open gas tank PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 349 of 1825

6-4 ENGINE GENERAL INFORMATION

Bent connecting rod.

HEAVY KNOCK H0"FVVI"F TORQUE APPLIED

Broken balancer, or pulley hub. Replace parts as e Exhaust system grounded. Reposition as

necessary. necessary.

Loose torque converter bolts. Flywheel

cracked.

e Excessive main bearing clearance. Replace as

Accessory belts too tight or nicked. Replace

necessary.

and/or tension to specs as necessary.

e Excessive rod bearing clearance. Replace as

necessary.

LIGHT KNOCK HOT

Detonation or spark knock. Check operation of e Loose torque converter bolts.

EST or ESC (See Section

6D or 6E). Check e Exhaust leak at manifold. Tighten bolts and/or

engine timing and fuel quality.

replace gasket.

8 Excessive rod bearing clearance. Replace

bearings as necessary.

KNOCKS ON INITIAL START-UP BUT ONLY LASTS A FEW SECONDS

Noisy mechanical fuel pump. Replace pump.

When the engine is stopped, some valves

will be open. Spring pressure against lifters

Improper oil viscosity. Install proper oil viscosity will

tend to bleed lifter down. Attempts to

for expected temperatures. See Owner's Manual. repair

should be made only if the problem

is consistent.

Hydraulic lifter bleed down. Clean, test and @ Excessive crankshaft end clearance. Replace

replace as necessary. crankshaft

thrust bearing.

@ Excessive front main bearing clearance. Replace

worn parts.

KNOCKS AT IDLE HOT

Loose or worn drive belts. Tension and/or @ Excessive piston pin clearance. Ream and install

replace as necessary. oversize pins. (VIN R and 2) or replace piston

A/C Compressor or generator bearing. Replace and

pin.

as necessary.

e Connecting rod alignment. Check and replace

rods as necessary.

Noisy mechanical fuel pump. Replace pump.

8 Insufficient piston to bore clearance. Hone bore

Valve train. Replace parts as necessary. and

fit new piston.

@ Loose crankshaft balancer. Torque and/or

Improper oil viscosity. Install proper viscosity oil

replace worn parts.

for expected temperature4 See Owner" e Piston pin offset to wrong side. Install correct

ENGINE OVERHEATS

Coolant system leak, oil cooler system leak, or

2. Belt slipping or damaged. Replace tensioner, or

coolant recovery system not operating. Check for belt, as required.

leaks and correct as required. Check coolant

3. Thermostat stuck closed. Check and replace if

recovery tank, hose and radiator cap.

required.

4. Electrical cooling fan operation. See the

ELECTRICAL TROUBLESHOOTING

MANUAL.

5. Head gasket leaking. Check and repair as

required.

Page 419 of 1825

68-8 ENGINE COOLING

However, there are limits to the tensioner's ability to

The tensioner has rovisions for a visual check to

compensate for varying lengths of belts. With the

ten- verify that it is in t e "operating range" (see Figures

sioner outside of its operating range, poor tension

608 and 609). R

control andlor damage to the tensioner may result.

ALUMINUM RADIATOR REPAIR

This radiator utilizes an aluminum core with

plastic side tanks. The core and side tanks can be

replaced separately and core repair is easily made with

the hot melt adhesive method. A transaxle oil cooler

is located in one of the side tanks. The oil cooler can

be replaced. The drain cock is located on the lower part

of one of the tanks. The drain cock is also serviceable.

Core

The core is made of aluminum and is of the

crossflow design. It utilizes large tubes that resist

plugging, and repairs to the tubes and core are easily

made using the hot melt adhesive method.

The core is attached to the tanks by clinched tabs

on the core that can be bent back if tank or core

replacement is required.

If the damage to a tube is too severe, a tube can

be blocked or plugged as explained in "Tube Blocking.

" No more than two tubes should ever be blocked on

a core. Also replace the core if more than three tabs are

broken on one side, or if two adjacent tabs are broken.

Tanks

The tanks are attached to the core by the use of

clinched tabs. The clinched tabs can be bent back if the

tanks need to be removed from the core. Bend the tabs

back only enough to remove the tank. Overbending

will weaken the tabs.

A high temperature rubber gasket is used to seal

the mating surface between the core and the tank. (See

Fig. 8). The gasket must be replaced any time a tank

is removed from the core.

Transaxle Oil Cooler

The transaxle oil cooler is located in one of the

radiator side tanks. The oil cooler can be replaced by

removing the tank from the core.

A leaking oil cooler gasket can be replaced

without removing the tank from the core.

Drain Cock

The aluminum/plastic radiator utilizes a two

piece plastic drain cock and a rubber seal. The drain

cock is serviceable (See Fig.

9).

ALUMINUM RADIATOR SERVICE

The aluminum-plastic radiator can be repaired at

the dealership. The following components are easily

replaced:

e Core

e Tanks and gaskets

o Oil coolers and gaskets

e Drain cock and gasket The

tanks cannot be repaired if broken or

cracked. The radiator core can be replaced and the new

core used with the original tanks and oil cooler.

Precautions

As with all cooling system service, take measures

to prevent personal injury and damage to the system.

CAUTION: To help avoid the danger of

being burned, do not remove the

radiator cap while the engine and

radiator are

still hot. Scalding fluid

and steam can be blown out under

pressure if the

cap is taken off too

soon.

NOTICE: DO NOT USE "BOIL OUT" TANKS

OR VATS. Common service methods may

actually destroy an aluminum radiator. Caustic or

lye cleaning solutions must NOT be used for

aluminum radiators.

e Do not open the hood if you can see, or hear,

steam or coolant escaping from the engine

compartment.

e Do not remove radiator cap if radiator feels

warm.

e Do not remove the radiator cap or coolant

recovery tank cap if the coolant in the recovery

tank looks like it is boiling.

Wear eye protection.

e Wear gloves to protect your hands against

excessive heat, or the effects of chemicals on your

skin.

o Prevent dirt and water from entering the

transmission oil cooler.

e Do not use boil-out tanks, or vats, or other tanks

that have been used for copper and brass

radiators. The flux, acid, and caustic cleaners

remaining in these tanks will attack the

aluminum and cause radiator failure.

A separate

test tank containing clean water is strongly

recommended for servicing aluminum-plastic

radiators.

RIOTICE: Never use shop air that is not regulated

at

20 psi (138 kPa) to pressure test radiator.

Pressures over

20 psi (138 kPa) will damage the

radiator.

DIAGNOSIS

Leak Testing

Some core leaks can be detected by merely adding

water to the radiator. It is helpful to clean the core so

that the damaged area can be more easily found.

Page 422 of 1825

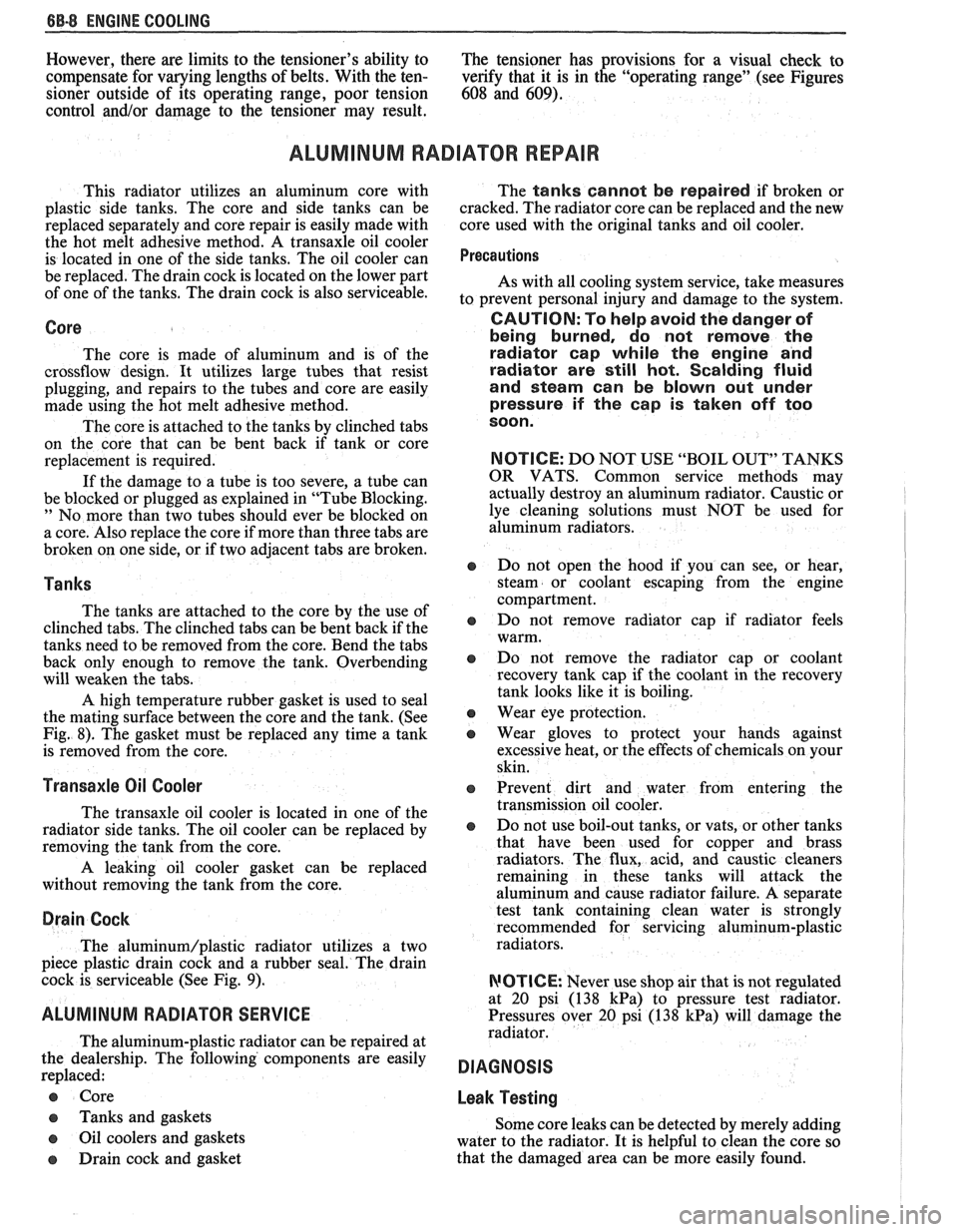

(1/4") beyond the leak or damage area is enough to

make an effective repair. (Fig. 14).

d""U,"

Fig. 14 Fins Removed from Damaged Area

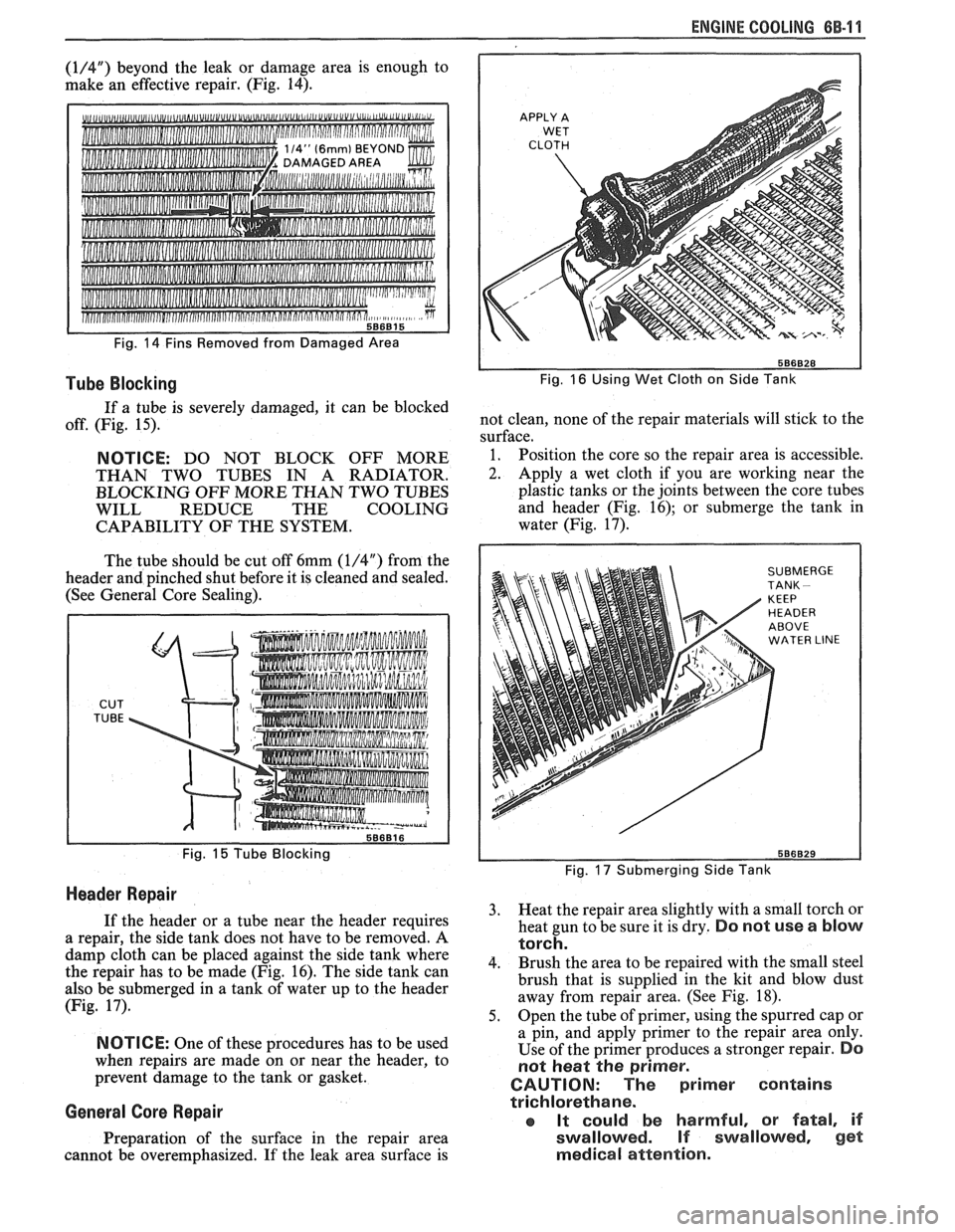

Tube Blocking

If a tube is severely damaged, it can be blocked

off. (Fig. 15).

NOTICE: DO NOT BLOCK OFF MORE

THAN TWO TUBES IN A RADIATOR.

BLOCKING OFF MORE THAN TWO TUBES

WILL REDUCE THE COOLING

CAPABILITY OF THE SYSTEM.

The tube should be cut off 6mm

(1/4") from the

header and pinched shut before it is cleaned and sealed.

(See General Core Sealing).

CUT

TUBE

Fig. 15 Tube Blocking

Header Repair

If the header or a tube near the header requires

a repair, the side tank does not have to be removed.

A

damp cloth can be placed against the side tank where

the repair has to be made (Fig. 16). The side tank can

also be submerged in a tank of water up to the header

(Fig. 17).

NOTICE: One of these procedures has to be used

when repairs are made on or near the header, to

prevent damage to the tank or gasket.

General Gore Repair

Preparation of the surface in the repair area

cannot be overemphasized. If the leak area surface is

ENGINE COOLING 6B-11

Fig. 16 Using Wet Cloth on Side Tank

not clean, none of the repair materials will stick to the

surface.

1. Position the core so the repair area is accessible.

2. Apply a wet cloth if you are working near the

plastic tanks or the joints between the core tubes

and header (Fig. 16); or submerge the tank in

water (Fig. 17).

SUBMERGE TANK -

Fig. 17 Submerging Side Tank

3. Heat the repair area slightly with a small torch or

heat gun to be sure it is dry.

Do not use a blow

torch.

4. Brush

the area to be repaired with the small steel

brush that is supplied in the kit and blow dust

away from repair area. (See Fig. 18).

5. Open

the tube of primer, using the spurred cap or

a pin, and apply primer to the repair area only.

Use of the primer produces a stronger repair.

Do

not heat the primer.

CAUTION: The primer contains

trichlorethane.

aa It could be harmful, or fatal, if

swallowed. If swaIIowed, gel

medical attention.

Page 423 of 1825

88-12 ENGINE COOLING

Fig. 18 Cleaning Area With Steel Brush

e Use with adequate ventilation.

In case of eye contact, flush with

plenty of water and get medical

attention.

In case of body

contact, wash

thoroughly with soap

and water.

Do not

mix the primer with water.

6. Scrub the repair area with a cotton swab until a

fresh swab stays clean. The clear, yellow-brown

coating does not have to be removed (Fig. 19).

Fig. 19 Scrubbing Area with Primer

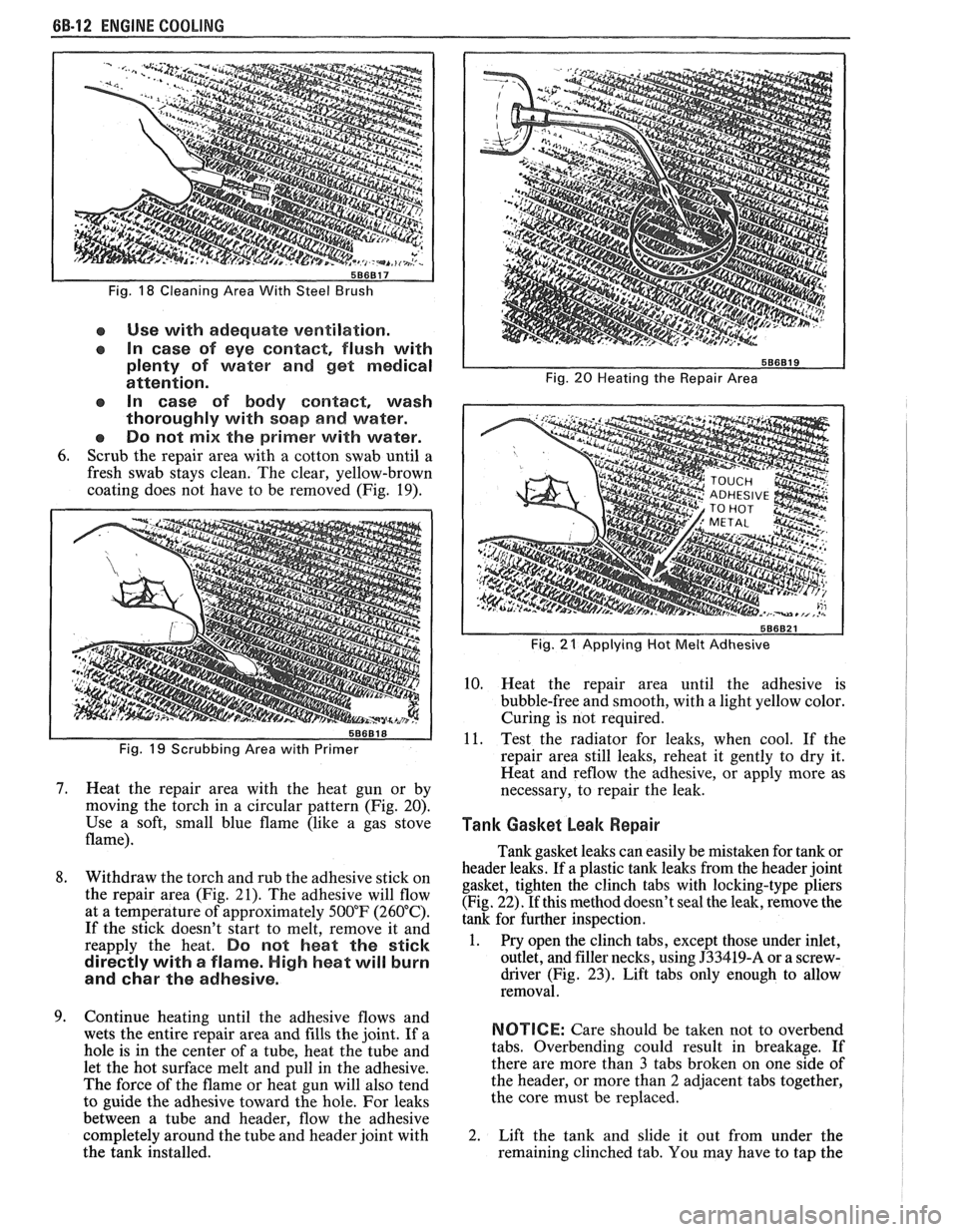

7. Heat the repair area with the heat gun or by

moving the torch in a circular pattern (Fig. 20).

Use a soft, small blue flame (like a gas stove

flame).

8. Withdraw the torch and rub the adhesive stick on

the repair area (Fig. 21). The adhesive will flow

at a temperature of approximately 500°F (260°C).

If the stick doesn't start to melt, remove it and

reapply the heat.

Do not heat the stick

directly with

a flame. High heat will burn

and

char the adhesive.

9. Continue heating until the adhesive flows and

wets the entire repair area and fills the joint. If a

hole is in the center of a tube, heat the tube and

let the hot surface melt and pull in the adhesive.

The force of the flame or heat gun will also tend

to guide the adhesive toward the hole. For leaks

between a tube and header, flow the adhesive

completely around the tube and header joint with

the tank installed.

Fig. 20 Heating the Repair Area

I

Fig. 21 Applying Hot Melt Adhesive I

10. Heat the repair area until the adhesive is

bubble-free and smooth, with a light yellow color.

Curing is not required.

11. Test the radiator for leaks, when cool. If the

repair area still leaks, reheat it gently to dry it.

Heat and

reflow the adhesive, or apply more as

necessary, to repair the leak.

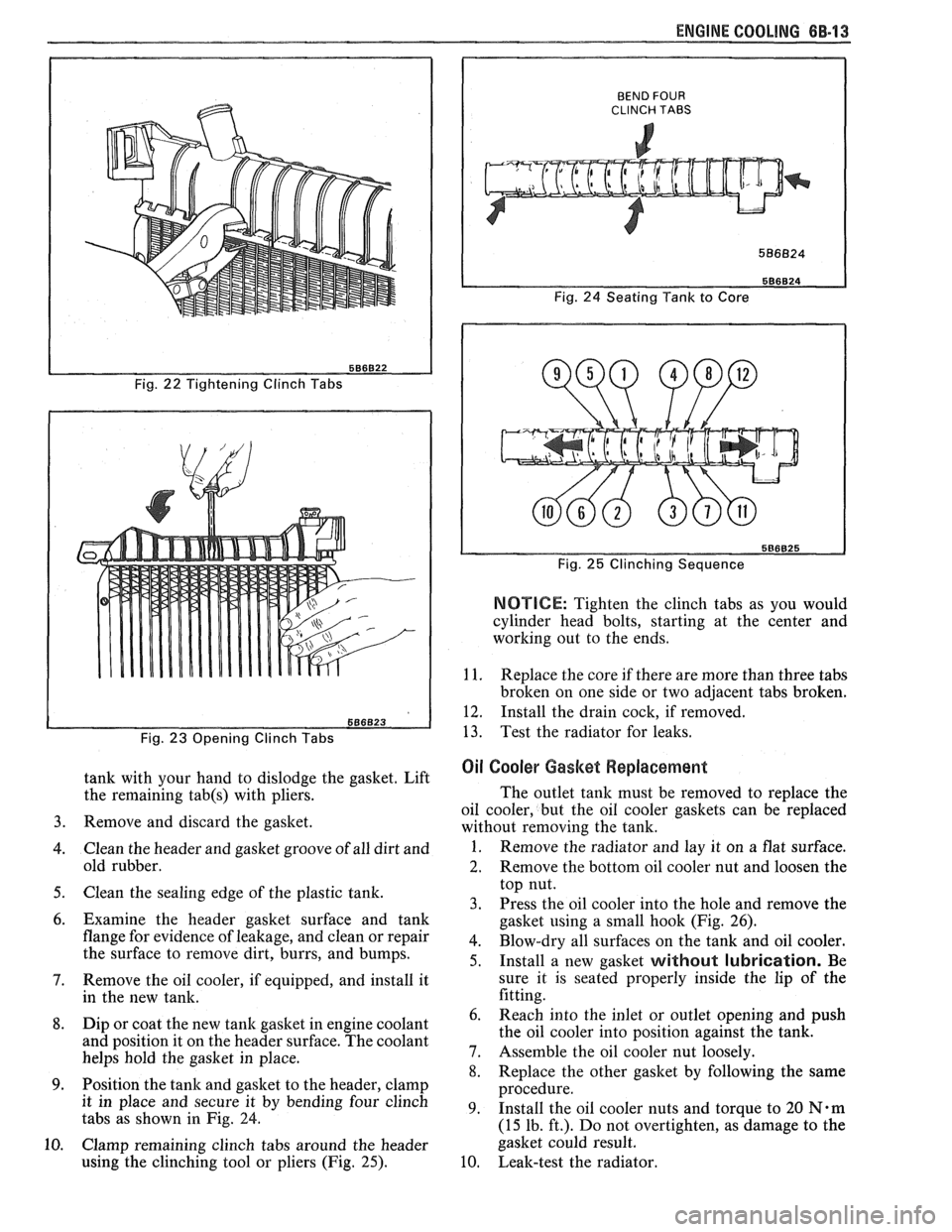

Tank Gasket beak Repair I 1

Tank gasket leaks can easily be mistaken for tank or

header leaks. If a plastic tank leaks from the header joint

gasket, tighten the clinch tabs with locking-type pliers

(Fig. 22). If this method doesn't seal the leak, remove the

tank for further inspection.

1. Pry open the clinch tabs, except those under inlet,

outlet, and filler necks, using

J33419-A or a screw-

driver (Fig.

23). Lift tabs only enough to allow

removal.

NOTICE: Care should be taken not to overbend

tabs. Overbending could result in breakage. If

there are more than

3 tabs broken on one side of

the header, or more than

2 adjacent tabs together,

the core must be replaced.

2. Lift the tank and slide it out from under the

remaining clinched tab. You may have to tap the

Page 424 of 1825

ENGINE COOLING 6B-13

Fig. 22 Tightening Clinch Tabs

Fig.

23 Opening Clinch Tabs

tank with your hand to dislodge the gasket. Lift

the remaining

tab(s) with pliers.

Remove and discard the gasket.

Clean the header and gasket groove of all dirt and

old rubber.

Clean the sealing edge of the plastic tank.

Examine the header gasket surface and tank

flange for evidence of leakage, and clean or repair

the surface to remove dirt, burrs, and bumps.

Remove the oil cooler, if equipped, and install it

in the new tank.

Dip or coat the new

tank gasket in engine coolant

and position it on the header surface. The coolant

helps hold the gasket in place.

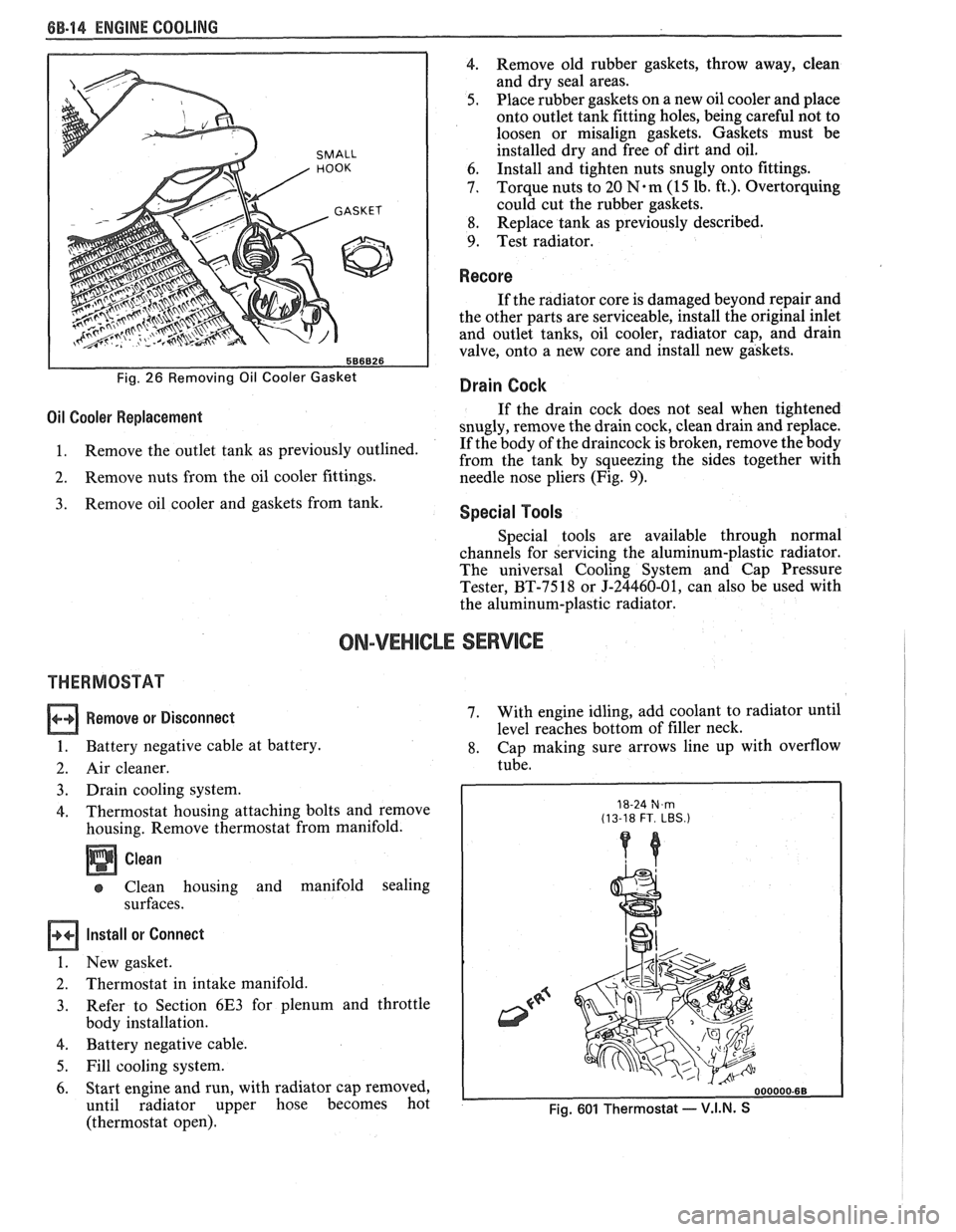

Position the tank and gasket to the header, clamp

it in place and secure it by bending four clinch

tabs as shown

in Fig. 24.

Clamp remaining clinch tabs around the header

using the clinching tool or pliers (Fig.

25).

BEND FOUR CLINCH TABS

Fig. 24 Seating Tank to Core

Fig.

25 Clinching Sequence

NOTICE: Tighten the clinch tabs as you would

cylinder head bolts, starting at the center and

working out to the ends.

1 1. Replace the core if there are more than three tabs

broken on one side or two adjacent tabs broken.

12. Install the drain cock, if removed.

13. Test the radiator for leaks.

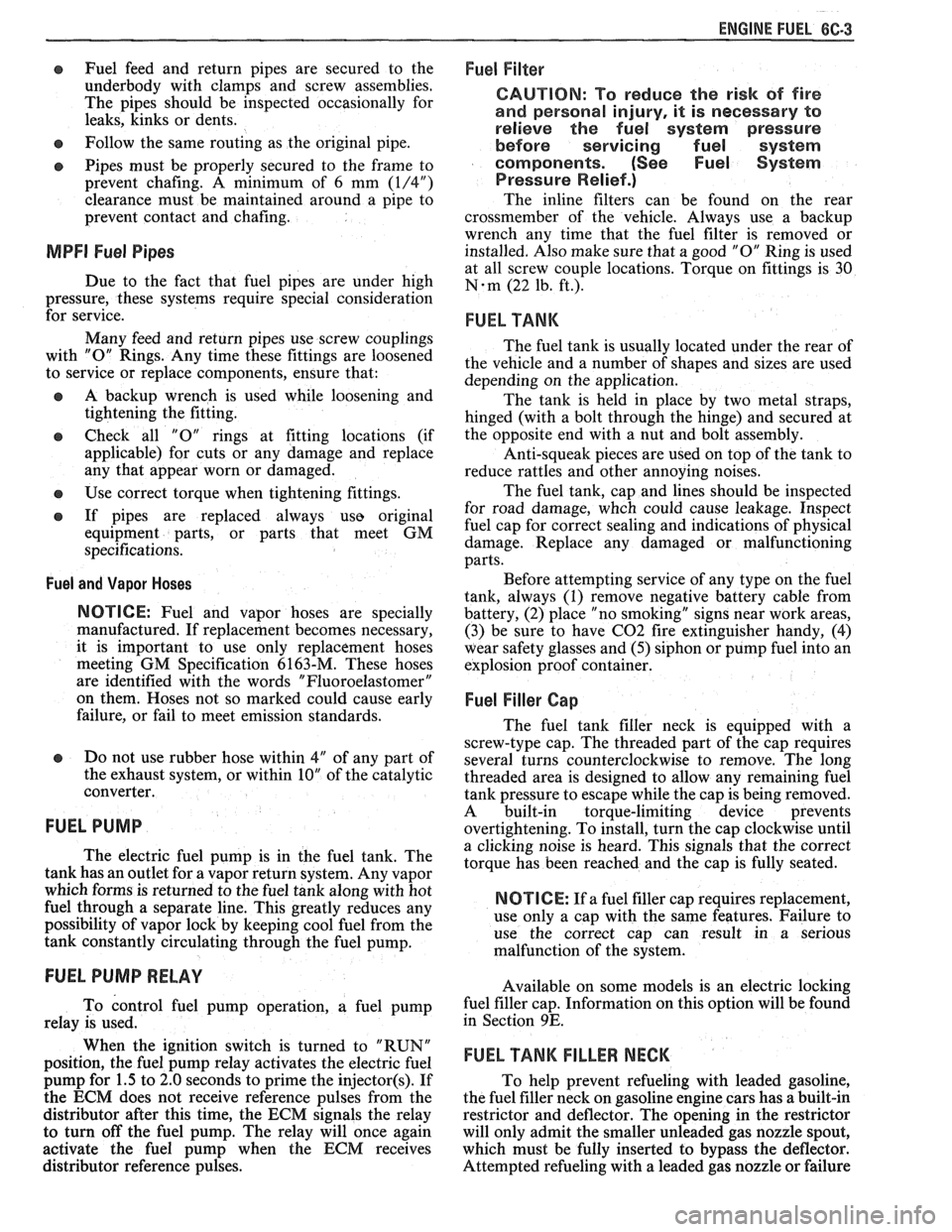

Oil Cooler Gasket Replacement

The outlet tank must be removed to replace the

oil cooler, but the oil cooler gaskets can be replaced

without removing the tank.

1. Remove the radiator and lay it on a flat surface.

2. Remove the bottom oil cooler nut and loosen the

top nut.

3. Press the oil cooler into the hole and remove the

gasket using a small hook (Fig. 26).

4. Blow-dry all surfaces on the tank and oil cooler.

5. Install a new gasket without lubrication. Be

sure it is seated properly inside the lip of the

fitting.

Reach into the inlet or outlet opening and push

the oil cooler into position against the tank.

Assemble the oil cooler nut loosely.

Replace the other gasket by following the same

procedure.

Install the oil cooler nuts and torque to

20 N.m

(15 lb. ft.). Do not overtighten, as damage to the

gasket could result.

Leak-test the radiator.

Page 425 of 1825

6B-I4 ENGINE COOLING

SMALL

586826

Fig. 26 Removing Oil Cooler Gasket

4. Remove old rubber gaskets, throw away, clean

and dry seal areas.

5. Place rubber gaskets on a new oil cooler and place

onto outlet tank fitting holes, being careful not to

loosen or misalign gaskets. Gaskets must be

installed dry and free of dirt and oil.

6. Install

and tighten nuts snugly onto fittings.

7. Torque nuts

to 20

N.m (15 lb. ft.). Overtorquing

could cut the rubber gaskets.

8. Replace

tank as previously described.

9. Test radiator.

Recore

If the radiator core is damaged beyond repair and

the other parts are serviceable, install the original inlet

and outlet tanks, oil cooler, radiator cap, and drain

valve, onto a new core and install new gaskets.

Drain Cock

Oil Cooler Replacement If the drain cock does not seal when tightened

snugly, remove the drain cock, clean drain and replace.

1. Remove

the outlet tank as previously outlined. If

the body of the draincock is broken, remove the body

from the tank by squeezing the sides together with

2. Remove nuts from the oil cooler fittings.

needle nose pliers (Fig. 9).

Remove oil cooler and gaskets from tank. Special Tools

Special tools are available through normal

channels for servicing the aluminum-plastic radiator.

The universal Cooling System and Cap Pressure

Tester, BT-7518 or J-24460-01, can also be used with

the aluminum-plastic radiator.

ON-VEHICLE SERVICE

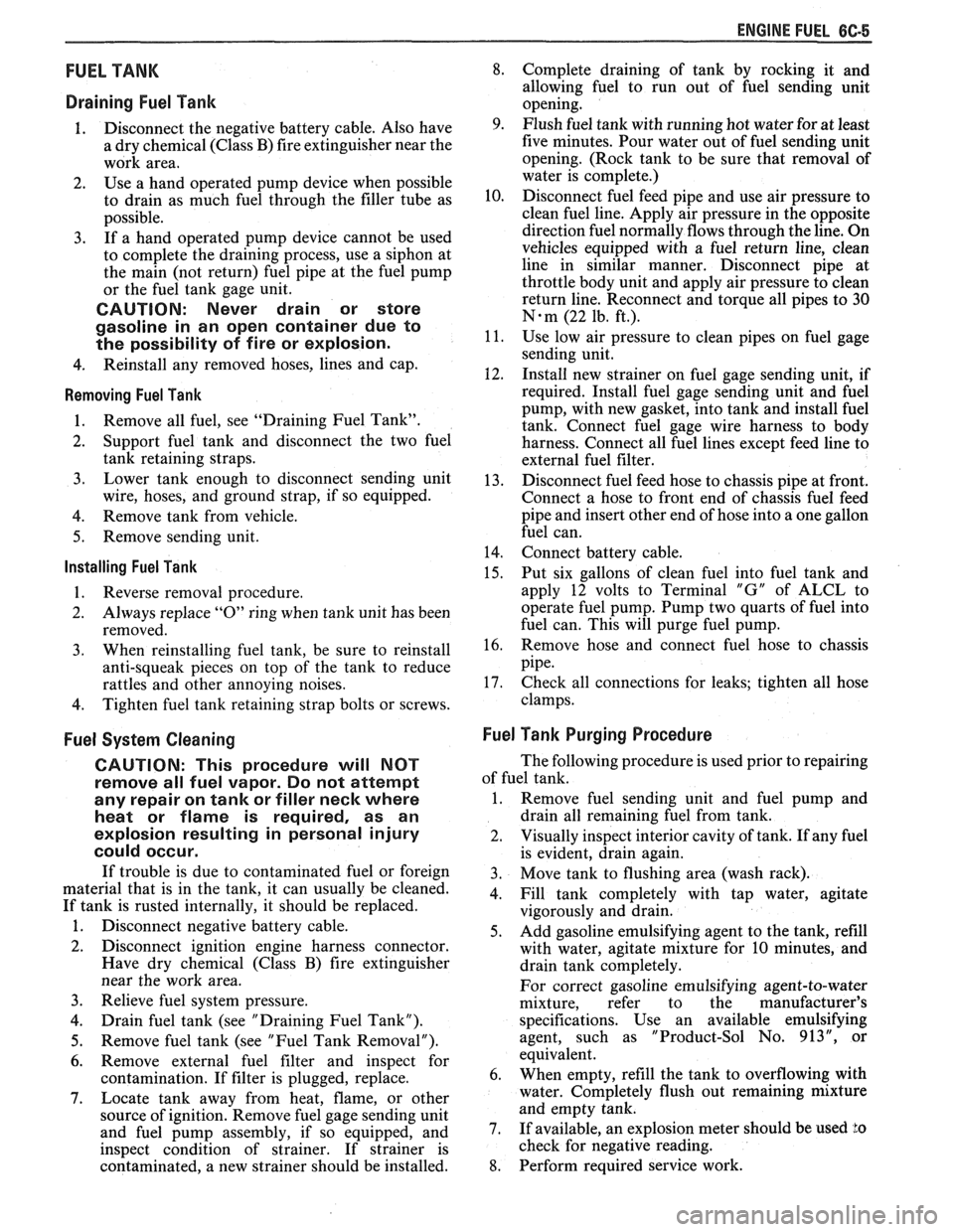

THERMOSTAT

Remove or Disconnect

1. Battery negative cable at battery.

2. Air cleaner.

3. Drain cooling system.

4. Thermostat housing attaching bolts and remove

housing. Remove thermostat from manifold.

Clean

Clean housing and manifold sealing

surfaces.

Install or Connect

1. New gasket.

2. Thermostat in intake manifold.

3. Refer

to Section 6E3 for plenum and throttle

body installation.

4. Battery negative cable.

5. Fill cooling system.

6. Start engine and run, with radiator cap removed,

until radiator upper hose becomes hot

(thermostat open). 7.

With

engine idling, add coolant to radiator until

level reaches bottom of filler neck.

8. Cap making sure arrows line up with overflow

tube.

18-24 N,m (13-18 FT. LBS.)

Fig. 601 Thermostat - V.I.N. S

Page 434 of 1825

ENGINE FUEL 6C.3

a Fuel feed and return pipes are secured to the

underbody with clamps and screw assemblies.

The pipes should be inspected occasionally for

leaks, kinks or dents.

e Follow the same routing as the original pipe.

e Pipes must be properly secured to the frame to

prevent chafing. A minimum of 6 mm

(1/4")

clearance must be maintained around a pipe to

prevent contact and chafing.

MPFl Fuel Pipes

Due to the fact that fuel pipes are under high

pressure, these systems require special consideration for service.

Many feed and return pipes use screw couplings

with

"0" Rings. Any time these fittings are loosened

to service or replace components, ensure that:

a A backup wrench is used while loosening and

tightening the fitting.

e Check all "0" rings at fitting locations (if

applicable) for cuts or any damage and replace

any that appear worn or damaged.

e Use correct torque when tightening fittings.

If pipes are replaced always use original

equipment parts, or parts that meet GM

specifications.

Fuel and Vapor Hoses

NOTICE: Fuel and vapor hoses are specially

manufactured. If replacement becomes necessary,

it is important to use only replacement hoses

meeting GM Specification 6163-M. These hoses

are identified with the words "Fluoroelastomer"

on them. Hoses not so marked could cause early

failure, or fail to meet emission standards.

e Do not use rubber hose within 4" of any part of

the exhaust system, or within

10" of the catalytic

converter.

FUEL PUMP

The electric fuel pump is in the fuel tank. The

tank has an outlet for a vapor return system. Any vapor

which forms is returned to the fuel tank along with hot

fuel through a separate line. This greatly reduces any

possibility of vapor lock by keeping cool fuel from the

tank constantly circulating through the fuel pump.

FUEL PUMP RELAY

To control fuel pump operation, a fuel pump

relay is used.

When the ignition switch is turned to "RUN"

position, the fuel pump relay activates the electric fuel

pump for

1.5 to 2.0 seconds to prime the injector(s). If

the ECM does not receive reference pulses from the

distributor after this time, the ECM signals the relay

to turn off the fuel pump. The relay will once again

activate the fuel pump when the

ECM receives

distributor reference pulses.

Fuel Filter

CAUTION: To reduce the risk of fire

and personal injury, it is necessary

to

relieve the fuel system pressure

before servicing fuel system

components. (See Fuel System

Pressure Relief.)

The inline filters can be found on the rear

crossmember of the vehicle. Always use a backup

wrench any time that the fuel filter is removed or

installed. Also make sure that a good

"0" Ring is used

at all screw couple locations. Torque on fittings is

30

N-m (22 lb. ft.).

FUEL TANK

The fuel tank is usually located under the rear of

the vehicle and a number of shapes and sizes are used

depending on the application.

The tank is held in place by two metal straps,

hinged (with a bolt through the hinge) and secured at

the opposite end with a nut and bolt assembly.

Anti-squeak pieces are used on top of the tank to

reduce rattles and other annoying noises.

The fuel tank, cap and lines should be inspected

for road damage, whch could cause leakage. Inspect

fuel cap for correct sealing and indications of physical

damage. Replace any damaged or malfunctioning

parts.

Before attempting service of any type on the fuel

tank, always

(1) remove negative battery cable from

battery, (2) place "no smoking" signs near work areas,

(3) be sure to have C02 fire extinguisher handy, (4)

wear safety glasses and

(5) siphon or pump fuel into an

explosion proof container.

Fuel Filler Gap

The fuel tank filler neck is equipped with a

screw-type cap. The threaded part of the cap requires

several turns counterclockwise to remove. The long

threaded area is designed to allow any remaining fuel

tank pressure to escape while the cap is being removed.

A built-in torque-limiting device prevents

overtightening. To install, turn the cap clockwise until

a clicking noise is heard. This signals that the correct

torque has been reached and the cap is fully seated.

N OTI G E: If a fuel filler cap requires replacement,

use only a cap with the same features. Failure to

use the correct cap can result in a serious

malfunction of the system.

Available on some models is an electric locking

fuel filler cap. Information on this option will be found

in Section

9E.

FUEL TANK FILLER NECK

To help prevent refueling with leaded gasoline,

the fuel filler neck on gasoline engine cars has a built-in

restrictor and deflector. The opening in the restrictor

will only admit the smaller unleaded gas nozzle spout,

which must be fully inserted to bypass the deflector.

Attempted refueling with a leaded gas nozzle or failure

Page 436 of 1825

ENGINE FUEL CC-5

FUEL TANK

Draining Fuel Tank

1. Disconnect the negative battery cable. Also have

a dry chemical (Class B) fire extinguisher near the

work area.

2. Use a hand operated pump device when possible

to drain as much fuel through the filler tube as

possible.

3. If

a hand operated pump device cannot be used

to complete the draining process, use a siphon at

the main (not return) fuel pipe at the fuel pump

or the fuel tank gage unit.

CAUTION: Never drain or store

gasoline in an open container due to

the possibility of fire or explosion.

4. Reinstall any removed hoses, lines and cap.

Removing Fuel Tank

1. Remove all fuel, see "Draining Fuel Tank".

2. Support

fuel tank and disconnect the two fuel

tank retaining straps.

3. Lower tank enough to disconnect sending unit

wire, hoses, and ground strap, if so equipped.

4. Remove tank from vehicle.

5. Remove sending unit.

Installing Fuel Tank

1. Reverse removal procedure.

2. Always replace "0" ring when tank unit has been

removed.

3. When reinstalling fuel tank, be sure to reinstall

anti-squeak pieces on top of the tank to reduce

rattles and other annoying noises.

4. Tighten fuel tank retaining strap bolts or screws.

Fuel System Cleaning

CAUTION: This procedure will NOT

remove all fuel vapor. Do not attempt

any repair

on tank or filler neck where

heat or flame is required, as an

explosion resulting in personal injury

could occur.

If trouble is due to contaminated fuel or foreign

material that is in the tank, it can usually be cleaned.

If tank is rusted internally, it should be replaced.

1. Disconnect negative battery cable.

2. Disconnect ignition engine harness connector.

Have dry chemical (Class B) fire extinguisher

near the work area.

3. Relieve fuel system pressure.

4. Drain fuel tank (see "Draining Fuel Tank").

5. Remove fuel tank (see "Fuel Tank Removal").

6. Remove external fuel filter and inspect for

contamination. If filter is plugged, replace.

7. Locate tank away from heat, flame, or other

source of ignition. Remove fuel gage sending unit

and fuel pump assembly, if so equipped, and

inspect condition of strainer. If strainer is

contaminated, a new strainer should be installed.

8. Complete draining of tank by rocking it and

allowing fuel to run out of fuel sending unit

opening.

9. Flush fuel tank with running hot water for at least

five minutes. Pour water out of fuel sending unit

opening. (Rock tank to be sure that removal of

water is complete.)

10. Disconnect fuel feed pipe and use air pressure to

clean fuel line. Apply air pressure in the opposite

direction fuel normally flows through the line. On

vehicles equipped with a fuel return line, clean

line in similar manner. Disconnect pipe at

throttle body unit and apply air pressure to clean

return line. Reconnect and torque all pipes to 30

N-m (22 1b. ft.).

11. Use low air pressure to clean pipes on fuel gage

sending unit.

112. Install new strainer on fuel gage sending unit, if

required. Install fuel gage sending unit and fuel

pump, with new gasket, into tank and install fuel

tank. Connect fuel gage wire harness to body

harness. Connect all fuel lines except feed line to

external fuel filter.

13. Disconnect fuel feed hose to chassis pipe at front.

Connect a hose to front end of chassis fuel feed

pipe and insert other end of hose into a one gallon

fuel can.

14. Connect battery cable.

15. Put six gallons of clean fuel into fuel tank and

apply 12 volts to Terminal

"G" of ALCL to

operate fuel pump. Pump two quarts of fuel into

fuel can. This will purge fuel pump.

16. Remove hose and connect fuel hose to chassis

pipe.

17. Check all connections

for leaks; tighten all hose

clamps.

Fuel Tank Purging Procedure

The following procedure is used prior to repairing

of fuel tank.

1. Remove fuel sending unit and fuel pump and

drain all remaining fuel from tank.

2. Visually inspect interior cavity of tank. If any fuel

is evident, drain again.

3. Move tank to flushing area (wash rack).

4. Fill tank completely with tap water, agitate

vigorously and drain.

5. Add gasoline emulsifying agent to the tank, refill

with water, agitate mixture for 10 minutes, and

drain tank completely.

For correct gasoline emulsifying agent-to-water

mixture, refer to the

manufacturer's

specifications. Use an available emulsifying

agent, such as "Product-Sol No.

913", or

equivalent.

6. When empty, refill the tank to overflowing with

water. Completely flush out remaining mixture

and empty tank.

7. If available, an explosion meter should be used Lo

check for negative reading.

8. Perform required service work.

Page 594 of 1825

DRIVEABILITY AND EMISSIONS 5.8L (VIN E) 6EZ-C3-1

SECTION C3

EVAPORATIVE EMISSION CONTROL SVSEENI (EECS)

CONTENTS

........................ GENERAL DESCRIPTION ............... C3-1 DIAGNOSIS C3-2

.......... PURPOSE ........................ C3-1 VISUAL CHECK OF CANISTER C3-2

.......... VAPOR CANISTER.. ................. C3-1 CANISTER PURGE SOLENOID C3-2

................. EVAPORATIVE EMISSION SYSTEM.. ..... C3-1 ON-CAR SERVICE C3-2

............ IN-TANK PRESSURE CONTROL VALVE . . C3-2 FUEL VAPOR CANISTER R/R C3-2

.................. RESULTS OF INCORRECT OPERATION .... C3-2 CANISTER HOSES.. C3-2

................ PARTS INFORMATION C3-2

GENERAL DESCRIPTION

PURPOSE

The basic evaporative emission control system

(EECS) used on all vehicles is the charcoal canister

storage method. This method transfers fuel vapor

from the fuel tank to an activated carbon (charcoal)

storage device (canister) to hold the vapors when the

vehicle is not operating. When the engine is running,

the fuel vapor is purged from the carbon element by

intake air flow and consumed in the normal

combustion process.

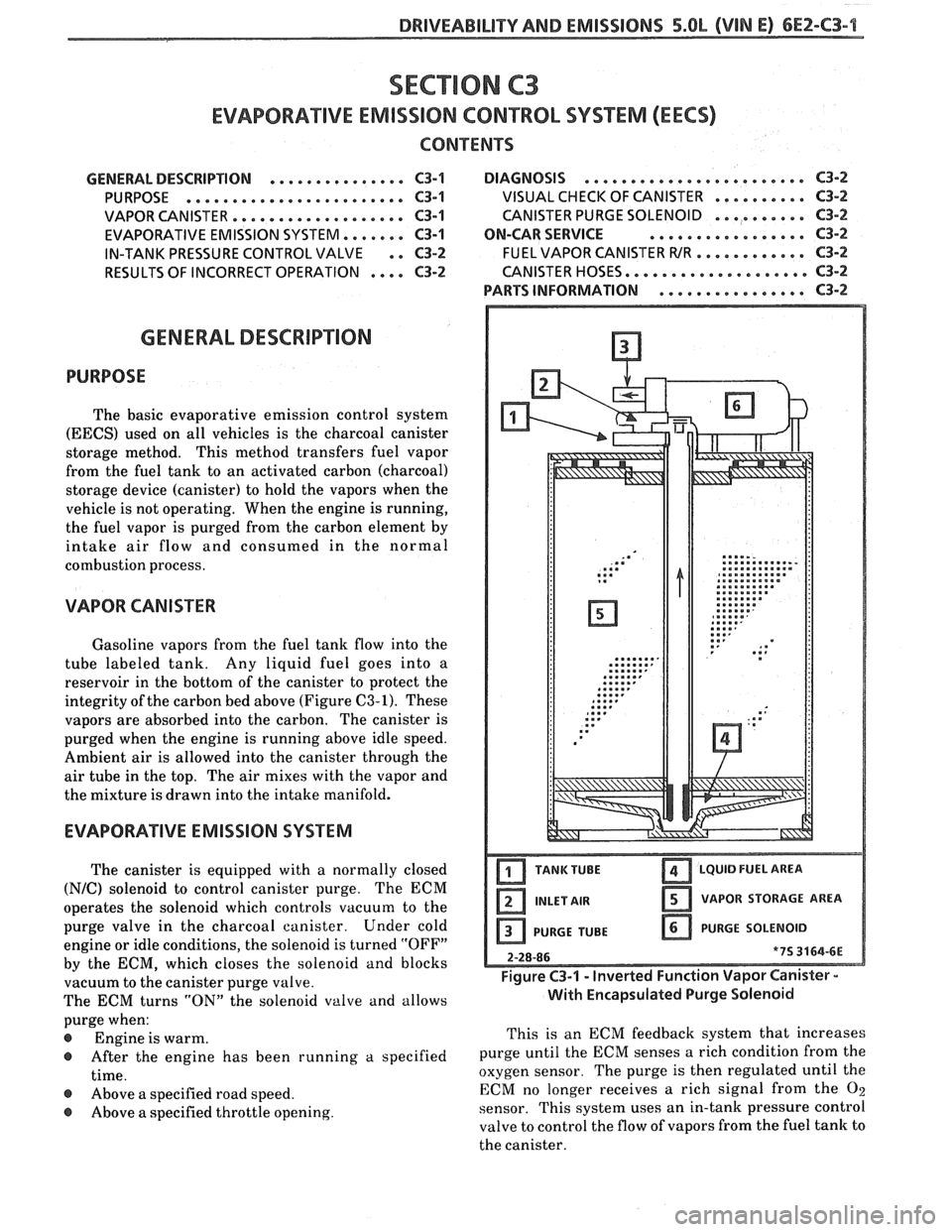

VAPOR CANISTER

Gasoline vapors from the fuel tank flow into the

tube labeled tank. Any liquid

fuel goes into a

reservoir in the bottom of the canister to protect the

integrity of the carbon bed above (Figure C3-1). These

vapors are absorbed into the carbon. The canister is

purged when the engine is running above idle speed.

Ambient air is allowed into the canister through the

air tube in the top. The air mixes with the vapor and

the mixture is drawn into the intake manifold.

EVAPORATIVE EMISSION SYSTEM

The canister is equipped with a normally closed

(N/C) solenoid to control canister purge. The ECM

operates the solenoid which controls vacuum to the

purge valve in the charcoal canister. Under cold

engine or idle conditions, the solenoid is turned "OFF"

by the ECM, which closes the solenoid and blocks

vacuum to the canister purge valve.

The ECM turns "ON" the solenoid valve and allows

purge when:

@ Engine is warm.

@ After the engine has been running a specified

time.

@ Above a specified road speed.

@ Above a specified throttle opening.

TANKTUBE LQUID FUEL AREA

INLET AIR VAPOR STORAGE AREA

PURGE TUBE PURGE

SOLENOID

Figure C3-1 - Inverted Function Vapor Canister -

With Encapsulated Purge Solenoid

This is an ECM feedback system that increases

purge until the ECM senses a rich condition from the

oxygen sensor. The purge

is then regulated until the

ECM no longer receives a rich signal from the

O2

sensor. This system uses an in-tank pressure control

valve to control the flow of vapors from the fuel tank to

the canister.

Page 671 of 1825

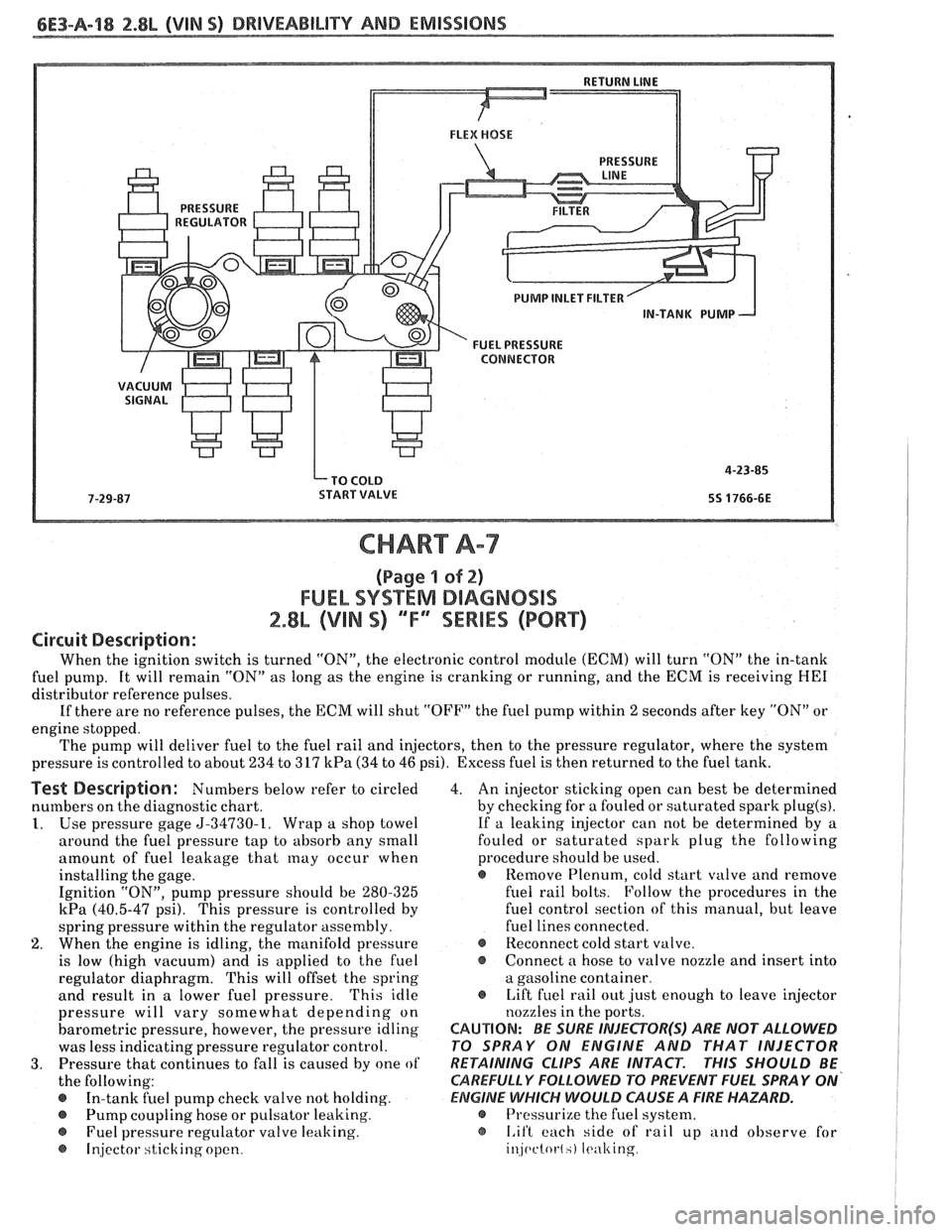

6E3-A-I8 2.8b (VIN 5) DRIVEABILITY AND EMISSIONS

PUMP INLET FILTER

IN-TANK PUMP

FUEL

PRESSURE CONNECTOR

CHART A-7

(Page 4 of 2)

FUEL SYSTEM DsAGNOSBS

2.8L (VIN S) ""FYSERBES (PORT)

Circuit Description:

When the ignition switch is turned "ON", the electronic control module (ECM) will turn "ON" the in-tank

fuel pump. It will remain "ON" as long as the engine is cranking or running, and the ECM is receiving

HE1

distributor reference pulses.

If there are no reference pulses, the ECM will shut "OFF" the fuel pump within

2 seconds after key "ON" or

engine stopped.

The pump will deliver fuel to the fuel rail and injectors, then to the pressure regulator, where the system

pressure is controlled to about 234 to 317

kPa (34 to 46 psi). Excess fuel is then returned to the fuel tank.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. Use pressure gage 5-34730-1. Wrap a shop towel

around the fuel pressure tap to absorb any small

amount of fuel leakage that

may occur when

installing the gage.

Ignition "ON", pump pressure should be 280-325

kPa (40.5-47 psi). This pressure is controlled by

spring pressure within the regulator assembly.

2. When the engine is idling, the manifold pressure

is low (high vacuum) and is applied to the fuel

regulator diaphragm. This will offset the spring

and result in a lower fuel pressure.

'This idle

pressure will vary somewhat depending on

barometric pressure, however, the pressure idling

was less indicating pressure regulator control.

3. Pressure that continues to fall is caused by one of

the following:

In-tank fuel pump check valve not holding.

@ Pump coupling hose or pulsator leaking.

Fuel pressure regulator valve leaking.

@ Injector sticking open. 4.

An injector sticking open can best be determined

by checking for a fouled or saturated spark

plug(s).

If a leaking injector can not be determined by a

fouled or saturated spark plug the following

procedure should be used.

e Remove Plenum, cold start valve and remove

fuel rail bolts. Follow the procedures in the

fuel control section of this manual, but leave

fuel lines connected.

@ Reconnect cold start valve.

@ Connect a hose to valve nozzle and insert into

a gasoline container.

@ Lift fuel rail out just enough to leave injector

nozzles in the ports.

CAUTION: BE SURE INJEePOR(S) ARE NOT ALLOWED

PO SPRAY ON ENGINE AND THAT INJECTOR

RETAINING

CLIPS ARE INTACT. PHIS SHOULD BE

CAREFULLY

FOLLOWD PO PREVENT FUEL SPRAY ON'

ElZIGlNE WHICH WOULD CAUSE A FIRE HAZARD.

@ Pressurize the fuel system.

@ I.if't each side of rail up and observe for

injc~ctot-l.) It.ulting