battery PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 2 of 1825

1988

SER

This manual applies to the 1988 Pontiac Firebird Models.

It contains the latest product information available at the

time of publication approval. lnformation pertaining to

the operation of the vehicle is contained in the Owner's

Manual which accompanies each vehicle. The right is

reserved to make changes at any time without notice.

Any references to brand names in this manual is intended

merely as an example of the types of

lubricant% tools,

materials, etc, recommended for use in servicing 1988

Pontiac Models. In all cases, an equivalent may be used.

PONTIAC DIVISION

GENERAL

MOTORS CORPORATION

PONTIAC, MICHIGAN 48053

1987 General Motors Corp. All Rights Reserved.

No part of this publication may be reproduced, stored in any

retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical,

photocopying, recording or otherwise, without the prior written

permission of General Motors Corp. This includes all text,

illustrations, tables and charts.

S-881 OF 9-87 Printed in Canada

TABLE OF CONTENTS

SECTION NAME

GENERAL INFORMATION

OA. General lnformation

OB. Maintenance & Lubrication

1 SECT.

HEATING AND AIR CONDITIONING

1A. Heating and Ventilation

1 B. Air Conditioning

1D1. R-4 AIC Com~ressor Overhaul

FRAME AND BUMPERS

2B. Bumpers 2C. Chassis Sheet Metal

STEERING, SUSPENSION, WHEELS

AND TIRES

3. Diagnosis

3A. Wheel Alignment

3B5. Steering Wheels and Columns 3B6. Steering Linkage 3B7. Power Steering Gear and Pump

3C. Front Suspension

3D. Rear Suspension

3E. Tires and Wheels

FINAL DRIVE

4A. Propeller Shaft

4B. Rear Axle

4B1. Bora-Warner Axle

BRAKES 5. Brakes 5A3. Comoosite Master Cvlinder 5B1. Disc r rake Caliper ~ssembly - 300013100 Series 5B6. Disc Brake Caliper Assembly - 3548

Series

5C3. Direct Torque Drum Brake Assembly 5D2. Power Head Assembly - Tandem Diaohraam 5F. ~~ecifications and Special Tools

ENGINE 6. Engine General lnformation 6A2. 2.8L 6A3. 5.OL & 5.7L 6B. Engine Cooling

6C. En~ine Fuel

6D. ~ngine Electrical 6D1. Battery 6D2. Cranking System 6D3. Charging System 6D4. Ignition System 6D5. Engine Wiring

6E. Driveabilitv and Emissions

6E2. ~missions' 6E3. Emissions - PFI

6F. Engine Exhaust

TRANSMISSION 7A. Automatic Transmission - General

lnformation

7A1. Automatic Transmission - On-Car

Service

700R4. Automatic Transmission Hydraulic Diagnosis

700R4. Automatic Transmission Unit Repair

76. 5-Speed Manual Transmission

7C. Clutch

CHASSIS ELECTRICAL 8A. Electrical Diagnosis

8B. Lighting and Horns

8C. Instrument

Panel, Gages

& Console

8E. Windshield Wiper &Washer System

ACCESSORIES 9A. Radio Systems and Antennas 9B. Cruise Control 9G. Miscellaneous Accessories

I BODY SERVICE MANUAL END

OF

MANUAL

Page 36 of 1825

HEATING AND VENTILATION 1.4-1 3

ON-VEHICLE SERVICE

HEATER ELECTRICAL WIRING

The heater wiring diagrams are shown in

Electrical Diagnosis, Section

8A, and should be

referred to for diagnosis of electrical problems in the

heater system.

HEATER CONTROL ASSEMBLY AND BLOWER

SWITCH

Remove or Disconnect

1. Negative battery cable.

2.

Control/radio console trim plate.

3. Three

(3) controller retaining screws and pull

controller out from console.

4. Control cables and electrical connections.

5. Blower switch from controller if either switch or

controller requires replacement. If controller is

being replaced, transfer blower switch to new

controller.

Install or Connect

1. When installing controller, install lower right

screw first to properly align controller in console.

2. Blower switch to controller.

3. Control cables and electrical connections.

4. Three (3) controller retaining screws and

controller to console.

5. Control/radio console trim plate.

6. Negative battery cable.

TEMPERATURE CONTROL, POWER VENT,

HEATER DEFROST CABLE

Remove or Disconnect

1. Hush panel(s) (see Section 8C):

a. Temperature

cable - R.H. hush panel.

b.

Heateddefrost cable - R.H. hush panel.

c. Vent

cable

- L.H. hush panel.

2.

Control/radio console trim plate.

3. Three (3) controller retaining screws and pull

controller out from console.

4. Control cable requiring replacement at control

end.

5. Cable at mode control end (temperature cable:

remove cable link cover at crank location).

Install or Connect

1. When installing controller, install right lower

screw first to align control in console.

2. Cable

at mode control end (temperature cable:

install cable link cover at crank location).

3. Control cable at control end.

4. Three (3) controller retaining screws and

contoller in console.

5. Control/radio console trim plate.

6. Hush panel(s) (see Section 8C).

7. Fully cycle controls to adjust cables and check for

proper operation.

HEATER CORE

Remove or Disconnect

Battery ground cable.

Drain cooling system.

Heater inlet and outlet hoses from heater core.

Right lower hush panel (see Section

8C).

ECM attaching screw and move aside.

Right lower I.P. trim panel (see Section

8C).

Lower right I.P. carrier-to-cowl screw.

Four (4) heater case cover screws. Upper left screw

may be reached with a long socket extension through

the I.P. openings exposed by removal of the lower

right I.P. trim panel. Carefully lift the lower right

corner of the I.P. to align socket extension.

Heater case cover.

Core support plate and baffle screws.

Heater core, support plate and baffle from case.

Install or Connect

1. Heater core, support plate and baffle to case.

2. Core support

plate and baffle screws.

3. Heater case cover.

4. Four (4) heater case cover screws.

5. Lower right I.P. carrier-to-cowl screw.

6. Right lower I.P. trim panel (see Section 8C).

7. ECM.

8. Right lower hush panel (see Section

8C).

9. Heater inlet and outlet hoses to heater core.

10. Refill cooling system and check for leaks.

11. Battery ground cable.

VENT CONTROL CABLE (RAM VENT)

Remove or Disconnect 1

1. Hush panel(s) (see Section 8C). R.H. cable

replacement will require removal of both L.H.

and R.H. hush panels.

2. Two

(2) retaining screws and individual vent

control.

3. Unclip

cable control clamp at vent duct and

disengage formed end of cable from door lever.

1 Install or Connect

1. Cable control clamp at vent duct and install

formed end of cable on door lever.

2, Two (2) retaining screws and individual vent

control.

3. Hush

panel@) (see Section 8C).

4. Cycle

control fully and check for proper

operation.

HEATER CONTROL WIRING I

Remove or Disconnect

1. Negative battery cable.

Page 37 of 1825

1A-14 HEATING AND VENTILATION

2. Control/radio console trim plate and hush

panels.

3. Three (3) screws holding controller in console

and pull controller out far enough to disconnect

electrical connectors.

4. Blower motor and blower resistor electrical

connections.

5. Carefully pull cowl grommet from cowl and pull

wiring harness through cowl hole into engine

compartment.

Install or Connect

1. When reinstalling controller, install lower right

screw first to align controller.

2. Cowl grommet on cowl and wiring harness.

3. Blower motor and blower resistor electrical

connections.

4. Three (3) screws holding controller in console

and connect electrical connectors.

5. Control/radio console trim plate and hush

panels.

6. Negative battery cable.

HEATER/VENTILATION/DEFROSTER DUCTS

See section 8C for removal.

LOWER (FLOOR) HEATER OUTLET

Remove or Disconnect

1. Console (see Section 8C).

2. L.H. and R.H. hush panels. (see Section 8C).

3. Two (2) floor outlet retaining screws.

4. Floor outlet from core case.

Install or Connect

1. Floor outlet to core case.

2. Two (2) floor outlet retaining screws.

3. L.H. and R.H. hush panels.

4. Console.

BLOWER MOTOR

Remove or Disconnect

1. Negative battery cable.

2. Electrical connections at blower motor and

blower resistor.

3. Blower motor cooling tube.

4. Blower motor retaining screws and remove

motor/cage assembly from case.

5. Holding blower motor cage, remove cage

retaining screw and slide cage from motor shaft.

Install or Connect

1. Blower motor cage and retaining screw.

2. Blower

motor retaining screws and

motor/cage

assembly in case.

3. Blower motor cooling tube.

4. Electrical connections at blower motor and

blower resistor.

5. Negative battery cable.

6. Reinstall radio capacitor in proper location, if so

equipped.

Page 55 of 1825

18-12 AIR CONDITIONING

ELEGTRICAWACUUM SYSTEM

DIAGNOSIS

When diagnosing problems in the electrical sys-

tems of the air conditioning system, consult section

8A.

LEAK TESTING THE REFRIGERANT

SYSTEM

Whenever a refrigerant leak is suspected in the

system or a service operation performed which results

in disturbing lines or connections, it is advisable to

test for leaks.

Liquid Leak Detectors

There are a number of locations (fittings,

valves, etc.) on the air conditioning system where a

liquid leak detector solution may be used to pinpoint

refrigerant leaks.

By applying test solution to the area in question

with the swab that is attached to the bottle cap, bub-

bles will form within seconds if there is a leak.

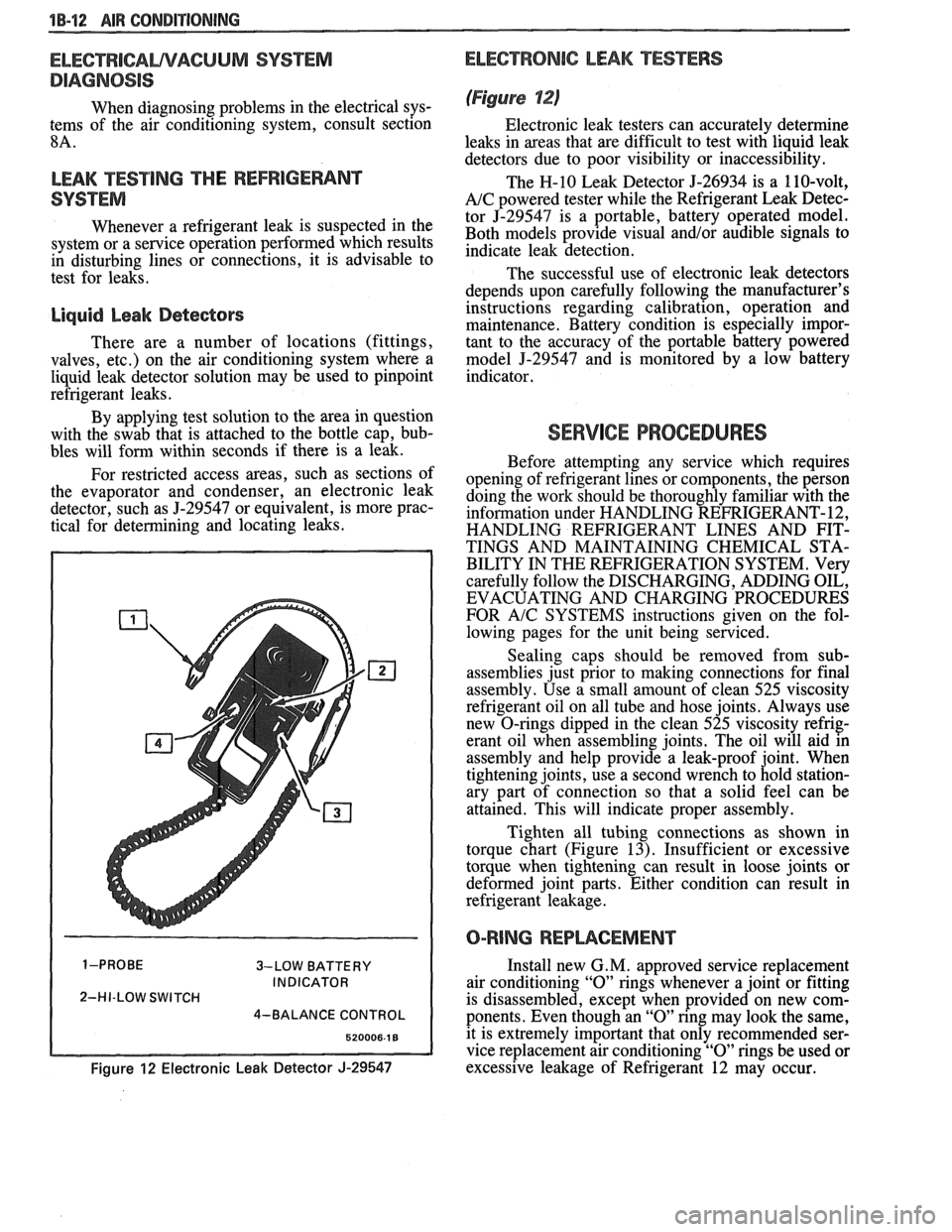

For restricted access areas, such as sections of

the evaporator and condenser, an electronic leak

detector, such as

5-29547 or equivalent, is more prac-

tical for determining and locating leaks.

3-LOW BATTERY

INDICATOR

2-HI-LOW SWITCH

4-BALANCE CONTROL

Figure 12 Electronic Leak Detector J-29547

ELECTRONIC LEAK TESTERS

(Figure 12)

Electronic leak testers can accurately determine

leaks in areas that are difficult to test with liquid leak

detectors due to poor visibility or inaccessibility.

The H-10 Leak Detector 5-26934 is a 110-volt,

A/C powered tester while the Refrigerant Leak Detec-

tor J-29547 is a portable, battery operated model.

Both models provide visual

and/or audible signals to

indicate leak detection.

The successful use of electronic leak detectors

depends upon carefully following the manufacturer's

instructions regarding calibration, operation and

maintenance. Battery condition is especially impor-

tant to the accuracy of the portable battery powered

model

5-29547 and is monitored by a low battery

indicator.

SERVICE PROCEDURES

Before attempting any service which requires

opening of refrigerant lines or components, the person

doing the work should be thoroughly familiar with the

information under HANDLING REFRIGERANT- 12,

HANDLING REFRIGERANT LINES AND FIT-

TINGS AND MAINTAINING CHEMICAL STA-

BILITY IN THE REFRIGERATION SYSTEM. Very

carefully follow the DISCHARGING, ADDING OIL,

EVACUATING AND CHARGING PROCEDURES

FOR

A/C SYSTEMS instructions given on the fol-

lowing pages for the unit being serviced.

Sealing caps should be removed from sub-

assemblies just prior to making connections for final

assembly. Use a small amount of clean 525 viscosity

refrigerant oil on all tube and hose joints. Always use

new O-rings dipped in the clean 525 viscosity refrig-

erant oil when assembling joints. The oil will aid in

assembly and help provide a leak-proof joint. When

tightening joints, use a second wrench to hold station-

ary part of connection so that

a solid feel can be

attained. This will indicate proper assembly.

Tighten all tubing connections as shown in

torque chart (Figure

13). Insufficient or excessive

torque when tightening can result in loose joints or

deformed joint parts. Either condition can result in

refrigerant leakage.

O-RING REPWCEMENT

Install new G. M. approved service replacement

air conditioning

"0" rings whenever a joint or fitting

is disassembled, except when provided on new com-

ponents. Even though an

"0" ring may look the same,

it is extremely important that only recommended ser-

vice replacement air conditioning

"0" rings be used or

excessive leakage of Refrigerant 12 may occur.

Page 63 of 1825

18-28 AIR CONDITIONING

DO NOT REPLACE the accumulator assembly

when:

1. Merely a dent is found in the outer shell of the

accumulator.

2. A

vehicle is involved in a collision and no phys-

ical perforation to the accumulator is found.

OM-VEHICLE SERVICE

R-"1 CHARGING CAPACITIES

The 420ml (14 fl. oz.) disposable can of R-12

refrigerant is equivalent to .399 kg (. 88 lb.).

BLOWER MOTOR

a Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove motor cooling tube.

3. Disconnect electrical connections.

4. Remove blower motor attaching screws, remove

motor and case assembly.

5. Loosen retaining nut and remove blower cage

from motor shaft.

6. Inspect blower cage for broken vanes, etc.

Replace if necessary.

Install or Connect

1. Reverse removal procedure to reinstall. Replace

seals or sealant as required.

HI-BLOWER RELAY

Relay is a plug-in type with connector mounted

on top of the evaporator case.

BLOWER RESISTOR

Remove or Disconnect

1. Disconnect negative battery cable.

2. Disconnect electrical connections.

3. Remove two (2) screws, remove resistor.

Install or Connect

1. Reverse removal procedure to reinstall.

CONTROLLER, BLOWER SWITCH OR

WCUUM VALVE

Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove NC control-radio console trim plate.

3. Remove three (3) NC control retaining screws.

4. Pull A/C control out and disconnect electrical

and vacuum connections and remove tempera-

ture cable.

5. Remove A/C control and replace vacuum valve

or blower switch as required.

Install or Connect

1. Reverse removal procedure to reinstall. Install

lower right screw in controller first to align con-

troller in console.

TEMPERATURE CONTROL CABLE,

VACUUM HARNESS

Remove or Disconnect

1. Remove the following hush panel(s):

a. Vacuum Harness - R.H. and L.H. hush

panel.

b. Temperature Cable

- R.H. hush panels.

Remove

controller/radio console trim plate.

Remove three (3) controller screws and pull

controller partially out of console.

Disconnect controller

end(s) of temperature

cable

andlor vacuum harness.

Disconnect component

end(s) of temperature

cable

andlor vacuum harness.

Install or Conned

1. Reverse removal procedure to reinstall. When

installing controller, install lower right screw

first to align controller location. Replace any

retaining straps, etc. removed.

2. Perform functional check of controller.

CONTROL WlRlNG HARNESS

a Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove

control/radio console trim plate and

hush panels (see Section

8C).

3. Remove three (3) screws holding control in con-

sole and pull control out far enough to discon-

nect electrical and vacuum connector. Remove

controller.

4. Remove instrument panel carrier (see Section

8C).

5. Remove heater case covers (core and mode door

sides).

6. Remove two (2) interior screws and one (1)

exterior nut holding case to cowl. Pull left side

of case back to gain access to harness at cowl.

Case will still be retained by one (I) screw

behind the evaporator core

- do not attempt

complete removal of case. -

7. Loosen cowl grommet and disconnect purple

vacuum line.

Page 64 of 1825

AIR CONDITIONING 18-21

8. Disconnect blower motor

and blower resistor

electrical connection.

9. Remove hi-blower relay connector from evapo-

rator case.

10. Carefully pull

cowl grommet from cowl and pull

wiring

hmess into engine compartment.

Install or Connect

1. Reverse removal procedure to

reinstall. When

reinstalling controller, install lower right screw

first to align controller.

ACNENTILATIONIDEFROSVER DUCTS

See section 8C for removal.

HEATER CORE

Remove or Disconnect

1. Negative battery cable.

2. Drain cooling system.

3. Remove heater inlet and outlet hoses

from

heater core.

4. Remove right lower hush panel (see Section

8C).

5. Remove right

lower I.P. trim panel (see Section

8C) .

6. Remove lower right I.P. carrier to cowl screw.

7. Remove ECM attaching screws and move to the

side.

8. Remove four

(4) heater case cover screws.

Upper left screw may be reached with a long

318 ' socket extension through the I.P. openings

exposed by removal of the lower right I.P. trim

panel. Carefully lift the lower right corner of the

I.P. to align socket extension.

9. Remove heater case cover.

10. Remove core support plate

and baffle screws.

- -

11. Remove

heater core, support plate and baffle

from case.

Install or Conned

1. Reverse removal procedure to reinstall. Restore

all seals

and/or sealant disturbed during removal

procedure.

2. Refill cooling system and check for leaks.

LOWER (FLOOR) )-IEA"FEB$OU"fET

Remove or Disconnect

1. Console. (See Section 8C.)

2. L.H. and R.H. hush panels.

3. Two (2) floor outlet retaining screws.

4. Floor outlet from core case.

lnstall or Connect

1. Floor outlet to core case.

2. Two (2) floor outlet retaining screws.

3. L.H. and R.H. hush panels.

4. Console.

HEATER MODULE (CASE)

Remove or Disconnect

1. Disconnect negative battery cable.

2. Drain cooling system.

3. Remove hush panels and instrument panel car-

rier (see Section

8C).

4. Remove lower heater outlets.

5. Disconnect control cables and vacuum hoses at

module and controller.

6. Remove heater core.

7. Remove two (2) interior screws and one (I)

exterior nut holding case to cowl.

8. Remove evaporator core.

9. Remove screw holding case to cowl from engine

compartment side.

10. Remove case (module).

11. Transfer usable parts to new case (module).

lnstall or Conned

1. Reverse removal procedure to reinstall.

2. Refill coolant system.

3. Recharge

A/C system.

4. Inspect A/C and cooling system for leaks.

NC PRESSURE CYCLING SWITCH

Do not discharge A/C system. Pressure cycling

switch is mounted on

a Schrader-type valve.

Remove or Disconnect

1. Disconnect switch electrical connection.

2. Remove switch.

Install or Connect

1. Reverse removal procedure to reinstall. Tighten

switch to

4-5.5 N*m (35-49 in. lb.).

Ale CONTROL VACUUM TANK

Remove or Disconnect

1 . Disconnect vacuum hoses.

2. Remove vacuum

tank attaching screws, remove

tank.

lndall or Connect

1. Reverse removal procedure to

reinstall.

Page 115 of 1825

26-8 CHASSIS SWEET METAL

3. Remove headlight bezel.

4. If necessary, move battery rearward to gain

access to rear screw.

5. Lower headlights.

6. Loosen two body screws and adjust headlight

body.

7. If a satisfactory appearance is still not obtained,

remove lower air deflector to gain access to

number 1 and number 2 screws.

8. Loosen two body screws and adjust headlight

body.

9. Repeat procedure, if necessary, to obtain a satis-

factory appearance.

10. Re-position battery and tighten hold-down

screw to specifications.

11. Install lower air deflector.

12. Install headlight bezel.

TO SET FRONT TO REAR

GAP between

headlight door and hood, proceed as follows:

1. Open hood.

2. Raise headlights.

3. Remove headlight bezel.

4. Lower headlights.

5. Loosen two body assembly screws and adjust

headlight body assembly.

6. If a satisfactory appearance is still not obtained,

remove lower air deflector to gain access to two

lower screws.

7. Loosen two lower screws and adjust headlight

body assembly.

8. Repeat procedure, if necessary.

9. Install lower air deflector.

10. Install headlight bezel.

TO SET SIDE-TO-SIDE GAP between head-

light door and hood and headlight door and fender,

proceed as follows:

Open hood.

Raise headlights. Remove headlight bezel.

If necessary, move battery rearward to gain

access to rear screw.

Lower headlights.

Loosen three body screws and adjust headlight

body.

If a satisfactory appearance is still not obtained,

remove lower air deflector to gain access to two

lower screws.

Loosen two lower screws and adjust headlight

body.

Repeat procedure, if necessary.

Re-position battery and tighten hold-down

screw to specifications.

Install lower air deflector.

Install headlight bezel. TO

SET CONTOUR of headlight door to hood,

proceed as follows:

1. Open hood.

2. Raise headlights.

3. Remove headlight bezel.

4. Lower headlights.

5. Loosen two (2) screws and adjust headlight

body assembly.

6. If a satisfactory appearance is still not obtained,

remove lower air deflector to gain access to two

lower screws.

7. Loosen two lower screws and adjust headlight

body assembly.

8. Repeat procedure, if necessary.

9. Install lower air deflector.

10. Install headlight bezel.

HEADLIGHT BODY ASSEMBLY

Remove or Disconnect

1. Rear headlight door attaching screws.

2. Raise headlight doors.

3. Headlight bezel attaching screws.

4. Front headlight door attaching screws and

remove headlight door.

5. Electrical connection at bulb.

6. Lower air deflector (one side only).

7. Headlight body assembly attaching screws and

disconnect electrical connection at actuator

connector.

8. Link.

9. Actuator crank arm.

10. Actuator retaining screws and remove actuator.

11. Unhook headlight capsule lower retaining

spring and remove headlight capsule assembly.

12. Headlight body assembly attaching brackets and

fasteners.

Install or Connect

1. Headlight body assembly attaching brackets and

fasteners.

2. Headlight capsule lower retaining spring and

install headlight capsule

3. Acuator retaining screws and install actuator.

4. Actuator crank arm.

5. Link.

6. Headlight body assembly attaching screws and

connect electrical connection at actuator

connector.

7. Lower air deflector (one side only).

8. Electrical connection at bulb.

9. Front headlight door attaching screws and install

headlight door.

Page 116 of 1825

10. Headlight bezel attaching screws.

11. Lower headlight doors.

12. Rear headlight door attaching screws.

ACTUATOR

Remove or Disconnect

1. Battery.

2. Raise headlight door manually.

3. Headlight bezel attaching screws.

4. Pry off link assembly.

5. Actuator crank arm attaching screw. Support the

crank

arm during removal so as not to damage

the actuator.

6. Actuator electrical connector.

7. Actuator attaching screws and remove actuator.

Install or Connect

1, Actuator attaching screws and install actuator.

2, Actuator electrical connector.

3. Actuator crank arm attaching screw.

4. Link assembly.

5. Headlight bezel attaching screws.

6. Battery.

HOOD HINGE

Hood hinges are fastened to the fender panel.

Two gas struts are used (one at each hinge); both ends

of which are fastened to the front portion of the hinge

assembly. This construction provides hold-open

power. Several struts are used depending upon hood

material and configuration. Make certain both struts

have the same color coding if the struts are to be

replaced.

FENDER PANEL

An outer fender panel with a plastic inner panel

is used. Care should be used in handling raw fenders

due to the lack of fender rigidity prior to installation.

See the illustrated service procedures for installation.

Remove or Disconnect

1. Raise car part way on hoist.

2. Lower air deflector attaching screws and push-

in retainer to wheelhouse and remove both sides

of air deflector.

3. Fascia to fender attaching nuts.

4. Wheelhouse to fender inner panel attaching

screws.

5. Lower fender brace attaching screws.

6. Lower rear fender attaching screw.

7. Hood hinge to fender attaching screws and prop

hood open.

-

8. The upper fender attaching screws.

CHASSIS SHEET METAL 2C-9

9. Antenna escutcheon from fender.

10. Side marker lamp electrical connection and

remove the fender from the vehicle.

11. Strip the fender of the side marker lamp, fender

wheelhouse, fasteners and moldings.

install or Conned

To install, reverse removal procedure.

FRONT END PANEL

Remove or Disconnect

1. Raise car part way on hoist.

2. Lower air deflector attaching screws and push-

in retainer to wheelhouse and remove both sides

of air deflector.

3. Fascia to fender attaching nuts.

4. Fascia to reinforcement push-in retainers.

5. Lower car.

6. Parking lamp attaching screws.

7. Upper reinforcement attaching screws and

remove front end panel.

8. Left and right grilles.

9. Front end panel reinforcement attaching screws

and fasteners from fascia.

Install or Conned

To install, reverse removal procedure.

FIREBIRD AERO ACCESSORIES

BOOR LOWER AIR

DEFLECmR

Remove or Disconnect

1. All door trim pad hardware.

2. Loosen bottom and sides of door trim pad. Do

not remove pad.

3. Gently lift bottom of door trim pad to gain

access to nuts.

4. Three nuts (Acl) from inside door panel.

5. Two external nuts (#2) from door panel.

6. Deflector.

NOTICE: If studs that are attached to the deflec-

tor come out with the nut, they can be reinstalled

in the deflector. Remove nut from stud and rein-

stall stud in deflector.

Install or Conned

To install, reverse removal procedure.

Page 160 of 1825

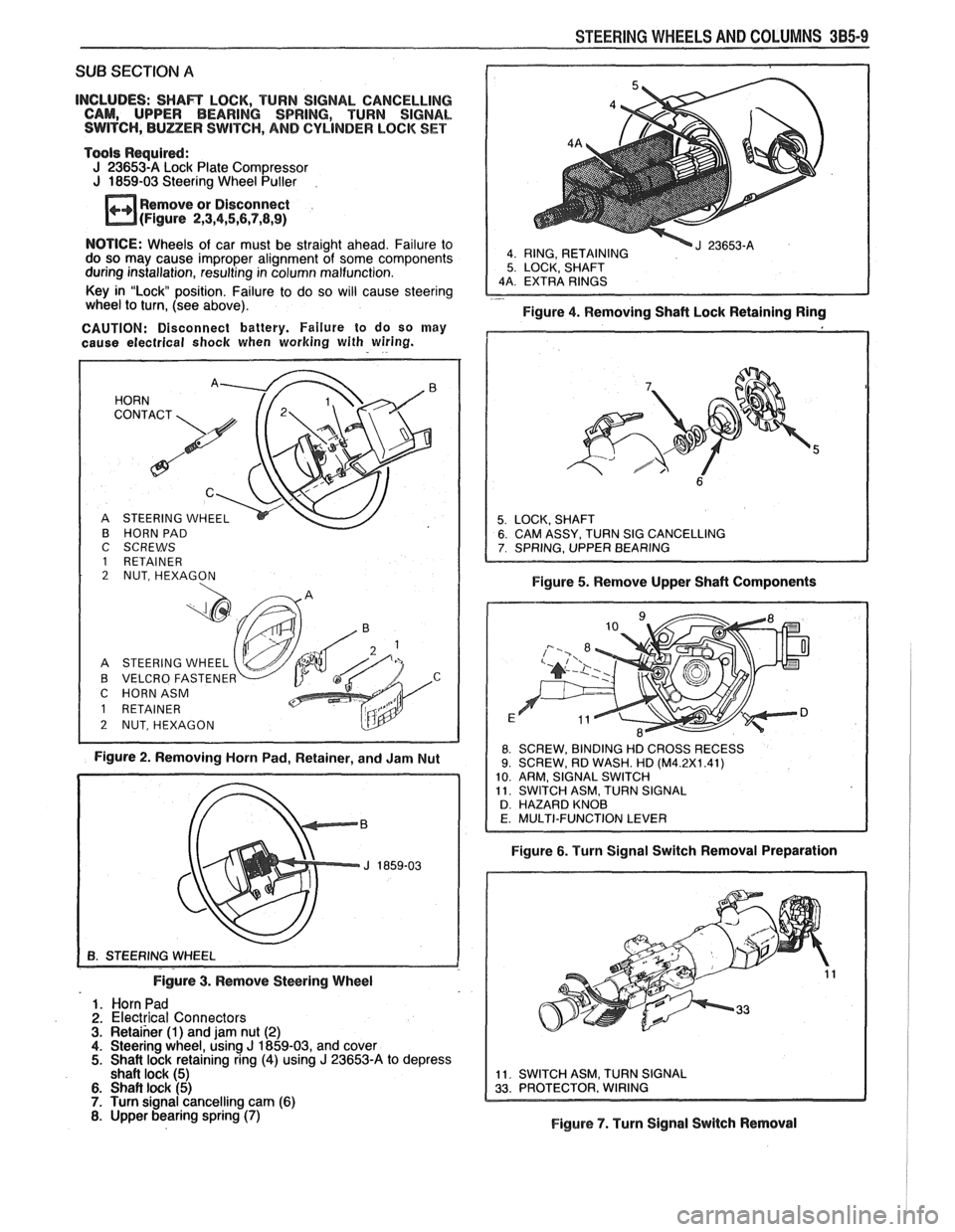

STEERING WHEELS AND COLUMNS 385-9

SUB SECTION A

INCLUDES: SHAR LOCK, TURN SIGNAL CANCELLING

CAM, UPPER BEARING SPRING, TURN SIGNAL

SWITCH,

BULZER SWITCH, AND CYLINDER LOCK SET

Tools Required:

J 23653-A Lock Plate Compressor

J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figure

2,3,4,5,6,7,8,9)

4 RING, RETAINING 5 LOCK, SHAFT

NOTICE: Wheels of car must be straight ahead. Failure to

do so may cause improper alignment of some components

during installation, resulting in column malfunction.

Key in "Lock position. Failure to do so will cause steering

- wheel to turn, (see above).

Figure 4. Removing Shaft Lock Retaining Ring

CAUTION: Disconnect battery. Failure to do so may

cause electrical

shock when working with wiring.

B HORN PAD

C SCREWS

1 RETAINER 2 NUT, HEXAGON

A STEERING WHEEL

B VELCRO FASTENE

C HORNASM

Figure 2. Removing Horn Pad, Retainer, and Jam Nut Figure

5. Remove Upper Shaft Components

8 SCREW,

BINDING HD CROSS RECESS 9. SCREW, RD WASH. HD (M4.2X1.41)

10 ARM, SIGNAL SWITCH

11 SWITCH ASM, TURN SIGNAL

D HAZARD KNOB

Figure 6. Turn Signal Switch Removal Preparation

Figure

3. Remove Steering Wheel

1. Horn Pad

2. Electrical Connectors 3. Retaiher (1) and jam nut (2) 4. Steering wheel, using J 1859-03, and cover 5. Shait lock retaining ring (4) using J 23653-A to depress

shaft lock (5)

6. Shaft lock (5) 7. Turn signal cancelling cam (6) 8. Upper bearing spring (7) Figure 7. Turn Signal Switch Removal

Page 166 of 1825

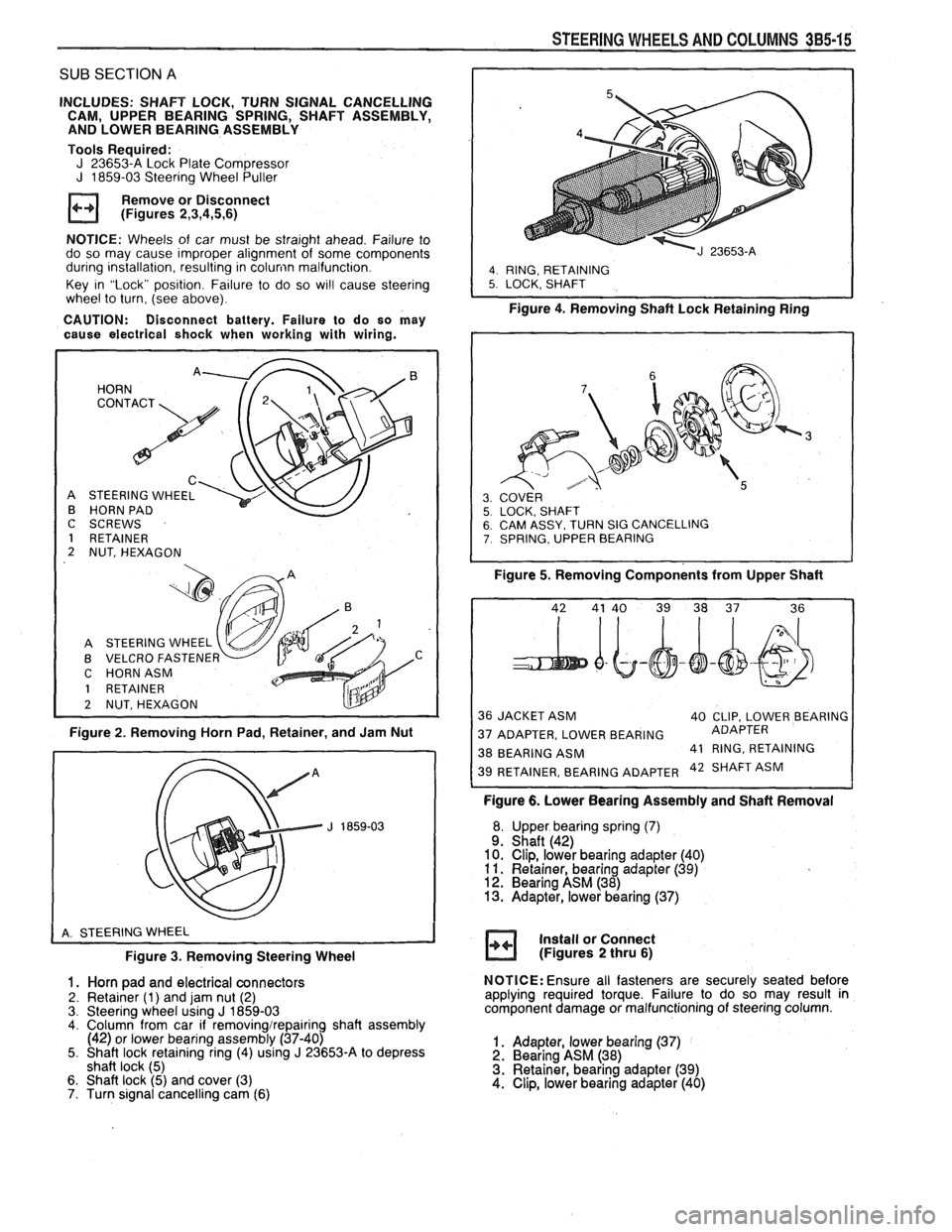

SUB SECTION A

INCLUDES: SHAFT LOCK, TURN SIGNAL CANCELLING

CAM, UPPER BEARING SPRING, SHAFT ASSEMBLY,

AND LOWER BEARING ASSEMBLY

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figures

2,3,4,5,6)

NOTICE: Wheels of car must be straight ahead. Failure to

do so may cause improper alignment of some components

during installation, resulting in

colunin malfunction.

Key in "Lock" position. Failure to do so

wi!l cause steering

wheel to turn, (see above).

CAUTION: Disconnect battery. Failure to do so may

cause electrical shock when working with wiring.

HORN

C

STEERING WHEEL

HORN PAD

I

C SCREWS

1 RETAINER

2 NUT, HEXAGON

A STEERING WHEEL

B VELCRO

FASTENEF v C HORNASM

1 RETAINER

2 NUTSHEXAGON

Figure 2. Removing Horn Pad, Retainer, and Jam Nut

Figure

3. Removing Steering Wheel

1. Horn pad and electrical connectors

2. Retainer (1) and jam nut (2)

3. Steering wheel using J 1859-03 4. Column from car if removingirepairing shaft assembly

(42) or lower bearing assembly (37-40)

5. Shaft lock retaining ring (4) using

J 23653-A to depress

shaft lock (5)

6. Shaft lock (5) and cover (3)

7. Turn signal cancelling cam (6)

STEERING WHEELS AND COLUMNS 385-15

I

4. RING, RETAINING 5. LOCK. SHAFT

Figure 4. Removing Shaft Lock Retainingain;

SY. TURN SIG CANCELLING , UPPER BEARING

Figure 5. Removing Components from Upper Shaft

36 JACKET ASM

40 CLIP, LOWER BEARING

37 ADAPTER, LOWER BEARING ADAPTER

38 BEARING

ASM 41

RING, RETAINING 42 SHAFT ASM

Figure 6. Lower Bearing Assembly and Shaft Removal

Upper bearing spring

(7) Shaft (42)

Clip, lower bearing adapter (40)

Retainer, bearing adapter

(39) Bearing ASM (38) Adapter, lower bearing (37)

Install or Connect

(Figures

2 thru 6)

NOTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

1. Adapter, lower bearing (37) 2. Bearing ASM (38)

3. Retainer, bearing adapter (39)

4. Clip, lower bearing adapter (40)