oil viscosity PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 55 of 1825

18-12 AIR CONDITIONING

ELEGTRICAWACUUM SYSTEM

DIAGNOSIS

When diagnosing problems in the electrical sys-

tems of the air conditioning system, consult section

8A.

LEAK TESTING THE REFRIGERANT

SYSTEM

Whenever a refrigerant leak is suspected in the

system or a service operation performed which results

in disturbing lines or connections, it is advisable to

test for leaks.

Liquid Leak Detectors

There are a number of locations (fittings,

valves, etc.) on the air conditioning system where a

liquid leak detector solution may be used to pinpoint

refrigerant leaks.

By applying test solution to the area in question

with the swab that is attached to the bottle cap, bub-

bles will form within seconds if there is a leak.

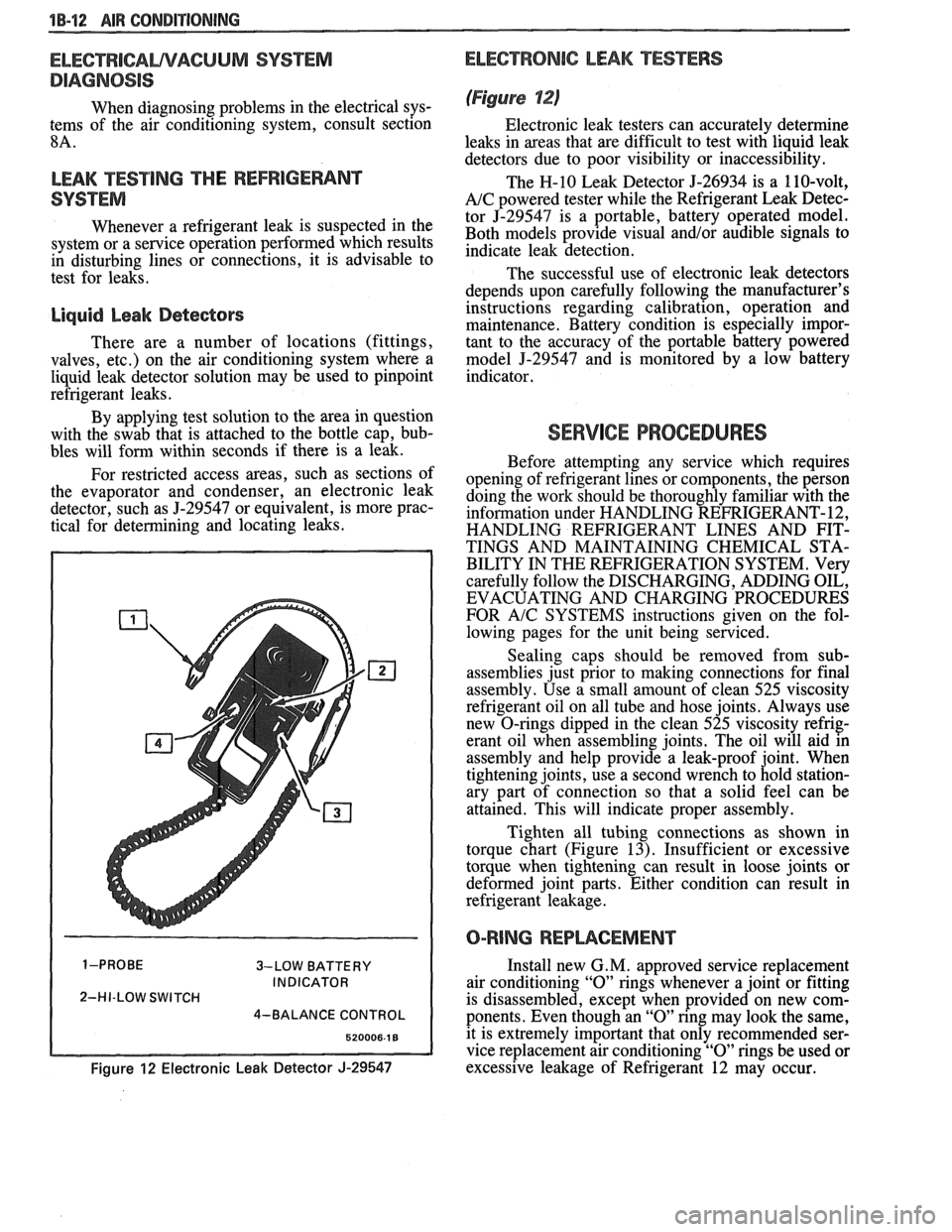

For restricted access areas, such as sections of

the evaporator and condenser, an electronic leak

detector, such as

5-29547 or equivalent, is more prac-

tical for determining and locating leaks.

3-LOW BATTERY

INDICATOR

2-HI-LOW SWITCH

4-BALANCE CONTROL

Figure 12 Electronic Leak Detector J-29547

ELECTRONIC LEAK TESTERS

(Figure 12)

Electronic leak testers can accurately determine

leaks in areas that are difficult to test with liquid leak

detectors due to poor visibility or inaccessibility.

The H-10 Leak Detector 5-26934 is a 110-volt,

A/C powered tester while the Refrigerant Leak Detec-

tor J-29547 is a portable, battery operated model.

Both models provide visual

and/or audible signals to

indicate leak detection.

The successful use of electronic leak detectors

depends upon carefully following the manufacturer's

instructions regarding calibration, operation and

maintenance. Battery condition is especially impor-

tant to the accuracy of the portable battery powered

model

5-29547 and is monitored by a low battery

indicator.

SERVICE PROCEDURES

Before attempting any service which requires

opening of refrigerant lines or components, the person

doing the work should be thoroughly familiar with the

information under HANDLING REFRIGERANT- 12,

HANDLING REFRIGERANT LINES AND FIT-

TINGS AND MAINTAINING CHEMICAL STA-

BILITY IN THE REFRIGERATION SYSTEM. Very

carefully follow the DISCHARGING, ADDING OIL,

EVACUATING AND CHARGING PROCEDURES

FOR

A/C SYSTEMS instructions given on the fol-

lowing pages for the unit being serviced.

Sealing caps should be removed from sub-

assemblies just prior to making connections for final

assembly. Use a small amount of clean 525 viscosity

refrigerant oil on all tube and hose joints. Always use

new O-rings dipped in the clean 525 viscosity refrig-

erant oil when assembling joints. The oil will aid in

assembly and help provide a leak-proof joint. When

tightening joints, use a second wrench to hold station-

ary part of connection so that

a solid feel can be

attained. This will indicate proper assembly.

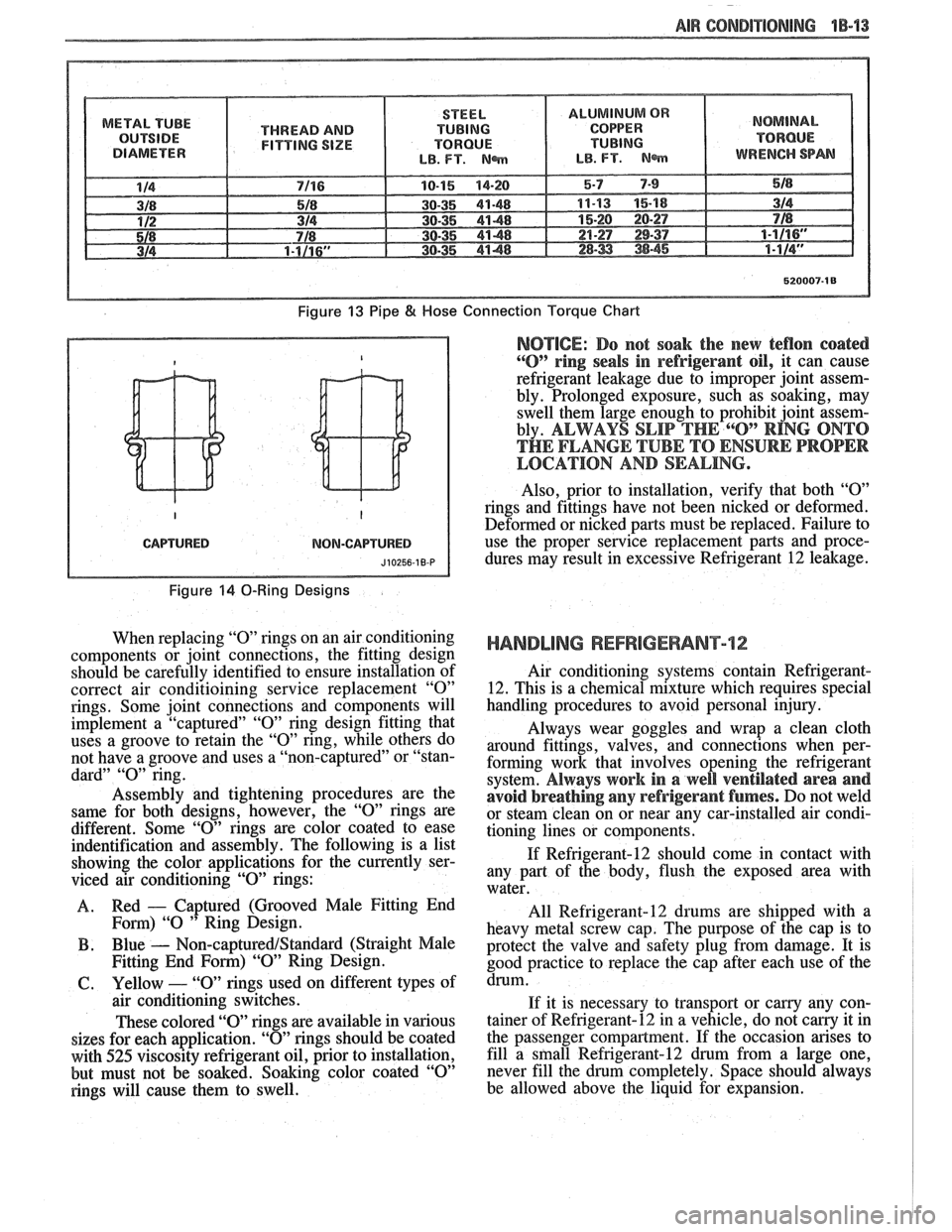

Tighten all tubing connections as shown in

torque chart (Figure

13). Insufficient or excessive

torque when tightening can result in loose joints or

deformed joint parts. Either condition can result in

refrigerant leakage.

O-RING REPWCEMENT

Install new G. M. approved service replacement

air conditioning

"0" rings whenever a joint or fitting

is disassembled, except when provided on new com-

ponents. Even though an

"0" ring may look the same,

it is extremely important that only recommended ser-

vice replacement air conditioning

"0" rings be used or

excessive leakage of Refrigerant 12 may occur.

Page 56 of 1825

-

AIR CONDlTlQNlNG 1B-'13

METAL TUBE

THREAD AND

FITTING SIZE

Figure 13 Pipe 8( Hose

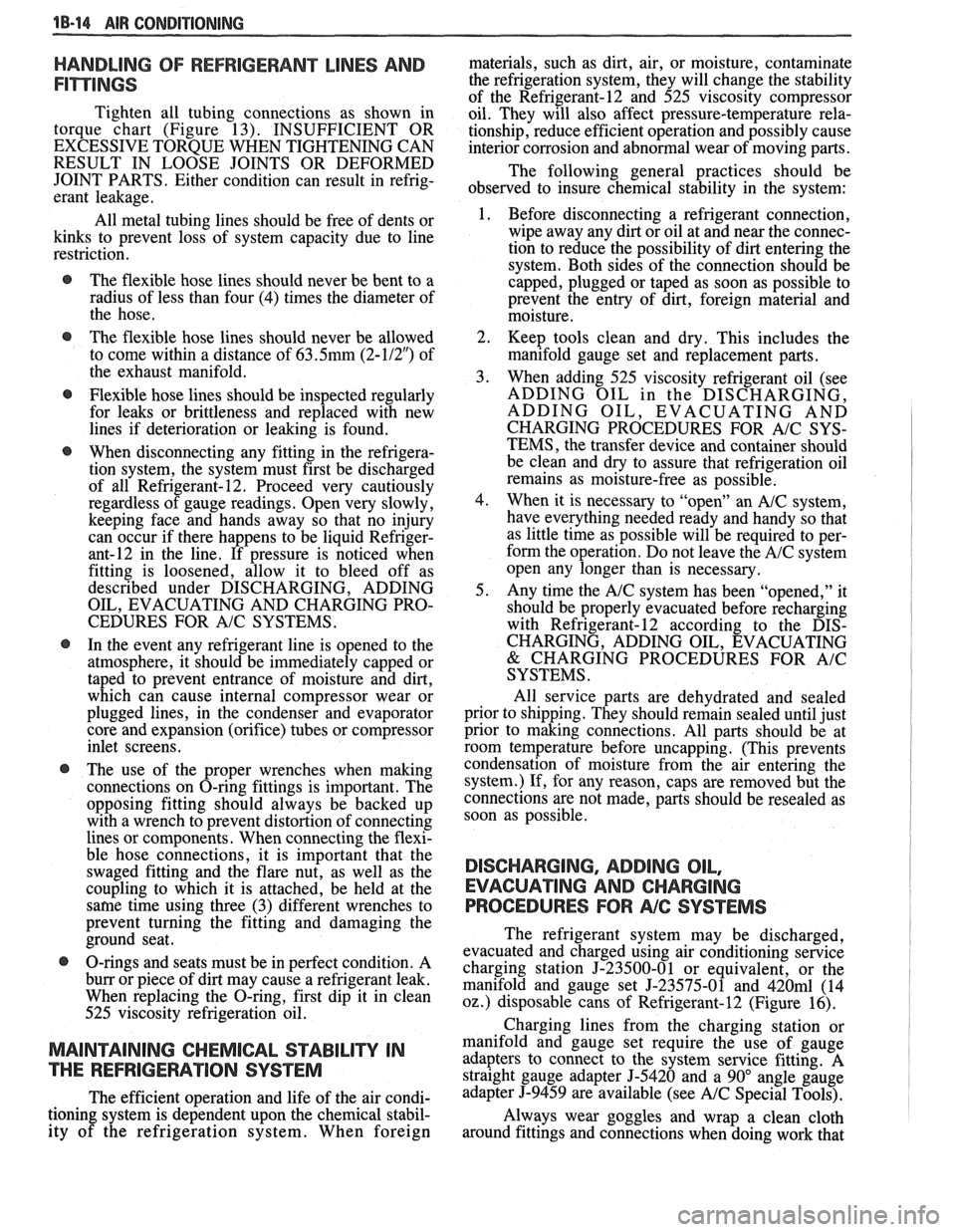

CAPTURED NOM-CAPTURED

Figure 14 0-Ring Designs

When replacing "0" rings on an air conditioning

components or joint connections, the fitting design

should be carefully identified to ensure installation of

correct air conditioining service replacement

"0"

rings. Some joint connections and components will

implement a "captured"

"0" ring design fitting that

uses a groove to retain the

"0" ring, while others do

not have a groove and uses a "non-captured" or "stan-

dard"

"0" ring.

Assembly and tightening procedures are the

same for both designs, however, the

"0" rings are

different. Some

"0" rings are color coated to ease

indentification and assembly. The following is a list

showing the color applications for the currently ser-

viced air conditioning

"0" rings:

A. Red

- Captured

(Grooved Male Fitting End

Fom) "0 " Ring Design.

B . Blue - Non-captured/Standard (Straight Male

Fitting End

Form) "09' Ring Design.

61. Yellow - "0" rings used on different types of

air conditioning switches.

These colored "O" rings are available in various

sizes for each application.

"0" rings should be coated

with

525 viscosity refrigerant oil, prior to installation,

but must not be soaked. Soaking color coated

"0"

rings will cause them to swell.

Connection Torque Chart

NOTICE: Do not soak the new teflon coated

"0" ring seals in refrigerant oil, it can cause

refrigerant leakage due to improper joint assem-

bly. Prolonged exposure, such as soaking, may

swell them large enough to prohibit joint assem-

bly.

ALWAYS SLIP THE 6"O" RING ONTO

THE FLANGE TUBE TO ENSURE PROPER

LOCATION AND SEALING.

Also, prior to installation, verify that both "09'

rings and fittings have not been nicked or deformed.

Deformed or nicked

parts must be replaced. Failure to

use the proper service replacement parts and proce- dures may result in excessive Refrigerant

12 leakage.

HANDLING REFRIGERANT12

Air conditioning systems contain Refrigerant-

12. This is a chemical mixture which requires special

handling procedures to avoid personal injury.

Always wear goggles and wrap a clean cloth

around fittings, valves, and connections when per-

forming work that involves opening the refrigerant

system.

Always work in a well ventilated area and

avoid breathing

any refrigerant fumes. Do not weld

or steam clean on or near any car-installed air condi-

tioning lines or components.

If Refrigerant-12 should come in contact with

any part of the body, flush the exposed area with

water.

All

Refrigerant-12 drums are shipped with a

heavy metal screw cap. The purpose of the cap is to

protect the valve and safety plug from damage. It is

good practice to replace the cap after each use of the

drum.

If it is necessary to transport or carny any con-

tainer of Refrigerant-12 in a vehicle, do not

carry it in

the passenger compartment. If the occasion arises to

fill a

sfnall Refrigerant-12 drum from a large one,

never fill the drum completely. Space should always

be allowed above the liquid for expansion.

Page 57 of 1825

18-14 AIR CONDITIONING

HANDLING OF REFRIGERANT LINES AND

FI-INGS

Tighten all tubing connections as shown in

torque chart (Figure 13). INSUFFICIENT OR

EXCESSIVE TORQUE WHEN TIGHTENING CAN

RESULT IN LOOSE JOINTS OR DEFORMED

JOINT PARTS. Either condition can result in refrig-

erant leakage.

All metal tubing lines should be free of dents or

kinks to prevent loss of system capacity due to line

restriction.

@ The flexible hose lines should never be bent to a

radius of less than four (4) times the diameter of

the hose.

@ The flexible hose lines should never be allowed

to come within a distance of

63.5mm (2-112") of

the exhaust manifold.

@ Flexible hose lines should be inspected regularly

for leaks or brittleness and replaced with new

lines if deterioration or leaking is found.

@ When disconnecting any fitting in the refrigera-

tion system, the system must first be discharged

of all Refrigerant- 12. Proceed very cautiously

regardless of gauge readings. Open very slowly,

keeping face and hands away so that no injury

can occur if there happens to be liquid

Refriger-

ant-12 in the line. If pressure is noticed when

fitting is loosened, allow it to bleed off as

described under DISCHARGING, ADDING

OIL, EVACUATING AND CHARGING PRO-

CEDURES FOR

A/C SYSTEMS.

@ In the event any refrigerant line is opened to the

atmosphere, it should be immediately capped or

taped to prevent entrance of moisture and dirt,

which can cause internal compressor wear or

plugged lines, in the condenser and evaporator

core and expansion (orifice) tubes or compressor

inlet screens.

@ The use of the proper wrenches when making

connections on O-ring fittings is important. The

opposing fitting should always be backed up

with a wrench to prevent distortion of connecting

lines or components. When connecting the flexi-

ble hose connections, it is important that the

swaged fitting and the flare nut, as well as the

coupling to which it is attached, be held at the

same time using three

(3) different wrenches to

prevent turning the fitting and damaging the

ground seat.

@ O-rings and seats must be in perfect condition. A

burr or piece of dirt may cause a refrigerant leak.

When replacing the O-ring, first dip it in clean

525 viscosity refrigeration oil.

MAINTAINING CHEMICAL STABILITY IN

THE

REFRIGERATION SYSTEM

The efficient operation and life of the air condi-

tioning system is dependent upon the chemical stabil-

ity of the refrigeration system. When foreign materials, such as

dirt, air, or moisture, contaminate

the refrigeration system, they will change the stability

of the Refrigerant-12 and 525 viscosity compressor

oil. They will also affect pressure-temperature rela-

tionship, reduce efficient operation and possibly cause

interior corrosion and abnormal wear of moving parts.

The following general practices should be

observed to insure chemical stability in the system:

1. Before disconnecting a refrigerant connection,

wipe away any dirt or oil at and near the connec-

tion to reduce the possibility of dirt entering the

system. Both sides of the connection should be

capped, plugged or taped as soon as possible to

prevent the entry of dirt, foreign material and

moisture.

2. Keep tools clean and dry. This includes the

manifold gauge set and replacement parts.

3. When adding 525 viscosity refrigerant oil (see

ADDING OIL in the DISCHARGING,

ADDING OIL, EVACUATING AND

CHARGING PROCEDURES FOR

AIC SYS-

TEMS, the transfer device and container should

be clean and dry to assure that refrigeration oil

remains as moisture-free as possible.

4. When it is necessary to "open" an

AIC system,

have everything needed ready and handy so that

as little time as possible will be required to per-

form the operation. Do not leave the

AIC system

open any longer than is necessary.

5. Any time the

A/C system has been "opened," it

should be properly evacuated before recharging

with Refrigerant- 12 according to the DIS-

CHARGING, ADDING OIL, EVACUATING

& CHARGING PROCEDURES FOR AIC

SYSTEMS.

All service parts are dehydrated and sealed

prior to shipping. They should remain sealed until just

prior to making connections. All parts should be at

room temperature before uncapping. (This prevents

condensation of moisture from the air entering the

system.) If, for any reason, caps are removed but the

connections are not made, parts should be resealed as

soon as possible.

DISCHARGING, ADDING OIL,

EVACUATING AND CHARGING

PROCEDURES FOR NC SYSTEMS

The refrigerant system may be discharged,

evacuated and charged using air conditioning service

charging station J-23500-01 or equivalent, or the

manifold and gauge set

5-23575-01 and 420ml (14

oz.) disposable cans of Refrigerant-12 (Figure 16).

Charging lines from the charging station or

manifold and gauge set require the use of gauge

adapters to connect to the system service fitting.

A

straight gauge adapter 5-5420 and a 90" angle gauge

adapter

5-9459 are available (see A/C Special Tools).

Always wear goggles and wrap a clean cloth

around fittings and connections when doing work that

Page 58 of 1825

AIR GONDlTlONlNG 1B-15

involves opening the refrigeration system. Always

work in a well ventilated area and avoid breathing any

refrigerant fumes. If liquid refrigerant comes into con-

tact with the eyes, injury may result.

@ Before removing and replacing any of the air

conditioning refrigeration lines or components,

the system must be completely discharged of

Refrigerant- 12.

@ Always use service valve and pressure gauge

sets during evacuation and charging procedures.

@ Always discharge system at low-side service fit-

ting and perform the entire evacuate and charg-

ing procedure through the low-side service

fitting.

@ Do not connect high-pressure line or any line to

the high-side

service fitting during discharging

and charging procedures.

CAUTION: Never remove a gauge line

from its adapter when line is connected

to

AIC system. Always remove the line

adapter from the service

fining to dis-

connect a line. Do not remove charging

hose at gauge set while

anached to ser-

vice low-side

fining. This will result in

complete discharge of system due to

the depressed Schrader valve in

service

low-side fining and may cause personal

injury due to escaping Refrigerant-12.

Discharging the NG System

In replacing any of the air conditioning refriger-

ation components, the system must be completely dis-

charged of Refrigerant- 12.

ALWAYS DISCHARGE SYSTEM AT

LOW-SIDE SERVICE FITTING.

1. With ignition turned "OFF," remove protective

cap from LOW-SIDE service fitting (on most

models) on Accumulator and connect charging

station

J-23500-01 or equivalent gauge set. If

charging station J-23500-01 or equivalent is not

being used, discharge system by slowly con-

necting a gauge hose to low-side

sewice fitting

on accumulator and discharging into oil bottle

(Figure 15). As hose is slowly tightened down

onto Schrader valve, Refrigerant-12 will begin

to discharge from the system into the container.

If no discharge occurs, check for missing or

defective Schrader depressor in hose fitting.

2. With the low-side of system fully discharged,

check high-side system fitting (on liquid line or

muffler) for remaining pressure.

3. If pressure is found, attempt to discharge high-

side using same procedure as used for low-side.

(This condition indicates a restriction on the

high-side and the cause must be diagnosed and

corrected before evacuating and charging the

system.)

4. When the system is completely discharged (no

vapor escaping with hose fully tightened down), measure, record

amount, and discard the col-

lected refrigerant oil. If the measured quantity is

15ml (112 fl. 02.) or more, this amount of new

525 viscosity refrigerant oil must be added to system, plus any quantity in removed parts

before system evacuation and charging with

Refrigerant-12 (see REFRIGERANT OIL DIS-

TRIBUTION for specific quantity of oil nor-

mally retained in removed parts).

Adding Oil to the Air Conditioning

Refrigerant System

ADDING OIL TO THE A/C SYSTEM should

take place AFTER discharge and BEFORE evacua-

tion procedures by removing the refrigeration suction

hose at the accumulator outlet pipe connection, pour-

ing the correct quantity of new refrigerant oil into the

hose or pipe and then properly reconnecting hose to

pipe (see REFRIGERANT OIL DISTRIBUTION for

specific quantity instructions).

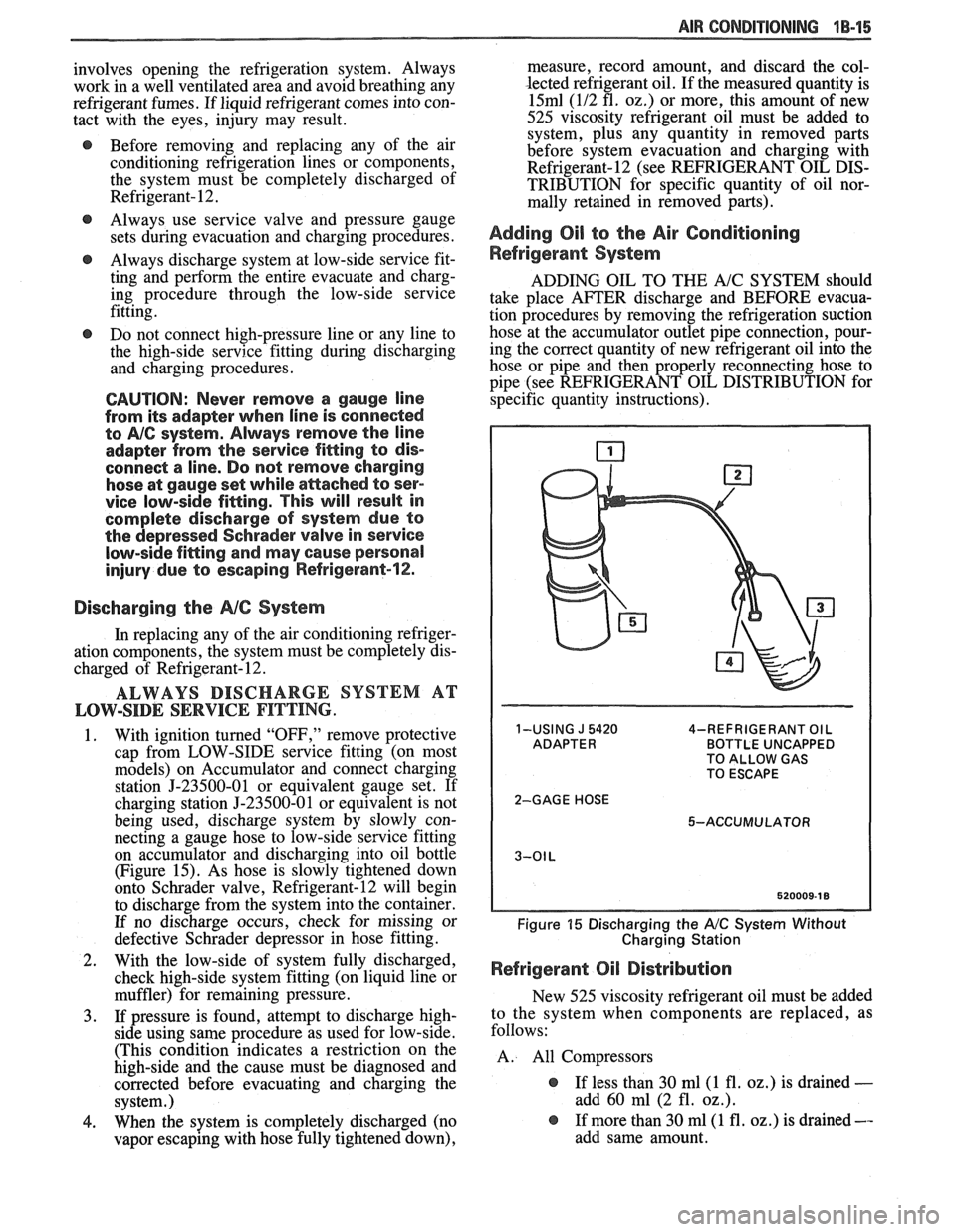

1-USING J 5420 4-REFRIGERANT OIL BOTTLE UNCAPPED

TO ALLOW GAS

TO ESCAPE

2-GAGE HOSE 5-ACCUMULATOR

Figure 15 Discharging the A/C System Without

Charging Station

Refrigerant Oil Distribution

New 525 viscosity refrigerant oil must be added

to the system when components are replaced, as

follows:

A. All Compressors

@ If less than 30 ml(1 fl. oz.) is drained -

add 60 ml (2 fl. oz.).

@ If more than 30 ml(1 fl. oz.) is drained --

add same amount.

Page 59 of 1825

"18-16 AIR CONDITIONING

B . Accumulator dehydrator

@ Add 105 ml (3.5 fl. 02.) to new

accumulator

C. Evaporator

@ Add 90 ml (3 fl. oz.) oil

D. Condenser

@ Add 30 ml (1 fl. 02.) oil

Refrigerant oil loss due to a large leak

If the refrigerant charge is aburptly lost due to a

large refrigerant leak, approximately 90

ml (3 fl. oz.)

of refrigerant oil will be

carried out of the system sus-

pended in the refrigerant. Any failure that caused an

abrupt refrigerant discharge will experience this oil

loss. Failures that allow the refrigerant to seep or

bleed off over time do not experience this oil loss.

Upon replacement of a component which

caused a large refrigerant leak, add 90 ml(3

fl. oz.) of

new 525 viscosity refrigerant oil plus the required

amount of oil for the particular component (as out-

lined above).

Add the oil directly to the replaced component if

possible. If the oil cannot easily be added to the

replaced part, add the oil to the accumulator.

Evacuating and Charging the A/C System

If the system has been opened for any repair, or

the Refrigerant-12 charge lost, the system must be

evacuated prior to charging.

Evacuating and charging is a combined proce-

dure, and all gauge lines must be purged with R-12

prior to charging.

There are three evacuate and charge procedures.

1.

J 23500-01 Charging Station Method

2. Disposable Can Method 3. Drum Method

NOTICE: Under no circumstances should alco-

hol be used in the system in an attempt to remove

moisture. Damage to the system components

could occur.

Gauge Calibration

Prior to evacuation, check the low-pressure

gauge for proper calibration and determine if vacuum

system is operating properly.

With the gauge disconnected from the refrigera-

tion system, be sure that the pointer indicates to the

center of

"0". Lightly tap gauge a few times to be sure

pointer is not sticking. If necessary, calibrate as

follows:

1. Remove cover from gauge.

2. Holding gauge pointer adjusting screw firmly

with one hand, carefully force pointer in the

proper direction to position pointer at the

"0"

position. Tap gauge a few times to be sure

pointer is not sticking. Replace gauge cover.

Vacuum System Check

Before connecting vacuum pump to the A/C

system, run pump connected to the low-pressure

gauge to determine the vacuum pump capability. If

the vacuum system is unable to reach

7 1 1.2-736.6mm

(28"-29") or more vacuum, the system should be

checked for leaks. If no leaks are found, the vacuum

pump may require repair.

5-23580-81 OR EQUIVALENT CHARGING

STATION METHOD.

Follow charging instructions provided with the

5-23500-01 Charging Station or equivalent in use with

the following exceptions:

1. Do

not connect the high-pressure line to the air

conditioning system.

2. Keep the high-pressure valve on the charging

station closed at all times.

3.

Perform the entire evacuate and charge proce-

dure through the accumulator low-side pressure service fitting.

4. Following these procedures will prevent acci-

dental high-side vehicle system pressure being

subjected to the charging station in the event an

error is made in valve sequence during compres-

sor operation to pull in the Refrigerant-12

charge.

DISPOSABLE CAN OR REFRIGERANT

DRUM METHOD.

If the Refrigerant-12 drum is used, place it on a

scale and note the total weight before charging. Watch

the scale during charging to determine the amount of

R-12 used.

If disposable

420ml (14 ounce) R-12 cans are

used, close the tapping valve and then attach

can(s)

following instructions included with the tapping valve

or tapping manifold adapter.

1. Connect manifold gauge set 5-23575-01 as fol-

lows. Also see Figure 16.

a. Eow-pressure gauge to accumulator fit-

ting.

b. Gauge set center hosk to Refrigerant-12

source.

c. High-pressure gauge to vacuum pump.

2. To begin evacuation of the

A/C system with

manifold gauge set and vacuum pump as illus-

trated in Figure 16, slowly open

high- and low-

side gauge valves and begin vacuum pump oper-

ation. Pump the system until the low-side gauge

reaches 7 1

1.2-736.6mm (28"-29") vacuum.

Note that in all evacuation procedures, the spec-

ification of 7 1

1.2-736.6mm (28"-29") vacuum is

used. This specification can only be reached at

or near sea level. For each

304.8m (1,000 feet)

above sea level, specification should be lowered

by one inch vacuum. At

1524m (5,000 feet)

elevation, only

584.2-609.6mm (23"-24") of

vacuum is required.

Page 62 of 1825

AIR CONDITIONING 18-19

3. Push the tube into the fitting, bottoming it out.

Tighten

@ Torque nut to 15 Nam (11 lbs. ft.).

4. Dissasemble the joint.

5. Lubricate the

"0" ring with clean 525 viscosity

refrigerant oil.

6. Install the

"0" ring

on the tube. (See figure 17b)

7. Reassemble joint.

Tighten

@ Torque nut to 15 Nem (11 lbs. ft.).

8. Evacuate, charge, and leak test the system.

EXPANSlON "%BE (ORIFICE) SERVlCE

Remove or Disconnect

1. Discharge system.

2. Loosen fitting

at liquid line to evaporator inlet

pipe and remove tube carefully with needle

nosed pliers or Tool

5-26549-C or equivalent.

Install or Connect

1. Install

new orifice tube with shorter screen end

in first.

2. Install

liquid line and torque to proper

specification.

3. Evacuate and charge system.

In the event that difficulty is encountered during

the removal of a restricted or plugged expansion tube

(orifice tube), the following procedure is recom-

mended:

1. Remove

as much of any impacted residue as

possible.

2. Carefully apply heat with heat gun (hair drier,

epoxy drier or equivalent) approximately

114

inch from dimples on inlet pipe. Do not over-

heat pipe.

NOTICE: If the system has a pressure switch

near the orifice tube location, it should be

removed prior to heating the pipe to avoid dam-

age to switch.

3. While applying heat, use orifice removal tool

5-26549-C to grip the orifice tube. Use a turning

motion along with a push-pull motion to loosen

to the impacted orifice tube and remove it.

4. Swab inside of evaporator inlet pipe with R-11.

5, Add

1 oz. of 525 viscosity refrigerant oil to

system.

6. Lubricate new orifice tube and O-ring with 525'

viscosity refrigerant oil and insert into inlet

pipe. Install in proper direction (smaller screen

first).

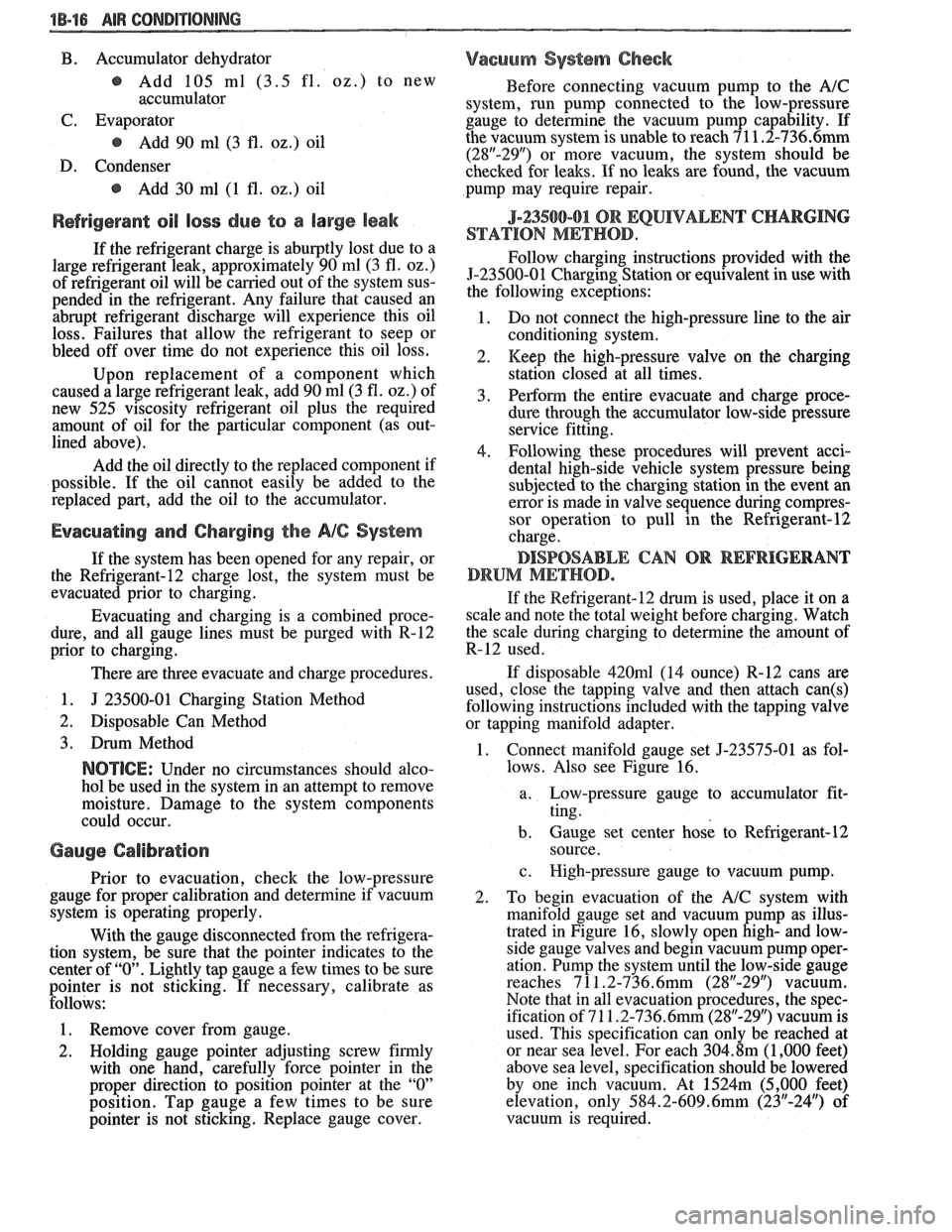

ACCUMULATOR ASSEMBLY SERVICE

The accumulator assembly for the refrigerant

system has a service replacement which includes two

(2) O-rings (for the inlet and outlet connections). The

desiccant within the shell is NOT serviced separately

- it is part of the sealed accumulator assembly. See

REFRIGERANT OIL DISTRIBUTION for condi-

tions when the accumulator must be removed from the

vehicle to measure the amount of oil present inside the

accumulator.

The accumulator assembly should ONLY be

replaced when:

1. A physical perforation to the accumulator is

found, resulting in a leak.

2. If the system is open to air for an extended

period of time (due to a front-end collision,

removed parts, ect.). The desiccant bag will be

saturated with moisture.

1 -ACCUMULATOR 9-CORE & CASE

2-EVAPORATOR BLOWER ASSEMBLY

10-A/C AIR

3-EVAPORATOR CORE 11-BI-LEVEL

4-BLOWER ASSEMBLY 5-AIR INLET ASSEMBLY

'IR

6-OUTSIDE AIR 13-DEFROST

AIR

7-INSIDE

AIR 14-SIDE WINDOW

DEFOG AIR

8-HEATER CORE

Figure 18 Functional Components

Page 66 of 1825

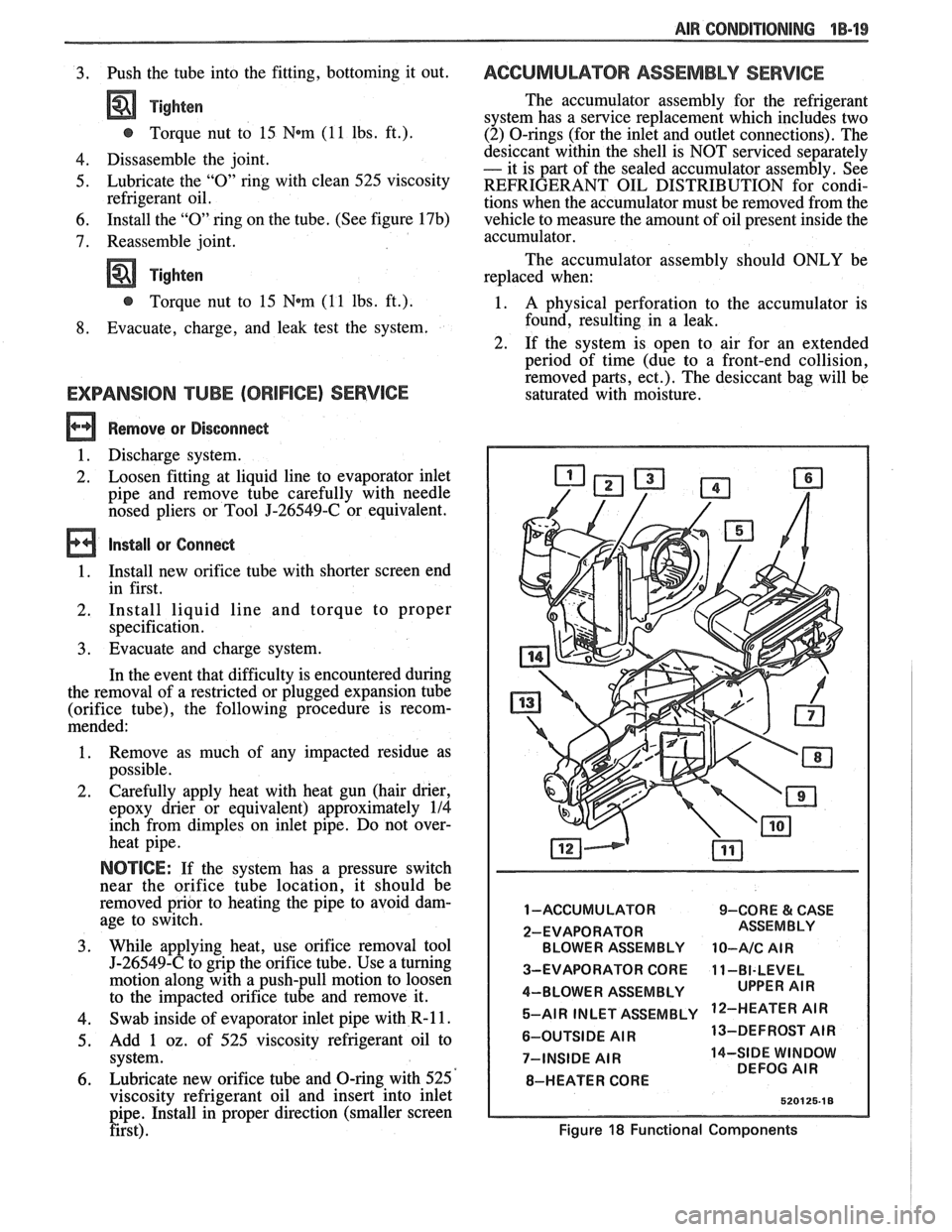

AIR CONDITIONING "18-23

10. CONTROL

14. LOWER MODE

DIAPHRAGM

16. DEFROST DIAPHRAGM

17. UPPER MODE

DIAPHRAGM

18. RECIRCULATION

5. TO WATER VALVE 19. lfVPUT (VIOLET)

6. A/C ELECTRICAL 20. DEFROST (BLUE)

21. LOWER MODE (TAN)

22. UPPER MODE (RED)

8. RECIRCULATION

DIAPHRAGM J~OZ~~-IB-F

Figure 20 AIC Vacuum Diagram

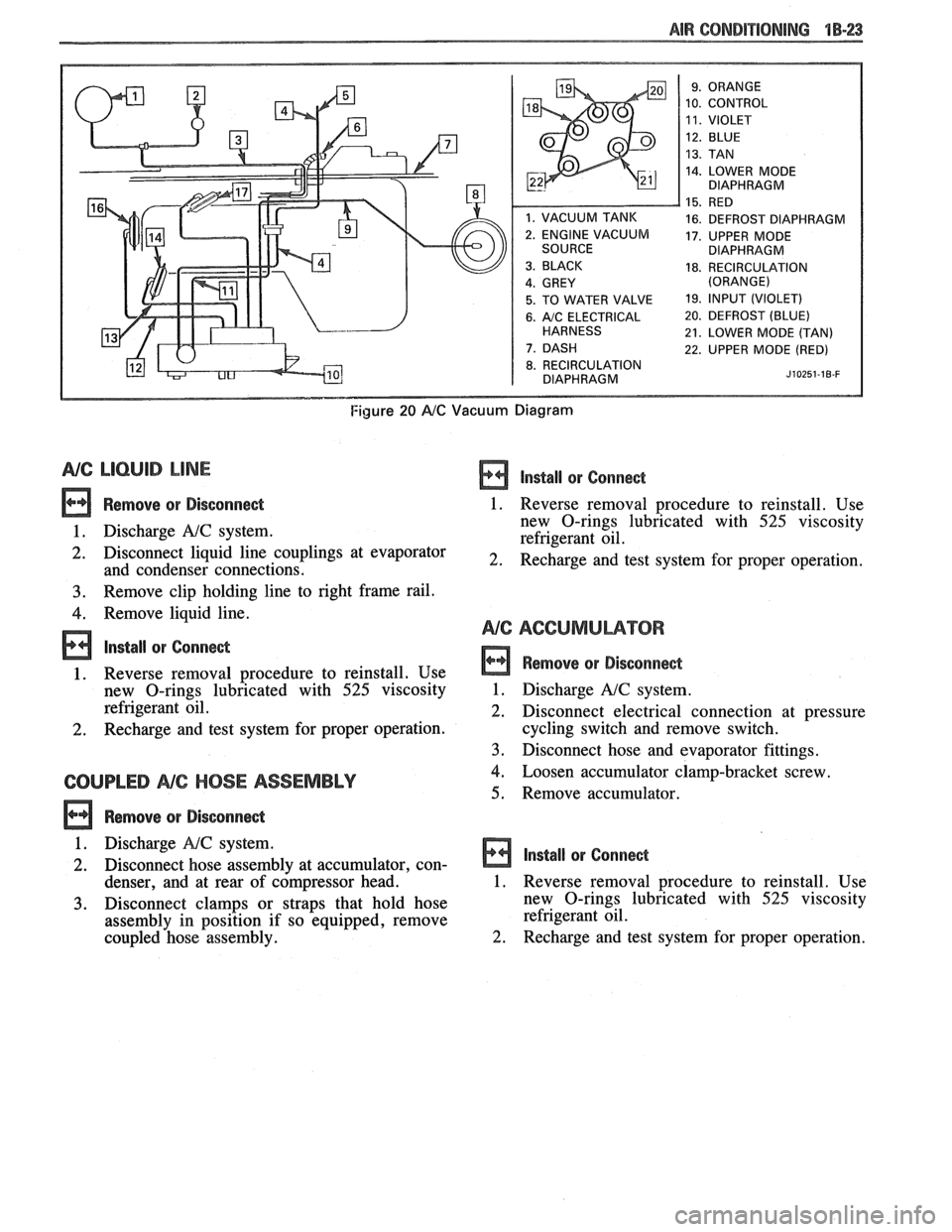

NG LlCbUlB LINE

Remove or Disconnect

1. Discharge A!C system.

2. Disconnect liquid line couplings at evaporator

and condenser connections.

3. Remove clip holding line to right frame rail.

4. Remove liquid line.

lnstall or Conne&

1. Reverse removal procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil.

2. Recharge and test system for proper operation.

COUPLED NC HOSE ASSEMBLY

Remove or Disconne&

lnstall or Conne&

1. Reverse removal procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil.

2. Recharge and test system for proper operation.

Remove or Disconnect

1. Discharge A!C system.

2. Disconnect electrical connection at pressure

cycling switch and remove switch.

3. Disconnect hose and evaporator fittings.

4. Loosen accumulator clamp-bracket screw.

5. Remove accumulator.

1. Discharge

NC system.

2. Disconnect hose assembly at accumulator, con- Install or Connect

denser, and at rear of c6mpressor head. 1. Reverse removal procedure to reinstall. Use

3. Disconnect clamps or straps that hold hose new

O-rings lubricated with 525 viscosity

assembly in position if so equipped, remove refrigerant

oil.

coupled hose assembly.

2. Recharge and test system for proper operation.

Page 67 of 1825

1B-24 AIR CONDPTIBNING

EVAPORATOR CORE

Remove QP Disconnect

1. Discharge A/C system.

2. Remove accumulator.

3. Remove two (2) screws and remove hi-blower

relay terminal.

4. Remove upper case screws.

5. Relocate wiring harness and remove dipstick.

6. Disconnect liquid line fitting.

7. Remove upper case and lift evaporator core out

of case (retain foam wedge).

Install or Connect

1. Reverse removal procedure to reinstall.

2. Recharge and test system for proper operation.

EVAPBRAWORCASE

Remove or Disconnect

1. Remove accumulator.

2. Remove blower motor.

3. Remove evaporator core.

Remove lower case to cowl screws (three driven from engine compartment, three driven from

interior).

Remove case from cowl.

Install or Connect

Reverse removal procedure to reinstall. Rein-

stall or replace gaskets, seal and sealant

removed during disassembly.

Recharge and test system for proper operation.

NG COMPRESSOR (TYPICAL)

Remove or Disconnect

1. Discharge A/C system.

2. Remove fitting block (coupled hose assembly)

bolt at rear of compressor.

3. Remove mounting bracket bolt(s) .

4. Remove drive belt (route lower loop behind har-

monic balancer to gain additional slack if

required).

5. Remove compressor. If complete compressor is

to be replaced, transfer usable switches, etc. to

new compressor.

Install or Connect

1. Reverse removal

procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil. Refer to Section

6B for drive belt

tension.

2. Evacuate and recharge system.

CONDENSER

a Remove or Disconnect

1. Discharge A/C system.

2. Disconnect coupled hose and liquid line fittings.

3, Remove screws retaining top radiator shield.

4. Remove top condenser retaining screws.

5. Carefully move (tilt) radiator rearward and lift

condenser out of radiator support.

6. Transfer brackets and mounts to new condenser

if replacement is necessary.

Install or Connect

1. Reverse removal procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil.

2. Recharge and test system for proper operation.

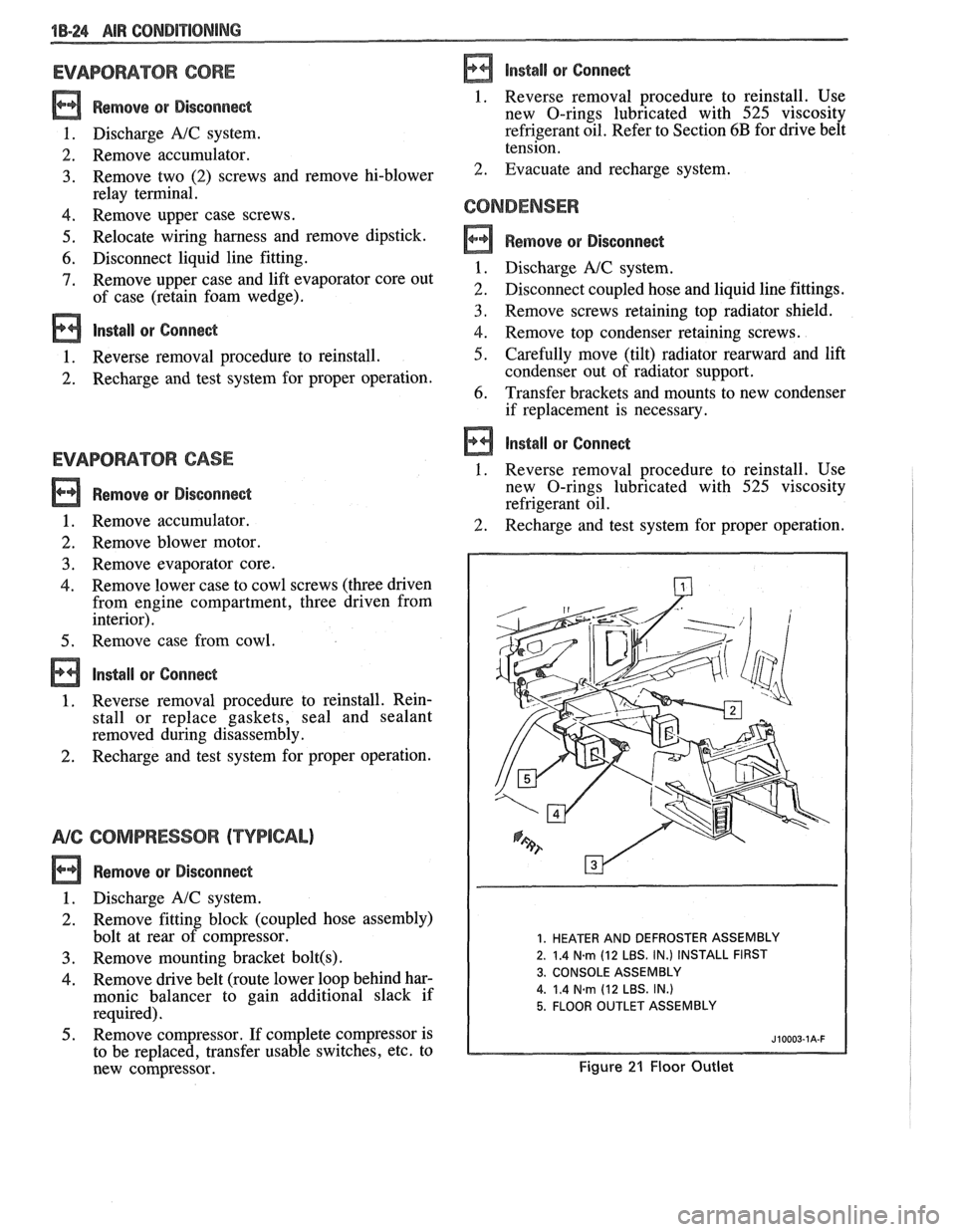

1. HEATER AND DEFROSTER ASSEMBLY

2. 1.4

N.m (12 LBS. IN.) INSTALL FIRST

3. CONSOLE ASSEMBLY

4.

1.4 Narn (12 LBS. IN.)

5. FLOOR OUTLET ASSEMBLY

Figure 21 Floor Outlet

Page 81 of 1825

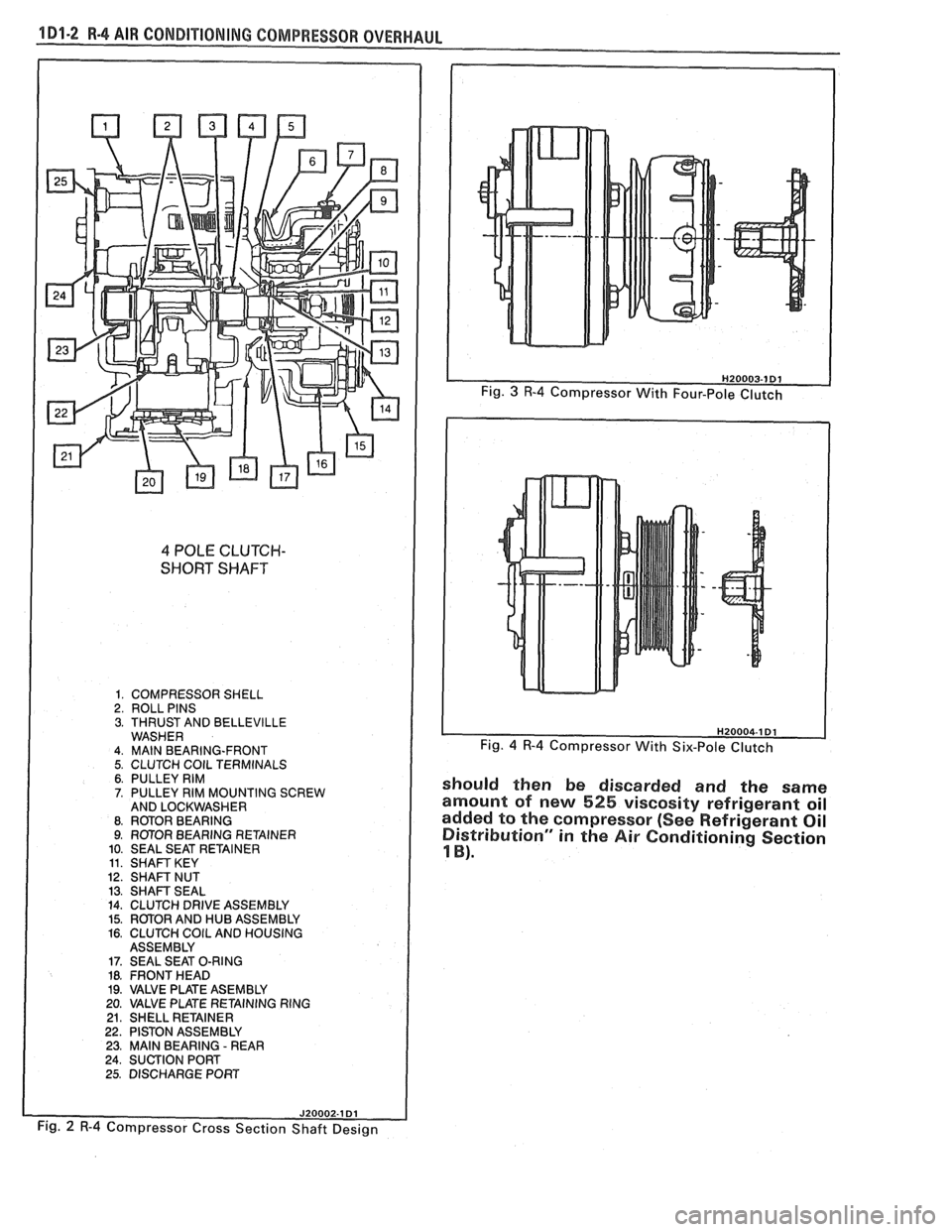

1 Dl-2 R-4 AIR CONDITIONING COMP

4 POLE CLUTCH-

SHORT SHAFT

1. COMPRESSOR SHELL 2. ROLL PINS 3. THRUST AND BELLEVILLE WASHER 4. MAlN BEARING-FRONT 5. CLUTCH COlL TERMINALS 6. PULLEY RIM 7. PULLEY RIM MOUNTING SCREW

AND LOCKWASHER

8. RmOR BEARING 9. ROTOR BEARING RETAINER

10. SEAL SEAT RETAINER

11. SHAFT KEY 12. SHAFT NUT 13. SHAFT SEAL 14. CLUTCH DRIVE ASSEMBLY 15. ROTOR AND HUB ASSEMBLY 16. CLUTCH COlL AND HOUSING

ASSEMBLY

17. SEAL SEAT O-RING 18. FRONT HEAD 19. VALVE PLATE ASEMBLY

20. VALVE PLATE RETAINING RING

21. SHELL RETAINER 22. PISTON ASSEMBLY 23. MAlN BEARING - REAR 24. SUCTION PORT

25. DISCHARGE PORT

Fig. 4 R-4 Compressor With Six-Pole Clutch

should then be discarded and the same

amount of new

525 viscosity refrigerant oil

added to the compressor (See Refrigerant Oil

Distribution" in

the Air Conditioning Section

1 B).

Fig. 2 R-4 Compressor Cross Section Shaft Design