overheating PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 20 of 1825

F CARLINE

ITEM 10

TransmissionRransaxle Service

The manual transmission or transaxle fluid does not

require changing. (Corvette only.) Change fluid in over-

drive unit every 30,000 miles (50 000 km).

For automatic transmissions or transaxles, change

both the fluid and filter every 15,000 miles (25 000 km) if

the car is mainly driven under one or more of these

conditions:

@ In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

@ In hilly or mountainous terrain.

@ Frequent trailer pulling.

@ Uses such as found in taxi, police car or delivery

service.

If you do not use your car under any of these condi-

tions, change both the fluid and filter every 100,000 miles

(160 000 km). See you Owner's Manual for further

details.

ITEM 11

Spark Plug Service*

Replace spark plugs with type listed in your Owner's

Manual.

ITEM 12

Spark Plug Wire Inspection*

Clean wires and inspect for burns, cracks or other dam-

age. Check the wire boot fit at distributor and at spark plugs.

Replace wires as needed.

ITEM 13

Positive Crankcase Ventilation (PCV) Valve

Inspection*

Inspect valve for proper function. Replace valve if

necessary as well as any worn, plugged or collapsed

hoses.

ITEM 14

EGR System Service*

Conduct EGR System Service as referenced in the

EGR System Chart shown in the appropriate 6E Section.

Also, refer to your GM maintenance schedule booklet for

specific applications.

ITEM 15

Air Cleaner and PCV Filter Replacement*

On 1.6 and 2.0 liter engines, replace every 50,000

miles (80 000 km). On all other engines, replace every

30,000 miles (50 000 km). Replace more often under

dusty conditions. Ask your dealer for the proper replace-

ment interval for your driving conditions.

MAINTENANCE AND LUBRICATION 08-3

ITEM 16

Engine Timing Check*

Adjust timing to underhood label specifications. If

no specifications are shown, no adjustment is needed.

ITEM 17

Fuel Tank, Cap and Lines Inspection*

Inspect fuel tank, cap and lines (including fuel rails

and injection assembly, if so equipped) for damage or

leaks. Inspect fuel cap gasket for an even filler neck

imprint or any damage. Replace parts as needed.

ITEM 18

Thermostatically Controlled Air Cleaner

Inspection*

If your car is equipped, inspect all hoses and ducts

for proper hookup. Make sure valve works properly.

OWNER INSPECTIONS AND SERVICES

Listed below are inspections and services which

should be made by either you or a qualified technician at

the intervals shown to help ensure proper safety, emission

performance and dependability of your car. Take any

problems promptly to your dealer or another qualified

technician for service advice. Whenever repairs are neces-

sary, have them completed at once. For your safety and

that of others, any safety-related parts that could have

been damaged in an accident should be inspected and all

needed repairs should be done before operating your car.

Be sure to use the proper fluids and lubricants as shown in

Figure OB-2.

WHILE OPERATING YOUR VEHICLE

Automatic transmissionltransaxle shift indi-

cator operation - Make sure the indicator points to the

gear chosen.

Horn operation - Blow the horn occasionally to

make sure it works. Check all button locations.

I

Brake system operation -- Be alert to abnormal

sounds, increased brake pedal travel or repeated pulling to

one side when braking. Also, if a brake warning light

comes on or flashes, or the anti-lock warning light (if

equipped) comes on or remains on, something may be

wrong with part of the brake system. Have it inspected and

repaired at once.

Exhaust system operation - Be alert to any

changes in the sound of the system or any smell of fumes.

These are signs the system may be leaking or overheating.

.

Have it inspected and repaired at once. Also see "Engine

Exhaust Gas Caution (Carbon Monoxide)" and "Catalytic

Converter" in your Owner's Manual.

*An Emission Control Service

Page 145 of 1825

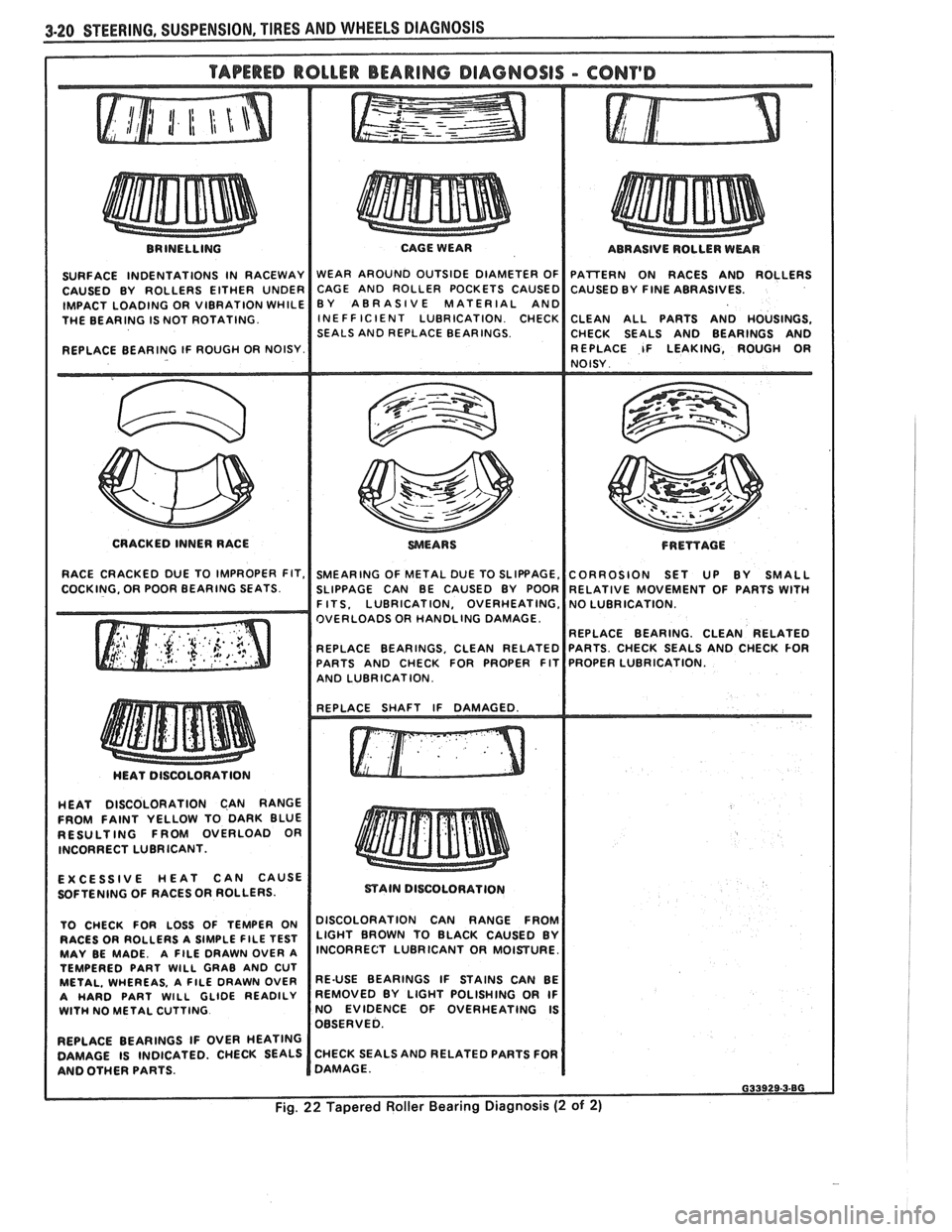

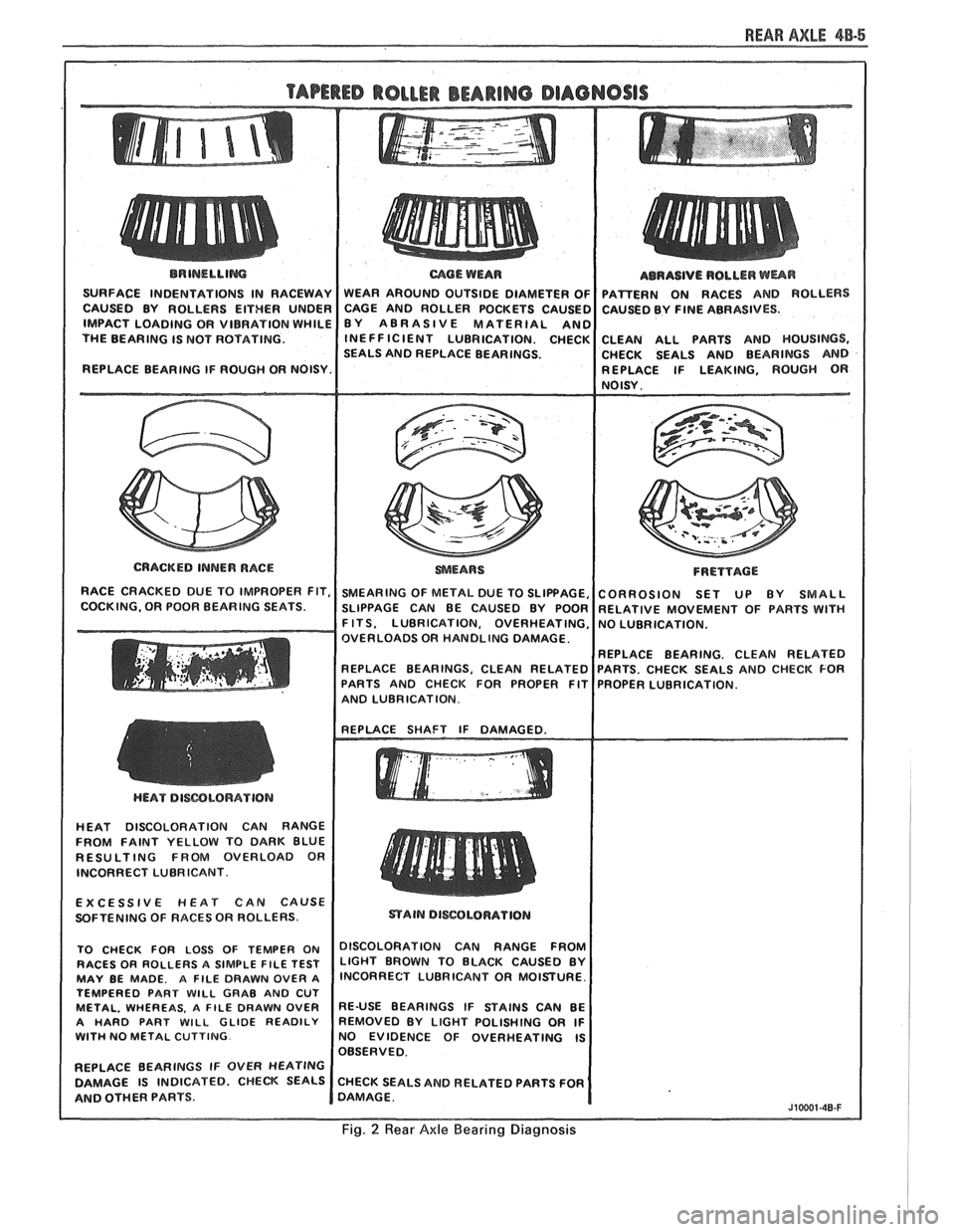

BRINELLING

SURFACE INDENTATIONS IN RACEWAY

CAUSED BY ROLLERS EITHER UNDER

IMPACT LOADING OR VIBRATION WHILE

THE BEARING IS NOT ROTATING.

REPLACE BEARING IF ROUGH OR NOISY. CAGE WEAR

WEAR AROUND OUTSIDE DIAMETER OF

CAGE AND ROLLER POCKETS CAUSED

BY ABRASIVE MATERIAL AND

INE FF IClENT LUBRICATION CHECK

SEALS AND REPLACE BEARINGS. ABRASIVE

ROLLER WEAR

PATTERN ON RACES AND ROLLERS

CAUSED BY

FINE ABRASIVES.

CLEAN ALL PARTS AND HOUSINGS,

CHECK SEALS AND BEARINGS AND

REPLACE IF LEAKING, ROUGH

OR NOISY

CRACKED INNER RACE

WEARS FRETfAGE

RACE CRACKED DUE TO IMPROPER FIT, SMEARING OF METAL DUE TO SLIPBAGE, CORROSION SET UP BY SMALL

COCKING. OR POOR BEARING SEATS. SLIPPAGE CAN BE CAUSED BY POOR RELATIVE MOVEMENT OF PARTS WITH I F ITS. LUBRICATION, OVERHEATING,

OVERLOADS OR HANDLING DAMAGE

REPLACE BEARING. CLEAN RELATED

REPLACE BEARINGS, CLEAN RELATED

PARTS AND CHECK FOR PROPER FIT

I AND LUBRICATION. I I

HEAT DISCOLORATION CAN RANGE

FROM FAINT YELLOW TO DARK BLUE

RESULTING FROM OVERLOAD OR

INCORRECT LUBRICANT.

EXCESSIVE HEAT CAN CAUSE

SOFTENING OF RACES

OR ROLLERS.

TO CHECK FOR LOSS OF TEMPER ON

RACES OR ROLLERS A SIMPLE

FlLE TEST MAY BE MADE. A FILE DRAWN OVER A

TEMPERED PART WlLL GRAB AND CUT

METAL. WHEREAS, A FlLE DRAWN OVER

A HARD PART WlLL GLIDE READILY WlTH NO METAL CUTTING

REPLACE BEARINGS IF OVER HEATING

DAMAGE IS INDICATED. CHECK SEALS

AND OTHER PARTS.

mAIN DISCOLORATION

I DISCOLORATION CAN RANGE FROM

LIGHT BROWN TO BLACK CAUSED BY

INCORRECT LUBRICANT OR MOISTURE.

RE-USE BEARINGS IF STAINS CAN BE

REMOVED BY LIGHT POLISHING OR IF

NO EVIDENCE OF OVERHEATING IS

OBSERVED.

CHECK SEALS AND RELATED PARTS FOR

DAMAGE.

Page 245 of 1825

4A-4 PROPELLER SHAFT

PROPELLER SHAFT BALANCING

Hose Clamp Method

Figures 4A- 1 1 thru 4A-13

1. Place the vehicle on a twin post hoist so that the

rear of the vehicle is supported on the rear axle

housing and the rear wheels are free to rotate.

Remove both rear wheel assemblies and reinstall

wheel lug nuts with flat sides next to

drums/discs.

2. Mark and number propeller shaft at four (4)

points 90 degrees apart at rear of shaft just

forward of balance weight, as shown.

3. Install two (2) hose clamps on the rear of the

propeller shaft and slide them rearward until the

clamps stop at the nearest balance weight welded

to the tube. Align both clamps at any one of the

four marks made on shaft in Step 2 and tighten.

Be sure sufficient clearance is maintained so that

clamp heads do not contact floor pan of vehicle

when axle is in contact with rebound bumper in

frame. In order to gain sufficient clearance, it

may be necessary to position the clamps over the

balance weights.

4. Run the vehicle through the speed range to 80-90

MPH (130-145

Km/h) and note amount of

imbalance.

CAUTION: All persons should stay

clear of universal joint and balance

weight areas to avoid possible injury.

Do not run on hoist for extended

periods due to the danger of

overheating the transmission or

engine.

5. Loosen clamps and rotate clamp heads 90 degrees

to the next mark on a propeller shaft. Tighten

clamps and repeat Step 4.

6. Repeat Step 5 until car has been run with clamp

heads located at all four marks on shaft.

7. Position clamps at point of least imbalance.

Rotate the clamp heads away from each other 45

degrees (one on each side of the position), as

shown. Run the vehicle and note if imbalance has

improved.

In some cases it may be necessary to use one

clamp or possibly three clamps in order to obtain

a good balance. Replace shaft if three hose clamps

do not improve the imbalance.

8. Continue to rotate the clamps apart in smaller

angular increments until the imbalance is at its

minimum.

9. Reinstall wheel assemblies and road test the

vehicle for final check of balance. A minimal

vibration felt in the vehicle on the hoist may not

show up during a road test.

Strobe Light Method

Figures 461- 1 1, $A- 14, and 4A- 15

If a wheel balancer of the strobe light type is

available, the use of such a unit will facilitate the

balancing of the propeller shaft. The balance pick-up

unit should be placed directly under the nose of the

rear axle carrier and as far forward as possible. 1.

Place

the vehicle on a twin post hoist so the rear of

the vehicle is supported on the rear axle housing and

the rear wheels are free to rotate. Lower rear hoist

and allow axle to rest on jackstands. The groove in

the rear hoist fixture could clamp the axle and de-

stroy the sensitivity of the operation. Remove both

rear wheel assemblies and reinstall wheel lug nuts

with flat sides next to the

drums/rotors.

2.

Mark and number drive shaft at 4 points 90

degrees apart at rear of shaft just forward of

balance weights, as shown.

3. Place the strobe light wheel balancer pick-up

under the nose of the carrier.

4. Run vehicle in gear at the speed where the

distrubance is at its peak, allow the driveline to

stabilize by holding at a constant speed. Point

strobe light up at the spinning propeller shaft and

note position of one of the reference numbers.

Shut off engine and position the propeller shaft so

the reference numbers will be in the same position

as was noted while the shaft was rotating.

When strobe light flashed, the heaviest point of

the shaft was at the bottom (6 o'clock). To

balance the propeller shaft, it would be necessary

to apply the balancing weights (hose clamps) 180

degrees away from the heaviest point or at the top

of the propeller shaft (12 o'clock).

5. Install two screw-type hose clamps on the

propeller shaft as close to the rear as possible.

Position both clamp heads 180 degrees from the

heaviest point of drive shaft as indicated by strobe

light. Tighten clamps.

NOTICE: Be sure sufficient clearance is

maintained so clamp heads do not contact floor

pan of vehicle when axle is in contact with rebound

bumper on frame. In order to gain. sufficient

clearance, it may be necessary to position the

clamps over the balance weights.

6. Run vehicle through the speed range 80-90

M.P.

H. (130-145 Km/h). If disturbance is gone,

nothing further need be done on the hoist. If the

disturbance is not gone and the strobe light shows

the clamp heads at the bottom (6 o'clock) of the

shaft, go to Step

7. If the strobe light shows the

two clamp heads at the top of the shaft, add one

more hose clamp and recheck. If the strobe light

shows the three clamp heads at the top of the

shaft, remove the propeller shaft and

reindex it

180 degrees on the rear axle pinion companion

flange. Recheck with no clamps. Repeat balance

starting with Step 5. If the shaft still needs more

than three hose clamps at the same clock position,

replace it. If the clamps are also 180 degrees from

their original position after the propeller shaft

was reindexed 180 degrees, the rear axle pinion

companion flange is out of balance and must be

replaced. DO NOT use more than three hose

clamps to balance the shaft. If the strobe light

shows the hose clamps at the bottom of the shaft,

but the disturbance still exists, go to Step

7.

Page 259 of 1825

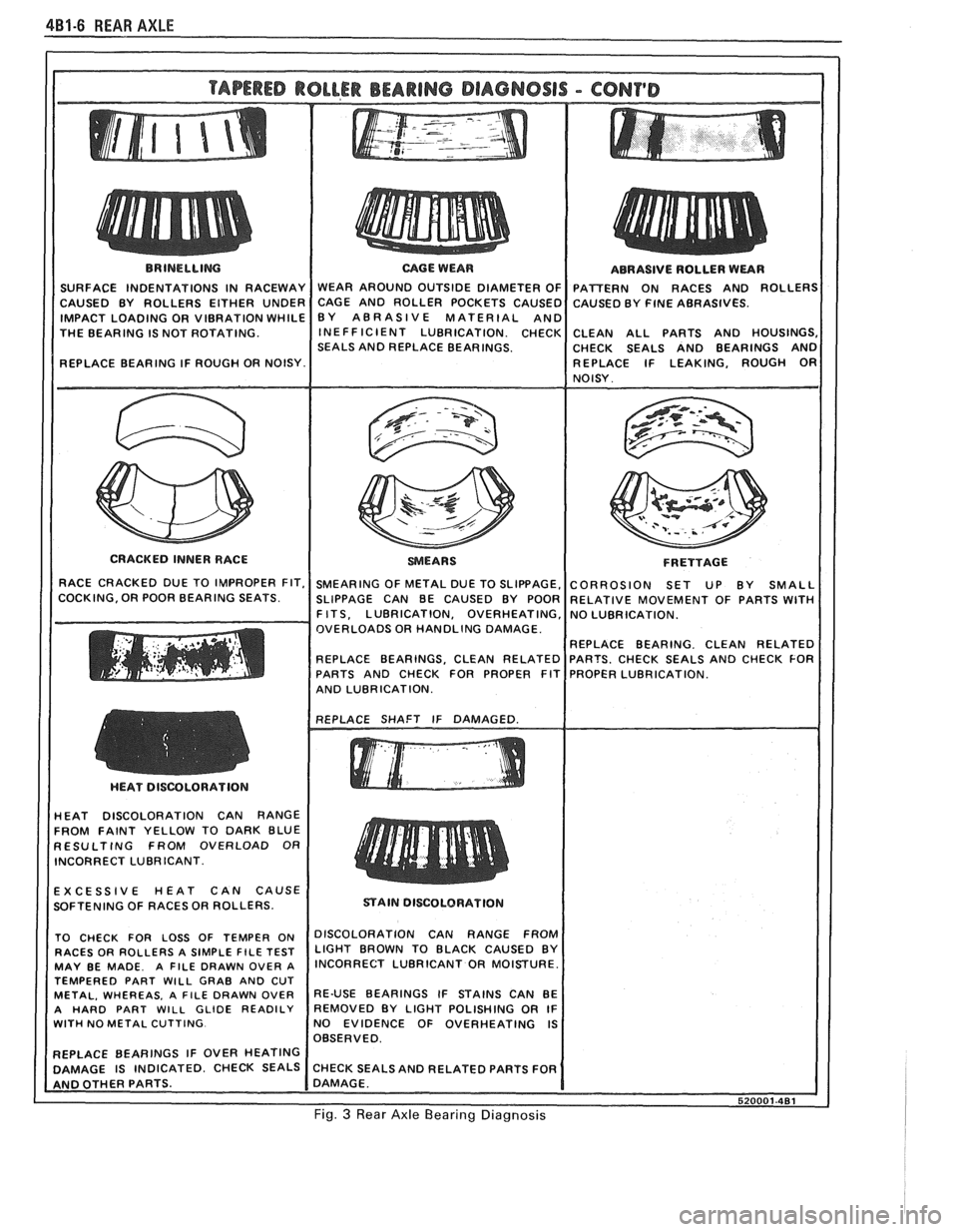

4B1-6 REAR AXLE

THE BEARING IS NOT ROTATING.

SEALS AND REPLACE BEARINGS. CHECK SEALS AND BEARINGS AND

CRACKED INNER RACE

F R ETTAGE

OVERLOADS OR HANDLING DAMAGE.

AND LUBRICATION.

HEAT DISCOLORATION CAN RANGE

FROM FAINT YELLOW TO DARK BLUE

RESULTING FROM OVERLOAD OR

INCORRECT LUBRICANT.

EXCESSIVE HEAT CAN CAUSE

SOFTENING OF RACES OR ROLLERS.

STAIN DISCOLORATION

TEMPERED PART

WILL GRAB AND CUT

WITH NO METAL CUTTING. NO EVIDENCE OF OVERHEATING IS

Fig. 3 Rear Axle Bearing Diagnosis

Page 278 of 1825

REAR AXLE 48-5

BRINELLIM

SURFACE INDENTATIONS IN RACEWAY

CAUSED BY ROLLERS EITHER UNDER

IMPACT LOADING OR VIBRATION WHILE

THE BEARING IS NOT ROTATING.

REPLACE BEARING IF ROUGH OR NOISY.

I

CRACKED INNER RACE

RACE CRACKED DUE TO IMPROPER FIT,

COCKING, OR POOR BEARING SEATS.

mOE WEAR

WEAR AROUND OUTSIDE DIAMETER OF

CAGE AND ROLLER POCKETS CAUSEC

BY ABRASIVE MATERIAL

AN0 INEFFICIENT LUBRICATION. CHECK

SEALS AND REPLACE BEARINGS.

SMEARING OF METAL DUE TO SLIPPAGE,

SLIPPAGE CAN BE CAUSED BY POOR

F ITS, LUBRICATION, OVERHEATING,

OVERLOADS OR HANDLING DAMAGE.

REPLACE BEARINGS. CLEAN RELATED

PARTS AND CHECK FOR PROPER FIT

AND LUBRICATION. ABRASIVE

ROLLER

WUR

PAmERN ON RACES AND ROLLERS

CAUSED BY FINE ABRASIVES.

CLEAN ALL PARTS AND HOUSINGS,

CHECK SEALS AND BEARINGS AND

REPLACE IF LEAKING, ROUGH

OR NOISY.

FRETTACE

CORROSION SET UP BY SMALL

RELATIVE MOVEMENT OF PARTS WlTH

NO LUBRICATION.

REPLACE BEARING. CLEAN RELATED

PARTS. CHECK SEALS AND CHECK FOR

PROPER LUBRICATION.

HEAT DISCOLORATION CAN RANGE

FROM FAINT YELLOW TO DARK BLUE

RESULTING FROM OVERLOAD OR

INCORRECT LUBRICANT.

EXCESSIVE

HEAT CAN CAUSE

SOFTENING OF RACES OR ROLLERS.

TO CHECK FOR LOSS OF TEMPER ON

DISCOLORATION CAN RANGE FFmM RACES OR ROLLERS A SIMPLE FILE TEST LIGHT BROWN TO BLACK CAUSED BY MAY BE MADE. A FILE DRAWN OVER A lNCORRECT LUBRICANT OR MOISTURE.

TEMPERED PART

WlLL GRAB AND CUT METAL, WHEREAS. A FILE DRAWN OVER RE-USE BEARINGS IF STAINS CAN BE

A HARD PART WILL GLIDE READILY REMOVED BY LIGHT POLISHING OR IF WITH NO METAL CUTTING NO EVIDENCE OF OVERHEATING IS

OBSERVED.

REPLACE BEARINGS IF OVER

HEATING

DAMAGE IS INDICATED. CHECK SEALS CHECK SEALS AND RELATED PARTS FOR

AND OTHER PARTS. DAMAGE.

J10001-40-F

Fig. 2 Rear Axle Bearing Diagnosis

Page 415 of 1825

BB.4 ENGINE COOLING

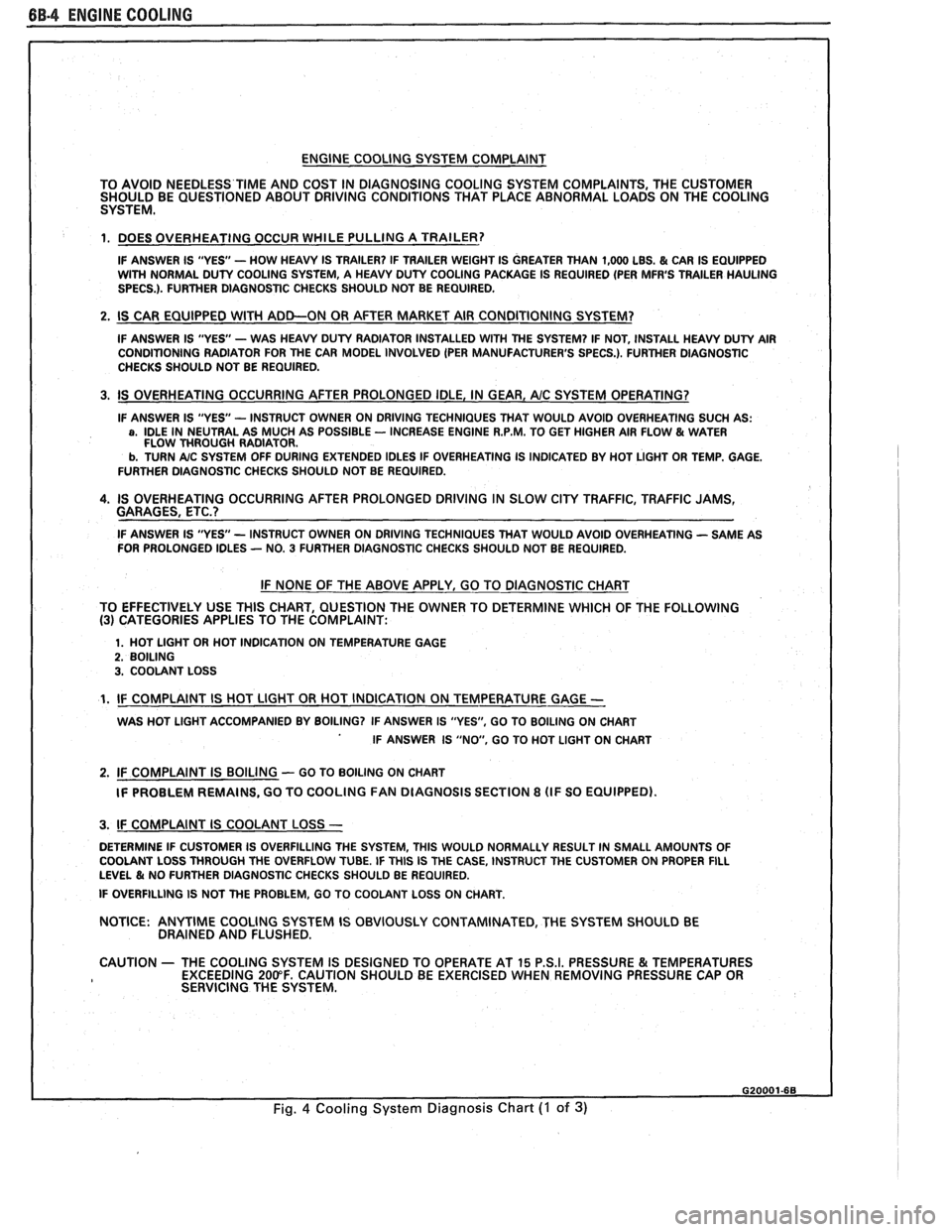

ENGINE COOLING SYSTEM COMPLAINT

TO AVOID NEEDLESS

TIME AND COST IN DIAGNOSING COOLING SYSTEM COMPLAINTS, THE CUSTOMER

SHOULD BE QUESTIONED ABOUT DRIVING CONDITIONS THAT PLACE ABNORMAL LOADS ON THE COOLING

SYSTEM.

1. DOES OVERHEATING OCCUR WHILE PULLING A TRAILER?

IF ANSWER IS "YES'- HOW HEAVY IS TRAILER? IF TRAILER WEIGHT IS GREATER THAN 1,000 LBS. & CAR IS EQUIPPED

WITH NORMAL DUTY COOLING SYSTEM, A HEAVY DUTY COOLING PACKAGE IS REQUIRED (PER MFR'S TRAILER HAULING

SPECS.). FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

2. IS CAR EQUIPPED WlTH ADD-ON OR AFTER MARKET AIR CONDITIONING SYSTEM?

IF ANSWER IS "YES"- WAS HEAVY DUTY RADIATOR INSTALLED WITH THE SYSTEM? IF NOT, INSTALL HEAVY DUTY AIR

CONDITIONING RADIATOR FOR THE CAR MODEL INVOLVED (PER MANUFACTURER'S SPECS.). FURTHER DlAGNOSTlC

CHECKS SHOULD NOT BE REQUIRED.

3. IS OVERHEATING OCCURRING AFTER PROLONGED IDLE, IN GEAR, AIC SYSTEM OPERATING?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING SUCH AS: a, IDLE IN NEUTRAL AS MUCH AS POSSIBLE - INCREASE ENGINE R.P.M. TO GET HIGHER AIR FLOW & WATER

FLOW THROUGH RADIATOR.

b. TURN A/C SYSTEM OFF DURING EXTENDED IDLES IF OVERHEATING IS INDICATED BY HOT LIGHT OR TEMP. GAGE.

FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

4. IS OVERHEATING OCCURRING AFTER PROLONGED DRIVING IN SLOW CITY TRAFFIC, TRAFFIC JAMS,

GARAGES, ETC.?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING - SAME AS

FOR PROLONGED IDLES - NO. 3 FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

IF NONE OF THE ABOVE APPLY, GO TO DIAGNOSTIC CHART

TO EFFECTIVELY USE THlS CHART, QUESTION THE OWNER TO DETERMINE WHICH OF THE FOLLOWING

(3) CATEGORIES APPLIES TO THE COMPLAINT:

1. HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE 2. BOILING 3. COOLANT LOSS

1. IF COMPLAINT IS HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE -

WAS HOT LlGHT ACCOMPANIED BY BOILING? IF ANSWER IS "YES", GO TO BOILING ON CHART

IF ANSWER IS "NO, GO TO HOT LlGHT ON CHART

2. IF COMPLAINT IS BOILING - GO TO BOILING ON CHART

IF PROBLEM REMAINS, GO TO COOLING

FAN DIAGNOSIS SECTION 8 (IF SO EQUIPPED).

I 3. IF COMPLAINT IS COOLANT LOSS -

DETERMINE IF CUSTOMER IS OVERFILLING THE SYSTEM, THlS WOULD NORMALLY RESULT IN SMALL AMOUNTS OF

I COOLANT LOSS THROUGH THE OVERFLOW TUBE. IF THlS IS THE CASE, INSTRUCT THE CUSTOMER ON PROPER FILL LEVEL & NO FURTHER DIAGNOSTIC CHECKS SHOULD BE REQUIRED.

I IF OVERFILLING IS NOT THE PROBLEM, GO TO COOLANT LOSS ON CHART.

NOTICE:

ANYTIME COOLING SYSTEM IS OBVIOUSLY CONTAMINATED, THE SYSTEM SHOULD BE

DRAINED AND FLUSHED.

1 CAUTION - THE COOLING SYSTEM IS DESIGNED TO OPERATE AT 15 P.S.I. PRESSURE & TEMPERATURES

EXCEEDING 200°F. CAUTION SHOULD BE EXERCISED WHEN REMOVING PRESSURE CAP OR

I SERVICING THE SYSTEM.

Fig. 4 Cooling System Diagnosis Chart (I of 3)

Page 417 of 1825

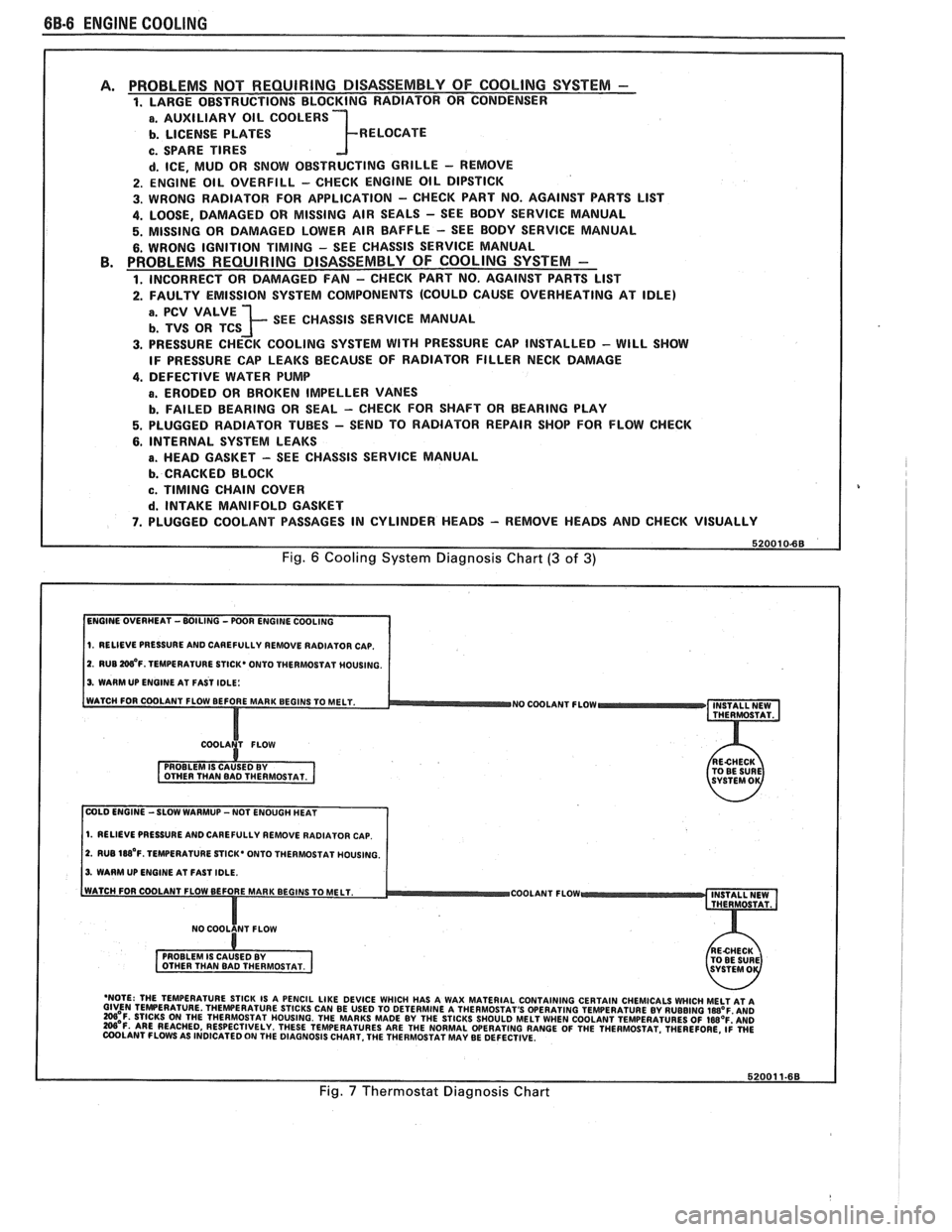

6B-8 ENGINE COOLING

PROBLEMS NOT REQUIRING DISASSEMBLY OF COOLING SYSTEM - 1. LARGE OBSTRUCTIONS BLOCKING RADIATOR OR CONDENSER

a. AUXILIARY OIL COOLERS

b. LICENSE PLATES R ELOCATE

c. SPARE TIRES

d. ICE, MUD OR SNOW OBSTRUCTING GRILLE - REMOVE

2. ENGINE OIL OVERFILL - CHECK ENGINE OIL DIPSTICK

3. WRONG RADIATOR FOR

APPLICATION - CHECK PART NO. AGAINST PARTS LlST

4. LOOSE, DAMAGED OR MISSING AIR SEALS - SEE BODY SERVICE MANUAL

5. MISSING OR DAMAGED LOWER AIR BAFFLE - SEE BODY SERVICE MANUAL

6. WRONG IGNITION TIMING - SEE CHASSIS SERVICE MANUAL PROBLEMS REQUIRING DISASSEMBLY OF COOLING SYSTEM -

1. INCORRECT OR DAMAGED FAN - CHECK PART NO. AGAINST PARTS LlST

2. FAULTY EMISSION SYSTEM COMPONENTS (COULD CAUSE OVERHEATING AT IDLE)

; SEE CHASSIS SERVICE MANUAL

3. PRESSURE CHECK COOLING SYSTEM WITH PRESSURE CAP INSTALLED - WILL SHOW

IF PRESSURE CAP LEAKS BECAUSE OF RADIATOR FILLER NECK DAMAGE

4. DEFECTIVE WATER PUMP

a. ERODED OR BROKEN IMPELLER VANES

b. FAILED BEARING OR SEAL - CHECK FOR SHAFT OR BEARING PLAY

5. PLUGGED RADIATOR TUBES - SEND TO RADIATOR REPAIR SHOP FOR FLOW CHECK

6. INTERNAL SYSTEM LEAKS

B. HEAD GASKET - SEE CHASSIS SERVICE MANUAL

b. CRACKED BLOCK

c. TIMING CHAIN COVER

d. INTAKE MANIFOLD GASKET

7. PLUGGED COOLANT PASSAGES IN CYLINDER HEADS - REMOVE HEADS AND CHECK VISUALLY

Fig. 6 Cooling System Diagnosis Chart (3 of 3)

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB W'F. TEMPERATURE STICK* ONTO THERMOSTAT MOUSING.

3. WARM UP ENGINE AT FAST IDLE:

WATCH FOR COOLANT FLOW BEFORE MAR

NO COOLANT FLOW INSTALL NEW

THERMOSTAT.

COLD ENGINE -SLOW WARMUP -NOT ENOUGH HEAT

1. RELIEVE PRESSURE AND CAREFULLY REMOVE RADIATOR CAP.

2. RUB 188'~. TEMPERATURE STICK' ONTO THERMOSTAT HOUSING.

3. WARM UP ENGINE AT FAST IDLE.

COOLANT FLOW

- 'NOTE: THE TEMPERATURE STICK IS A PENCIL LIKE DEVICE WHICH HAS A WAX MATERIAL CONTAINING CERTAIN CHEMICALS WHICH MELT AT A GIVEN TEMPERATURE THEWERATURE STICKS CAN BE USED TO DETERMINE A THERMOSTAT'S OPERATING TEMPERATURE BY RUBBING laB°F AN0 =OF. STICKS ON THE THERMOSTAT HOUSING. THE MARKS MADE BY THE STICKS SHOULD MELT WHEN COOLANT TEMPERATURES OF IWOF'AND W'F. ARE REACHED, RESPECTIVELY. THESE TEMPERATURES ARE THE NORMAL WERATING RANGE OF THE THERMOSTAT. THEREFORE, ~i WE COOLANT FLOWS AS INDICATED ON THE DIAGNOSIS CHART. THE THERMOSTAT MAY BE DEFECTIVE.

Fig. 7 Thermostat Diagnosis Chart

Page 453 of 1825

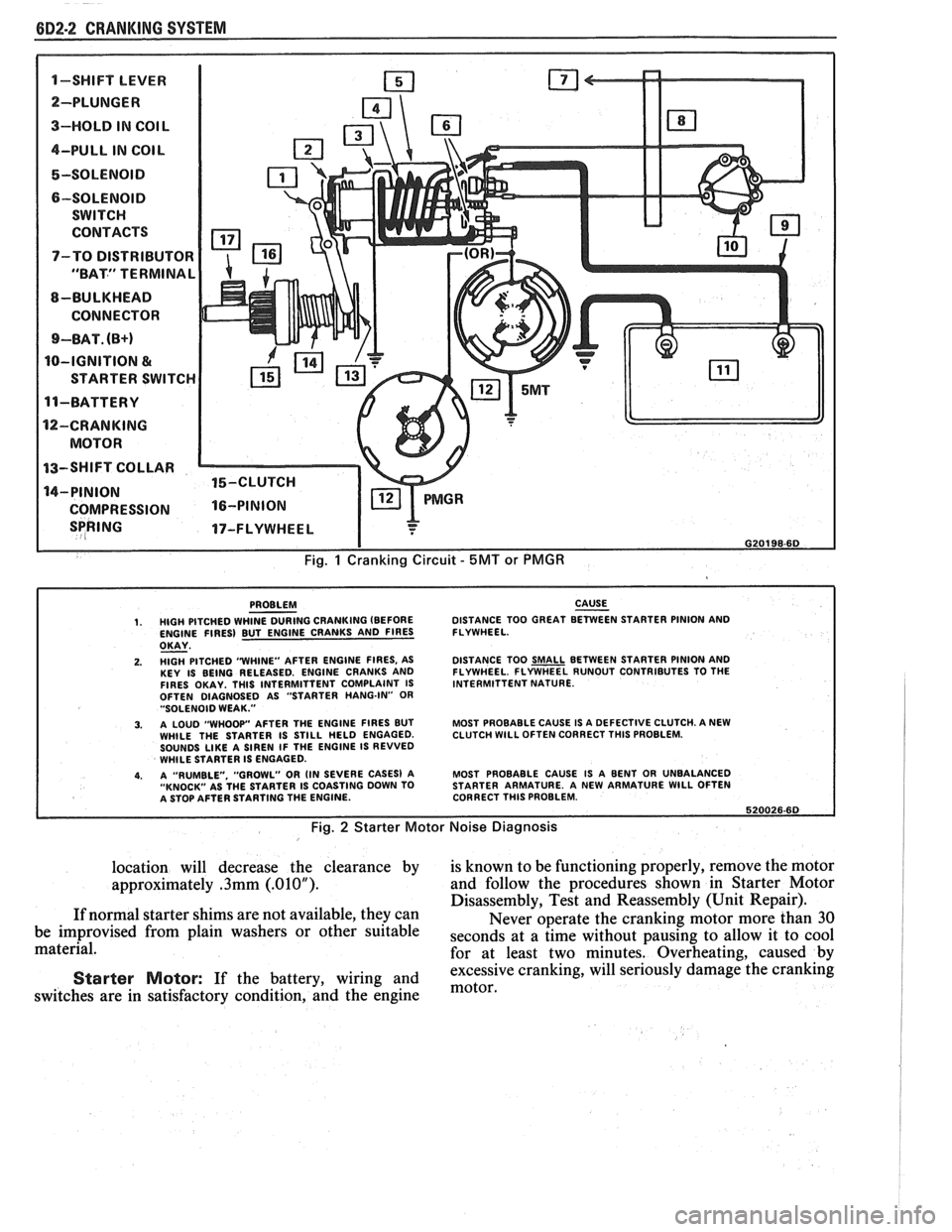

6D2-2 CRANKING SYSTEM

1-SWIFT LEVER m

SPRING 17-FLYWHEEL I

I G20198-6D

Fig. 1 Cranking Circuit - 5MT or PMGR

PROBLEM CAUSE - 1. HIGH PITCHED WHINE DURING CRANKING (BEFORE DISTANCE

TOO GREAT BETWEEN STARTER PINION AND

ENGINE FIRES) BUT ENGINE CRANKS AND FIRES FLYWHEEL.

OKAY - 2. HlGH PITCHED "WHINE"

AFTER ENGINE FIRES, AS

KEY IS BEING RELEASED. ENGINE CRANKS AND

FIRES OKAY. THlS INTERMITTENT COMPLAINT IS

OFTEN DIAGNOSED AS "STARTER HANG-IN"

OR "SOLENOID WEAK."

3. A LOUD "WHOOP" AFTER THE ENGINE FIRES BUT

WHILE THE STARTER IS STILL HELD ENGAGED.

SOUNDS

LIKE A SIREN IF THE ENGINE IS REVVED

WHILE STARTER IS ENGAGED.

4. A "RUMBLE. "GROWL" OR (IN SEVERE CASES) A

"KNOCK" AS THE STARTER IS COASTING DOWN TO

A STOP AFTER STARTING THE ENGINE. DISTANCE

TOO

SMALL BETWEEN STARTER PINION AND

FLYWHEEL. FLYWHEEL RUNOUT CONTRIBUTES TO THE

INTERMITTENT NATURE.

MOST PROBABLE CAUSE IS A DEFECTIVE CLUTCH. A NEW

CLUTCH

WlLL OFTEN CORRECT THlS PROBLEM.

MOST PROBABLE CAUSE IS A BENT OR UNBALANCED

STARTER ARMATURE. A NEW ARMATURE

WlLL OFTEN

CORRECT THlS PROBLEM.

620026.60

Fig. 2 Starter Motor Noise Diagnosis

location will decrease the clearance by is known to be functioning properly, remove the motor

approximately

.3mm (.01OU). and follow the procedures shown in Starter Motor

Disassembly, Test and Reassembly (Unit Repair).

If normal starter shims are not available, they can

Never operate the cranking motor more than 30

be improvised from plain washers or other suitable

seconds at a time without pausing to allow it to cool material.

for at least two minutes. Overheating, caused by

excessive cranking, will seriously

damage the cranking Starter Motor: If the battery, wiring and motor, switches are in satisfactory condition, and the engine

Page 460 of 1825

CRANKING SYSTEM BD2-9

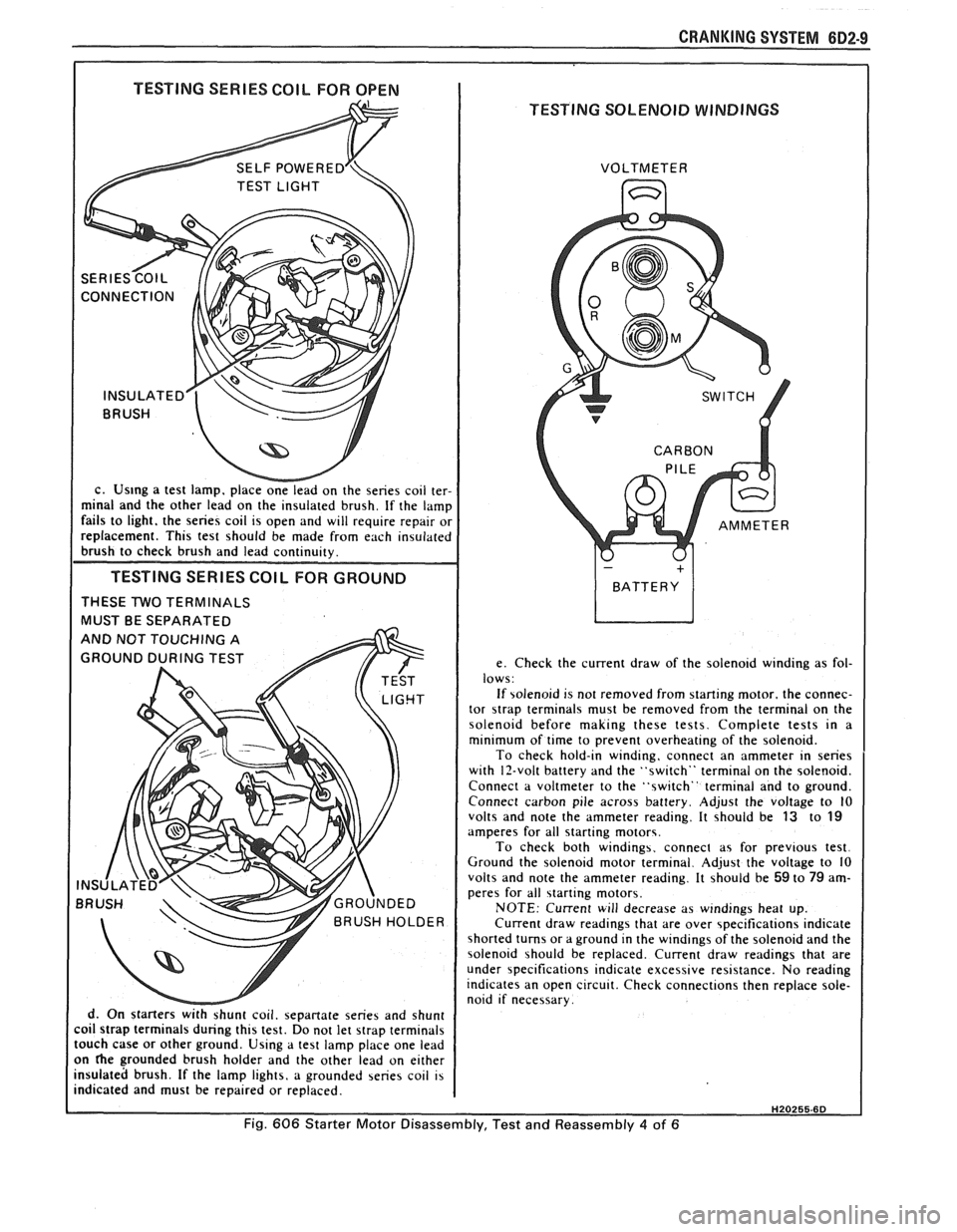

I TESTING SERIES COIL FOR OPEN I

TESTING SOLENOID WINDINGS

c. Us~ng a test lamp. place onelead on the series coil ter-

minal and the other lead on the insulated brush. If the lamp

fails to light. the series coil is open and will require repair or

replacement. This test should be made from each insulated

brush to check brush and lead continuity.

TESTING SERIES COlL FOR GROUND

THESE TWO TERMINALS

MUST BE SEPARATED

d. On starters

withshunt coil. sepanate series and shunt

coil strap terminals during this test. Do not let strap terminals

touch case or other ground. Using a test lamp place one lead

on

he grounded brush holder and the other lead on either

insulated brush. If the lamp lights, a grounded series coil is

indicated and must be repaired or replaced. VOLTMETER

e. Check the current draw of the solenoid winding as fol-

lows:

If solenoid is not removed from starting motor. the connec-

tor

strap terminals must be removed from the terminal on the

solenoid before making these tests. Complete tests in a

minimum of time to prevent overheating of the solenoid.

To check hold-in winding, connect an ammeter in series

with 12-volt battery and the "switch" terminal on the solenoid.

Connect a voltmeter to the "switch" terminal and to ground.

Connect carbon pile across battery. Adjust the voltage to

10 volts and note the ammeter reading. It should be 13 to 19 amperes for all starting motors.

To check both windings. connect as for previous test.

Ground the solenoid motor terminal. Adjust the voltage to 10

volts and note the ammeter reading. It should be

59 to 79 am-

peres for all starting motors.

NOTE: Current will decrease as windings heat up.

Current draw readings that are over specifications indicate

shorted turns or a ground in the windings of the solenoid and the

solenoid should be replaced. Current draw readings that are

under specifications indicate excessive resistance. No reading

indicates an open circuit. Check connections then replace sole-

noid if necessary.

H20255.6D

Fig. 606 Starter Motor Disassembly, Test and Reassembly 4 of 6

Page 472 of 1825

IGNITION SYSTEM 6B4-3

flash-over, which causes engine misfiring. Do not

mistake corona discharge for flash-over, or a shorted

insulator. Corona is a steady blue light appearing

around the insulator, just above the shell crimp. It is

the visible evidence of a high-tension field and has no

effect on ignition performance. Usually it can be

detected only in darkness. This discharge may repel

dust particles, leaving a clear ring on the insulator just

above the shell. This ring is sometimes mistakenly

regarded as evidence that combustion gases have blown

out between shell and insulator.

lgnition Switch

The mechanical switch is located in the steering

column on the right hand side just below the steering

wheel. The electrical switching portion of the assembly

is separate from the key and lock cylinder. However,

both are synchronized and work in conjunction with

each other through the action of the actuator rod

assembly.

For a complete explanation of the key and lock

cylinder, and the actuator rod assembly, see

STEERING, Section

38. See Section 8 for electrical

switching.

DIAGNOSIS

IGNITION SYSTEM

Spark Plugs

Worn or dirty plugs may give satisfactory

operation at idling speed, but at higher RPM they

frequently fail. Faulty plugs are indicated in a number

of ways: poor fuel economy, power loss, loss of speed,

hard starting and generally poor engine performance.

Spark plugs may also fail due to carbon fouling,

excessive gap, or a broken insulator. Fouled plugs may

be indicated by black carbon

deposits. The black deposits are usually the result of

slow-speed driving and short runs, where sufficient

engine operating temperature is seldom reached. Worn

pistons, rings, faulty ignition, over-rich carburetion

and spark plugs which are too cold will also result in

carbon deposits.

Excessive gap wear, on plugs of low mileage,

usually indicates the engine is operating at high speeds,

or loads that are consistently greater than normal, or

that a plug which is too hot is being used. Electrode

wear may also be the result of plug overheating,

causcd

by combustion gases leaking past the threads due to

insufficient torquing of the spark plug. Excessively lean

carburetion will also result in accelerated electrode

wear.

Broken insulators are usually the result of

improper installation, or carelessness when regapping

the plug. Broken upper insulators usually result from

a poor fitting wrench, or an outside blow. The cracked

insulator may not show up right away, but will as soon

as oil or moisture penetrates the crack. The crack is

usually just below the crimped part of shell and may

not be visible.

Broken lower insulators usually result from

carelessness when regapping and generally are visible.

This type of break may result from the plug operating

too "hot", which may happen in periods of high-speed

operation or under heavy loads. When regapping a

spark plug, always make the gap adjustment by

bending the ground (side) electrode. Spark plugs with

broken insulators should always be replaced.

HE1 Distributor

See Unit Repair for distributor disassembly, test

and reassembly of individual distributor components,

when the distributor is removed from the vehicle. See

On-Car Service for distributor removal and installation

and for component removal with distributor in car. See

Section 6E for

HE1 and EST diagnosis.

SERVICE PROCEDURES

IGNITION SYSTEM

Distributor Ignition

NOTICE: This procedure is generally true for

most carlines. Where procedure is different, or

where additional information is required, see

"ON-CAR SERVICE" for specific

carline.

HE1 DISTRIBUTOR

Service Precautions

1. When making compression checks, disconnect

the ignition switch feed wire at the distributor.

When disconnecting this connector,

do not use

a screwdriver or tool to release the locking tab, as

it may break.

2. No periodic lubrication is required. Engine oil

lubricates the lower bushing and an oil-filled

reservoir provides lubrication for the upper

bushing. 3.

The tachometer (TACH) terminal is next to the

ignition switch (BAT) connector on the

distributor cap.

NOTICE: The tachometer terminal must

NEVER be allowed to touch ground, as damage

to the module and/or ignition coil can result.

Some tachometers currently in use may NOT be

compatible with the High Energy Ignition System.

Consult the manufacturer of the tachometer if

questions arise.

4. Dwell adjustment is controlled by the module,

and cannot be adjusted.

5. The material used to construct the spark plug

cables is very soft. This cable will withstand more

heat and carry a higher voltage, but scuffing and

cutting become easier. The spark plug cables

must be routed correctly to prevent

chafing or

cutting. See Spark Plug Section. When removing