fuel cap release PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 433 of 1825

6C-2 ENGINE FUEL

components such as the accelerator pumps and/or

air-fuel mixture leaning effects.

Various types and concentrations of alcohols are

used in commercial gasoline. Some alcohols are more

detrimental to fuel system components than others. If

an excessive amount of alcohol in the fuel is suspected

as the cause of a driveability condition, the following

procedure may be used to detect the presence of

alcohol in the fuel.

In this procedure, water is used to

extract the alcohol from the fuel. However, the specific

type of alcohol is not determined.

The fuel sample should be drawn from the

bottom part of the tank so that any water, if already

present, can be detected. The sample should be bright

and clear. If the sample appears cloudy or

contaminated with water as indicated by a water layer

in the bottom part of the sample, this procedure should

not be used. The fuel system should then be cleaned

(See Fuel System Cleaning).

Testing Procedure

1. Using a 100 ml cylinder with 1 ml graduation

marks, fill with fuel to the 90 ml mark.

2. Add 10 ml of water to bring the total fluid volume

to 100 ml and install a stopper.

3. Shake vigorously for 10 to 15 seconds.

4. Carefully loosen stopper to release pressure.

5. Close the stopper and shake vigorously again for

10 to 15 seconds.

6. Carefully loosen

stopper to release pressure.

7. Put the graduated cylinder on a level surface for

approximately 5 minutes to allow adequate liquid

separation.

If alcohol is present in the fuel, the volume of the

lower layer, which would now contain alcohol and

water will be greater than 10 ml. For example, if the

volume of the lower layer is increased to 15 ml, it

would indicate at least 5 percent alcohol in fuel. The

actual amount of alcohol may be somewhat greater

because this procedure does not extract all of the

alcohol from the fuel.

FUEL METERING

Throttle Body lnjection

(TBI)

With Throttle Body Injection (TBI), an injection

unit is placed on the intake manifold where the

carburetor is normally mounted. The TBI unit is

computer controlled and supplies the correct amount

of fuel during all engine operating conditions. See

Section 6E2 for information relative to operation and

diagnosis of TBI units.

Port Fuel lnjection

The ECM is in complete control of this fuel

delivery system during all driving conditions.

The intake manifold is used only to let air into the

engine. Fuel is injected by separate injectors that are

mounted over the intake valve.

With the Port Injection System, there is no need

for a Thermac, EFE, Map Sensor, Baro Sensor, A.I.R.

System, or Dual Bed Converter. This

system provides better cold driveability,

lower exhaust emissions and better throttle response.

In Sequential Fuel Injection systems (SFI),

injectors turn on at every crankshaft revolution. The

ECM controls the injector "on" time so that the

correct amount of fuel is metered, depending on

driving conditions.

Two interchangeable

"0" rings are used on the

injector that must be inspected when the injectors are

removed. Check

"0" rings for cuts or other type of

damage and replace as necessary.

The air cleaner is remotely mounted near the

radiator. It is connected to the intake manifold by air

intake ducting.

Also, mounted between the air cleaner and

intake, are the mass air flow sensor and throttle body.

Cold driveability characteristics are greatly

improved with the aid of an engine coolant supply to

the throttle body for rapid warm up.

The throttle body design uses an integral Idle Air

Control to govern idle speed and a Throttle Position

Sensor (TPS). The IAC and TPS are both controlled

by the ECM.

A large diameter fuel rail is attached to the intake

manifold and supplies fuel to all the injectors.

A fuel pressure tap is located on the rail for quick

pressure checks.

Fuel is recirculated through the rail continually

while the engine is running. This removes air and

vapors from the fuel as well as keeping the fuel cool

during hot weather operation.

A fuel pressure regulator is mounted on the fuel

rail. It maintains a constant 36 psi pressure across the

injectors under all operating conditions. It is

accomplished by controlling the amount of fuel that is

recirculated back to the fuel tank, based on engine

demand.

The pressure regulator also uses an

"0" ring for

attachment. The

"0" ring used is the same one that is

used for the injectors.

Some engines also have an accumulator that is

located in the fuel feed line near the cowl area. It is used

to dampen the vibration that is caused by the

pressurized fuel and the pulsing of the injector.

See Section 6E3 for more information and

diagnosis.

Fuel Feed and Return Pipe

When replacing fuel feed and return pipes, always

replace them with welded steel tubing meeting GM

Specification

124M, or its equivalent. The replacement

pipe must use the same type of fittings as the original

pipes to ensure the integrity of the connection.

NOTICE: Do not replace fuel pipe with fuel hose

or any other type of tubing such as copper or

aluminum. Only tubing meeting the 124M

specification is capable of meeting all the pressure

and vibration characteristics necessary to ensure

the durability standard required.

Always check and replace any

"0" rings or

washers that appear damaged.

Page 472 of 1825

IGNITION SYSTEM 6B4-3

flash-over, which causes engine misfiring. Do not

mistake corona discharge for flash-over, or a shorted

insulator. Corona is a steady blue light appearing

around the insulator, just above the shell crimp. It is

the visible evidence of a high-tension field and has no

effect on ignition performance. Usually it can be

detected only in darkness. This discharge may repel

dust particles, leaving a clear ring on the insulator just

above the shell. This ring is sometimes mistakenly

regarded as evidence that combustion gases have blown

out between shell and insulator.

lgnition Switch

The mechanical switch is located in the steering

column on the right hand side just below the steering

wheel. The electrical switching portion of the assembly

is separate from the key and lock cylinder. However,

both are synchronized and work in conjunction with

each other through the action of the actuator rod

assembly.

For a complete explanation of the key and lock

cylinder, and the actuator rod assembly, see

STEERING, Section

38. See Section 8 for electrical

switching.

DIAGNOSIS

IGNITION SYSTEM

Spark Plugs

Worn or dirty plugs may give satisfactory

operation at idling speed, but at higher RPM they

frequently fail. Faulty plugs are indicated in a number

of ways: poor fuel economy, power loss, loss of speed,

hard starting and generally poor engine performance.

Spark plugs may also fail due to carbon fouling,

excessive gap, or a broken insulator. Fouled plugs may

be indicated by black carbon

deposits. The black deposits are usually the result of

slow-speed driving and short runs, where sufficient

engine operating temperature is seldom reached. Worn

pistons, rings, faulty ignition, over-rich carburetion

and spark plugs which are too cold will also result in

carbon deposits.

Excessive gap wear, on plugs of low mileage,

usually indicates the engine is operating at high speeds,

or loads that are consistently greater than normal, or

that a plug which is too hot is being used. Electrode

wear may also be the result of plug overheating,

causcd

by combustion gases leaking past the threads due to

insufficient torquing of the spark plug. Excessively lean

carburetion will also result in accelerated electrode

wear.

Broken insulators are usually the result of

improper installation, or carelessness when regapping

the plug. Broken upper insulators usually result from

a poor fitting wrench, or an outside blow. The cracked

insulator may not show up right away, but will as soon

as oil or moisture penetrates the crack. The crack is

usually just below the crimped part of shell and may

not be visible.

Broken lower insulators usually result from

carelessness when regapping and generally are visible.

This type of break may result from the plug operating

too "hot", which may happen in periods of high-speed

operation or under heavy loads. When regapping a

spark plug, always make the gap adjustment by

bending the ground (side) electrode. Spark plugs with

broken insulators should always be replaced.

HE1 Distributor

See Unit Repair for distributor disassembly, test

and reassembly of individual distributor components,

when the distributor is removed from the vehicle. See

On-Car Service for distributor removal and installation

and for component removal with distributor in car. See

Section 6E for

HE1 and EST diagnosis.

SERVICE PROCEDURES

IGNITION SYSTEM

Distributor Ignition

NOTICE: This procedure is generally true for

most carlines. Where procedure is different, or

where additional information is required, see

"ON-CAR SERVICE" for specific

carline.

HE1 DISTRIBUTOR

Service Precautions

1. When making compression checks, disconnect

the ignition switch feed wire at the distributor.

When disconnecting this connector,

do not use

a screwdriver or tool to release the locking tab, as

it may break.

2. No periodic lubrication is required. Engine oil

lubricates the lower bushing and an oil-filled

reservoir provides lubrication for the upper

bushing. 3.

The tachometer (TACH) terminal is next to the

ignition switch (BAT) connector on the

distributor cap.

NOTICE: The tachometer terminal must

NEVER be allowed to touch ground, as damage

to the module and/or ignition coil can result.

Some tachometers currently in use may NOT be

compatible with the High Energy Ignition System.

Consult the manufacturer of the tachometer if

questions arise.

4. Dwell adjustment is controlled by the module,

and cannot be adjusted.

5. The material used to construct the spark plug

cables is very soft. This cable will withstand more

heat and carry a higher voltage, but scuffing and

cutting become easier. The spark plug cables

must be routed correctly to prevent

chafing or

cutting. See Spark Plug Section. When removing

Page 744 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN S) 6E3-C2-9

26 FUEL PRESSURE CONNECTION ASSEMBLY

27 SEAL - FUEL PRESSURE CONNECTION ASSEMBLY

28 CAP - FUEL PRESSURE CONNECTION ASSEMBLY

55 FUEL BLOCK

Figure C2-10 Fuel Pressure Connection Assembly

FUEL BLOCK AND SEAL

Figure CZ-I 1

Remove or Disconnect

1. Negative battery terminal.

2. Engine components above fuel block.

I O-RING -FUEL INLET 2 O-RING . FUEL RETURN 11 FUEL RAlL ASSEMBLY 55 FUEL BLOCK 56 SEAL -FUEL BLOCK 57 SCREW ASSEMBLY - FUEL BLOCK ATTACHING 55 1461-6E

Figure C2-11 Fuel Block Assembly

Clean

@ Fuel block (55) and adiacent fuel line

connections with

AC ~elco X-30A or

equivalent.

3. Fuel inlet and return lines, and O-ring seals (1)

and (2).

- Discard O-ring seals.

4. Fuel block attaching screw assemblies

(57).

5. Fuel block (55) and seal (56). Discard seal.

FUEL RAlL

REL

85 INJECTOR -PORT

87 CLIP-INJECTOR RETAINER

Figure C2-12 Injector Removal

- @ Sealing surfaces of fuel block and fuel rail

assembly to ensure a good seal.

Install or Connect

1. New fuel block sea1 (56) on fuel rail assembly ( 1 I).

2. Fuel block (55) on seal.

3. Fuel block attaching screw assemblies (57).

Tighten

@ Attaching screw assemblies to 5.0 Nm (44.0

in. Ibs.

)

4. New O-ring seals (1) and (2) on fuel inlet and

return lines.

5. Fuel inlet and return lines.

6. Battery negative terminal.

Inspect

@ Energize fuel pump and check for fuel leaks

FUEL INJECTORS

Each port injector is located and held in position

by a retainer clip that must be rotated to release

and/or lock the injector in place, as shown in Figure

C2-12.

Port Injectors with lnjector Retaining Clips

Remove or Disconnect

1. Rotate injector retaining clip(s) (87) to unlocked

position.

2. Port in*jectors (85).

Page 897 of 1825

6E3-C2-"l s5.OL (VIN F) & 5.7b (VIN 8) DRIVEABILITY AND EMISSIONS

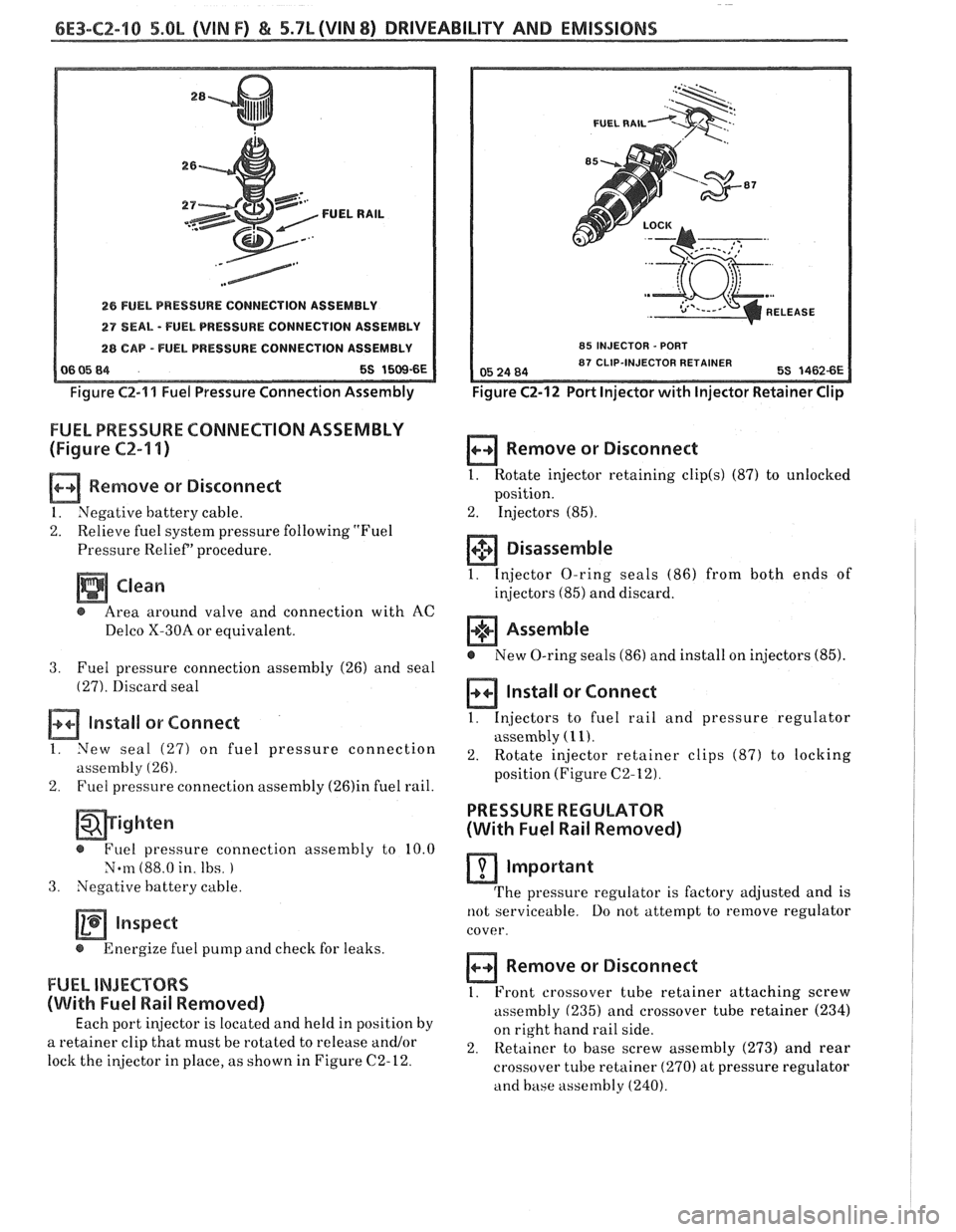

FUEL RAIL

26 FUEL PRESSURE CONNECTION ASSEMBLY

27 DEAL - FUEL PRESSURE CONNECTION ASSEMBLY

28 CAP -FUEL PRESSURE CONNECTION ASSEMBLY

06 85 84 5S 1509-6E

Figure

C2-'11 Fuel Pressure Connection Assembly

FUEL PRESSURE CONNECTION ASSEMBLY

(Figure

CZ-'I I)

Remove or Disconnect

1. Negative battery cable.

2. Relieve fuel system pressure following "Fuel

Pressure Relief' procedure.

a Clean

@ Area around valve and connection with AC

Delco X-30A or equivalent.

3. Fuel pressure connection assembly (26) and seal

(27). Discard seal

Install or Connect

I. New seal (27) on fuel pressure connection

assembly

(26).

2. Fuel pressure connection assembly (26)in fuel rail.

- @ Fuel pressure connection assembly to 10.0

Norn (88.0 in. Ibs.

3. Negative battery cable.

inspect

@ Energize fuel pump and check for leaks.

FUEL INJECTORS

(With Fuel Wail Removed)

Each port injector is located and held in position by

a retainer clip that must be rotated to release

and/or

lock the injector in place, as shown in Figure (22-12.

FUEL RAIL

I 85 INJECTOR - PORT I

Figure CZ-12 Port Injector with Injector Retainer Clip

a Remove or Disconnect

1. Rotate injector retaining clip(s) (87) to unlocked

position.

2. Injectors (85).

+$ Disassemble

1. Injector O-ring seals (86) from both ends of

injectors

(85) and discard.

Assemble

@ New O-ring seals (86) and install on injectors (85).

Install or Connect

1. Injectors

to fuel rail and pressure regulator

assembly

(1 1).

2. Rotate

injector retainer clips (87) to loclring

position (Figure C2-12).

PRESSURE REGULATOR

(With Fuel Rail Removed)

Important

The pressure regulator is factory adjusted and is

not serviceable. Do not attempt to remove regulator

cover.

Remove or Disconnect

1. Front crossover tube retainer attaching screw

assembly

(235) and crossover tube retainer (234)

on right hand rail side.

2. Retainer to base screw assembly (273)

and rear

crossover tube retainer

(270) at pressure regulator

and base assembly (240).