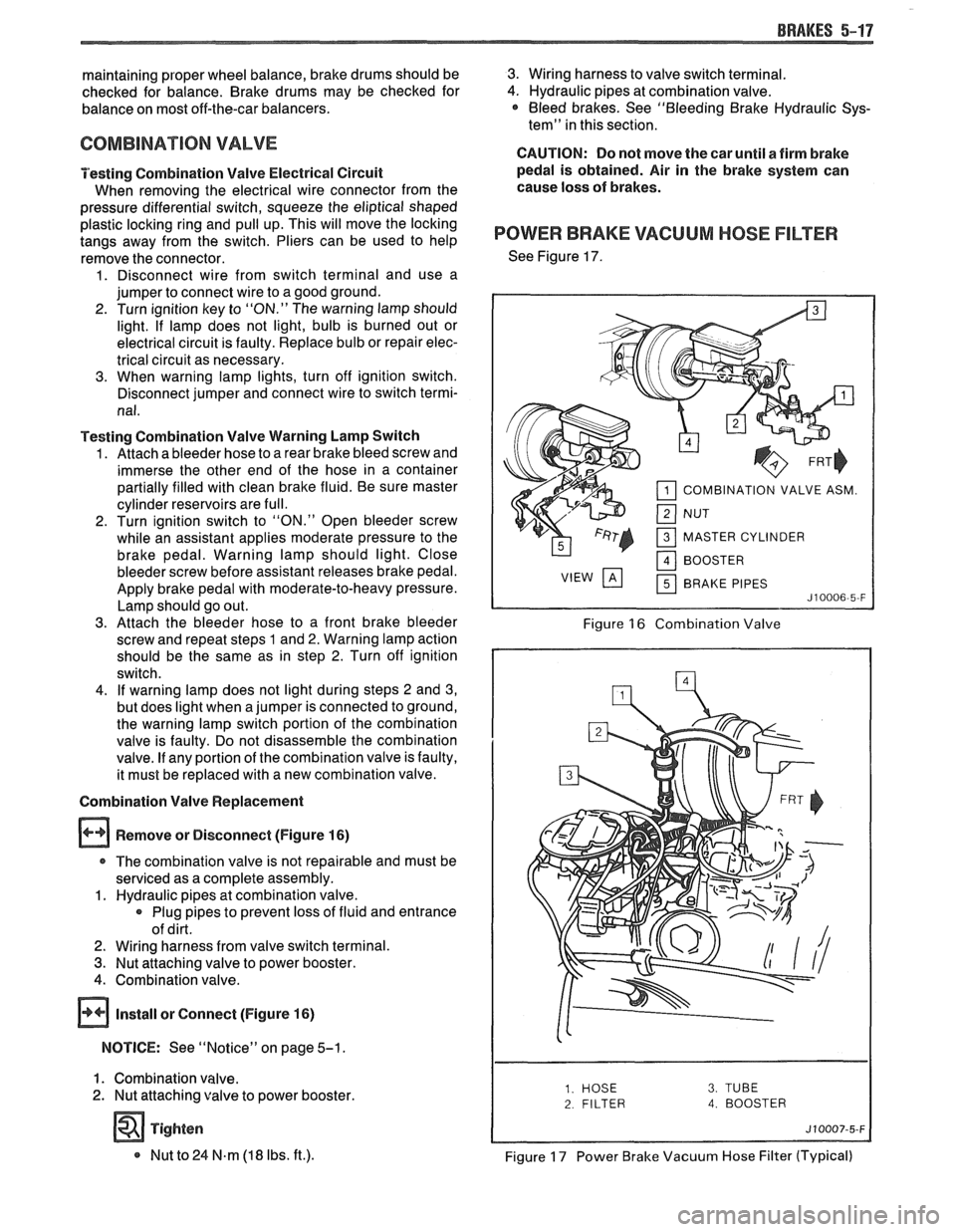

COMBINATION VALVE

Testing Combination Valve Electrical Circuit

When removing the electrical wire connector from the

pressure differential switch, squeeze the

eliptical shaped

plastic locking ring and pull up. This will move the locking

tangs away from the switch. Pliers can be used to help

remove the connector.

1. Disconnect wire from switch terminal and use a

jumper to connect wire to a good ground.

2. Turn ignition key to "ON." The warning lamp should

light. If lamp does not light, bulb is burned out or

electrical circuit is faulty. Replace bulb or repair elec-

trical circuit as necessary.

3. When warning lamp lights, turn off ignition switch.

Disconnect jumper and connect wire to switch termi-

nal.

Testing Combination Valve Warning Lamp Switch

1. Attach a bleeder hose to a rear brake bleed screw and

immerse the other end of the hose in a container

partially filled with clean brake fluid. Be sure master

cylinder reservoirs are full.

2. Turn ignition switch to "ON." Open bleeder screw

while an assistant applies moderate pressure to the

brake pedal. Warning lamp should light. Close

bleeder screw before assistant releases brake pedal.

Apply brake pedal with moderate-to-heavy pressure.

Lamp should go out.

3. Attach the bleeder hose to a front brake bleeder

screw and repeat steps

1 and 2. Warning lamp action

should be the same as in step

2. Turn off ignition

switch.

4. If warning lamp does not light during steps 2 and 3,

but does light when a jumper is connected to ground,

the warning lamp switch portion of the combination

valve is faulty. Do not disassemble the combination

valve.

If any portion of the combination valve is faulty,

it must be replaced with a new combination valve.

Combination Valve Replacement

Remove or Disconnect (Figure

16)

r The combination valve is not repairable and must be

serviced as a complete assembly.

1. Hydraulic pipes at combination valve.

Plug pipes to prevent loss of fluid and entrance

of dirt.

2. Wiring harness from valve switch terminal.

3. Nut attaching valve to power booster.

4. Combination valve.

@ Install or Connect (Figure 16)

NOTICE: See "Notice" on page 5-1.

1. Combination valve.

2. Nut attaching valve to power booster.

Tighten

* Nut to 24 N.m (18 Ibs. ft.).

3. Wiring harness to valve switch terminal.

4. Hydraulic pipes at combination valve. * Bleed brakes. See "Bleeding Brake Hydraulic Sys-

tem" in this section.

CAUTION: Do not move the car until a firm brake

pedal is obtained. Air in the brake system can

cause loss of brakes.

POWER BRAKE VACUUM HOSE FILTER

See Figure 17.

COMBINATION VALVE ASM.

MASTER CYLINDER BRAKE PIPES

Figure 16 Combination Valve

2 FILTER 4. BOOSTER

Figure 17 Power Brake Vacuum Hose Filter (Typical)

Page 336 of 1825

POWER HEAD ASSEMBLY 582-1

SECTION 582

POWER HEAD ASSEMBLY - TANDEM

APHRAGM

CONTENTS

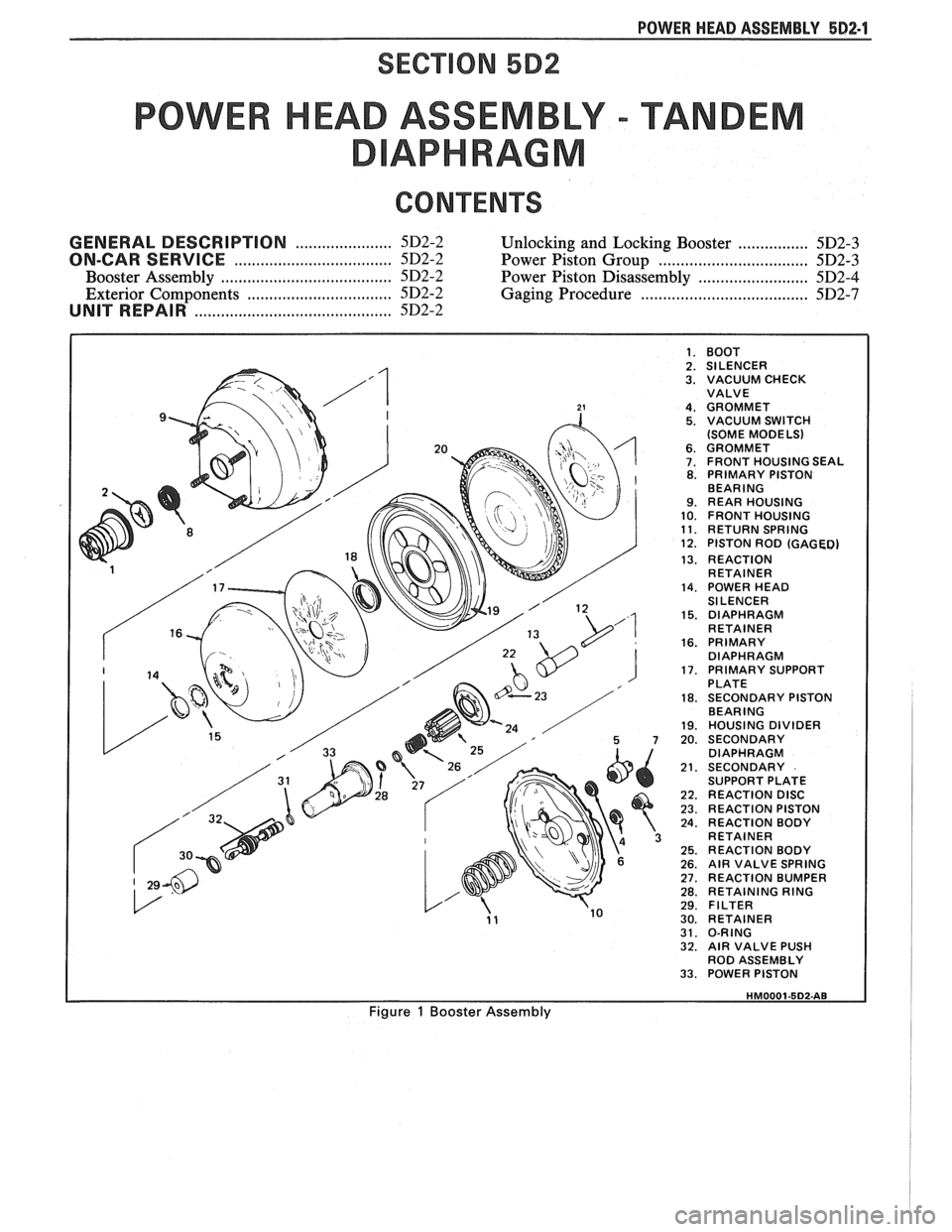

...................... GENERAL DESCRIPTION 5D2-2 Unlocking and Locking Booster ................ 5D2-3

................................. ON-CAR SERVICE 5D2-2 Power Piston Group ................................. 5D2-3

..................................... Booster Assembly 5D2-2 Power Piston Disassembly ......................... 5D2-4

................................. Exterior Components 5D2-2 Gaging Procedure ...................................... 5D2-7

......................................... UNIT REPAIR 5D2-2

I 1. BOOT I 2. SILENCER 3. VACUUM CHECK

VALVE

4. GROMMET 5. VACUUM SWITCH

(SOME MODELS)

6. GROMMET 7. FRONT HOUSING SEAL 8. PRIMARY PISTON

BEARING

9. REAR HOUSING 10. FRONT HOUSING 11. RETURN SPRING 12. PISTON ROD (GAGED)

13. REACTION

RETAINER

14. POWER HEAD

SILENCER

15. DIAPHRAGM

RETAINER

16. PRIMARY

DIAPHRAGM

17. PRIMARY SUPPORT

PLATE

18. SECONDARY PISTON

BEARING

19. HOUSING DIVIDER 20. SECONDARY

DIAPHRAGM

21. SECONDARY

SUPPORT PLATE

22. REACTION DISC 23. REACTION PISTON 24. REACTION BODY

RETAINER

25. REACTION BODY 26. AIR VALVE SPRING 27. REACTION BUMPER 28. RETAINING RING 29. FILTER 30. RETAINER 31. O-RING 32. AIR VALVE PUSH

ROD ASSEMBLY

33. POWER PISTON

Figure 1 Booster Assembly

Page 341 of 1825

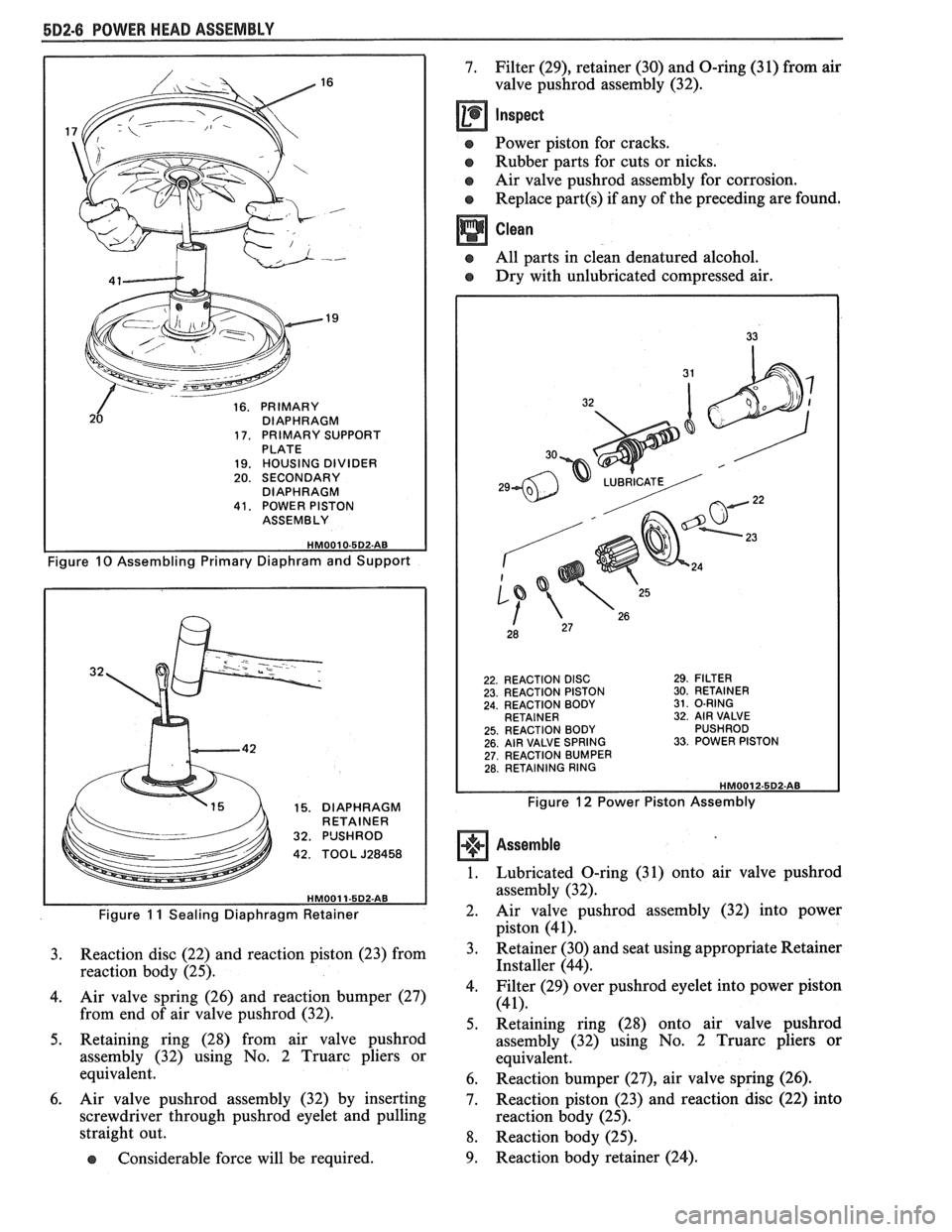

682-6 POWER HEAD ASSEMBLY

16. PRIMARY DIAPHRAGM

17. PRIMARY SUPPORT PLATE 19. HOUSING DIVIDER 20. SECONDARY

DIAPHRAGM

41. POWER PISTON ASSEMBLY

Figure 10 Assembling Primary Diaphram and Support

A, '15 h 15. DIAPHRAGM RETAINER 32. P'JSHROD

42. TOOL J28458

Figure 11 Sealing Diaphragm Retainer

3. Reaction disc (22) and reaction piston (23) from

reaction body

(25).

4.

Air valve spring (26) and reaction bumper (27)

from end of air valve pushrod (32).

5. Retaining ring (28) from air valve pushrod

assembly (32) using No. 2 Truarc pliers or

equivalent.

6. Air valve pushrod assembly (32) by inserting

screwdriver through

pushrod eyelet and pulling

straight out.

e Considerable force will be required.

7. Filter (29), retainer (30) and O-ring (3 1) from air

valve

pushrod assembly (32).

e Power piston for cracks.

e Rubber parts for cuts or nicks.

Air valve

pushrod assembly for corrosion.

Replace

part(s) if any of the preceding are found.

Clean

All parts in clean denatured alcohol.

e ~r~-with unlubricated compressed air.

22. REACTION DISC 29. FILTER 23. REACTION PISTON 30. RETAINER 24. REACTION BODY 31. O-RING RETAINER 32. AIR VALVE 25. REACTION BODY PUSHROD 26. AIR VALVE SPRING 33. POWER PISTON 27. REACTION BUMPER 28. RETAINING RING

HMO01 2.5D2-A6

Figure 12 Power Piston Assembly

Assemble

Lubricated O-ring (31) onto air valve pushrod

assembly (32).

Air valve pushrod assembly (32) into power

piston

(41).

Retainer (30) and seat using appropriate Retainer

Installer

(44).

Filter (29) over pushrod eyelet into power piston

(41).

Retaining ring (28) onto air valve pushrod

assembly (32) using No. 2 Truarc pliers or

equivalent.

Reaction bumper

(27), air valve spring (26).

Reaction piston (23) and reaction disc (22) into

reaction body

(25).

Reaction body (25).

Reaction body retainer (24).

Page 348 of 1825

ENGINE GENERAL INFORMATION 6-3

B, Section 6E2 - Fuel Injection (TBI)

B, Section 6E3 - Fuel Injection (Ported)

ENGINE MECHANICAL DIAGNOSIS

The following diagnostic information covers common problems and possible causes. When

the proper diagnosis is made, the problem should be corrected by adjustment, repair or part

replacement as required. Refer to the appropriate section of the manual for these procedures.

EXCESSIVE OIL LOSS

B, External oil leaks. Tighten bolts and/or replace o Continuous high speed driving, and/or severe

gaskets and seals as necessary. usage

such as trailer hauling, will normally cause

decreased oil mileage.

e Improper reading of dipstick. Check oil with car PCV system malfunctioning. on a level surface and allow adequate drain-down Valve guides and/or valve stem seals worn, or time.

seals omitted. Ream guides and install oversize

service valves and/or new valve stem seals.

Improper Use S.A'E' Piston rings broken, worn, or not seateded. Allow viscosity for prevailing temperatures. See

adequate time for rings to seat. Replace broken

Owner's Manual for proper specifications.

or worn rings, as necessary.

Piston improperly installed or misfitted.

LOW OIL PRESSURE

Slow idle speed. Set idle speed to correct

specification, if not ECM controlled.

Incorrect, or malfunctioning, oil pressure switch.

Incorrect, or malfunctioning, oil pressure gage.

Replace with proper gage.

.*

Improper oil viscosity, or diluted oil. install oil of

proper viscosity for expected temperature, or

install new oil if diluted with moisture or

unburned fuel mixtures.

o Oil pump worn or dirty.

e Plugged oil filter.

e Oil pickup screen loose or plugged.

B, Hole in oil pickup tube.

e Excessive bearing clearance. Replace if necessary.

o Cracked, porous or plugged oil galleys. Repair or

replace block.

o Galley plugs missing or misinstalled. Install

plugs, or repair as necessary.

VALVE TRAIN NOISE

e Low oil pressure. Repair as necessary. (See o Broken valve spring.

preceding diagnosis for low oil pressure.)

o Sticking valves.

o Loose rocker arm attachments. Inspect and B, Lifters worn, dirty, or defective. Clean, inspect,

test and replace as necessary.

repair as necessary.

o Camshaft worn, or poor machining. Replace

o Worn rocker arm and/or pushrod. camshaft.

B, Worn valve guides.

ENGINE KNOCK DIAGNOSIS

KNOCKS COLD AND CONTINUES FOR TWO TO THREE MINUTES

INCREASES

WITH TORQUE

o Vacuum operated EFE engines may have valve o Excessive piston to bore clearance. Replace

knock. Replace EFE valve. piston.

e Flywheel contacting splash shield. Reposition

splash shield.

e Loose or broken balancer or drive pulleys.

Tighten, or replace as necessary. Cold engine piston knock usually

disappears when the cylinder is grounded

out. Cold engine piston knock which

disappears in 1.5 minutes should be

considered acceptable.