seat adjustment PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 29 of 1825

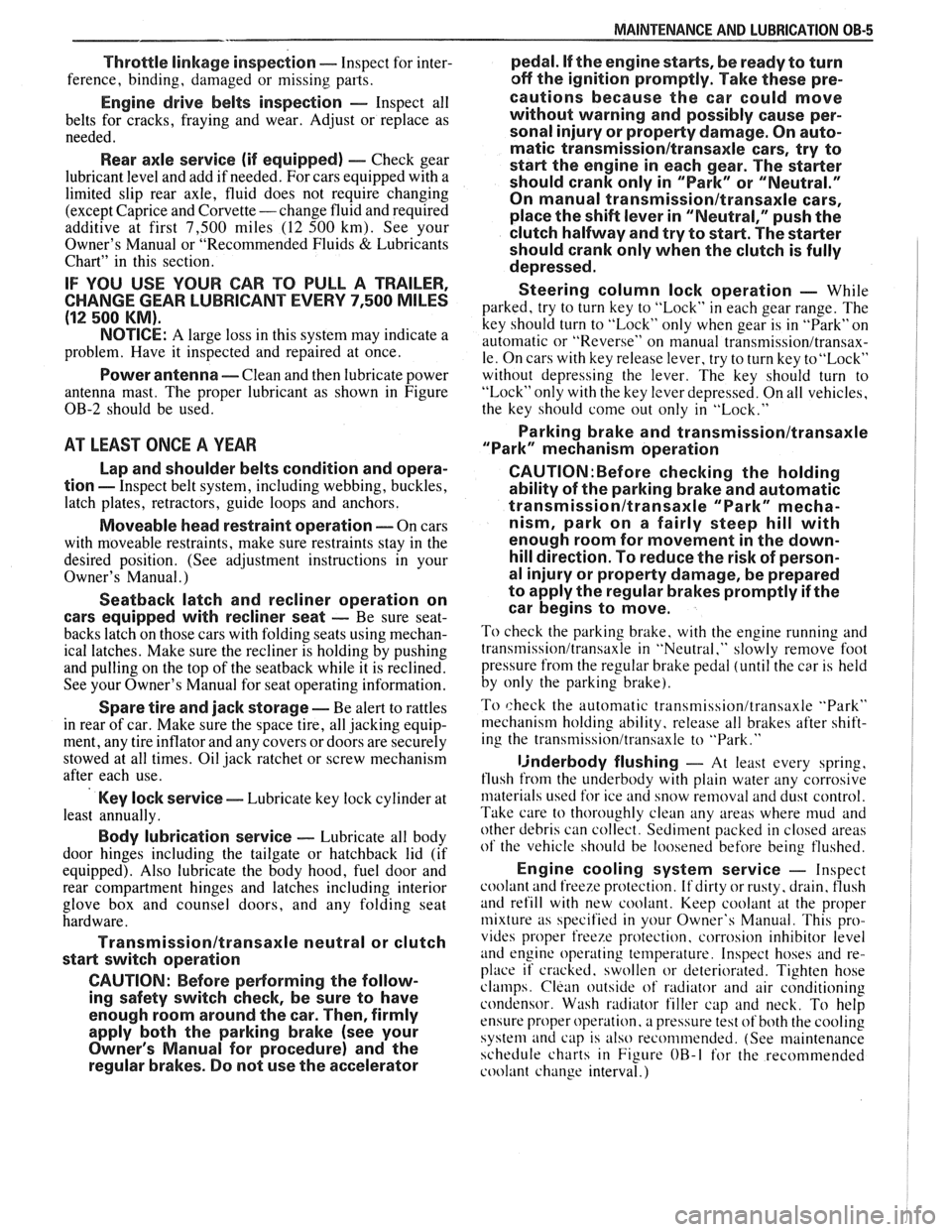

1A-6 HEATING AND VENTILATION

CHECK VEHICLE FOR

COLD AIR LEAKS AT DASH,

HEATER CASES AND FROM

VENTS. CHECK

UNDERSEAT FOR

OBSTRUCTIONS.

w

TEN FOR DOOR SLAM PRIOR TO THE END

CHECK THE TEMPERA-

TURE DOOR ADJUSTMENT,

CABLES, LINKAGE AND AD-

JUST TO FULL HOT. CHECK

I

WITH THE TEMPERATURE

DOOR FULL HOT, START THE

VEHICLE. CHECK THE TEMPER- ATURE OF THE HEATER INLET

AND OUTLET HOSES BY FEEL.

THE AIR TEMPERATURE

AROUND THE HOSES MUST BE AT LEAST

85OF.

I

WITH THE BLOWER ON

HIGH, MOVE THE TEMP-

ERATURE LEVER FROM

FULL HOT TO FULL

COLD AND LISTEN FOR

AIRFLOW CHANGE.

CHECK THE TEMPER-

ATURE DOOR AD-

JUSTMENT, CABLES,

CONTROL, LINKAGE

&

BETWEEN THE

COOLANT REPLACE.

Fig. 8 Insufficient Heating or Defrosting Diagnosis Procedure (2 of 2)

Page 114 of 1825

CHASSIS SHEET METAL 2@-7

3. During the above flash time period (1 to 10 min-

utes), apply appropriate "conventional" interior acrylic lacquer color as required and allow

painted part to dry for

4 to 5 hours before install-

ing on car.

RlGlD OW HARD ABS PMS"TIC PARTS

Rigid or hard ABS plastic requires no primer.

"Conventional" interior acrylic lacquers adhere satis-

factorily to hard ABS plastics.

Procedure

1. Wash part thoroughly with a cleaning solvent

(Acrylic-Clean, Pre-Kleano, Prep-Sol or equiv-

alent) to remove any dirt or grease.

2. Apply appropriate "conventional" interior

acrylic lacquer color. Apply only sufficient

color for proper hiding to avoid washout of

"grain" effect.

3. Allow to dry and then install part.

VINYL AND FLEXIBLE (Son) ABS

PLASTIC PARTS

The outer cover or skin material of "flexible"

instrument panel cover (pad) assemblies is made of an

ABSIPVC plastic blend. The same is true of many

"padded" door trim assemblies. The soft cushion pad-

ding under the I.P. skin is urethane foam plastic. The

most widely used

"flexible" vinyls (poly vinyl chlo-

ride)

are coated fabrics, such as used in seat trim,

some door trim assemblies, molded headlining panels

and sun visors. Most head rests are "flexible" vinyls.

Examples of "hard vinyls are: door and front seat

back assist handles and coat hooks.

The paint system of vinyl and flexible ABS

plastic involves the use of interior "vinyl" color and a

clear vinyl top coat.

Procedure

1. Wash part thoroughly with a vinyl cleaning and

preparation solvent ("Vinyl Press"

- Ditzler,

"Vinyl Prep Conditioner"

- Detroit Autobody

or equivalent) to remove greasy film or silicone.

Wipe off cleaner while still wet with clean,

lint-

free cloth.

2. Immediately after wiping face dry, apply inte-

rior "vinyl" color in wet coats allowing suffi-

cient flash time between coats (see label

directions on can). Use proper "vinyl" color as

designated by interior trim combinations. Apply

only sufficient color for proper hiding to avoid

washout of "grain" effect. No primer or

primer-

sealer is required.

3. Before the final vinyl color coat has dried, apply

two coats of clear vinyl top coat spray (instru-

ment panels will require the "nonglare" clear top

coat). Do not allow the first spray coat to com-

pletely dry before spraying on the second. Use

top coat with appropriate gloss level to match adjacent similar components. This

clear coat is

necessary to control the gloss requirement and

prevent

'tracking" (rubbing-off) of the color

coat after drying.

4. Allow to dry according to label directions before

installing part.

ON-VEHICLE SERVICE

CONCEALED HEADLIGHTS

The concealed headlights used on this model are

electrically operated. When the headlights are turned

on, solid state circuitry activates the actuators. This

same circuitry senses when the actuators stop moving

and removes the ground to deactivate the actuators.

When the headlights are turned off, the actuators run

in opposite direction closing the headlight doors.

Should an electrical failure occur in the head-

light circuit, they may be raised manually by rotating

the knob on the actuator in a counterclockwise direc-

tion until the headlights are fully open. The headlights

may be lowered by rotating the knob on the actuator in

a clockwise direction until the headlights are fully

closed.

For electrical circuit information and diagnosis,

refer to Section

8A of this manual.

If it is desired to raise the headlights with the

lights off, either of the following procedures may be

used:

1. Turn the lights on. After the headlights are

open, disconnect the electrical connections at

the actuator connectors. Turn the lights off. The

headlights will now remain in the open position.

2. Turn the parking lights on. Depress the head-

light rocker switch lightly. The headlights may

then be raised "up" fully with the lights off.

Adjust

Because of the number of adjustments possible

and the number of attaching points of the concealed

headlight body assembly

(9), only those attachments

which control the adjustment desired should be loos-

ened. Make one

adjbstment at a time.

NOTICE: The headlight door does NOT have

slotted mounting holes and therefore is not

adjustable by itself. This insures proper clearance

between the headlight door and the hood and

fenders in both the raised and lowered positions.

The entire headlight body assembly must be

adjusted to achieve the desired appearance and

fit. Care should be exercised when adjusting the

headlight body assembly. Severe hammer blows could damage the die cast aluminum headlight

body assembly.

TO RAISE OR LOWER the headlight body

assembly, proceed as follows:

1. Open hood.

2. Raise headlights.

Page 130 of 1825

STEERING. SUSPENSION. TIRES AND WHEELS DIAGNOSIS 3-5

High Lock Effort

rn lnspect

e Lock cylinder damaged

e Ignition switch damaged

o Rack preload spring broken or deformed

e Burrs on sector, rack, housing, support or

actuator rod coupling

,

e Bent sector shaft

e Damaged rack

e Extreme misalignment of' housing to cover

e Distorted coupling slot in rack

e Bent actuator rod

e Ignition switch mounting bracket bent

e Actuator rod restricted

e Improper shift linkage adjustment

Will Stick In "Start"

rn lnspect

e Actuator rod deformed

e Check items under "High Lock Effort"

Key Cannot Be Removed in "Off-Lock"

rn lnspect

e Ignition switch is not set correctly

e Damaged lock cylinder

e Linkage mis-adjusted

Lock Cylinder Can Be Removed

Inspect

e Lock cylinder retaining screw missing

High Effort In Lock Cylinder Between "Off" and

"Off-Lock"

lnspect

o Distorted rack

Lock Bolt Hits Shaft Lock In "Off" Position and

"Park"

lnspect

e Ignition switch is not set correctly

COLUMN

Noise In Column

Inspect

e Joints from the column to the steering gear 1

e Column not correctly aligned

e Horn contact ring not lubricated

e Lack of grease on bearings

o Loose sight shields

o Lower or upper steering shaft bearing worn or

broken

e Shaft lock snap ring not seated

o Spherical joint not lubricated

High Steering Shaft Effort

e Column assembly misaligned

e Improperly installed or deformed dust seal

e Damaged upper or lower bearing

e Flash on I.D. of shift tube

e Tight intermediate steering shaft universal joint

High Shift Effort (Automatic with Column Shift)

rn lnspect

e Column not aligned correctly in car

e Wave washer with burrs

e Improperly installed dust seal

o Lack of grease on seal or bearing

e Improper screws used for ignition switch

e Burr on upper or lower end of shift tube

e Lower bowl bearing not assembled correctly

Improper Shifting (Automatic with Column

Shift)

rn lnspect

e Sheared shift tube joint or lower shift lever weld

e Improper or loose linkage adjustment

e 1,oose shift lever

e Improper gate plate

Lash In Steering Column

lnspect

e 1.P.-to-column upper and lower bracket

nlounting bolts loose

e Broken weld nuts on jacket

e I.P. upper bracket capsule sheared

e Loose shoes in housing

e Loose tilt head pivot pins

e Loose shoe lock pin in support

e Loose support screws

e Column upper and lower bracket-to-jacket bolts

loose

e Loose lower bracket-to-adapter and bearing

assembly mounting screws

e Loose 1.P.-to-jacket mounting bolts

Housing Scraping On Bowl

rn Inspect

e Bowl bent or not concentric with hub

e Cover and housing end cap not properly installed

Page 139 of 1825

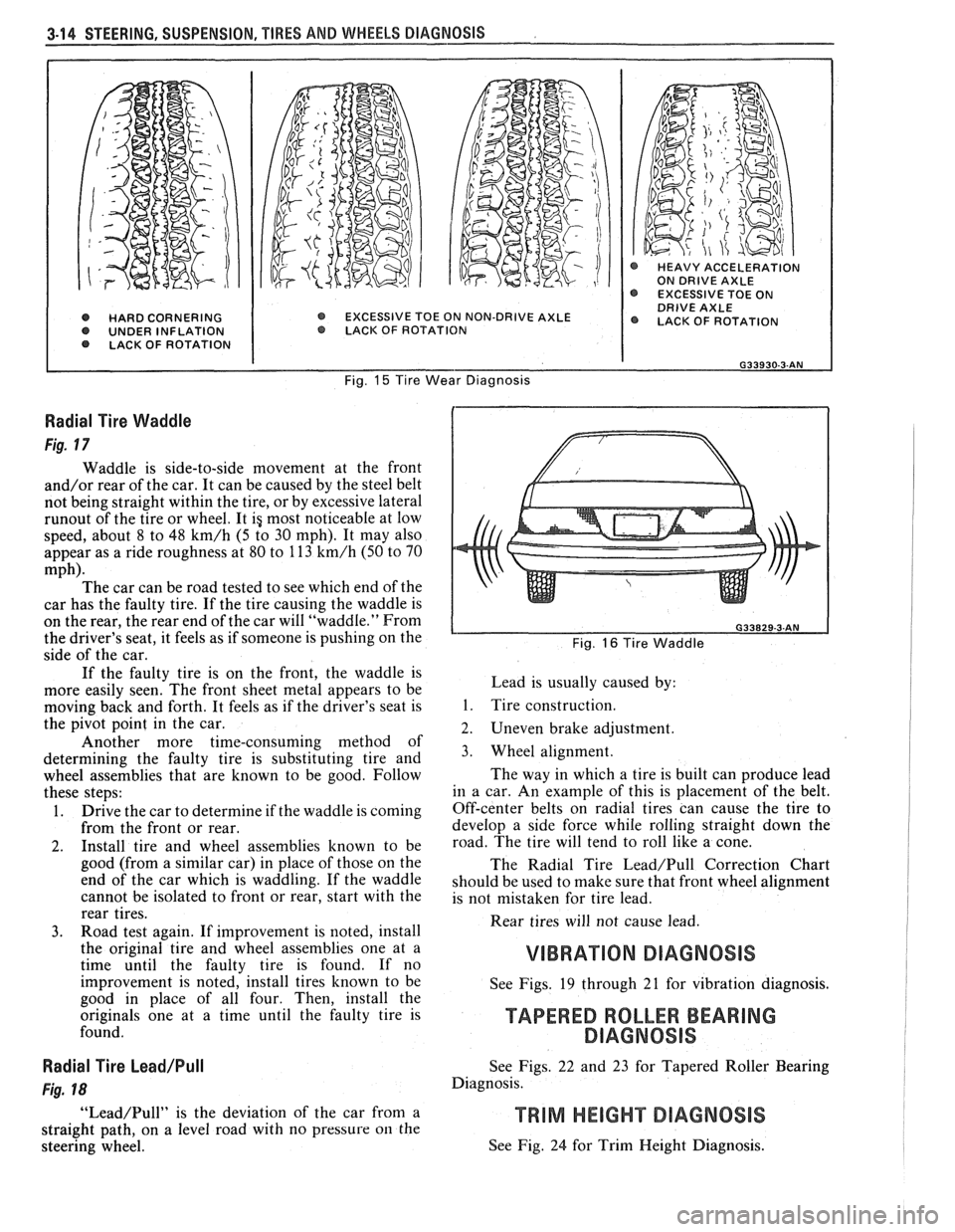

3-14 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

@ HARD CORNERING O UNDER INFLATION LACK OF ROTATION

@ HEAVY ACCELERATION ON DRIVE AXLE EXCESSIVE TOE ON DRIVE AXLE EXCESSIVE TOE ON NON-DRIVE AXLE @ LACK OF ROTATION O LACK. OF ROTAT ION

Fig. 15 Tire Wear Diagnosis

Radial Tire Waddle

Fig. 17

Waddle is side-to-side movement at the front

and/or rear of the car. It can be caused by the steel belt

not being straight within the tire, or by excessive lateral

runout of the tire or wheel. It ig most noticeable at low

speed, about 8 to 48

km/h (5 to 30 mph). It may also

appear as a ride roughness at 80 to 113

km/h (50 to 70

mph). The car can be road tested to see which end of the

car has the faulty tire. If the tire causing the waddle is

on the rear, the rear end of the car will "waddle." From

the driver's seat, it feels as if someone is pushing on the

side of the car.

If the faulty tire is on the front, the waddle is

more easily seen. The front sheet metal appears to be

moving back and forth. It feels as if the driver's seat is

the pivot point in the car.

Another more time-consuming method of

determining the faulty tire is substituting tire and

wheel assemblies that are known to be good. Follow

these steps:

1. Drive the car to determine if the waddle is coming

from the front or rear.

2. Install tire and wheel assemblies known to be

good (from a similar car) in place of those on the

end of the car which is waddling. If the waddle

cannot be isolated to front or rear, start with the

rear tires.

3. Road test again. If improvement is noted, install

the original tire and wheel assemblies one at a

time until the faulty tire is found. If no

improvement is noted, install tires known to be

good in place of all four. Then, install the

originals one at a time until the faulty tire is

found.

Radial Tire Lead/Pull

Fig. 18

"Lead/Pull" is the deviation of the car from a

straight path, on a level road with no pressure

on the

steering wheel.

L Fig. 16 Tire Waddle

Lead is usually caused by:

1. Tire construction.

2. Uneven brake adjustment.

3. Wheel alignment.

The way in which a tire is built can produce lead

in a car. An example of this is placement of the belt.

Off-center belts on radial tires can cause the tire to

develop a side force while rolling straight down the

road. The tire will tend to roll like a cone.

The Radial Tire

Lead/Pull Correction Chart

should be used to make sure that front wheel alignment

is not mistaken for tire lead.

Rear tires will not cause lead.

VIBRATION DIAGNOSIS

See Figs. 19 through 21 for vibration diagnosis.

TAPERED ROLLER BEARING

DlAGNOSlS

See Figs. 22 and 23 for Tapered Roller Bearing

Diagnosis.

See Fig. 24 for Trim Height Diagnosis.

Page 177 of 1825

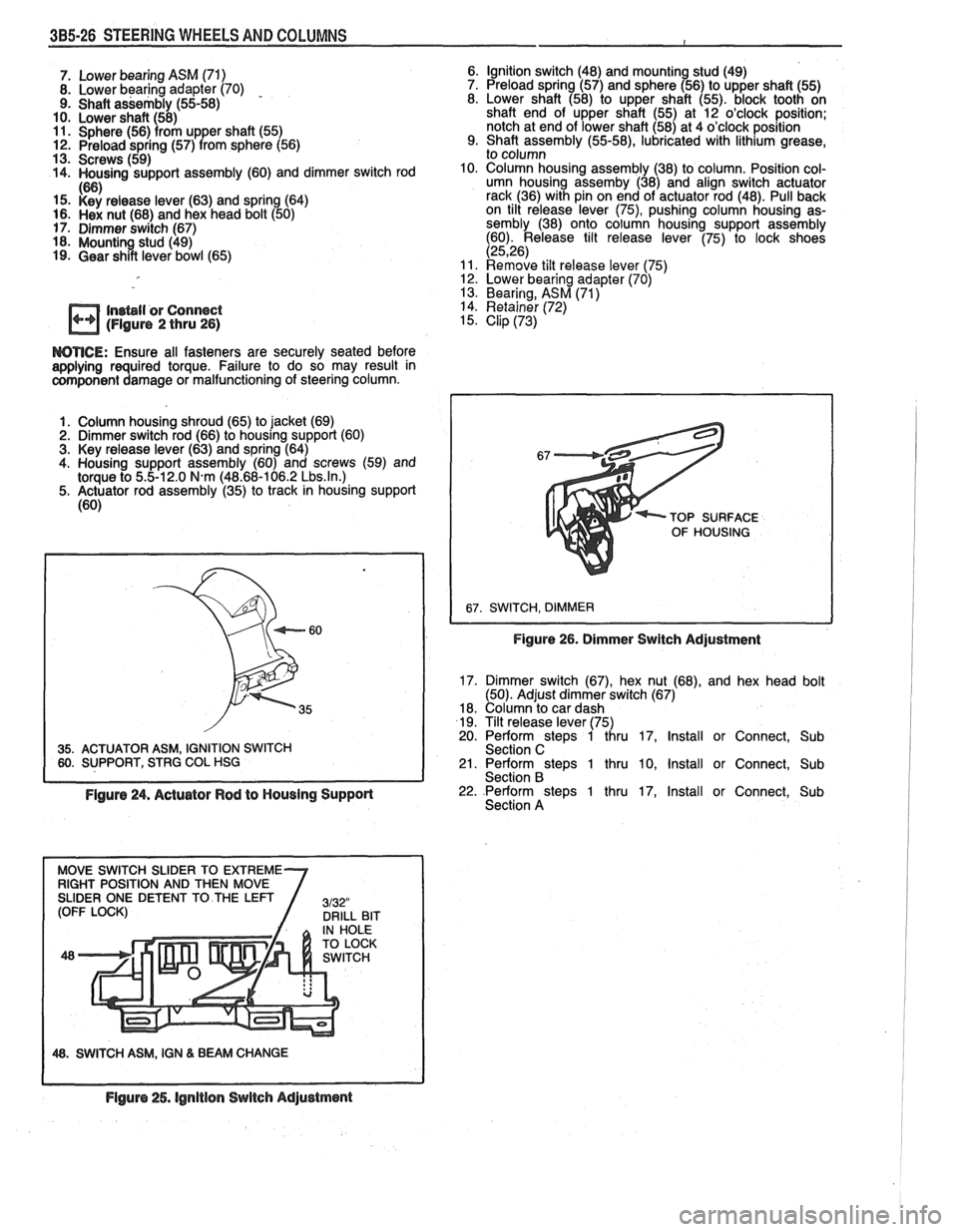

3B5-26 STEERING WHEELS AND COLUMNS

7. Lower bearing ASM (71)

8. Lower bearing adapter (70) - 9. Shaft assembly (55-58)

10. Lower shaft (58)

11. Sphere (56) from upper shaft (55) 12. Preload spring (57) from sphere (56)

13. Screws (59)

14. Housing support assembly (60) and dimmer switch rod

If%

15. i<'si release lever (63) and spring (64) 16. Hex nut (68) and hex head bolt (50)

17. Dimmer switch (67)

18. Mounting stud (49)

19. Gear shift lever bowl (65) Ignition switch (48)

and

mountin stud (49)

Preload spring (57) and sphere 156) to upper shaft (55)

Lower shaft (58) to upper shaft (55). block tooth on

shaft end of upper shaft (55) at 12 o'clock position;

notch at end of lower shaft (58) at 4 o'clock position

Shaft assembly

(55-58), lubricated with lithium grease,

to column

Column housing assembly (38) to column. Position col-

umn housing

assemby (38) and align switch actuator

rack (36) with pin on end of actuator rod (48). Pull back

on tilt release lever

(75), pushing column housing as-

sembly (38) onto column housing support assembly

(60). Release tilt release lever (75) to lock shoes

(2526) Remove tilt release lever 175) 12. Lower bearing adapter (70) '

13. Bearing, ASM (71)

In~bll or Connect 14. Retainer (72)

(Figure 2 thru 26) 15. Clip (73)

WTICE: Ensure all fasteners are securely seated before aaplying required torque. Failure to do so may result in component damage or malfunctioning of steering column.

1. Column housing shroud (65) to jacket (69)

2. Dimmer switch rod (66) to housing support (60)

3. Key release lever (63) and spring (64)

4. Housing support assembly (60) and screws (59) and

torque to

5.5-12.0 N.m (48.68-106.2 Lbs.ln.) 5. Actuator rod assembly (35) to track in housing support

(60)

35. ACTUATOR ASM, IGNITION SWITCH 60. SUPPORT, STRG COL HSG TOP

SURFACE

OF HOUSING

Figure 26. Dimmer Switch Adjustment

17. Dimmer switch (67), hex nut (68), and hex head bolt

(50). Adjust dimmer switch (67)

18. Column to car dash

19. Tilt release lever (75)

20. Perform steps 1 thru 17, Install or Connect, Sub

Section C

21. Perform steps 1 thru 10, Install or Connect, Sub

Section B

Figure 24. Actuator Rod to Housing Support 22. Perform steps 1 thru 17, Install or Connect, Sub

Section A

48. SWITCH ASM, IGN & BEAM CHANGE

Flgure 25. lgnitlon Switch Adjustment

Page 185 of 1825

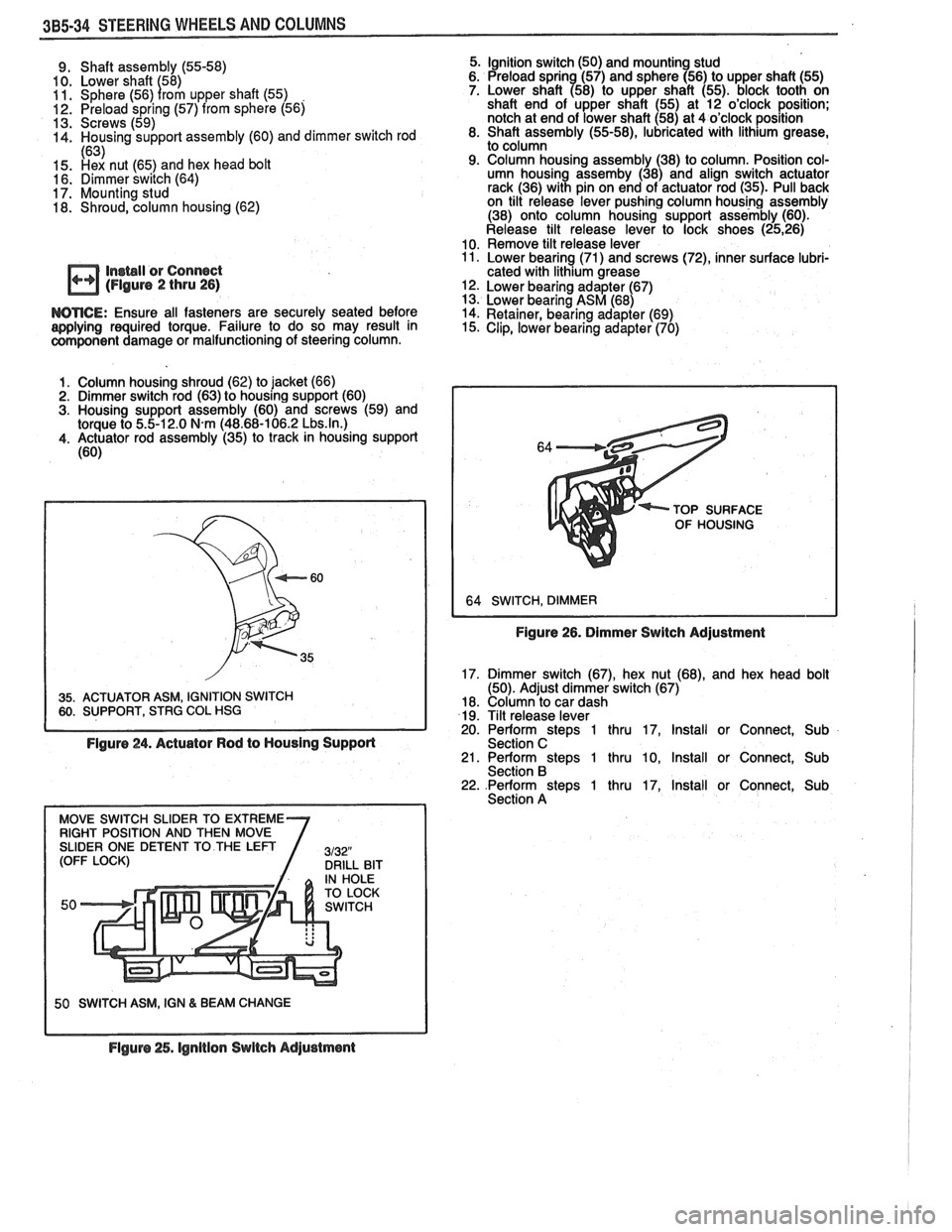

385.34 STEERING WHEELS AND COLUMNS

9. Shaft assembly (55-58)

10. Lower shaft 58)

11. Sphere (56)

I rom upper shaft (55) . 12. Preload spring (57) from sphere (56)

13. Screws (59)

14. Housing support assembly (60) and dimmer switch rod

(63) 15. h& nut (65) and hex head bolt

16. Dimmer switch (64)

17. Mounting stud 18. Shroud, column housing (62)

Insbll or Connect (Flgure 2 thru 26)

WTICE: Ensure all fasteners are securely seated before

applying required torque. Failure to do so may result in

component damage or malfunctioning of steering column.

Column housing shroud (62) to jacket (66)

Dimmer switch rod (63) to housing support (60)

Housing support assembly (60) and screws (59) and

torque to 5.5-12.0

N.m (48.68-106.2 Lbs.ln.) Actuator rod assembly (35) to track in housing support

(60)

35. ACTUATOR ASM, IGNITION SWITCH 60. SUPPORT, STRG COL HSG I

Figure 24. Actuator Rod to Housing Supporl

50 SWITCH ASM, IGN & BEAM CHANGE

5. Ignition switch (50) and mounting stud

6. Preload sprin (57) and sphere (56) to upper shaft (55)

7. Lower shaft

a58) to upper shaft (55). block tooth on

shaft end of upper shaft (55) at 12 o'clock position;

notch at end of lower shaft (58) at 4 o'clock position

8. Shaft assembly

(55-58), lubricated with lithium grease,

to column

9. Column housing assembly (38) to column. Position col-

umn housing assemby (38) and align switch actuator

rack (36) with pin on end of actuator rod (35). Pull back

on tilt release lever pushing column housing assembly

(38) onto column housing support assembly (60).

Release tilt release lever to lock shoes

(2526) 10. Remove tilt release lever 11. Lower bearing (71) and screws (72), inner surface lubri-

cated with lithium grease

12. Lower bearing adapter (67)

13. Lower bearing ASM (68)

14. Retainer, bearing adapter

(69) 15. Clip, lower bearing adapter (70)

TOP SURFACE

OF HOUSING

Figure 26. Dimmer Switch Adjustment

17. Dimmer switch

(67), hex nut (68), and hex head bolt

(50). Adjust dimmer switch (67)

18. Column to car dash

19. Tilt release lever

20. Perform

stem 1 thru 17. Install or Connect. Sub

Section C ' 21. Perform steps 1 thru 10, Install or Connect, Sub

Section B 22. .Perform steps 1 thru 17, Install or Connect, Sub

Section A

Flguro 25. lgnltion Switch Adjustment

Page 212 of 1825

FRONT SUSPENSION 3C-1

SEC"T0RI 3C

FRONT SUSPENS

NOTICE: All front suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of this part.

NOTICE: Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part

or

damage to the part may result.

CONTENTS

General lnformation ....................................................................................................... 3C-I

On-Car Service ................................................................................................................... 3C- I

Specifications ..................................................................................................................... 3C- 10

GENERAL INFORMATION

The front suspension is designed to allow each

wheel to compensate for changes in the road surface ON-CAR SERVICE

level without appreciably affecting the opposite wheel. WHEEL BEARINGS

Each wheel is independently connected to the frame by

The proper functioning of the front suspension

a steering

kunckle, strut assembly, ball joint, and lower cannot be maintained unless the front wheel tapered arm. The steering in a roller bearings are correctly adjusted. The bearings

prescribed three dimensional arc. The front wheels are

must be a slip fit on the spindle and the inside diameter held in proper relationship to each other by two tie rods of the bearings should be lubricated to insure proper which are connected to steering arms on the knuckles ~h~ spindle nut must be a free-running fit and to the relay rod assembly.

on the threads.

Coil chassis springs are mounted between the

spring housings on the front crossmember and the

lower control arms. Ride control is provided by double,

direct acting strut assemblies. The upper portion of

each strut assembly extends through the fender well

and attaches to the upper mount assembly with a nut.

Side roll of the front suspension is controlled by

a spring steel stabilizer shaft. It is mounted in rubber

bushings which are held to the frame side rails by

brackets. The ends of the stabilizer are connected to the

lower control arms by link bolts and are isolated by

rubber grommets.

The inner ends of the lower control arms have

pressed in bushings. Bolts (passing through the

bushings) attach the arm to the suspension

crossmember. The lower ball joint assembly is a press

fit in the arm and attaches to the steering knuckle with

a torque prevailing nut.

Rubber grease seals are provided at ball socket

assemblies to keep dirt and moisture from entering the

joint and damaging bearing surfaces.

Adjustment

Figure 602

NOTICE: See NOTICE on Page 3C-1

of this

section.

1. Remove dust cap from hub.

2. Remove cotter pin from spindle and spindle nut.

3. Tighten the spindle nut to 16 Nsm (12 lb. ft.)

while turning the wheel assembly forward by

hand to fully seat the bearings. This will remove

any grease or burrs which could cause excessive

wheel bearing play later.

4. Back off the nut to the "just loose" position.

5. Hand tighten the spindle nut. Loosen spindle nut

until either hole in the spindle lines up with a slot

in the nut. Not

nlore than 1/2 flat.

6. Install

new cotter pin. Bend the ends of the cotter

pin against nut, cut off extra length to ensure ends

will not interfere with the dust cap.

7. Measure the looseness in the hub assembly. There

will be

from .03 to . l3mm (.001 to .005 inches)

end play when properly adjusted.

8. Install dust cap on hub.

FRONT SUSPENSION

Refer to Fig. 610 for illustration of attachment

provisions for the bolted-on front suspension

suspension

crossmember.

Page 255 of 1825

4819 REAR AXLE

bears against the inner race of the front bearing and a

shoulder on the pinion stem. This spacer is used to

enable accurate bearing pre-load adjustment and

maintain a pre-load on both front and rear pinion

bearings, Adjustment of the fore and aft position of the

pinion is obtained by placing a shim between the rear

pinion bearing cup and axle housing. The differential

case is of two-piece construction and is supported in

the carrier by two tapered roller side bearings. Pre-load

rear axle case by inserting shims between the bearings

and the carrier. The rear axle case assembly is

positioned for proper ring gear to pinion backlash by

varying the shim thickness from side to side. The ring

gear is bolted to the case. Two side gears have splined

bores for driving the axle shafts. They are positioned

to turn in counterbored cavities in the case. The four

rear axle pinions have smooth bores and are held in

position by a pinion cross shaft, mounted and locked

in the rear axle case. All six gears are in mesh with each

other and because the pinion gears turn freely on their

shaft, they act as idler gears when the rear wheels are

turning at different speeds. The pinions and side gears

are backed by steel thrust washers.

LIMITED-SLIP REAR AXLE

The operation of the Limited-Slip differential is

the same as the standard differential, except that there

is additional friction provided by the conical clutches.

Under ordinary driving and cornering conditions, the

cones slip, allowing the outside wheel to turn faster

than the inner. Under poor traction conditions, such as

ice, snow, or loose gravel under one driving wheel, the

increased friction provided by the cones increases the

driving torque available to the wheel with the better

traction. The cones are spring loaded to provide the

increased driving torque under extremely low traction

conditions.

Operation

When the vehicle turns a corner, the outer rear

wheel must turn faster than the inner wheel. The inner

wheel, turning slower than the outer wheel, slows its

differential side gear (as the axle shaft is splined to the

side gear) and the differential pinion gears will roll

around the slowed differential side gear, driving the

other differential side gear and wheel faster.

DIAGNOSIS AND TESTING

Many noises reported as coming from the rear

axle assembly actually originate from other sources

such as tires, road surfaces, front wheel bearings, axle

bearing, engine, transmission, muffler or body

drumming. A thorough and careful check should be

made to determine the source of the noise before

disassembling the rear axle. Noise which originates in

other places cannot be corrected by adjustment or

replacement of parts in the differential. It should also

be remembered that rear axle gears, like any other

mechanical device, are not absolutely quiet and should

be accepted as being commercially quiet unless some

abnormal noise is present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant, approximately 10 miles.

3. Note speed and RPM at which noise occurs. Stop

car and put transmission in neutral. Run engine

slowly up and down through engine speeds,

corresponding to car speed at which noise was

most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure

for test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring seat

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets. The track bar and torque arm must be

bolted securely. Metal-to-metal contact at those

points may result in telegraphing road noise and

normal axle noise which would not be

objectionable if dampened by bushings.

AXLE NOISES

After the noise has been determined as being in

the axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

making repairs if necessary.