park assist PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 114 of 1825

CHASSIS SHEET METAL 2@-7

3. During the above flash time period (1 to 10 min-

utes), apply appropriate "conventional" interior acrylic lacquer color as required and allow

painted part to dry for

4 to 5 hours before install-

ing on car.

RlGlD OW HARD ABS PMS"TIC PARTS

Rigid or hard ABS plastic requires no primer.

"Conventional" interior acrylic lacquers adhere satis-

factorily to hard ABS plastics.

Procedure

1. Wash part thoroughly with a cleaning solvent

(Acrylic-Clean, Pre-Kleano, Prep-Sol or equiv-

alent) to remove any dirt or grease.

2. Apply appropriate "conventional" interior

acrylic lacquer color. Apply only sufficient

color for proper hiding to avoid washout of

"grain" effect.

3. Allow to dry and then install part.

VINYL AND FLEXIBLE (Son) ABS

PLASTIC PARTS

The outer cover or skin material of "flexible"

instrument panel cover (pad) assemblies is made of an

ABSIPVC plastic blend. The same is true of many

"padded" door trim assemblies. The soft cushion pad-

ding under the I.P. skin is urethane foam plastic. The

most widely used

"flexible" vinyls (poly vinyl chlo-

ride)

are coated fabrics, such as used in seat trim,

some door trim assemblies, molded headlining panels

and sun visors. Most head rests are "flexible" vinyls.

Examples of "hard vinyls are: door and front seat

back assist handles and coat hooks.

The paint system of vinyl and flexible ABS

plastic involves the use of interior "vinyl" color and a

clear vinyl top coat.

Procedure

1. Wash part thoroughly with a vinyl cleaning and

preparation solvent ("Vinyl Press"

- Ditzler,

"Vinyl Prep Conditioner"

- Detroit Autobody

or equivalent) to remove greasy film or silicone.

Wipe off cleaner while still wet with clean,

lint-

free cloth.

2. Immediately after wiping face dry, apply inte-

rior "vinyl" color in wet coats allowing suffi-

cient flash time between coats (see label

directions on can). Use proper "vinyl" color as

designated by interior trim combinations. Apply

only sufficient color for proper hiding to avoid

washout of "grain" effect. No primer or

primer-

sealer is required.

3. Before the final vinyl color coat has dried, apply

two coats of clear vinyl top coat spray (instru-

ment panels will require the "nonglare" clear top

coat). Do not allow the first spray coat to com-

pletely dry before spraying on the second. Use

top coat with appropriate gloss level to match adjacent similar components. This

clear coat is

necessary to control the gloss requirement and

prevent

'tracking" (rubbing-off) of the color

coat after drying.

4. Allow to dry according to label directions before

installing part.

ON-VEHICLE SERVICE

CONCEALED HEADLIGHTS

The concealed headlights used on this model are

electrically operated. When the headlights are turned

on, solid state circuitry activates the actuators. This

same circuitry senses when the actuators stop moving

and removes the ground to deactivate the actuators.

When the headlights are turned off, the actuators run

in opposite direction closing the headlight doors.

Should an electrical failure occur in the head-

light circuit, they may be raised manually by rotating

the knob on the actuator in a counterclockwise direc-

tion until the headlights are fully open. The headlights

may be lowered by rotating the knob on the actuator in

a clockwise direction until the headlights are fully

closed.

For electrical circuit information and diagnosis,

refer to Section

8A of this manual.

If it is desired to raise the headlights with the

lights off, either of the following procedures may be

used:

1. Turn the lights on. After the headlights are

open, disconnect the electrical connections at

the actuator connectors. Turn the lights off. The

headlights will now remain in the open position.

2. Turn the parking lights on. Depress the head-

light rocker switch lightly. The headlights may

then be raised "up" fully with the lights off.

Adjust

Because of the number of adjustments possible

and the number of attaching points of the concealed

headlight body assembly

(9), only those attachments

which control the adjustment desired should be loos-

ened. Make one

adjbstment at a time.

NOTICE: The headlight door does NOT have

slotted mounting holes and therefore is not

adjustable by itself. This insures proper clearance

between the headlight door and the hood and

fenders in both the raised and lowered positions.

The entire headlight body assembly must be

adjusted to achieve the desired appearance and

fit. Care should be exercised when adjusting the

headlight body assembly. Severe hammer blows could damage the die cast aluminum headlight

body assembly.

TO RAISE OR LOWER the headlight body

assembly, proceed as follows:

1. Open hood.

2. Raise headlights.

Page 128 of 1825

STEERING, SUSPENSION, VIBES AND WHEELS DIAGNOSIS 3-3

Steering Wheel Kick-Back (Power)

Inspect

e Air in system

e Loose steering gear mounting

e Joints from column to steering gear loose or worn

e Tie rod ends loose

Worn or missing check valve

(800 series)

e Wheel bearings worn

e See "Too Much Play In Steering" for other

possible causes.

Steering Wheel Surges Or Jerks (Power)

Inspect

Hydraulic system - Make pressure test with gage

J 5176-D or

J 25323

e Sluggish steering gear valve

Loose pump drive belt

Cupped Tires

Inspect

Front-wheel or rear-wheel alignment

e Strut dampeners or shock absorbers weak

e Wheel bearing worn

e Excessive tire or wheel runout

e Worn ball joint

a Loose steering gear adjustment

POWER RECIRCULATING BALL

SEERING GEAR DIAGNOSIS

Hissing Noise

There is some noise in all power steering systems.

One of the most common is a hissing sound when the

steering wheel is turned and the car is not moving. This

noise will be most evident when turning the wheel

while the brakes are applied. There is no relationship

between this noise and steering performance. Do not

replace the valve unless the "hissing" noise is extremely

objectionable. A replacement valve will also have a

slight noise, and is not always a cure for the condition.

Check that the intermediate shaft joints are not loose.

Rattle or Chucking Noise

Inspect -

Pressure hose grounding out

e Tie rod ends loose

e Steering gear attachment loose

a Loose pitman shaft "over-center" adjustment.

A slight rattle may occur on turns because of

increased clearance off the "high point". This is

normal and clearance must not be reduced below

specified limits to eliminate this slight rattle.

Poor Return of Steering Wheel to Center

Front-wheel alignment

Wheel bearing worn

Tie rod end binding

Ball joint binding

Steering wheel rubbing against turn signal

housing

Steering gear adjustments

Tight or frozen intermediate steering shaft

Sticky or plugged spool valve

Momentary Increase in Effort Whsn Turning

Wheel Fast to Right or Left

Inspect

High internal leakage

Steering Wheel Surges or Jerks When Turning

With

Engine Running Especially During Parking

ln8pe~t

e Insufficient pump pressure

Sticky flow control valve

Excessive Wheel Kickback or Loose Steering

Air in system

Steering gear attachment loose

Tie rod ends loose

Wheel bearings worn

Steering gear flexible coupling loose on shaft or

rubber disc mounting nuts loose

Loose thrust bearing preload adjustment

Excessive "over-center" lash

Worn pressure port check valve

Hard Steering or Lack of Assist

(Especially During Parking)

-

Brakes applied while turning steering wheel

Intermediate shaft damaged or worn

e Sticky flow control valve

Insufficient pump pressure

Excessive internal pump leakage

Excessive internal steering gear leakage

STEERING LINKAGE DIAGNOSIS

Excessive Play or Looseness in Steering Systern

inspect

r, Worn upper ball joints

e Steering gear worm bearings loosely adjusted

Page 329 of 1825

5C3-2 DIRECT TORQUE DRUM BRAKE ASSEMBLY

GENERAL DESCRIPTION

This drum brake asembly is a duo-servo, direct

torque design. In the duo-servo brake, the force which

the wheel cylinder applies to the primary shoe is

multiplied by the primary lining friction to provide a

very large force applied to the secondary shoe. With

the direct torque design, torque from the brake shoes

is transferred directly through the anchor pin to the

axle flange. Adjustment for both the primary and

secondary shoe and linings is automatic during reverse

brake applications.

Important

a Replace all components included in repair kits

used to service this drum brake.

a Lubricate parts as specified.

e Do not use lubricated shop air on brake parts as

damage to rubber components may result.

a If any hydraulic components is removed or

disconnected, it will be necessary to bleed all or

part of the brake system.

s Replace shoe and linings in axle sets only.

e The torque values specified are for dry,

unlubricated fasteners.

e Perform service operations on a clean bench free

from all mineral oil materials.

CAUTION: When servicing brake

parts, do not create dust by grinding or

sanding brake linings or by cleaning

wheel brake parts with a dry brush or

with compressed air.

A water

dampened cloth should be used.

Many

brake parts contain asbestos fibers

which can become airborne if dust is

created during servicing. Breathing

dust containing asbestos fibers may

cause serious bodily harm.

ON-CAR SERVICE

BRAKE COMPONENTS

Tool Required:

J 8049 Brake Spring Remover and Installer

J 8057 Brake Spring Pliers

J 29839 Brake Cylinder Retainer Remover

See Figures 2,3 and 4

Remove or Disconnect

1.

Raise car and suitably support, see Section OA.

e Mark relationship of wheel to axle flange.

2. Wheel and tire.

e Mark relationship of drum to axle flange.

3. Brake drum.

a If dificulty is encountered in removing

drum the following steps may be of

assistance:

@ Make sure parking brake is released.

a Back off parking brake cable

adjustment.

a Remove adjusting hole cover or

knockout plate from backing plate and

back off adjusting screw using screw

driver and adjusting tool.

a Use a rubber mallet to tap gently on

outer rim of the drum and/or around

inner drum diameter by spindle. Take

car not to deform by excessive use of

force.

4. Return springs (1 and 2) using

J 8049 pliers.

5. Hold-down springs (3) and pins (5) using suitable

pliers.

6. Lever pivot (4).

7. Actuator link (6) while lifting up on actuator

lever

(7).

8. Actuator lever (7) and lever return spring (8).

9.

Shoe guide (9), parking brake strut (10) and strut

spring

(1 1).

10. Shoe and lining assemblies (12 and 13) after

disconnecting parking brake cable.

11. Adjusting screw assembly (29) and spring (14).

12. Parking brake lever (18) by unhooking lever tab

from secondary shoe (13) slot.

e If any parts are of doubtful strength or quality

due to discoloration from heat, over-stress, or are

worn, the parts should be replaced.

Page 1117 of 1825

7A-2 AUTOMATIC TRANSMISSION

I I

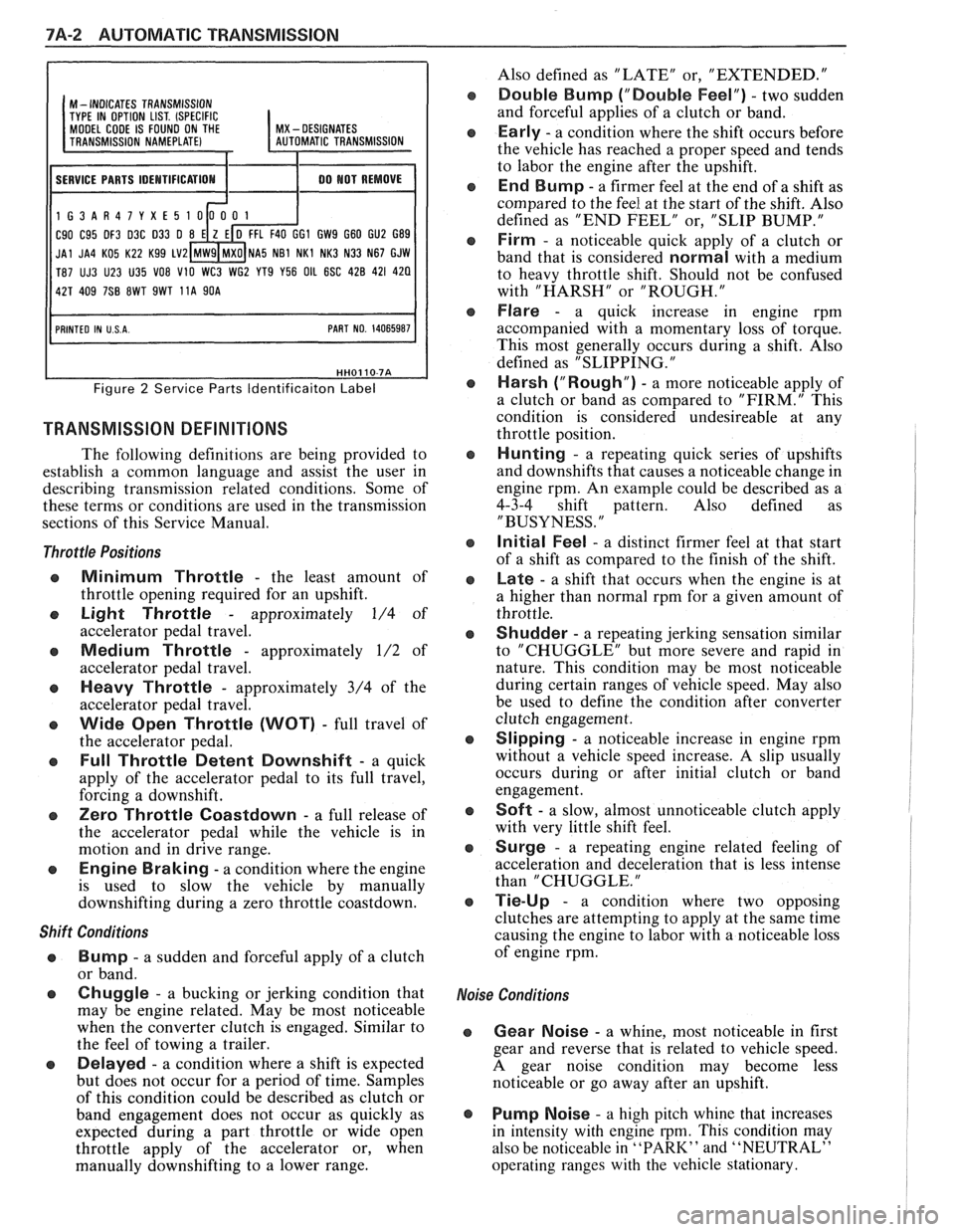

M - INDICATES TRANSMISSION

TYPE IN OPTION LIST. (SPECIFIC MODEL CODE IS FOUND ON THE I MX - DESIGNATES

11 SERVICE PARTS IDEMTIFICATIOM I 1 00 MOT REMOVE I

1G3AR47YXE5

C90 C95 DF3 D3C 033 0 GI GW9 G60 GU2 G89

JAl JA4 KO5 K22 Kg9 LV2 NA5 NB1 NKl NK3 N33 N67 GJW

T87 UJ3 U23 U35

VO8 V10 WC3 WG2 YT9 Y56 OIL 6SC 428 421 420

Figure 2 Service Parts ldentificaiton Label

TRANSMISSION DEFINITIONS

The following definitions are being provided to

establish a common language and assist the user in

describing transmission related conditions. Some of

these terms or conditions are used in the transmission

sections of this Service Manual.

Throttle Positions

Minimum Throttle - the least amount of

throttle opening required for an upshift.

Light Throttle - approximately 1/4 of

accelerator pedal travel.

Medium Throttle - approximately 1/2 of

accelerator pedal travel.

Heavy Throttle - approximately 3/4 of the

accelerator pedal travel.

Wide Open Throttle (WOT) - full travel of

the accelerator pedal.

Full Throttle Detent Downshift - a quick

apply of the accelerator pedal to its full travel,

forcing a downshift.

Zero Throttle Coastdown - a full release of

the accelerator pedal while the vehicle is in

motion and in drive range.

Engine Braking - a condition where the engine

is used to slow the vehicle by manually

downshifting during a zero throttle coastdown.

Shift Conditions

'a Bump - a sudden and forceful apply of a clutch

or band.

Q Chuggle - a bucking or jerking condition that

may be engine related. May be most noticeable

when the converter clutch is engaged. Similar to

the feel of towing a trailer.

e Delayed - a condition where a shift is expected

but does not occur for a period of time. Samples

of this condition could be described as clutch or

band engagement does not occur as quickly as

expected during a part throttle or wide open

throttle apply of the accelerator or, when

manually downshifting to a lower range. Also

defined as "LATE" or, "EXTENDED."

Double Bump ("Double Feel") - two sudden

and forceful applies of a clutch or band.

Early - a condition where the shift occurs before

the vehicle has reached a proper speed and tends

to labor the engine after the upshift.

End Bump - a firmer feel at the end of a shift as

compared to the feel at the start of the shift. Also

defined as "END FEEL" or, "SLIP BUMP."

Firm - a noticeable quick apply of a clutch or

band that is considered

normal with a medium

to heavy throttle shift. Should not be confused

with "HARSH" or "ROUGH."

Flare - a quick increase in engine rpm

accompanied with a momentary loss of torque.

This most generally occurs during a shift. Also

defined as "SLIPPING.

"

Harsh ("Rough") - a more noticeable apply of

a clutch or band as compared to "FIRM." This

condition is considered undesireable at any

throttle position.

Hunting - a repeating quick series of upshifts

and downshifts that causes a noticeable change in

engine rpm. An example could be described as a

4-3-4 shift pattern. Also defined as

"BUSYNESS.

"

Initial Feel - a distinct firmer feel at that start

of a shift as compared to the finish of the shift.

Late - a shift that occurs when the engine is at

a higher than normal rpm for a given amount of

throttle.

Shudder - a repeating jerking sensation similar

to "CHUGGLE" but more severe and rapid in

nature. This condition may be most noticeable

during certain ranges of vehicle speed. May also

be used to define the condition after converter

clutch engagement.

Slipping - a noticeable increase in engine rpm

without a vehicle speed increase.

A slip usually

occurs during or after initial clutch or band

engagement.

Soft - a slow, almost unnoticeable clutch apply

with very little shift feel.

Surge - a repeating engine related feeling of

acceleration and deceleration that is less intense

than "CHUGGLE.

"

Tie-Up - a condition where two opposing

clutches are attempting to apply at the same time

causing the engine to labor with a noticeable loss

of engine rpm.

,e Conditions

Gear Noise - a whine, most noticeable in first

gear and reverse that is related to vehicle speed.

A gear noise condition may become less

noticeable or go away after an upshift.

Pump Noise - a high pitch whine that increases

in intensity with engine

rpm. This condition may

also be noticeable in

"PARK" and "NEUTRAL"

operating ranges with the vehicle stationary.