low beam PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 135 of 1825

3-10 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

Reminder Keeps Operating With Key In Lock

Cylinder, Driver's Door Open Or Closed; Ceases

When Key Is Removed

Inspect

s Door jamb switch on driver's side misadjusted or

inoperative.

e Wire from signal switch to door jamb switch

shorted.

A. This condition indicates the lock cylinder or

the reminder switch is at fault. To verify,

check for continuity at the

"E" and "F"

male column connector contacts, with the

key removed from the lock cylinder. If

continuity exists, the fault is in the column.

B. Insert the key into the lock, then turn the

lock toward the "Start" position. If the

reminder stops when the key is in the

"Run" position or when it is turned past

"Run" toward "Start," the problem is a

sticky lock cylinder actuator.

COLUMN-MOUNTED DIMMER SWITCH

No "Low" or "High" Beam

Inspect

e Loose connector at dimmer switch

e Improper adjustment

e Internally damaged or worn switch. Check the

continuity on the switch at the It. green and at the

tan switch terminals by pushing in the plunger all

the way.

A click should be heard. If there is no

continuity, replace the dimmer switch. If there is

continuity, refer

to'section 8A for electricaldiag-

nosis.

PIVOT AND SWITCH ASSEMBLY

Switch Inoperative: No "Low," "High" and/or

"Wash"

e Loose body-to-switch connector

a Broken or damaged switch

Internally damaged or worn switch. Connect a

new switch without removing the old one. If the

system functions, replace the switch. If the

system doesn't function, refer to Section

8A for

electrical diagnosis.

STEERING GEAR AND PUMP LEAKS

General Procedure

Inspect

s Overfilled reservoir

s Fluid aeration and overflow

e , Hose connections

Verify exact point of leakage Example:

Torsion bar, stub shaft and

adjuster seals are close together; the exact

spot where the system is leaking may not be

clear.

Example: The point from which the fluid is

dripping is not necessarily the point where

the system is leaking; fluid overflowing from

the reservoir, for instance.

e When service is required:

A. Clean leakage area upon disassembly.

B. Replace leaking seal.

C. Check component sealing surfaces for

damage.

D. Reset bolt torque to specifications, where

required.

Some complaints about the power steering system

may be reported as:

A. Fluid leakage on garage floor

B. Fluid leaks visible on steering gear or pump

C. Growling noise, especially when parking or

when engine is cold

D. Loss of power steering when parking

E. Heavy steering effort

When troubleshooting these kinds of complaints,

check for an external leak in the power steering system.

For further diagnosis of leaks, refer to External

Leakage Check in this section.

External Leakage Check

Fig. 12

The purpose of this procedure is to pinpoint the

location of the leak.

In some cases, the leak can easily be located. But,

seepage-type leaks may be more difficult to isolate. To

locate seepage leaks, use the following method.

1. With the engine off, wipe dry the complete power

steering system.

2. Check the fluid level in the pump's reservoir. Add

fluid if necessary.

3. Start the engine, then turn the steering wheel

from stop to stop several times. Do not hold it at

a stop for any length of time, as this can damage

the power steering pump. It is easier if someone

else operates the steering wheel while you search

for the seepage.

4. Find the exact area of the leak and repair leak.

SEAL REPLACEMENT

RECOMMENDATIONS

Lip seals, which seal rotating shafts, require

special treatment. This type of seal is used on the

steering gear and on the drive shaft of the pump. When

there is a leak in one of these areas, always replace the

seal(s), after inspecting and thoroughly cleaning the

sealing surfaces. Replace the shaft only if very severe

pitting is found. If the corrosion in the lip seal contact

zone is slight, clean the surface of the shaft with crocus

cloth. Replace the shaft only if the leakage cannot be

stopped by first smoothing with crocus cloth.

Page 152 of 1825

STEERING WHEELS AND COLUMNS 385.1

SECTION 3B5

STEER NG WHEELS AND COLUMNS

NOTICE: All steering wheel and column fasteners are important attaching parts in that they could affect

the performance of vital parts and systems, and/or could result in major repair expense. They

must be replaced

with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. 'Torque values must be used as specified during reassembly

to assure proper retention of all parts. There is to be no welding as

it may result in extensive damage and weakening

of the metal.

For prevailing torque

nut(s) and bolts(s), refer to the "Reuse of Prevailing Torque Nut(<) and Bolt(s) " chart

in Section OA.

CONTENTS

..................... ................................................................... GENERAL DESCRIPTION .. 3B5-1 ............................................. ........................ MAINTENANCE AND ADJUSTMENTS .. 3B5-1 ON-CAR SERVICE ........................................................................................................ 3B5-2

Steering Column ............................................................................................................ 3B5-2 ......................................................................................................... Intermediateshaft 3B5-3

Park Lock Cable .................................................................... 3B54 ......................................................................................... Checking For Accident Damage 3B5-5 ............................................................................ Unit Repair Intermediate Shaft Assembly 3B5-6

..................................................................................... Standard Column @lanual Trans) 3B5-7 ......................................................... ....................... Standard Column (Auto Trans) .. 3B5-13 Tilt Column (Manual Trans) ............................................................................................. 3B5-19

Tilt Column (Auto Trans). ................................................................................................ 3B5-27

................ .................... TORQUE SPECIFICATIONS .. .. 3B5-35

SPECIAL TOOLS .......................................................................................................... 3B5-35

GENERAL DESCRIPTION

STEERING COLUMN

The function locking energy absorbing steering

column includes three important features in addition

to the steering function:

1. 'The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of an injury to the driver of the car.

2. The ignition switch and lock are mounted

conveniently on this column.

3. With the column mounted lock, the ignition and

steering operations can be locked to inhibit theft

of the car.

The turn signal lever provides for control of

headlight beams, windshield washer and wipers.

The column may be easily

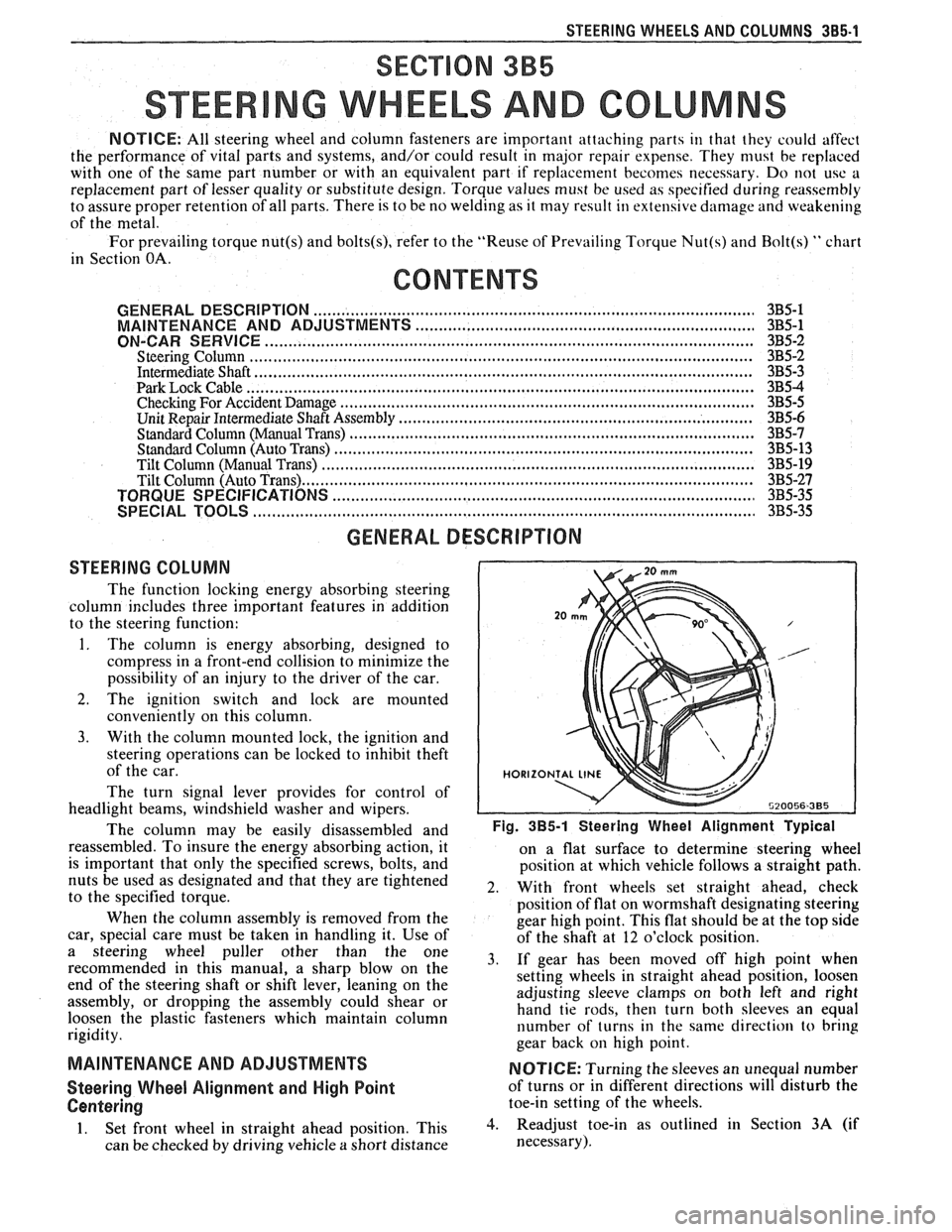

disassembled and Fig. 385-1 Steering Wheel Alignment ~ypical

reassembled. To insure the energy absorbing action, it

on a flat surface to determine steering wheel

is important that only the specified screws, bolts, and

position at which vehicle follows a straight path.

nuts be used as designated and that they are tightened

2. With front wheels set straight ahead, check to the specified torque.

position of flat on wormshaft designating steering

When the column assembly is removed from the

gear high point. This flat should be at the top side

car, special care must be taken in handling it. Use of

of the shaft at 12 o'clock position.

a steering puller other than the One 3, if gear has been moved off high when recommended in this manual, a sharp blow on the

setting wheels in straight ahead position, loosen

end of the steering shaft or shift lever, leaning on the

assembly, or dropping the assembly could shear or adjusting

sleeve clamps on both left and right

hand tie rods, then turn both sleeves an equal

loosen the plastic fasteners which maintain column

rigidity. number

of turns in the same direction

to bring

gear back

on high point.

MAINTENANCE AND ADJUSTMENTS NOTICE: Turning the sleeves an unequal number

Steering Wheel Alignment and High Point of turns or in different directions will disturb the

Centering toe-in setting of the wheels.

1. Set front wheel in straight ahead position, This 3. Readjust toe-in as outlined in Section 3A (if

can be checked by driving vehicle

a short distance necessary).

Page 177 of 1825

3B5-26 STEERING WHEELS AND COLUMNS

7. Lower bearing ASM (71)

8. Lower bearing adapter (70) - 9. Shaft assembly (55-58)

10. Lower shaft (58)

11. Sphere (56) from upper shaft (55) 12. Preload spring (57) from sphere (56)

13. Screws (59)

14. Housing support assembly (60) and dimmer switch rod

If%

15. i<'si release lever (63) and spring (64) 16. Hex nut (68) and hex head bolt (50)

17. Dimmer switch (67)

18. Mounting stud (49)

19. Gear shift lever bowl (65) Ignition switch (48)

and

mountin stud (49)

Preload spring (57) and sphere 156) to upper shaft (55)

Lower shaft (58) to upper shaft (55). block tooth on

shaft end of upper shaft (55) at 12 o'clock position;

notch at end of lower shaft (58) at 4 o'clock position

Shaft assembly

(55-58), lubricated with lithium grease,

to column

Column housing assembly (38) to column. Position col-

umn housing

assemby (38) and align switch actuator

rack (36) with pin on end of actuator rod (48). Pull back

on tilt release lever

(75), pushing column housing as-

sembly (38) onto column housing support assembly

(60). Release tilt release lever (75) to lock shoes

(2526) Remove tilt release lever 175) 12. Lower bearing adapter (70) '

13. Bearing, ASM (71)

In~bll or Connect 14. Retainer (72)

(Figure 2 thru 26) 15. Clip (73)

WTICE: Ensure all fasteners are securely seated before aaplying required torque. Failure to do so may result in component damage or malfunctioning of steering column.

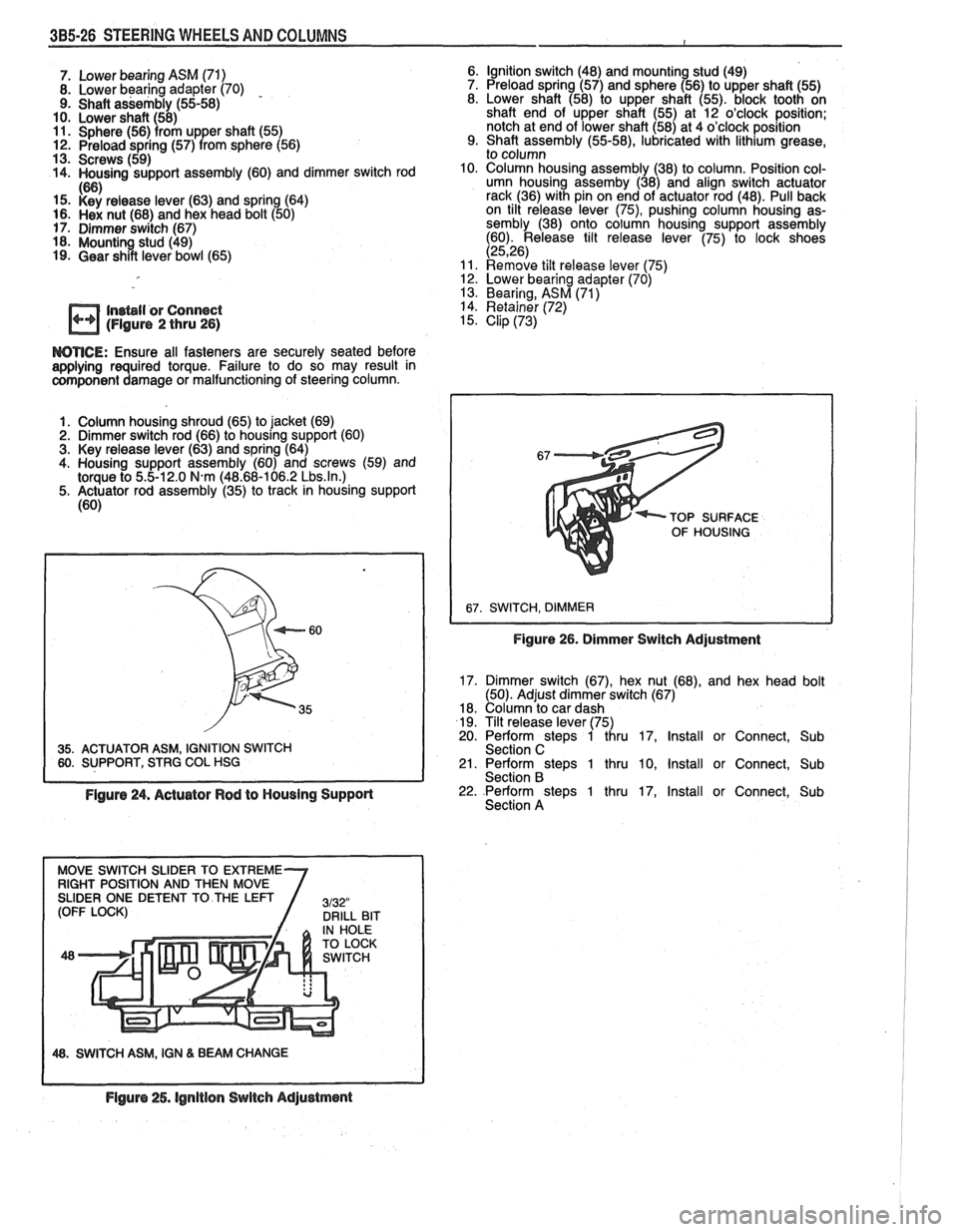

1. Column housing shroud (65) to jacket (69)

2. Dimmer switch rod (66) to housing support (60)

3. Key release lever (63) and spring (64)

4. Housing support assembly (60) and screws (59) and

torque to

5.5-12.0 N.m (48.68-106.2 Lbs.ln.) 5. Actuator rod assembly (35) to track in housing support

(60)

35. ACTUATOR ASM, IGNITION SWITCH 60. SUPPORT, STRG COL HSG TOP

SURFACE

OF HOUSING

Figure 26. Dimmer Switch Adjustment

17. Dimmer switch (67), hex nut (68), and hex head bolt

(50). Adjust dimmer switch (67)

18. Column to car dash

19. Tilt release lever (75)

20. Perform steps 1 thru 17, Install or Connect, Sub

Section C

21. Perform steps 1 thru 10, Install or Connect, Sub

Section B

Figure 24. Actuator Rod to Housing Support 22. Perform steps 1 thru 17, Install or Connect, Sub

Section A

48. SWITCH ASM, IGN & BEAM CHANGE

Flgure 25. lgnitlon Switch Adjustment

Page 185 of 1825

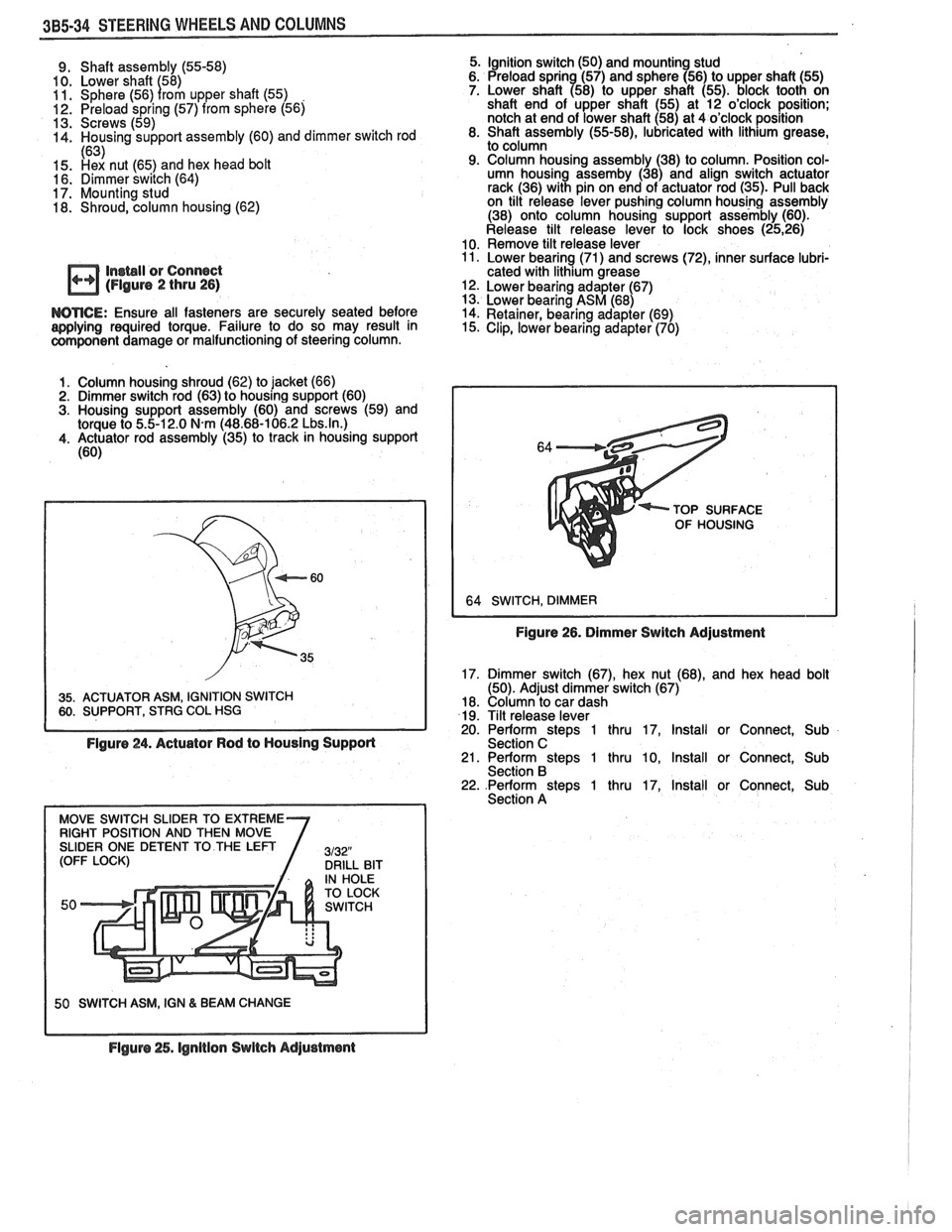

385.34 STEERING WHEELS AND COLUMNS

9. Shaft assembly (55-58)

10. Lower shaft 58)

11. Sphere (56)

I rom upper shaft (55) . 12. Preload spring (57) from sphere (56)

13. Screws (59)

14. Housing support assembly (60) and dimmer switch rod

(63) 15. h& nut (65) and hex head bolt

16. Dimmer switch (64)

17. Mounting stud 18. Shroud, column housing (62)

Insbll or Connect (Flgure 2 thru 26)

WTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

Column housing shroud (62) to jacket (66)

Dimmer switch rod (63) to housing support (60)

Housing support assembly (60) and screws (59) and

torque to 5.5-12.0

N.m (48.68-106.2 Lbs.ln.) Actuator rod assembly (35) to track in housing support

(60)

35. ACTUATOR ASM, IGNITION SWITCH 60. SUPPORT, STRG COL HSG I

Figure 24. Actuator Rod to Housing Supporl

50 SWITCH ASM, IGN & BEAM CHANGE

5. Ignition switch (50) and mounting stud

6. Preload sprin (57) and sphere (56) to upper shaft (55)

7. Lower shaft

a58) to upper shaft (55). block tooth on

shaft end of upper shaft (55) at 12 o'clock position;

notch at end of lower shaft (58) at 4 o'clock position

8. Shaft assembly

(55-58), lubricated with lithium grease,

to column

9. Column housing assembly (38) to column. Position col-

umn housing assemby (38) and align switch actuator

rack (36) with pin on end of actuator rod (35). Pull back

on tilt release lever pushing column housing assembly

(38) onto column housing support assembly (60).

Release tilt release lever to lock shoes

(2526) 10. Remove tilt release lever 11. Lower bearing (71) and screws (72), inner surface lubri-

cated with lithium grease

12. Lower bearing adapter (67)

13. Lower bearing ASM (68)

14. Retainer, bearing adapter

(69) 15. Clip, lower bearing adapter (70)

TOP SURFACE

OF HOUSING

Figure 26. Dimmer Switch Adjustment

17. Dimmer switch

(67), hex nut (68), and hex head bolt

(50). Adjust dimmer switch (67)

18. Column to car dash

19. Tilt release lever

20. Perform

stem 1 thru 17. Install or Connect. Sub

Section C ' 21. Perform steps 1 thru 10, Install or Connect, Sub

Section B 22. .Perform steps 1 thru 17, Install or Connect, Sub

Section A

Flguro 25. lgnltion Switch Adjustment

Page 1167 of 1825

Page

Air Conditioning

Air Delivery

Electronic

.................... 68-0

Manual

....................... 65-0

Blower Controls

Electronic

.................... 66-0

Manual

....................... 63-0

Compressor Controls Electronic

.................... 67-0

Manual

....................... 64-0

................... System Check 62-0

Alarms (Audible)

Chime

......................... 77-0

Antenna(Power) ................... 151-0

Brakes

................. Warning System 41-0

................... Charging system 30-7

...................... Cigar Lighter 114-0

Circuit Breaker Details

PWR ACC Circuit

.......... Breaker 10.1.10.3.10.5.1 1.3

WDO Circuit Breaker

10.1. 10.3. 10.5. 11-4

.......... Component Location Views 201-0

Connectors (Harness Connector Faces) 202-0

el00 .......................... 202-0

............... Junction Block ((2238) 202-2

Coolant Fan

....................... 31-0

Cruise Control

..................... 34-0

Defogger

......................... 61-0

Digital Clock

...................... 150-0

Displays Digital Cluster

.................. 82-0

Coolant Temperature

........... 82-2

Page

......................... Fuel 82-3

................... Oil Pressure 82-2

.................. Speedometer 82-3

................. Door Locks (Power) 130-0

...... Driver Information Center (DIC) 86-0

Engines

... Multi-Port Fuel Injection (VIN S) 20-0

.... Multi-Port Fuel Injection (VIN 8) 23-0

.... Throttle

Body Injection (VIN E) 22-0

...... Tuned

Port Injection (VIN F) 21-0

................. Fuse Block Details 11-0

Fuse Details

........... INST LP 10.0.10.2.10.4.1 1.1

.............. TAIL 10.0.10.2.10.4.1 1.2

................ CRANK 10.0.10.2.1 0.4

.............. CTSY 10~0.10.2.10.4.1 1.2

......... STOP HAZ 10.1.10.3.10.5.1 1.3

............ RADIO 10.1.10.3.10.5.1 1.4

............ WIPER 10.1.10.3.10.5.1 1.4

.................... HATCH 10.2.1 0.4

........... HTR AlC 10.1.10.3.10.5.1 1.4

........... CIH.FAN 10.1.10.3.10.5.1 1.4

......... TURN BIU 10.1.10.3.10.5.1 1.4

............ GAGES 10.1.10.3.10.5.1 1.4

ECM-IGN

(V6 VIN S. V8 VIN F.

........ V8 VIN 8. V8 VIN E) 10.1.1 1.7

............ INJ 1 (V6 VIN S) 10.1.1 1.10

......... FPIINJ 2 (V6 VIN S) 10.1.1 1.10

... INJ 1 (V8 VIN F. V8 VIN 8) 10.3.1 1.11

FPIINJ 2 (V8 VIN F. V8 VIN 8) 10.3.1 1.11

............ CLSTR 10.1.10.3.10.5.1 1.13

............. FPIINJ 2 (V8 VIN E) 11-12

Page

Gages

................... Gages Cluster 81-0

........... Coolant Temperature 81-2

......................... Fuel 81-3

................... Oil Pressure 81-2

.................. Speedometer 81-3

................ Ground Distribution 14-0

Harness Routing Views

............. 203-0

........................... Heater 60-0

............................ Horns 40-0

Indicators

.................. Digital Cluster 82-0

................ Brake Warning 82-4

.................. Fasten Belts 82-1

...................... Hi Beam 82-1

...................... Security 82-1

............ Service Engine Soon 82-4

......................... Shift 82-5

......................... Turn 82-1

................... Gages Cluster 81-0

................ Brake Warning 81-0

.................. Fasten Belts 81-0

...................... Hi Beam 81-0

............ Service Engine Soon 81-0

......................... Shift 81-1

......................... Turn 81-0

Instrument Panel

Digital Cluster

.................. 82-0

Gages Cluster

................... 81-0

............ Interior Lights Dimming 117-0

...................... Introduction 2-0

Lights (Exterior)

........................ Back Up 112-0

...................... Fog 100.3,10 3.0

Page 1181 of 1825

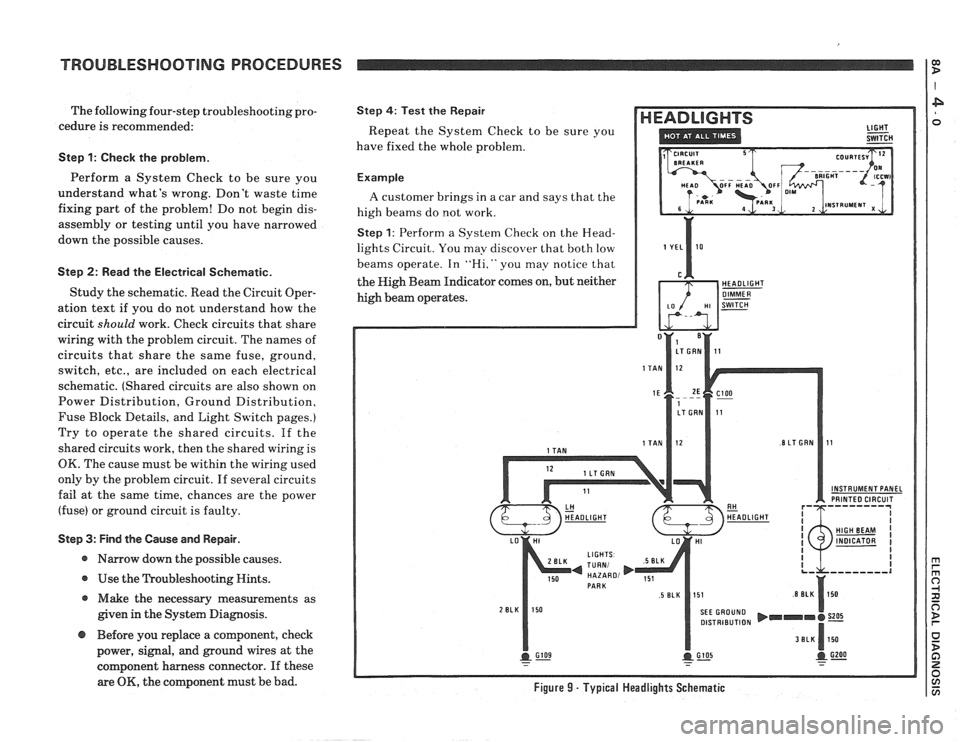

TROUBLESHOOTING PROCEDURES

The following four-step troubleshooting pro-

cedure is recommended:

Step 1: Check the problem.

Perform a System Check to be sure you

understand what's wrong. Don't waste time

fixing part of the problem! Do not begin dis-

assembly or testing until you have narrowed

down the possible causes.

Step 2: Read the Electrical Schematic.

Study the schematic. Read the Circuit Oper-

ation text if you do not understand how the

circuit

should work. Check circuits that share

wiring with the problem circuit. The names of

circuits that share the same fuse, ground,

switch, etc., are included on each electrical

schematic. (Shared circuits are also shown on

Power Distribution, Ground Distribution,

Fuse Block Details, and Light Switch pages.)

Try to operate the shared circuits. If the

shared circuits work, then the shared wiring is

OK. The cause must be within the wiring used

only by the problem circuit. If several circuits

fail at the same time, chances are the power

(fuse) or ground circuit is faulty.

Step 3: Find the Cause and Repair.

* Narrow down the possible causes.

@ Use the Troubleshooting Hints.

@ Make the necessary measurements as

given in the System Diagnosis.

Step 4: Test the Repair

Repeat the System Check to be sure you

have fixed the whole problem.

Example

A customer brings in a car and says that the

high beams do not work.

Step 1: Perform a System Check on the Head-

lights Circuit. You may discover that both low

beams operate. In

"Hi," you may notice that

the High Beam Indicator comes on, but neither

high beam operates.

INSTRUMENT PANEL PRINTED CIRCUIT

DISTRIBUTION

@ Before you replace a component, check

power, signal, and ground wires at the

component harness connector. If these

are

OK, the component must be bad. Figure 9 - Typical Headlights Schematic

Page 1182 of 1825

TROUBLESHOOTING PROCEDURES

Step 2: Read the Headlights electrical sche-

matic, see figure

9. This is the step that will

save you time and labor. Remember, it is

essential to understand how a circuit

should

work, before trying to figure out why it

doesn't.

After you understand how the circuit should

operate, read the schematic again, this time

keeping in mind what you have learned by

operating the circuit.

Since both low beams work. you know that

the

Light Switch. the YEI, wire. the I,o con-

tacts of the Headlight Dimmer Switch. termi-

nal

1E of C100. the TAN wires. and grounds

6105 and G 109 are all good.

Furthermore, since you saw that the High

Beam Indicator came on when the Headlight

Dimmer Switch was moved to Hi. you know

that the Hi contacts of the

dimmer switch and

the

I,T GRN wire between the dimmer switch

and ClOO are good.

At this point. you could test for

voltage at

the RH Headlight with the dimmer switch in

Hi. However. it is extremely unlikely that the

high beam filaments have burned out in

both

headlights. or that both headlight connections

are bad. The cause must be a bad connection at

C100, or a break in the I,T GRN wire between

ClOO and the RH Headlight.

I,T GRN wire, locate the exact trouble point,

and make the repair.

Step 4: Check the repair by performing a sys-

tem check on the Headlights circuit. This, of

course, means making sure that both high

beams, both low beams, and the High Beam

Indicator are all working.

Now suppose that the symptoms were dif-

ferent. You may have operated the Headlights

and found that the low beams were working,

but neither the high beams nor the High Beam

Indicator were working. Looking at the sche-

matic, you might conclude the

following.

It is unlikely that both high beam filaments

and the High Beam Indicator have all burned

out at once. The cause is probably the dimmer

switch or its connector.

You have quickly narrowed the possible

causes down to one specific area, and have

done absolutely

no work on the car itself.

Step 3: Find the cause and repair it. Using the

Component Location List and the correspond-

ing figure. you can quickly find ClOO and the

Page 1406 of 1825

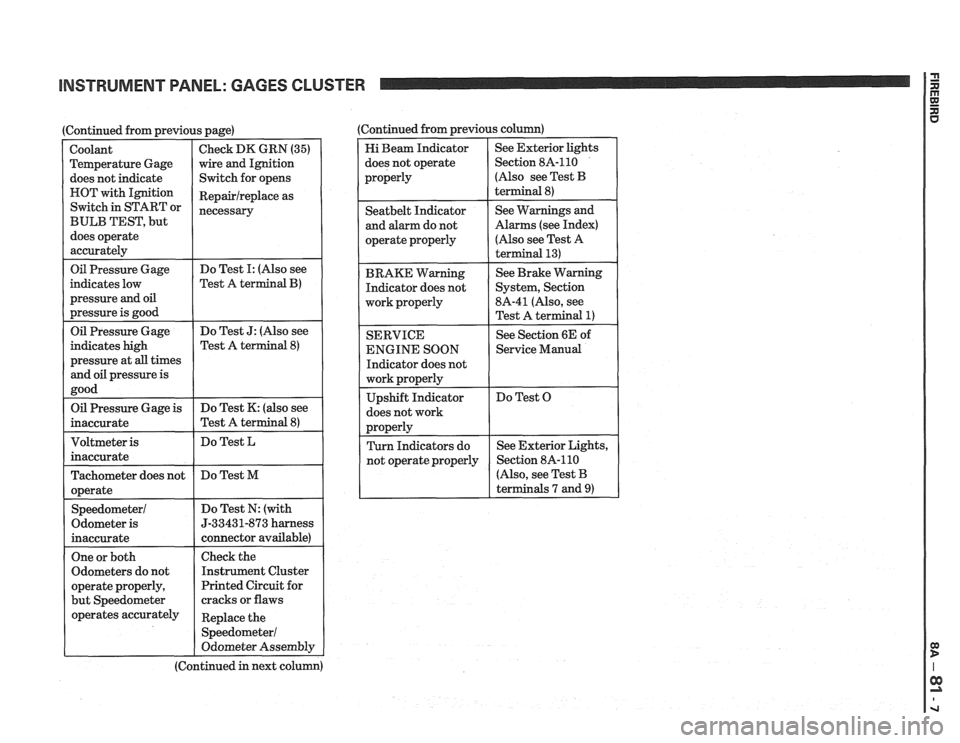

INSTRUMENT PANEL: GAGES CLUSTER

I Oil Pressure Gage

(Continued from previous page)

indicates low

pressure

and oil

pressure is good

Coolant

Temperature Gage

does not indicate

HOT with Ignition

Switch in START or

BULB TEST, but

does operate

accurately

Do Test I: (Also see

Test A

terminal B)

Check DK GRN (35)

wire and Ignition

Switch for opens

Repairlreplace as

necessary

Oil Pressure Gage

indicates high

pressure at

all times

and oil pressure is

good Do

Test

J: (Also see

Test A terminal

8)

Oil Pressure Gage is

inaccurate Do

Test K: (also see

Test A terminal

8)

Do Test L

Tachometer does not

operate

Speedometer1

Odometer is

inaccurate Do

Test M

Do Test N: (with

5-33431-873 harness

connector available)

One or both

Odometers do not

operate properly,

but Speedometer

operates accurately

I

Check the

Instrument Cluster

Printed Circuit for

cracks or flaws

Replace the

Speedometer1

Odometer Assembly

(Continued in next column) (Continued from previous

column)

Hi Beam Indicator

does not operate

properly See

Exterior lights

Section 8A-110

(Also see Test

B

terminal 8)

I operate properly

I

(Also see Test A

I

Seatbelt Indicator

and alarm do not

BRAKE Warning Indicator does not

work properly

I

See Warnings and

Alarms (see Index)

SERVICE

ENGINE SOON

Indicator does not

does not work See

Brake Warning

System, Section

8A-41 (Also, see

Test A terminal

1)

See Section 6E of

1 Service Manual

Do Test O

r

(Also, see Test B

terminals 7 and

9)

Page 1450 of 1825

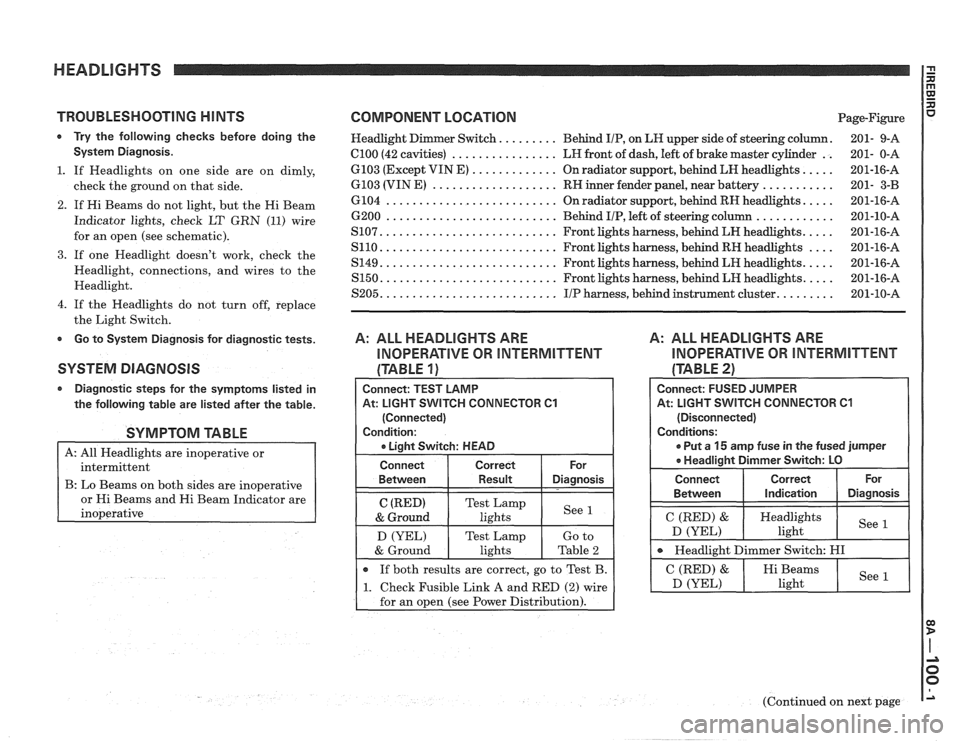

TROUBLESHOOTING HINTS COMPONENT LOCATION Page-Figure

* Try the following checks before doing the Headlight Dimmer Switch. ........ Behind IIP, on LH upper side of steering column. 201- 9-A

System Diagnosis. el00 (42 cavities) ................ LH front of dash, left of brake master cylinder .. 201- 0-A

.... ............. 1. If Headlights on one side are on dimly, 6103 (Except VIN E)

On radiator support, behind LH headlights. 201-16-A

........... ................... check the ground on that side. 6103 (VIN E) RN inner fender panel, near battery 201- 3-B

2. If Hi Beams do not light, but the Hi Beam

Indicator lights, check LT

GRN (11) wire

for an open (see schematic).

3. If one Headlight doesn't work, check the

Headlight, connections, and wires to the

Headlight.

4. If the Headlights do not turn off, replace

the Light Switch.

Go to System Diagnosis for diagnostic tests.

SYSTEM DIAGNOSIS

Diagnostic steps for the symptoms listed in

the following table are listed after the table.

SYMPTOM TABLE

A: All Headlights are inoperative or

intermittent

B: Lo Beams on both sides are inoperative

s and Hi Beam Indicator are

.... .......................... 6104 On radiator support, behind RH headlights. 201-16-A

............ 6200 .......................... Behind IIP, left of steering column 201-10-A

.... .......................... S107. Front lights harness, behind LH headlights. 201-16-A

.... .......................... S110. Front lights harness, behind RH headlights 201-16-A

.... .......................... S149. Front lights harness, behind LH headlights. 201-16-A

.... S150. .......................... Front lights harness, behind LH headlights. 201-16-A

........ S205. .......................... IIP harness, behind instrument cluster. 201-10-A

A: ALL HEADLIGHTS ARE

INOPERATIVE OR INTERMITTENT

(TABLE 1)

A: ALL HEADLIGHTS ARE

INOPERATIVE OR INTERMITTENT

(TABLE 21

Connect: TEST LAMP

At: LIGHT

SVVITCH CONNECTOR C1

(Connected)

Condition:

r Liaht Switch: HEAD

Connect Correct

Between Result Diagnosis

C (RED) Test Lamp

& Ground lights See 1

D

(YEL) Test Lamp

If both results are correct, go to Test B.

1 1. Check Fusible Link A and RED (2) wire

for an open (see Power Distribution).

Connect: FUSED JUMPER

At: LIGHT

SWITCH CONNECTOR C1

(Disconnected)

Conditions:

r Put a 15 amp fuse in the fused jumper

* Headliaiht Dimmer Switch: LO

I Connect 1 Correct ( or 1

Between I Indication 1 Diagnosis I I

I C (RED) & ( Heydlights I See D (YEL) ight

I Headlight Dimmer Switch: HI I

(Continued on next page