fuel tank removal PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 346 of 1825

ENGINE GENERAL INFORMATION 6-1

SECTION 6

NE GENERAL NFORMAT

Description ............................................................... 6 TBI ...................................... .. ...... 6E2 ................ Engine Mechanical Multi Port Fuel Injection (MPFI) 6E3 -

............................................... 2.8L V-6 ....................................................... 6A2 Exhaust Systems 6F

5.OL V-8 ......................................................... 6A3 ~~~~~~l ~~f~~~~ti~~ ..................................... 6-2

............................ Engine Cooling ...................................................... 6B Engine Performance Diagnosis 6-3 ............................. Engine Fuel 6C Engine Mechanical Diagnosis

6-3 ........................................................... ................................... Engine Knock Diagnosis 6-4

Engine Electrical ................................................... 6D Compression Test ...................................... ... 6-5

................... Driveability and Emission Controls ...................... 6E Oil Leak Detection .. ..................... 6-5

ALL NEW GENERAL MOTORS VEHICLES ARE CERTIFIED BY THE UNITED STATES

ENVIRONMENTAL PROTECTION AGENCY AS CONFORMING TO THE REQUIREMENTS OF

THE REGULATIONS FOR THE CONTROL OF AIR POLLUTION FROM NEW MOTOR VEHICLES.

THlS CERTIFICATION IS CONTINGENT ON CERTAIN ADJUSTMENTS BEING SET TO

FACTORY STANDARDS. IN MOST CASES, THESE ADJUSTMENT POINTS EITHER HAVE

BEEN PERMANENTLY SEALED AND/OR MADE INACCESSIBLE TO PREVENT

INDISCRIMINATE OR ROUTINE ADJUSTMENT IN THE FIELD. FOR

THlS REASON, THE

FACTORY PROCEDURE FOR TEMPORARILY REMOVING PLUGS, CAPS, ETC., FOR

PURPOSES OF SERVICING THE PRODUCT MUST BE STRICTLY FOLLOWED AND,

WHEREVER PRACTICABLE, RETURNED TO THE ORIGINAL INTENT OF THE DESIGN.

DESCRIPTION OF: SECTION 6

SECTION 6A - ENGINE MECHANICAL used for each carburetor. TBI units are described in

This section general contains information on the Section 6E.

mechanical parts of the engine, such as block,

crankshaft, pistons, valve train, and camshaft, that are

common to most engines. Overhaul procedures,

removal and replacement procedures, and

s~ecifications are also covered. Subsections furnish

detailed information on each specific engine. Service

SECTION 6D - ENG l N E ELECTRICAL

information is also given that relates to that engine's

use in each

Carline. Specific subsections are: Items

covered in this section are battery,

generator, starter, primary and secondary ignition,

6A2

- 2.8L V-6 Engine

engine wire harness, spark plugs and wires, and

6A3

- 5.OL V-8 Engine

ignition switch.

SECTION 6B - ENGINE COOLING

Engine cooling system components such as

radiator, water pump, thermostat, and cooling fan, are

covered in this section. Accessory drive belts are also

covered, along with cooling system capacities.

SECTION 6C - FUEL SYSTEM

This section contains information on all the parts

of the fuel system

except the carburetor, or Throttle

Body Injection unit (TBI) itself. Items covered are fuel

tank, fuel pump, and fuel lines. Specific subsections are

SECTION 6E - DRIVEABILITY AND EMISSIONS

This section covers emission control systems

general information, and diagnostic procedures which

will lead to repairing performance and driveability

related problems for gasoline engine equipped vehicles.

All emission components are covered, as well as all

removal and replacement procedures. Instructions on

use of special tools are also given. Specific sections are:

6E

- Driveability and Emissions

6E2

- Fuel Injection (TBI)

Page 436 of 1825

ENGINE FUEL CC-5

FUEL TANK

Draining Fuel Tank

1. Disconnect the negative battery cable. Also have

a dry chemical (Class B) fire extinguisher near the

work area.

2. Use a hand operated pump device when possible

to drain as much fuel through the filler tube as

possible.

3. If

a hand operated pump device cannot be used

to complete the draining process, use a siphon at

the main (not return) fuel pipe at the fuel pump

or the fuel tank gage unit.

CAUTION: Never drain or store

gasoline in an open container due to

the possibility of fire or explosion.

4. Reinstall any removed hoses, lines and cap.

Removing Fuel Tank

1. Remove all fuel, see "Draining Fuel Tank".

2. Support

fuel tank and disconnect the two fuel

tank retaining straps.

3. Lower tank enough to disconnect sending unit

wire, hoses, and ground strap, if so equipped.

4. Remove tank from vehicle.

5. Remove sending unit.

Installing Fuel Tank

1. Reverse removal procedure.

2. Always replace "0" ring when tank unit has been

removed.

3. When reinstalling fuel tank, be sure to reinstall

anti-squeak pieces on top of the tank to reduce

rattles and other annoying noises.

4. Tighten fuel tank retaining strap bolts or screws.

Fuel System Cleaning

CAUTION: This procedure will NOT

remove all fuel vapor. Do not attempt

any repair

on tank or filler neck where

heat or flame is required, as an

explosion resulting in personal injury

could occur.

If trouble is due to contaminated fuel or foreign

material that is in the tank, it can usually be cleaned.

If tank is rusted internally, it should be replaced.

1. Disconnect negative battery cable.

2. Disconnect ignition engine harness connector.

Have dry chemical (Class B) fire extinguisher

near the work area.

3. Relieve fuel system pressure.

4. Drain fuel tank (see "Draining Fuel Tank").

5. Remove fuel tank (see "Fuel Tank Removal").

6. Remove external fuel filter and inspect for

contamination. If filter is plugged, replace.

7. Locate tank away from heat, flame, or other

source of ignition. Remove fuel gage sending unit

and fuel pump assembly, if so equipped, and

inspect condition of strainer. If strainer is

contaminated, a new strainer should be installed.

8. Complete draining of tank by rocking it and

allowing fuel to run out of fuel sending unit

opening.

9. Flush fuel tank with running hot water for at least

five minutes. Pour water out of fuel sending unit

opening. (Rock tank to be sure that removal of

water is complete.)

10. Disconnect fuel feed pipe and use air pressure to

clean fuel line. Apply air pressure in the opposite

direction fuel normally flows through the line. On

vehicles equipped with a fuel return line, clean

line in similar manner. Disconnect pipe at

throttle body unit and apply air pressure to clean

return line. Reconnect and torque all pipes to 30

N-m (22 1b. ft.).

11. Use low air pressure to clean pipes on fuel gage

sending unit.

112. Install new strainer on fuel gage sending unit, if

required. Install fuel gage sending unit and fuel

pump, with new gasket, into tank and install fuel

tank. Connect fuel gage wire harness to body

harness. Connect all fuel lines except feed line to

external fuel filter.

13. Disconnect fuel feed hose to chassis pipe at front.

Connect a hose to front end of chassis fuel feed

pipe and insert other end of hose into a one gallon

fuel can.

14. Connect battery cable.

15. Put six gallons of clean fuel into fuel tank and

apply 12 volts to Terminal

"G" of ALCL to

operate fuel pump. Pump two quarts of fuel into

fuel can. This will purge fuel pump.

16. Remove hose and connect fuel hose to chassis

pipe.

17. Check all connections

for leaks; tighten all hose

clamps.

Fuel Tank Purging Procedure

The following procedure is used prior to repairing

of fuel tank.

1. Remove fuel sending unit and fuel pump and

drain all remaining fuel from tank.

2. Visually inspect interior cavity of tank. If any fuel

is evident, drain again.

3. Move tank to flushing area (wash rack).

4. Fill tank completely with tap water, agitate

vigorously and drain.

5. Add gasoline emulsifying agent to the tank, refill

with water, agitate mixture for 10 minutes, and

drain tank completely.

For correct gasoline emulsifying agent-to-water

mixture, refer to the

manufacturer's

specifications. Use an available emulsifying

agent, such as "Product-Sol No.

913", or

equivalent.

6. When empty, refill the tank to overflowing with

water. Completely flush out remaining mixture

and empty tank.

7. If available, an explosion meter should be used Lo

check for negative reading.

8. Perform required service work.

Page 437 of 1825

86-8 ENGINE FUEL

Fuel Tank Leak Test Procedure

Plug all outlets. Before removing a fuel tank for

a suspected fuel leak, make sure that it is not one of the

fuel hoses that is leaking onto the tank.

On-Car Test

If fuel is leaking from tank, replace tank.

Off-Car Pest

Apply a small amount of air pressure to tank

through vent tube (approximately

7 to 10 kPa or 1 to

1-1/2 lbs. of pressure).

NOTICE: More than 1-1/2 pounds of pressure

will damage tank permanently.

Test repaired area for leaks with soap solution, or

by submersion. If leak is noted, replace tank.

ACCELERATOR CONTROLS

The accelerator control system is cable type.

There are no linkage adjustments.

As there are no adjustments, the specific cable for

each application must be used. Only the specific

replacement part will work.

When work has been performed on accelerator

controls, always check to ensure that all components

are installed as removed and that all linkage and cables

are not rubbing or binding in any manner.

Accelerator Control Cable

Refer to On-Car Service for removal and

installation of accelerator control cable.

When performing service on the accelerator

control cable, observe the following:

s Retainer must be installed with tangs secured

over head of stud.

s Conduit fitting at both ends of cable must have

locking tangs expanded and locked in attaching

holes.

s The braided portion of the accelerator cable

assembly must not come in contact with the front

of dash sealer during assembly, repair or

replacement of the assembly.

e Flexible components (hoses, wires, conduits, etc.)

must be routed within

50.0mm (2.0 in.) of moving

parts of accelerator linkage, outboard of support,

unless routing is positively controlled.

Whenever disconnecting or replacing parts, lube

pivot points with Accelerator Linkage Lubricant

1052541, or equivalent.

Accelerator Pedal

When performing service on the accelerator

pedal, observe the following:

s The mounting surface between support and dash

panel must be free of insulation. The carpet and

padding in pedal and tunnel area must be

positioned to lay flat and be free of wrinkles and

bunches.

s Slip accelerator control cable through slot in rod

and then install retainer in rod, being sure it is seated.

Care must be utilized in pressing the

retainer into hole in rod, to assure the cable is not

kinked or damaged in any way.

s After securing all components of the accelerator

linkage, linkage must operate freely, without

binding, between full closed throttle and full wide

open throttle.

e Wire, hoses, cables or other obstructions must

not be placed within 13mm

(33/64 in.) of cable

or rod at any point in their travel.

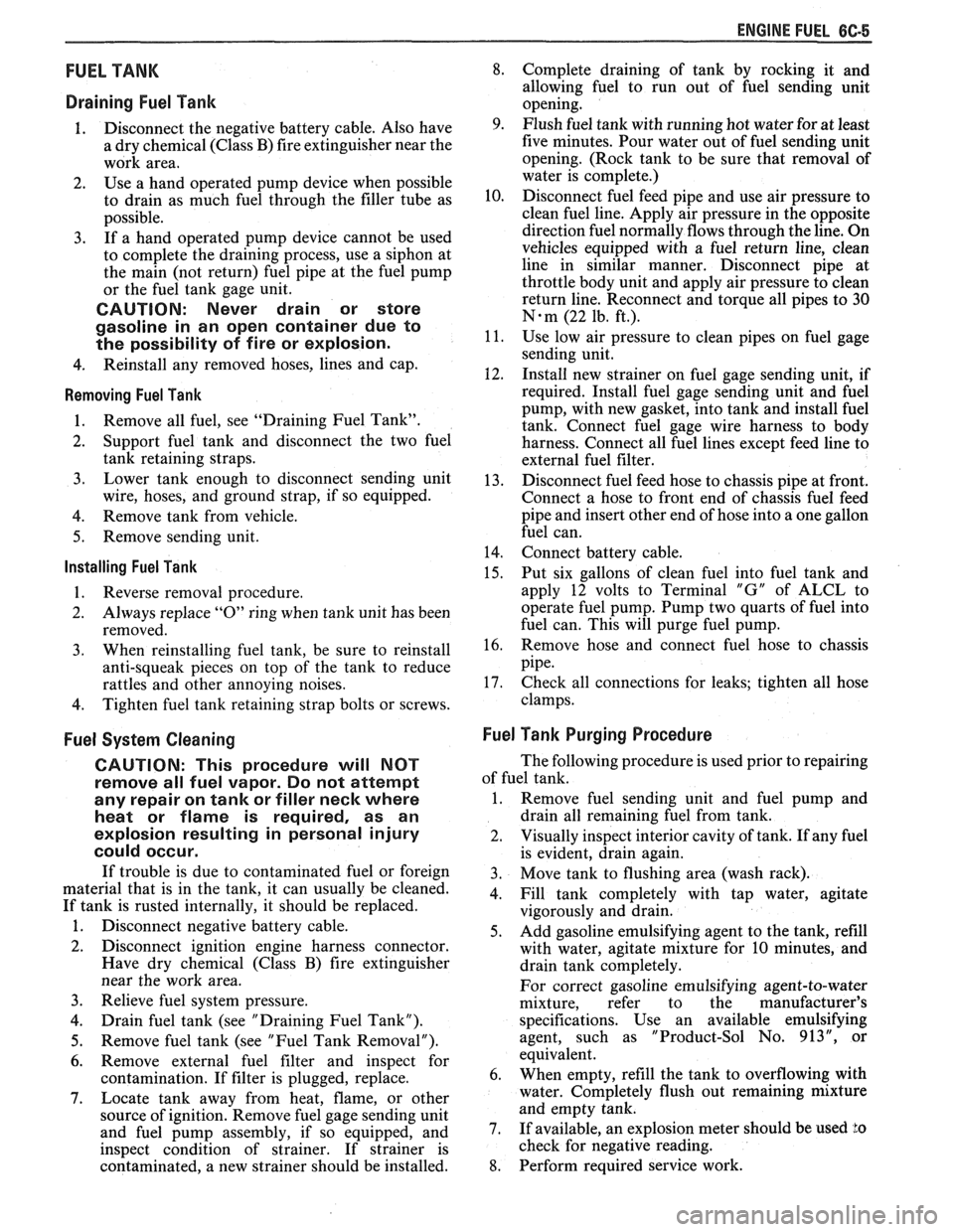

Fig. 1 Throttle Body - LB9 Shown

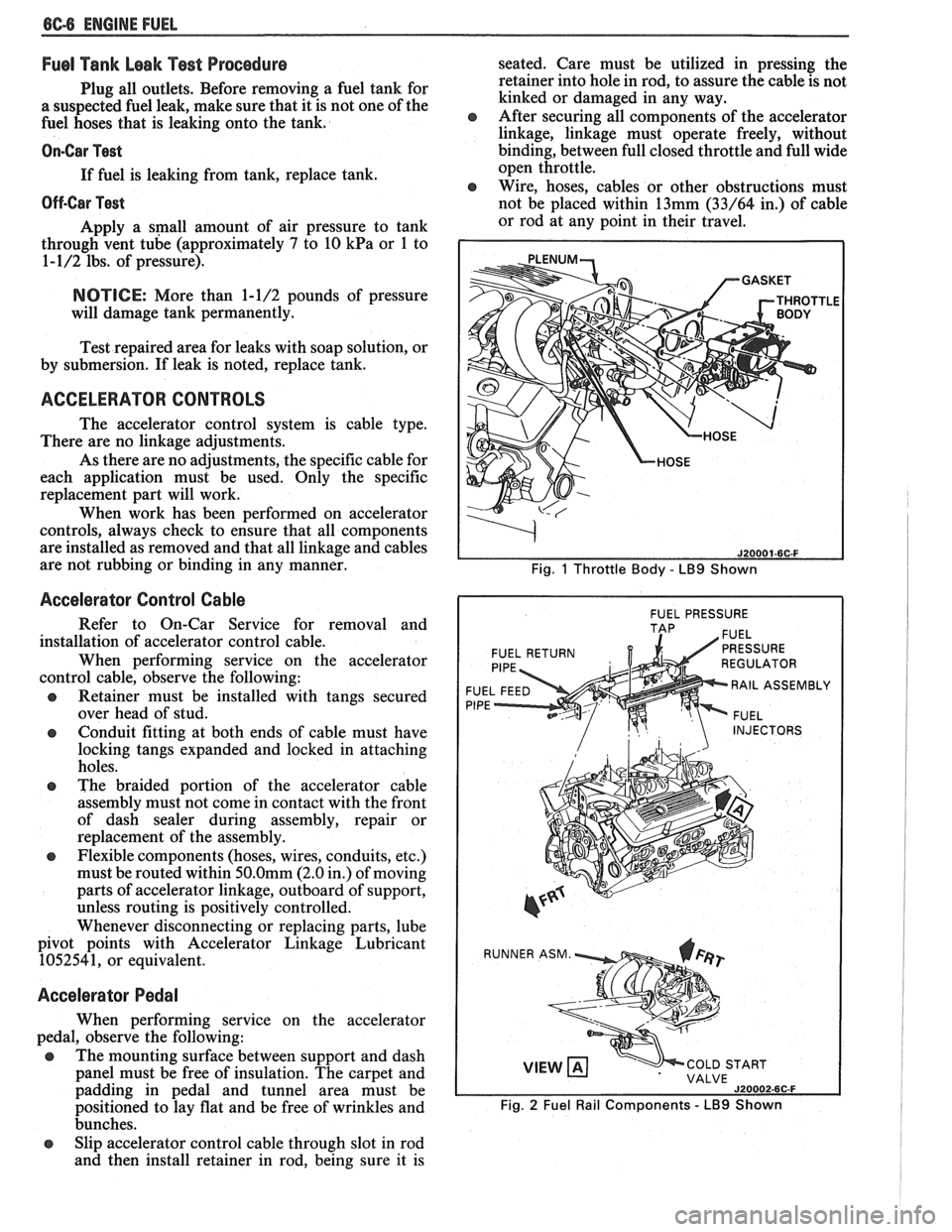

I FUEL PRESSURE I

FUEL RETURN

F

RAIL ASSEMBL

P

INJECTORS

VIEW COLD START

VALVE

J20002-6C-F

Fig. 2 Fuel Rail Components - LB9 Shown

Page 962 of 1825

DRIVEABILITY AND EMISSIONS . FUEL INJECIION 6E-1

DRBVEABILIW AND EMISSIONS

CONEENTS

General Information . Section 6E

Driveability and Emissions . Fuel Injected (TBI) . Section 6EZ

Driveability and Emissions . Fuel injected (PORT) . Section 6E3

..................... DRIVEABILITY 6E-1

........................ EMISSIONS 6E-1

MAINTENANCE SCHEDULE ............ 6E-1

VEHICLE EMISSIONS CONTROL

............. INFORMATION UBEL 6E-3

.................... INTRODUCTION 6E-3

.......... Electronic Engine Control 6E-3

What This Section Contains .......*. 6E-3

............. Blocking Drive Wheels 6E-3

.............. Cold Oxygen Sensor 6E-3

VISUAUPHYSICAL UNDERWOOD

..................... INSPECTION 6E-3

BASIC KNOWLEDGE REQUIRED ........ 6E-3

.............. Basic Electric Circuits 6E-3

Use of Circuit Testing Tools ......... 6E-4

Use of Digital Volt-Ohm Meter (DVM) . . 6E-4

DIAGNOSTIC INFORMATION .......... 6E-4

"Service Engine Soon" Light ........ 6E-4

Intermit . "Service Engine Soon" Light . . 6E-4

................... Trouble Codes 6E-4

.................. ALDL Connector 6E-4

Diagnostic Mode ................. 6E-4

Field Service Mode ................ 6E-5

............ Clearing Trouble Codes 6E-5

............. ECM Learning Ability 6E-5

DRIVEABILITY AND EMISSIONS ......... 6E-5

SECTIONS 6E2 and 6E3 SUMMARY ...... 6E-5

SECTION A ....................... 6E-6

Diagnostic Procedure Summary ...... 6E-6

ALDL "SCAN" TOOLS ................ 6E-6

Normal (Open) Mode ............. 6E-6

ALDL (1 OK. or Special) Mode ......... 6E-7

Factory Test (Backup or 3.9K) Mode .... 6E-7

DRIVEABILITY

The driveability diagnosis procedures apply to

various systems in current GM vehicles

. The

procedures assume that the vehicle worked right at

one time and the problem is due to time, wear. dirt or

other causes

. Start with the introduction that follows .

This will describe a systematic diagnostic procedure .

Any system disconnected during diagnosis should

be reconnected

. This includes wires, hoses. linkage.

etc . When removing air cleaner. plug hose fittings

that could cause an air leak

.

"SCAN" TOOLS LIMITATIONS AND USE ... 6E-7

Intermittent Conditions ........... 6E-7

"SCAN" TOOL POSITIONS ............ 6E-7

SECTION B . DRIVEABILITY SYMPTOMS . . 6E-10

SECTION C- COMPONENT SYSTEMS ..... 6E-10

Electronic Control Module (ECM) ..... 6E-10

Fuel Control System ............... 6E-10

Electric Fuel Pump (In-tank) ........ 6E-10

....... Evaporative Emission Control 6E-10

Electronic Spark Timing (EST) ....... 6E-10

....... Electronic Spark Control (ESC) 6E-10

Air Injection Reaction (A.I.R.). ........ 6E-10

......... Early Fuel Evaporation (EFE) 6E-10

Exhaust Gas Recirculation (EGR) ...... 6E-11

Transmission Convefler Clutch (TCC) . . 6E-11

.............. Shift Light Control ; . 6E-I I

................ NC Clutch Control 6E-11

........ Electric Cooling Fan Control 6E-11

Positive Crankcase Ventilation (PCV)

...... or Crankcase Ventilation (CV) 6E-11

Thermostatic Air Cleaner (THERMAC) . . 6E-11

ABBREVIATIONS & GLOSSARY OF TERMS .. 6E-1 1

............ WIRING HARNESS SERVICE 6E-14

......................... GENERAL 6E-14

WIREHARNESS.... ............*.... 6E-15

CONNECTORS .....e..e..ee...~.e.. 6E-15

................... Weather-Pack 6E-15

.................. Compact Three 6E-16

Metri-Pack Series 150 . Terrn'l Removal 6E-16

...................... Micro-Pack 6E-16

...... TOOLS NEED TO SERVICE SYSTEM 6E-17

GENERAL SPECIFICATIONS ............. 6E-23

EMISSIONS

The exhaust emission control systems used on

General Motors engines perform a specific function to

lower exhaust emissions while maintaining good fuel

economy and driveability

.

MAINTENANCE SCHEDULE

Refer to the General Motors Maintenance

Schedule in Section

"OB" of the Chassis Service

Manual for the maintenance service that should be

performed to retain emission control performance

.

Page 1404 of 1825

INSTRUMENT PANEL: GAGES CLUSTER

TROUBLESHOOTING HINTS COMPONENT LOCATION Page-Figure

* For a list of possible symptoms, go to System Coolant Temperature Sender (VIN E) Lower LH side of engine ....................

Diangosis. Coolant Temperature Sender (VIN F)

....................... .................... * For Instrument Cluster removal and replace- (VIN 8). Lower

LH side of engine

ment procedures, see Section 8C of the Ser- Coolant Temperature Sender (VIN S) Top LN front of engine, behind A/C Compressor.

.................. ..................... vice Manual. Fuel Tank Unit Top center of fuel tank.

..................... ...... * Try the following checks before doing the Sys- Fuse Block. Behind

LH side of IIP, below light switch.

................. tem Check. Ignition Switch. Behind IIP, on

top side of steering co

....... ........... Oil Pressure Sender (VIN E) Top rear of engine, near distributor. 1. Check GAGES Fuse by observing the . ........... Oil Pressure Sender (VIN F) (VIN 8) Top

rear of engine, near distributor.

BRAKE Warning Indicator with the Igni- Oil Pressure Sender (VIN S) ........ Lower LN side of engine .................... tion Switch in RUN and the Park Brake ................ .. el00 (42 cavities) LN

front of dash, left of brake master cylinder

applied.

................. C313 (3 cavities) Below

center of back seat. ...................

2. Check ground 6200. . 6118 (VIN F) (VIN 8) ............. Rear of RN cylinder head. ...................

.................... ................... 3. Check case ground of Coolant Temperature 6118

(VIN S) Rear

of RH cylinder head.

.......................... ............ Sender. 6200 Behind I/P, left of steering column ' h .......................... 4. Check case ground of Oil Pressure Sender. 6304 Under rear seat,

on support bracket

.......................... S204. IIP harness, behind instrument cluster. ........ 5. Check Indicator bulbs. .......................... ........ S205. I/P harness, behind instrument cluster. * Go to System Check for a guide to normal .......................... S217. I/P harness, behind center of IIP .............. operation.

* Go to Systern Diagnosis for diagnostic tests.

SYSTEM CHECK

* Use the System Check Table as a guide to

normal operation. Refer to the diagnosis given

if other results occur.

* Tests follow in System Diagnosis.

Page 1405 of 1825

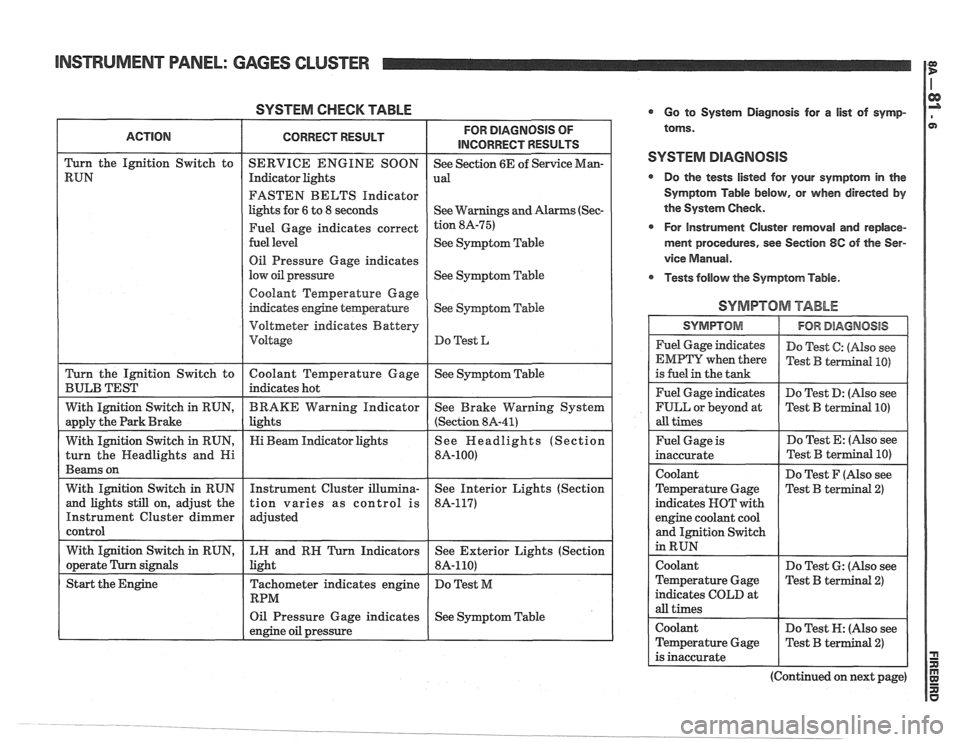

SYSTEM CHECK TABLE

FASTEN BELTS Indicator

lights for

6 to 8 seconds

See

Symptom Table

Oil Pressure Gage indicates

See

Syqtom Table

Coolant Temperature Gage

Voltmeter indicates Battery

Oil Pressure Gage indicates

See Symptom Table

engine oil pressure

L

Go to System Diagnosis for a list of symp-

toms.

SYSTEM DIAGNOSIS

Do the tests listed for your symptom in the

Symptom Table below, or when directed

by

the System Check.

r For Instrument Cluster removal and replace-

ment procedures, see Section

8C of the Ser-

vice

Manual.

Tests follow the Symptom Table.

SYMPTOM TABLE

I SYMPTOM 1 IFORDlAGMOSlS I

Fuel Gage indicates

EMPTY when there

is fuel in the tank

Fuel Gage indicates

FULL or beyond at

all times Do

Test

C: (Also see

Test

B terrnind PO)

Do Test D: (Nso see

Test

B terIllinal PO)

Fuel Gage is

inaccurate

Coolant

Temperature Gage

indicates NOT with

engine coolant cool

and Ignition Switch

in RUN Do

Test E: (Also see

Do Test F (Also see

Test B terminal

2)

coolant

Temperature Gage

indicates COLD at

all times Do

Test

6: (Also see

Test

B terminal 2)

Coolant Do Test N: (Also see

Temperature Gage

Test

B terminal 2)

is inaccurate

(Continued on next page)

Page 1420 of 1825

INSTRUMENT PANEL: DIGITAL CLUSTER a

TROUBLESHOOTING HINTS COMPONENT LOCATION u Page-Figure

0 For a list of symptoms and their diagnosis. go

to System Diagnosis

.

0 For Instrument Cluster removal and replace-

ment procedures see Section

86 of the Ser-

vice Manual

.

* Try the following checks before doing the

System Check

.

1 . Check the CLSTR Fuse .

2 . Check the CTSY Fuse .

3 . Check the TAIL Fuse .

Coolant Temperature Sender (VIN E) Lower LH side of engine ....................

Coolant Temperature Sender (VIN F)

(VIN 8)

........................ Lower LH side of engine ....................

Fuel Tank Unit .................. Top center of fuel tank ......................

Fuse Block ...................... Behind LH side of IIP. below light switch .......

Ignition Coil (VIN E) ............. Top center rear of engine ....................

Ignition Coil (VIN F)(VIN 8) ....... RH rear side of engine ......................

Ignition Switch .................. Behind IIP. on top side of steering column ......

Oil Pressure Sender (VIN E) ....... Top rear of engine. near distributor ............

Oil Pressure Sender (VIN F) (VIN 8) . Top rear of engine. near distributor ............

Oil Pressure Sender (VIN S) ........ Lower LH side of engine ....................

................ .. 4 . Check the GAGES Fuse . el00 (42 cavities) LH

front of dash. left of brake master cylinder 201- 0-A

C114

(1 cavity) (VIN E) ............ Taped to engine harness. above rear of engine

5 . If more than one indicator is out. check the C114 (1 cavity) (VIN F) (VIN 8) ..... Taped to engine harness. above rear of engine ... 201- 7-B

battery voltage inputs . . C207 (15 cavities) ................ Behind RH side of IIP near ECM ............. 201-13-A

................. .................... * Go to System Check for a guide to C313 (3 cavities) Below

center of back seat 201- 9-C operation . 6118 (VIN F) (VIN 8) ............. Rear of RH cylinder head .................... 201- 5-A

0 Go to System Diagnosis for diagnostic tests . 6200 .......................... Behind IIP. left of steering column ............ 201-10-A

6304

.......................... Under rear seat. on support bracket

SYSTEM CHECK S143 (VIN F) (VIN 8) ............. Engine harness. RH front of dash ............. 201- 6-A

0 Use the System Check able as a guide to S201 ........................... IIP harness. behind instrument cluster ......... 201-10-A

normal operation . Refer to the diagnosis S203 ........................... I/P harness. behind instrument cluster ......... 201-10-A

........................... ......... given if other results occur . S204 IIP harness. behind instrument cluster 201-10-A

........................... ......... Tests follow in System Diagnosis . S205 IIP harness. behind instrument cluster 201-10-A

S217 ........................... IIP harness. behind center of IIP .............. 201-10-A

S225 ........................... IIP harness. behind instrument cluster ......... 201-10-A

(Continued on next page)

Page 1736 of 1825

REAR QUARTERS - F STYLE 8H-1

SECTION 6H

REAR QUARTERS

NOTICE: The anti-theft label found on some major sheet metal, engines, and transmissions must be masked

prior to painting, rustproofing, undercoating, etc. The mask

must be removed following the above operations.

Failure to keep the label clean and readable may result in liability for violation of Federal Vehicle Theft Prevention

Standard, and subject the vehicle owner to possible suspicion that the part was stolen.

CONTENTS

Quarter Trim .................................................... 6H- 1

Lower Trim Finishing Panel ....................... 6H- 1

Body Lock Pillar Trim Finishing

Panel

., ....................................................... 6H- 1

Upper Trim Finishing Panel Insert ............. 6H- 1

....................................................... Speakers 6H- 1

Lift Window Upper Finishing

Molding

..................................................... 6H-2

....................... Upper Trim Finishing Panel 6H-2

QUARTER TRlM

QUARTER LOWER TRlM FINISHING PANEL

Removal and Installation (Fig. 1)

Remove body lock pillar finishing panel (Fig. 3).

Remove rear

seatback lock striker.

Remove retaining screw in rearward area of

quarter lower trim panel.

Remove rear screws from sill plate and carpet

retainer (Fig.

2).

Grasp quarter lower trim panel with hand; then

pull forward and down to disengage from

pinchweld flange at weatherstrip and quarter

upper trim finishing panel.

Remove seat belt through slot in trim panel.

Remove quarter lower trim finishing panel from

car by lifting up on rear portion of sill plate and

carpet retainer; then pull quarter trim rearward.

To install, place panel retaining slots under

quarter upper trim panel and apply upward

pressure to secure.

Position panel assembly to body. Thread lap and

shoulder belt through respective slots in panel.

Install attaching screws to secure panel to body.

Replace all previously removed components.

BODY LOCK PILLAR TRlM FINISHING PANEL

Removal and lnstallation (Fig. 3)

1. Remove trim panel attaching screws.

2. Using trim removing tool J-24595B, BT-7323A

or equivalent, carefully disengage nylon fasteners

that retain body lock pillar panel to quarter upper

trim finishing panel.

3. To install, reverse removal procedures. Spare

Tire Cover Trim Finishing

Panel

........................................................ 6H-3

Rear Stowage Compartment Box

Assembly

................................................... 6H-4

Luggage Shade Cover Assembly

................. 6H-4

Exterior Moldings

........................................... 6H-6

Fuel Tank Filler Door and Pocket

Assembly

....................................................... 6H-7

Spoiler Extension

............................ .. ........... 6H-7

QUARTER UPPER TRlM FINISHING PANEL

INSERT

Removal and Installation (Fig. 4)

1. Remove coat hook.

2. Grasp panel insert with hand and pull upward to

disengage retainers from cutout slots in quarter

upper trim finishing panel (Fig. 4).

3. To install, reverse removal procedures.

REAR QUARTER SPEAKERS

The rear quarter speakers are installed to a

speaker retainer. The retainer and speaker are then

attached to the quarter inner panel by screws.

Standard Speakers

Remove or Disconnect

1. Quarter upper trim finishing panel insert

2. Screws securing speaker retainer

3. Disconnect electrical

connector from speaker

4. Speaker

Install or Connect

1. Speaker to body

2. Electrical connector

3. Screws securing speaker to retainer

4. Quarter upper trim finishing panel insert

Subwoofer Speakers (2FS/FW/FX Styles)

Remove or Disconnect (Fig. 5)

1.

Quarter upper trim finishing panel insert (Fig. 4)

2. Body lock pillar trim finishing panel (Fig. 3)

3. Two rear screws from carpet retainer (Fig.

2)

4.

Quarter lower trim finishing panel

Page 1742 of 1825

REAR QUARTERS - F STYLE 6N-7

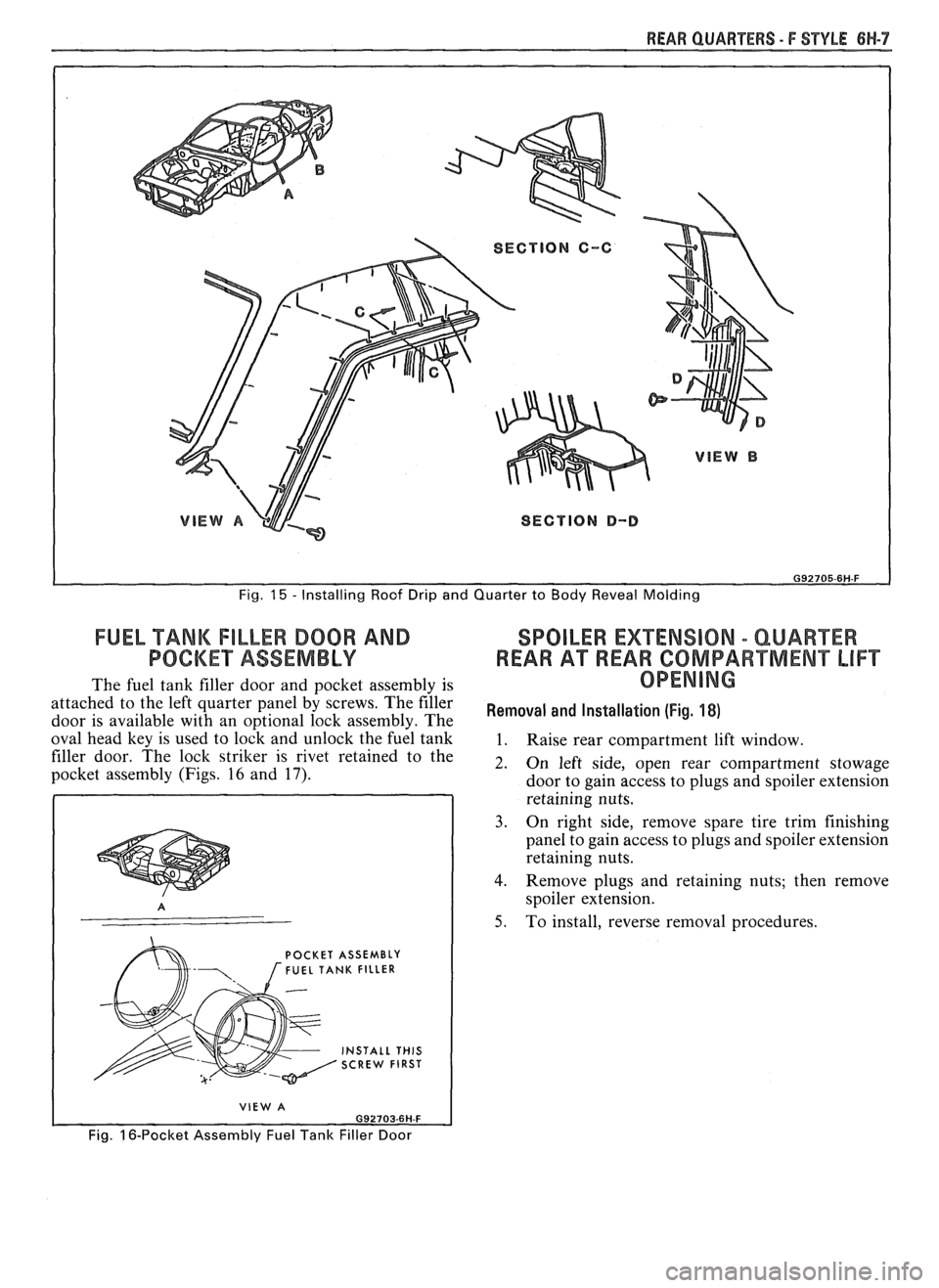

Fig. 15 - Installing Roof Drip and Quarter to Body Reveal Molding

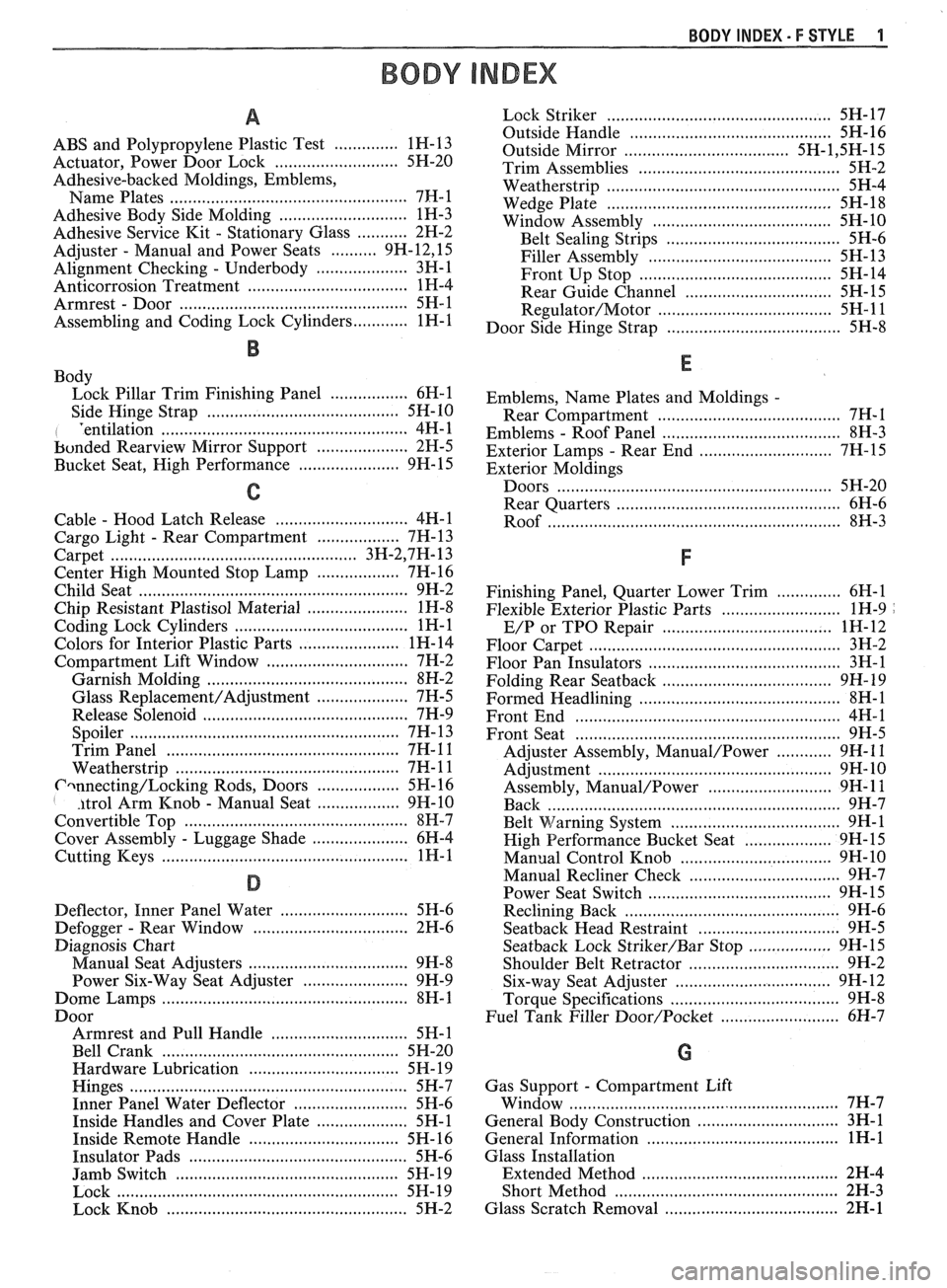

FUEL TANK FILLER DOOR AND SPOILER EXTENSION - QUAREER

POCKET ASSEMBLY REAR A"FREAR COMPARTMENT LIFT

The fuel tank filler door and pocket assembly is OPENING

attached to the left quarter panel by screws. The filer Removal and (Fig, door is available with an o~tional lock assemblv. The

oval head key is used to

loik and unlock the fuil tank 1. Raise rear compartment lift window.

filler door. The lock striker is rivet retained to the

2. 0, left side, open rear compartment stowage pocket assembly (Figs. 16 and 17). door to gain access to plugs and spoiler extension

retaining nuts.

3. On right side, remove spare tire trim finishing

panel to gain access to plugs and spoiler extension

retaining nuts.

4. Remove plugs and retaining nuts; then remove

spoiler extension.

5. To install, reverse removal procedures.

POCKET ASSEMBLY FUEL TANK FILLER

INSTALL THIS SCREW FIRST

VIEW A

Fig. 16-Pocket Assembly Fuel Tank Filler Door

Page 1812 of 1825

BODY INDEX . F STYLE 1

BODY INDEX

a

ABS and Polypropylene Plastic Test .............. 1 H- 13

Actuator. Power Door Lock

.......................... 5H-20

Adhesive-backed Moldings. Emblems. Name Plates

.................................................... 7FI-1

Adhesive Body Side Molding ............................ 1H-3

Adhesive Service

Kit . Stationary Glass ........... 2H-2

Adjuster

. Manual and Power Seats .......... 9H.12. 15

Alignment Checking

. Underbody .................... 3H-1

Anticorrosion Treatment

................................... 1H-4

Armrest

. Door ................................................. 5H-1

Assembling and Coding

Lock Cylinders ............ 1H-1

B

Body

Lock Pillar Trim Finishing Panel

................. 6H-1

Side Hinge Strap

......................................... 5H-10

I 'entilation ................................... .... ............... 4H-1

bonded

Rearview Mirror Support .................... 2H-5

Bucket Seat. High Performance

...................... 9H- 15

C

............................. Cable . Hood Latch Release 4H-1

Cargo Light

. Rear Compartment .................. 7H- 13

..................................................... Carpet 3H.2,7 H. 13

Center High Mounted Stop Lamp

.................. 7H-16

Child Seat

........................................................... 9H-2

Chip Resistant Plastisol Material

...................... 1H-8

...................................... Coding Lock Cylinders 1

H- 1

Colors for Interior Plastic Parts ...................... 1H-14

............................. Compartment Lift Window 7H-2

Garnish Molding

........................................ 8H-2

Glass

Replacement/Adjustment .................... 7H-5

Release Solenoid

.......................................... 7H-9

.......................................................... Spoiler 7H- 13

.................................................. Trim Panel 7H- 1 1

................................................ Weatherstrip 7H- 1 1

Cwnecting/Locking Rods, Doors .................. 5H- 16 I . itrol Arm Knob . Manual Seat .................. 9H-10

Convertible Top

................................................ 8H-7

Cover Assembly

. Luggage Shade ..................... 6H-4

................................................... Cutting Keys 1H- 1

D

............................ Deflector. Inner Panel Water 5H-6

Defogger

. Rear Window .................................. 2H-6

Diagnosis Chart

................................... Manual Seat Adjusters 9H-8

Power Six-Way Seat Adjuster

....................... 9H-9

Dome Lamps

...................................................... 8H-1

Boor Armrest and Pull Handle

.............................. 5H-1

Bell Crank

.................................................... 5H-20

Hardware Lubrication

................................. 5H- 19

Hinges

............................................................. 5H-7

Inner Panel Water Deflector

......................... 5H-6

Inside Handles and Cover Plate

.................... 5H-1

Inside Remote Handle

................................. 5H-16

Insulator Pads

............................................. 5H-6

Jamb Switch

................................................. 5H-19

Lock

.............................................................. 5H- 19

Lock Knob

..................................................... 5H-2

................................................. Lock Striker 5H- 17

............................................ Outside Handle 5H- 16

Outside Mirror

................................... 5H- 1.5 H. 15

Trim Assemblies

............................................ 5H-2

................................................... Weatherstrip 5H-4

................................................. Wedge Plate 5H-18

....................................... Window Assembly 5H- 10

...................................... Belt Sealing Strips 5H-6

........................................ Filler Assembly 5H- 13

.......................................... Front Up Stop 5H-14

................................ Rear Guide Channel 5H- 15

Regulator/Motor .................................... 5H-11

...................................... Door Side Hinge Strap 5H-8

Emblems.

Name Plates and Moldings .

Rear Compartment ........................................ 7H-I

. ....................................... Emblems Roof Panel 8H-3

. ............................. Exterior Lamps Rear End 7H-15

Exterior Moldings

Doors

............................................................ 5H-20

............................................... Rear Quarters 6H-6

.............................................................. Roof 8W-3

Finishing Panel. Quarter Lower Trim .............. 6H-1

Flexible Exterior Plastic Parts

.......................... 1H-9 .

.................................. E/P or TPO Repair 1H-12

Floor Carpet

................................................... 3H-2

Floor Pan Insulators

............................ .. ........ 3H-1

Folding Rear

Seatback ........................ ... ...... 9H- 19

Formed Headlining

.......................................... 8H-1

........................................................ Front End 4H-1

.......................................................... Front Seat 9H-5

............ Adjuster Assembly. Manual/Power 9H- 1 1

................................................... Adjustment 9H- 10

........................... Assembly. Manual/Power 9H- 1 1

................................................................ Back 9H-7

. ................................ Belt Warning System .... 9H-1

................... High Performance Bucket Seat 9H-

15

............................... Manual Control Knob 9H- 10

................................. Manual Recliner Check 9H-7

........................................ Power Seat Switch 9H- 15

............................................. Reclining Back 9H-6

............................... Seatback Head Restraint 9H-5

.................. Seatback Lock Striker/Bar Stop 9H-15

................................. Shoulder Belt Retractor 9H-2

................................. Six-way Seat Adjuster 9H-12

................................... Torque Specifications 9H-8

Fuel Tank Filler

Door/Pocket ........................ 6H-7

Gas Support

. Compartment Lift

........................................................... Window 7H-7

............................... General Body Construction 3H-1

.......................................... General Information 1H-1

Glass Installation

........................................... Extended Method 2H-4

................................................. Short Method 2H-3

...................................... Glass Scratch Removal 2H- 1