fuse PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 30 of 1825

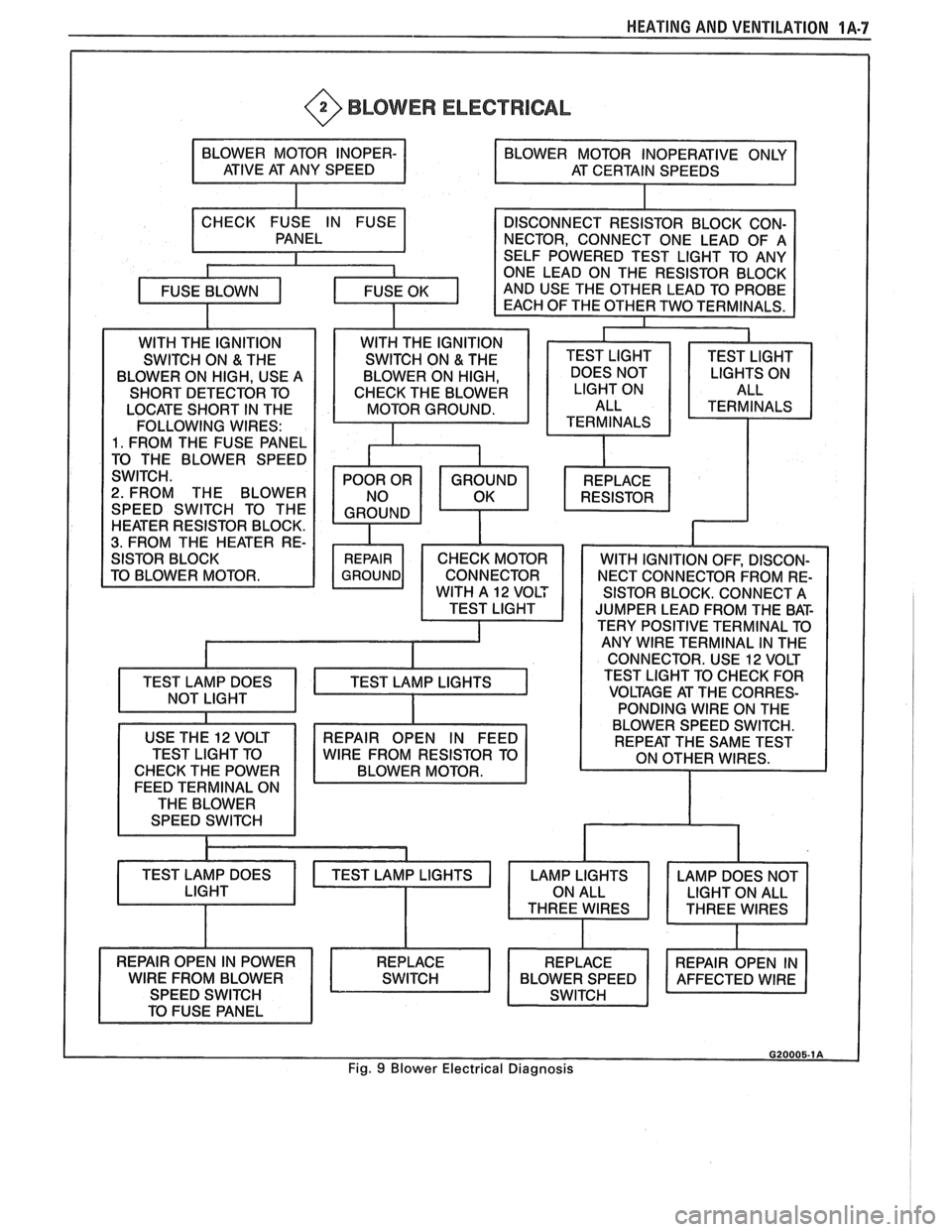

HEATING AND VENTILATION 1A-7

@ BLOWER ELECTRICAL

LOCATE SHORT IN THE

FOLLOWING WIRES:

1. FROM THE FUSE PANEL

2. FROM THE BLOWER

SPEED SWITCH TO THE

HEATER RESISTOR BLOCK.

3. FROM THE HEATER RE-

SISTOR BLOCK. CONNECT A

JUMPER LEAD FROM THE BAT-

TERY POSITIVE TERMINAL TO

ANY

WlRE TERMINAL IN THE

CONNECTOR. USE

12 VOLT

TEST LIGHT TO CHECK FOR

VOLTAGE AT THE CORRES-

PONDING WIRE ON THE

USE THE

12 VOLT

TEST LIGHT TO

CHECK THE POWER

FEED TERMINAL ON

THE BLOWER

SPEED SWITCH

TEST LAMP DOES BLOWER

SPEED SWITCH.

REPAIR OPEN IN FEED

WlRE FROM RESISTOR TO

BLOWER MOTOR.

Fig. 9 Blower Electrical Diagnosis

Page 51 of 1825

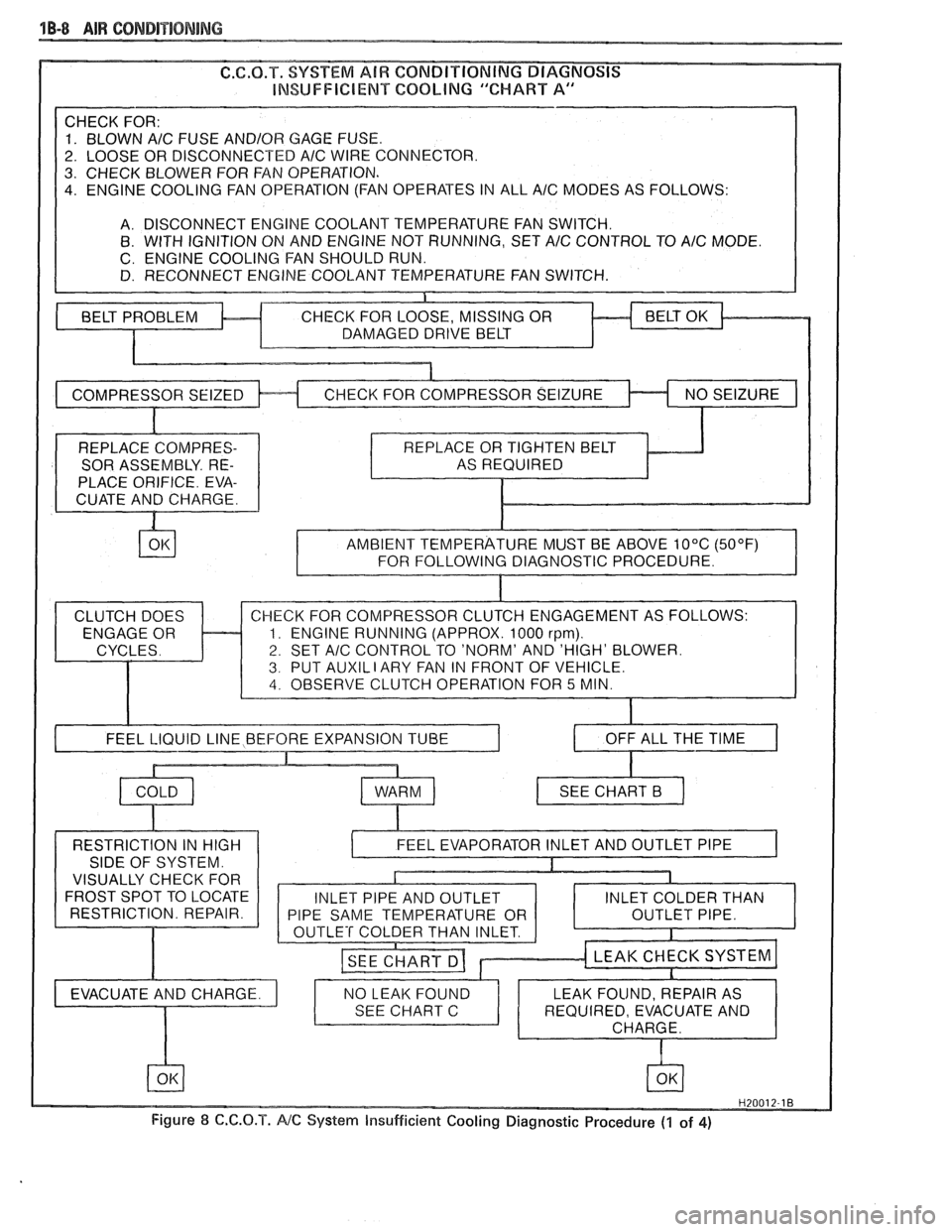

1B-8 AIR CONDITIONING

INSUFFICIENT COQblNG "CHART A

A/C FUSE AND/OR GAGE FUSE.

OR DISCONNECTED

AlC WIRE CONNECTOR.

. CHECK BLOWER FOR FAN OPERATION.

. ENGINE COOLING FAN OPERATION (FAN OPERATES IN ALL A/C MODES AS FOLLOWS:

A. DISCONNECT ENGINE COOLANT TEMPERATURE FAN SWITCH.

8. WITH IGNITION ON AND ENGINE NOT RUNNING, SET A/C CONTROL TO A/C MODE.

C. ENGINE COOLING FAN SHOULD RUN.

D. RECONNECT ENGINE COOLANT TEMPERATURE FAN SWITCH.

REPLACE COMPRES-

SOR ASSEMBLY. RE-

PLACE ORIFICE. EVA-

CUATE AND CHARGE. AS

REQUIRED

AND 'HIGH' BLOWER.

T

AUXIL I ARY FAN IN T OF VEHICLE.

I OFF ALL THE TIME I

RESTRICTION IN HIGH

SIDE OF SYSTEM.

VISUALLY CHECK FOR

FROST SPOT TO LOCATE

RESTRICTION. REPAIR.

Figure

8 C.C.O.T. NC System Insufficient Cooling Diagnostic Procedure (1 of 4)

Page 132 of 1825

STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS 3-7

e To determine if turn signal switch is inoperative,

substitute new turn signal switch into circuit and

operate switch by hand.

If the car's lights operate

normally, turn signal switch is inoperative.

Front Or Rear Turn Signal Lights Not Flashing

Inspect

s Burned-out or damaged turn signal bulb

e High resistance conection to ground at bulb

socket

s Loose chassis-to-column connector. Disconnect

column-to-chassis connector and connect new

turn signal switch into system and operate switch

by hand.

A. If turn signal lights are now on and flashing,

turn signal switch is inoperative.

B. If car lights do not operate, refer to Section

8A

for electrical diagnosis.

Turn Indicator Panel Lights

Inspect

Burned out bulbs or opens, grounds in the wiring

harness from the front turn signal bulb socket to the

indicator lights. Refer to Section

8A for electrical

diagnosis.

Stop Light Mot On When Turn Indicated

Inspect

s Loose column-to-chassis connection

e Disconnect the column-to-chassis connector and

connect the new turn signal switch into the

system and operate the switch by hand.

A. If the brake lights work when the switch is

in the turn position, the turn signal switch

is inoperative.

B. If the brake lights do not work, refer to Section

8A for electrical diagnosis.

Turn Signal Lights Flash Very Slowly

e Loose chassis-to-column connection

a Disconnect the column-to-chassis connector and

connect a new turn signal switch into the system

and operate the switch by hand.

A. If the lights flash at a normal rate, the turn

signal switch is inoperative.

B. If the Lights still flash very slowly, refer to

Section

8A for electrical diagnosis.

Hazard Signal Lights Will Not Flash - Turn

Signal Functions Normally

~"SPBC~

a Blown fuse

Inoperative hazard warning flasher

e Loose chassis-to-column connection

s Disconnect the column-to-chassis connector and

connect a new turn signal switch into the system,

then press in the hazard warning button and

watch the hazard warning lights.

A. If the lights now work normally, the turn

signal switch is inoperative.

B. If the lights do not flash, check the wiring

harness. Refer to Section

8A for electrical

diagnosis.

IGNITION SWITCH

Electrical System Will Not Function

Damaged ign~rion switch

e Ignition switch not adjusted properly

e Loose connector at the ignition switch

Switch Will Not Turn

Inspect

Damaged ignition switch

Switch Cannot Be Set Correctly

Inspect

Switch actuator rod deformed

e Sector to rack engaged in wrong tooth

KEY REMINDER

Figs. 1 through 11 ,

Weminder Continues To Operate With Key Out,

But Stops When Driver's Door Is Closed

e Chips, foreign material in lock cylinder bore

Sticky lock cylinder actuator tip

Damaged or broken reminder switch

Reminder Does Not Sound With Key Fully

Inserted In Lock Cylinder And The Driver's Door

Open

Inspect

1. Power not available to reminder. Refer to Sec-

tion

8A for electrical diagnosis.

2. Open in chassis wiring. Check by separating

chassis-to-column connector. Connect terminals

"E" and "F" female contacts on the chassis

connector (a bent paper clip will work). If the

reminder sounds, repair chassis wiring. If the

reminder does not sound, go to Step

A.

A. Connect a continuity meter (light) to the

male

"E" and "F" column connector

contacts. Push the key all the way into the

lock cylinder. If the light is on when the key

Page 255 of 1825

4819 REAR AXLE

bears against the inner race of the front bearing and a

shoulder on the pinion stem. This spacer is used to

enable accurate bearing pre-load adjustment and

maintain a pre-load on both front and rear pinion

bearings, Adjustment of the fore and aft position of the

pinion is obtained by placing a shim between the rear

pinion bearing cup and axle housing. The differential

case is of two-piece construction and is supported in

the carrier by two tapered roller side bearings. Pre-load

rear axle case by inserting shims between the bearings

and the carrier. The rear axle case assembly is

positioned for proper ring gear to pinion backlash by

varying the shim thickness from side to side. The ring

gear is bolted to the case. Two side gears have splined

bores for driving the axle shafts. They are positioned

to turn in counterbored cavities in the case. The four

rear axle pinions have smooth bores and are held in

position by a pinion cross shaft, mounted and locked

in the rear axle case. All six gears are in mesh with each

other and because the pinion gears turn freely on their

shaft, they act as idler gears when the rear wheels are

turning at different speeds. The pinions and side gears

are backed by steel thrust washers.

LIMITED-SLIP REAR AXLE

The operation of the Limited-Slip differential is

the same as the standard differential, except that there

is additional friction provided by the conical clutches.

Under ordinary driving and cornering conditions, the

cones slip, allowing the outside wheel to turn faster

than the inner. Under poor traction conditions, such as

ice, snow, or loose gravel under one driving wheel, the

increased friction provided by the cones increases the

driving torque available to the wheel with the better

traction. The cones are spring loaded to provide the

increased driving torque under extremely low traction

conditions.

Operation

When the vehicle turns a corner, the outer rear

wheel must turn faster than the inner wheel. The inner

wheel, turning slower than the outer wheel, slows its

differential side gear (as the axle shaft is splined to the

side gear) and the differential pinion gears will roll

around the slowed differential side gear, driving the

other differential side gear and wheel faster.

DIAGNOSIS AND TESTING

Many noises reported as coming from the rear

axle assembly actually originate from other sources

such as tires, road surfaces, front wheel bearings, axle

bearing, engine, transmission, muffler or body

drumming. A thorough and careful check should be

made to determine the source of the noise before

disassembling the rear axle. Noise which originates in

other places cannot be corrected by adjustment or

replacement of parts in the differential. It should also

be remembered that rear axle gears, like any other

mechanical device, are not absolutely quiet and should

be accepted as being commercially quiet unless some

abnormal noise is present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant, approximately 10 miles.

3. Note speed and RPM at which noise occurs. Stop

car and put transmission in neutral. Run engine

slowly up and down through engine speeds,

corresponding to car speed at which noise was

most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure

for test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring seat

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets. The track bar and torque arm must be

bolted securely. Metal-to-metal contact at those

points may result in telegraphing road noise and

normal axle noise which would not be

objectionable if dampened by bushings.

AXLE NOISES

After the noise has been determined as being in

the axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

making repairs if necessary.

Page 257 of 1825

481-4 REAR AXLE

Gear Noise

Gear noise (whine) is audible from 20 to 55 mph

under four driving conditions:

1. Light Acceleration - Accelerate slowly.

2. Road Load

- Car

driving load or constant speed.

3. Float - Using enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast - Throttle closed and car in gear.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

Knock At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Backlash Clunk

Excessive clunk with acceleration and deceleration

is caused by worn differential pinion gear shaft, excessive

clearance between axle shaft and side gear splines, exces-

sive clearance between side gear hub and counterbore in

case, worn pinion and side gear teeth, worn thrust washers

and excessive drive pinion and ring gear backlash. Re-

move worn parts and replace as required, selecting close

fitting parts when possible. Adjust pinion and ring gear

backlash.

DIAGNOSIS

1. Noise

is the same in "Light Acceleration" or

"Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

d. Rear axle bearing noise.

2. Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

3. Noise tone lowers as car speed is lowered.

a. Tire noise.

b. Front

wheel bearings and rear axle bearings.

c. Gear noise.

4. Similar noise is produced with car standing and

driving. a.

Engine noise.

b. Transmission noise.

c. Exhaust noise.

5. Vibration.

a. Rough rear axle bearing.

b. Unbalanced or damaged propeller shaft.

c. Tire unbalance.

d. Worn universal joint in propeller shaft.

e. Mis-indexed propeller shaft at pinion

flange.

f. Pinion flange runout too great.

6. A knock or click approximately every two

revolutions of the rear wheel.

a. A rear axle bearing.

b. Worn case.

7. Noise most pronounced on turns.

a. Rear axle side gear and pinion noise,

differential gear noise.

b. Axle bearings.

8. A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. All bearing noise.

9. Drive noise, coast noise or float noise.

a. Ring

and pinion gear noise.

b. Front

pinion bearing noise, coast or drive.

c. Axle bearing noise.

10. Clunk

on

acceleration or deceleration.

a. Worn

rear axle pinion shaft splines.

b. Side

gear hub counterbore in case worn

oversize.

c. Worn U-joints.

d. Excessive transmission backlash.

e. Worn axle shaft splines.

11. Chatter on turns.

a. Wrong

lube in rear axle.

b. Clutch

cone worn or spalled.

12. Clunk

or knock on rough road operation.

a. Worn suspension bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A carefull diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Before disassembling the rear axle, the following

checks should be made with the results recorded and

analyzed: 1) Backlash;

2) Total Assembly Preload; 3)

Tooth Contact Pattern Test; 4) Fluid Level; and 5)

Fluid Contamination.

If axle shaft end play is excessive then check

bearings, retainer, and bolts securing backing plate.

The axle bearings could be worn and need replacement.

The four bolts or nuts securing the brake backing plate

may be loose, stripped, or missing. If the inner bearing

retainer worked loose it must be replaced.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

Page 276 of 1825

REAR AXLE 4B-3

Noise which originates in other places cannot be

corrected by adjustment or replacement of parts in the

differential. It should also be remembered that rear

axle gears, like any other mechanical device, are not

absolutely quiet and should be accepted as being

commercially quiet unless some abnormal noise is

present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant.

3. Note speed and RPM at which noise occurs. Then

stop car and with automatic transmission in neutral,

run engine slowly up and down through engine speeds, corresponding to car speed at which noise

was most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure for

test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets.

Metal-to-metal contact at those points

may result in telegraphing road noise and normal axle

noise which would not be objectionable if

dampened by bushings.

AXLE NOISES

Gear Noise

After the noise has been determined as being in

the

axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

maki~~g repairs if necessary.

Gear noise (whine) is audible from 20 to

55 mph

under four driving conditions:

1. Drive - Acceleration or heavy pull.

2. Road Load - Car driving load or constant speed.

3. Float

- Using

enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast

- Throttle closed and car in gear. Gear

noise most frequently has periods where noise is

more prominent, usually 30 to 40 mph and 50 to

55 mph.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

I(noclc At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Baclclash Clunk

Excessive clunk with acceleration and

deceleration is caused by worn differential pinion shaft,

excessive clearance between axle shaft and side gear

splines, excessive clearance between side gear hub and

counterbore in case worn pinion and side gear teeth,

worn thrust washers and excessive drive pinion and

rear gear backlash. Remove worn parts and replace as

required, selecting close fitting parts when possible.

Adjust pinion and ring gear backlash.

REAR AXLE STANDARD AND LIMITED-SLIP

1. Noise is the same in "Drive" or "Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

Page 435 of 1825

6C-4 ENGINE FUEL

to fully insert the unleaded gas nozzle will result in

gasoline splashing back out of the filler neck.

Fuel Gage Sending Unit

The fuel gage sending unit is attached to the top

of the fuel tank. It is held in place with a cam lock ring

and a gasket is used between the tank and sending unit.

Sending units have three hoses attached. One line

is for the fuel feed. The second line is connected to the

vapor canister, to keep fuel vapor from getting into the

air (see Section 6E). The third line is used as a fuel

return line to the tank.

On some sending units a wire is attached to the

unit. On others the connectors attach directly to the

sender.

When a fuel gage sending unit is removed always

make sure to install the gasket and any power or

ground leads that were removed.

DIAGNOSIS

Fuel system diagnostic procedures are located in

Section(s) 6E1 thru 6E3.

SERVICE PROCEDURES

If the fuel system is suspected of delivering an

improper amount of fuel, it should be inspected and

tested in the vehicle, as follows:

1. Make certain that there is fuel in the tank.

2. With the engine running, inspect for leaks at all

fuel feed pipe and hose connections from

fuel

tank to injection pump. Tighten any loose

connections. Inspect all hoses for flattening or

kinks which would restrict the flow of fuel. Air

leaks or restrictions on suction side of fuel pump

will seriously affect pump output.

FUEL SYSTEM PRESSURE RELIEF

CAUTION: To reduce risk of fire and

personal injury, it is necessary to

relieve duel system pressure before

servicing fuel system components. To

do this:

Remove "fuel pump" fuse from fuse

block in passenger compartment.

e Crank engine - engine will start and run

until fuel supply remaining in fuel lines is

consumed. Engage starter for

3.0

seconds to assure relief of any remaining

pressure.

e With ignition "OFF", replace duel pump

fuse.

Unless this procedure

is followed before

servicing fuel lines

or connections, fuel

spray could occur.

When repair to the fuel system has been

completed, start engine and check all connections that

were loosened for possible leaks.

Refer to Section 6E for additional diagnosis of

engine fuel system.

Fuel Pump Flow Test

1. Test fuel

pump by connecting hose from EFI fuel

feed line to a suitable unbreakable container.

Apply battery voltage to the fuel pump test

terminal (terminal

"G" of ALCL).

2. Fuel pump should supply

1/2 pint or more in 15

seconds.

3. If flow is below minimum, check for fuel

restriction. If there is no restriction, check pump

pressure.

Fuel System Pressure Test

This test must be performed when diagnosing the

fuel system.

CAUTION: To reduce the risk of fire

and personal injury, it is necessary to

relieve fuel system pressure before

servicing fuel system components on

the

TBI system. To do this:

s Remove "Fuel Pump" fuse from fuse block in

passenger compartment.

e Crank engine. Engine will start and run until fuel

remaining in fuel lines is consumed. Crank the

starter for three seconds to assure that any

remaining pressure is relieved.

e With the ignition off, replace the "Fuel Pump"

fuse.

1. Obtain two

sections of

3/8" steel tubing. Each

should be about 254 mm (10 inches) long.

I

Double-flare one end of each section.

2. Install a flare nut on each section. Connect each i

of the above sections of tubing into the "flare nut 1

to flare nut adapters" that are included in J-29658 i

Gage Adapters.

3. Attach the

pipe and adapter assemblies to the

J-29658 gage.

4. Hoist the car.

5. Disconnect

front fuel feed hose from the fuel pipe

on the body.

1

6. Install a

254 mm (10 inch) length of 3/8" fuel

hose onto the fuel feed pipe on the body. Attach 1

I the other end of the hose onto one of the sections

of pipe mentioned in Step 1. Secure the hose

connections with clamps.

7. Attach the front fuel feed hose onto the other

i

section of tubing mentioned in Step 1. Secure the I

hose connection with a clamp. I

8. Start

the engine and check for leaks. I 9. Observe

the fuel pressure reading. It should be 62

to 90

kPa (9 to 13 psi). If not, refer to the I

appropriate Emissions Section.

10. Depressurize

the fuel system and remove the gage I

with adapters. Reconnect the fuel feed hose to the

pipe and torque the clamp to

1.7 N.m (1 5 lb. in.).

11. Lower

the car. Start the engine and check for fuel

leaks.

Fuel System Pressure Test- MPFl

Fuel system diagnosis is in Section 6E3, Chart

A-7.

Page 493 of 1825

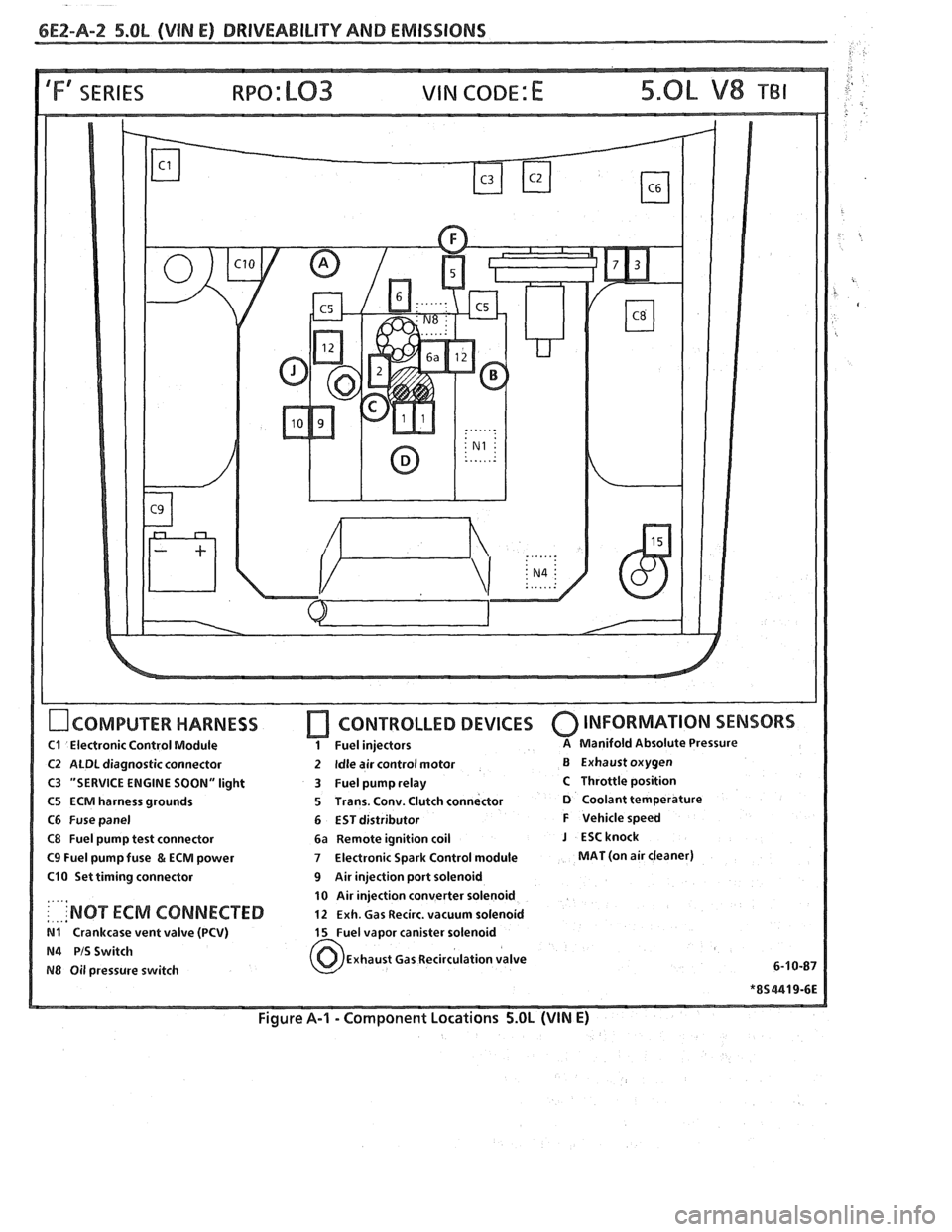

6E2-A-2 5.OL (VIN E) DRIVEABILIW AND EMISSIONS

IFf SERIES VIN CODE: E

OCOMPUTER HARNESS

C1 Electronic Control Module

C2 ALDL diagnostic connector

C3 "SERVICE ENGINE SOON" light

C5 ECM harness grounds

C6 Fuse panel

C8 Fuel pump test connector

C9 Fuel pump fuse & ECM power

C10 Set timing connector

....,

: . ... 'NOT ECM CONNECTED

N1 Crankcase vent valve (PCV)

N4 PIS Switch

N8 Oil pressure switch

[7 CONTROLLED DEVICES 0 INFORMATION SENSORS

1 Fuel injectors A Manifold Absolute Pressure

2 Idle air control motor B Exhaust oxygen

3 Fuel pump relay

C Throttle position

5 Trans. Conv. Clutch connector

D Coolant temperature

6 EST distributor

F Vehicle speed

6a Remote ignition coil

J ESCknock

7 Electronic Spark Control module MAT (on air cleaner)

9 Air injection port solenoid

10 Air injection converter solenoid

12 Exh. Gas Recirc. vacuum solenoid

15 Fuel vapor canister solenoid

Exhaust Gas Recirculation valve

6-1

0-87

Figure A-I - Component Locations 5.OL (VIN E)

Page 501 of 1825

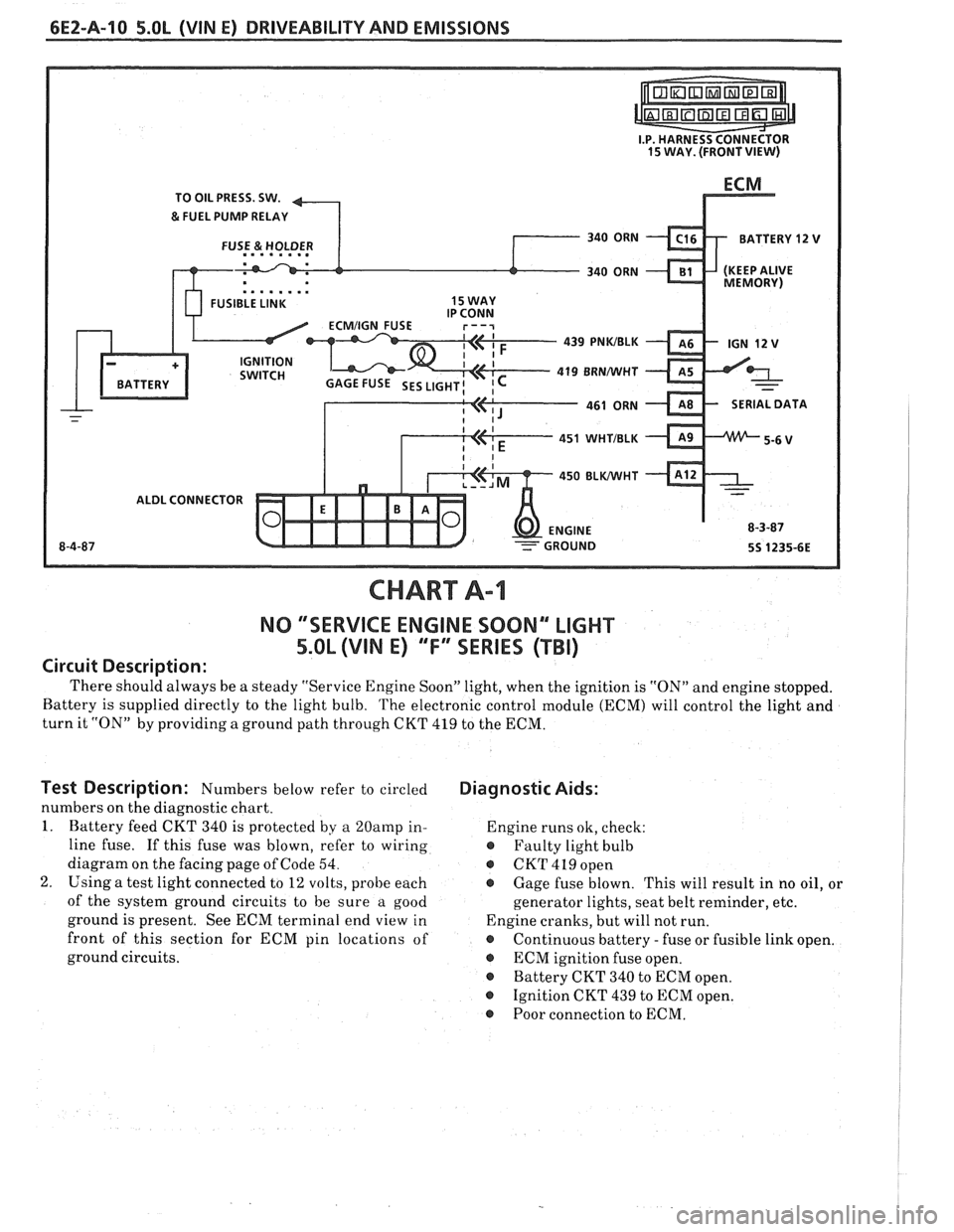

6EZ-A-10 5.0L (VIN E) DRIVEABILITY AND EMISSIONS

TO OIL PRESS. SW.

&FUEL PUMP RELAY

BATTERY

12 V

. . . . . . . . FUSIBLE LINK 15 WAY

439 PNWBLK

419

BRNNVHT

SERIAL DATA

451

WHTIBLK

450 BLWHT

ALDL CONNECTOR

NO "SERVICE ENGINE SOON" "LIGHT

5.OL (VIN E) "F'" SERIES (TBI)

Circuit Description:

There should always be a steady "Service Engine Soon" light, when the ignition is "ON" and engine stopped.

Battery is supplied directly to the light bulb.

The electronic control module (ECM) will control the light and

turn it "ON" by providing a ground path through CKT 419 to the ECM.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. Battery feed CKT 340 is protected by a

20amp in-

line fuse. If this fuse was blown, refer to wiring

diagram on the facing page of Code 54.

2. Using a test light connected to 12 volts, probe each

of the system ground circuits to be sure

a good

ground is present. See ECM terminal end view in

front of this section for ECM pin locations of

ground circuits.

Diagnostic Aids:

Engine runs ok, check:

@ Faulty light bulb

@ CKT419open

@ Gage fuse blown. This will result in no oil, or

generator lights, seat belt reminder, etc.

Engine cranks, but will not run.

@ Continuous battery - fuse or fusible link open.

@ ECM ignition fuse open.

@ Battery CKT 340 to ECM open.

o Ignition CKT 439 to ECM open.

@ Poor connection to ECM.

Page 502 of 1825

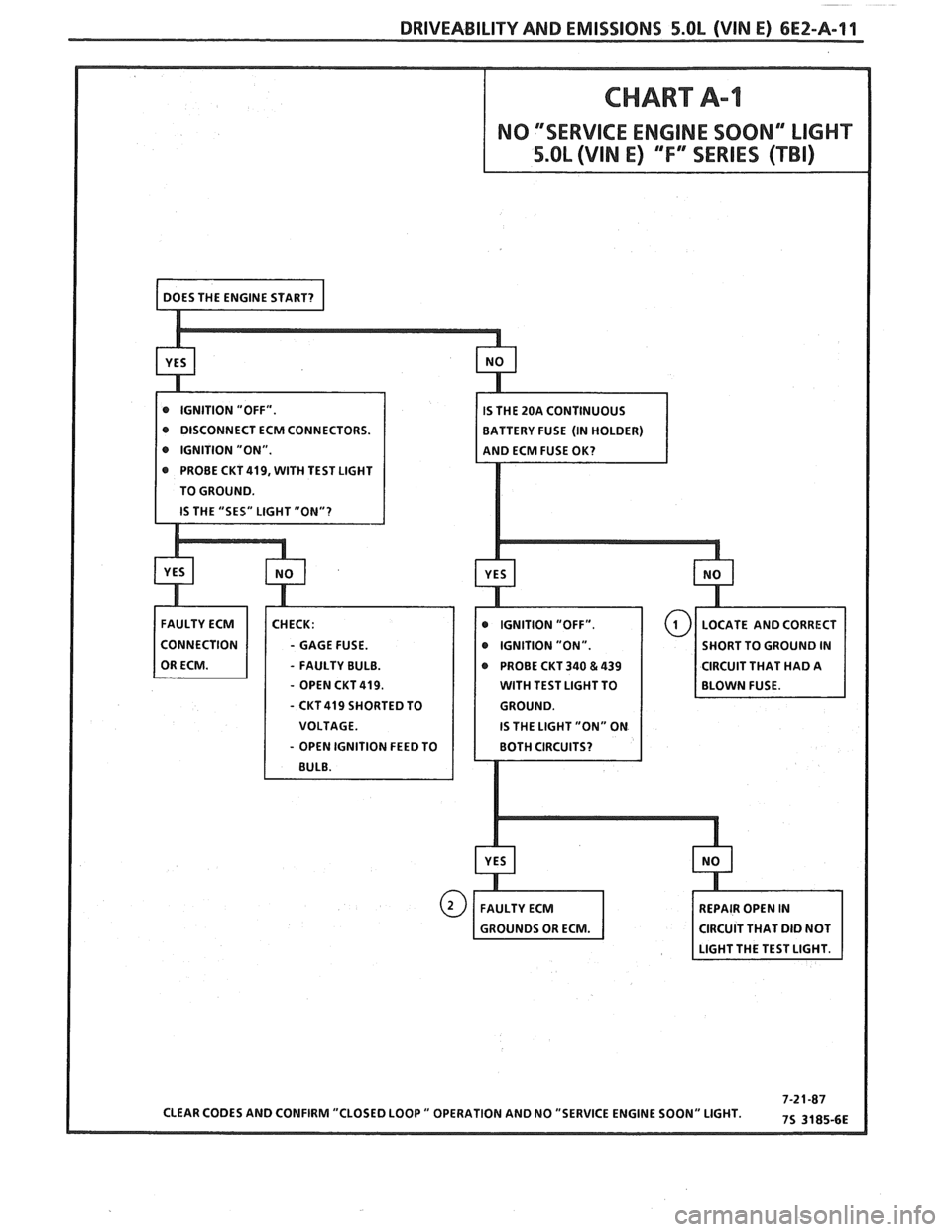

DRIVEABILITY AND EMISSIONS 5.OL (VIN E) 6EZ-A-11

@ DISCONNECT ECM CONNECTORS.

@ IGNITION "ON".

@ PROBE CKT 419, WlTH TEST LIGHT

TO GROUND.

- GAGE FUSE. IGNITION "ON". SHORT TO GROUND IN

- FAULTY BULB. 0 PROBE CKT 340 81 439 CIRCUIT THAT HAD A

- OPEN CKT 419. WITH TEST LIGHT TO

- CKT419 SHORTED TO