cooling PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 2 of 1825

1988

SER

This manual applies to the 1988 Pontiac Firebird Models.

It contains the latest product information available at the

time of publication approval. lnformation pertaining to

the operation of the vehicle is contained in the Owner's

Manual which accompanies each vehicle. The right is

reserved to make changes at any time without notice.

Any references to brand names in this manual is intended

merely as an example of the types of

lubricant% tools,

materials, etc, recommended for use in servicing 1988

Pontiac Models. In all cases, an equivalent may be used.

PONTIAC DIVISION

GENERAL

MOTORS CORPORATION

PONTIAC, MICHIGAN 48053

1987 General Motors Corp. All Rights Reserved.

No part of this publication may be reproduced, stored in any

retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical,

photocopying, recording or otherwise, without the prior written

permission of General Motors Corp. This includes all text,

illustrations, tables and charts.

S-881 OF 9-87 Printed in Canada

TABLE OF CONTENTS

SECTION NAME

GENERAL INFORMATION

OA. General lnformation

OB. Maintenance & Lubrication

1 SECT.

HEATING AND AIR CONDITIONING

1A. Heating and Ventilation

1 B. Air Conditioning

1D1. R-4 AIC Com~ressor Overhaul

FRAME AND BUMPERS

2B. Bumpers 2C. Chassis Sheet Metal

STEERING, SUSPENSION, WHEELS

AND TIRES

3. Diagnosis

3A. Wheel Alignment

3B5. Steering Wheels and Columns 3B6. Steering Linkage 3B7. Power Steering Gear and Pump

3C. Front Suspension

3D. Rear Suspension

3E. Tires and Wheels

FINAL DRIVE

4A. Propeller Shaft

4B. Rear Axle

4B1. Bora-Warner Axle

BRAKES 5. Brakes 5A3. Comoosite Master Cvlinder 5B1. Disc r rake Caliper ~ssembly - 300013100 Series 5B6. Disc Brake Caliper Assembly - 3548

Series

5C3. Direct Torque Drum Brake Assembly 5D2. Power Head Assembly - Tandem Diaohraam 5F. ~~ecifications and Special Tools

ENGINE 6. Engine General lnformation 6A2. 2.8L 6A3. 5.OL & 5.7L 6B. Engine Cooling

6C. En~ine Fuel

6D. ~ngine Electrical 6D1. Battery 6D2. Cranking System 6D3. Charging System 6D4. Ignition System 6D5. Engine Wiring

6E. Driveabilitv and Emissions

6E2. ~missions' 6E3. Emissions - PFI

6F. Engine Exhaust

TRANSMISSION 7A. Automatic Transmission - General

lnformation

7A1. Automatic Transmission - On-Car

Service

700R4. Automatic Transmission Hydraulic Diagnosis

700R4. Automatic Transmission Unit Repair

76. 5-Speed Manual Transmission

7C. Clutch

CHASSIS ELECTRICAL 8A. Electrical Diagnosis

8B. Lighting and Horns

8C. Instrument

Panel, Gages

& Console

8E. Windshield Wiper &Washer System

ACCESSORIES 9A. Radio Systems and Antennas 9B. Cruise Control 9G. Miscellaneous Accessories

I BODY SERVICE MANUAL END

OF

MANUAL

Page 8 of 1825

GENERAL INFORMATION OA-5

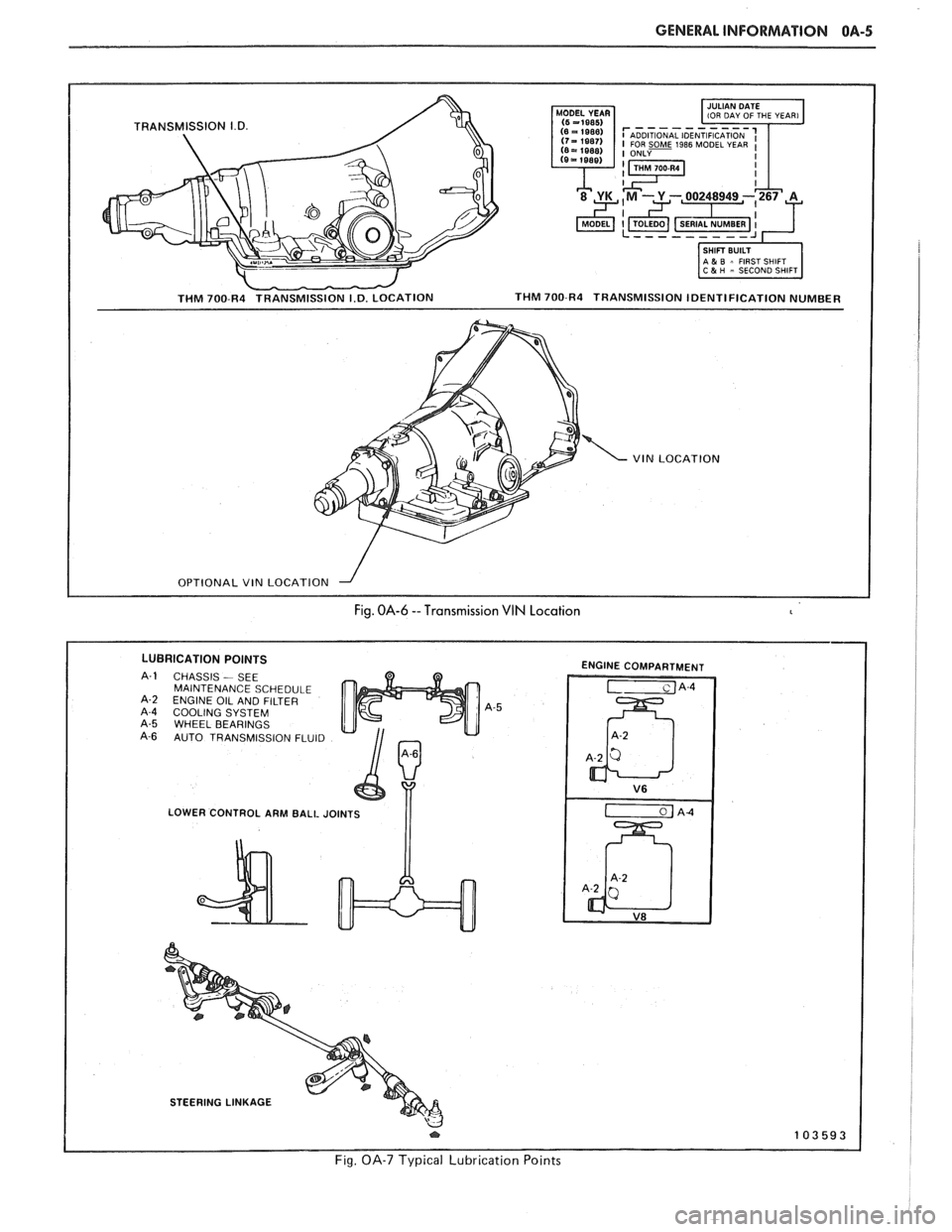

- THM 700-R4 TRANSMISSION I.D. LOCATION

1-1 IOU DAY OF THE YEAR1

I SHIFT BUILT 1 1 A & B = FIRST SHIFT 1 C 5 H - SECOND SHIFT

THM 700-R4 TRANSMISSION IDENTIFICATION NUMBER

VIN LOCATION

I OPTIONAL VIN LOCATION --I I

Fig. OA-6 --Transmission VIN Location

LUBRICATION POINTS

CHASSIS - SEE

MAINTENANCE SCHEDULE

ENGINE OIL AND FILTER

COOLING SYSTEM WHEEL BEARINGS

AUTO TRANSMISSION FLUID

LOWER CONTROL ARM BALL JOINTS

I I

ENGINE COMPARTMENT

STEERING LINKAGE

Fig. OA-7 Typical Lubrication Points

Page 10 of 1825

GENERAL INFORMATION OA-7

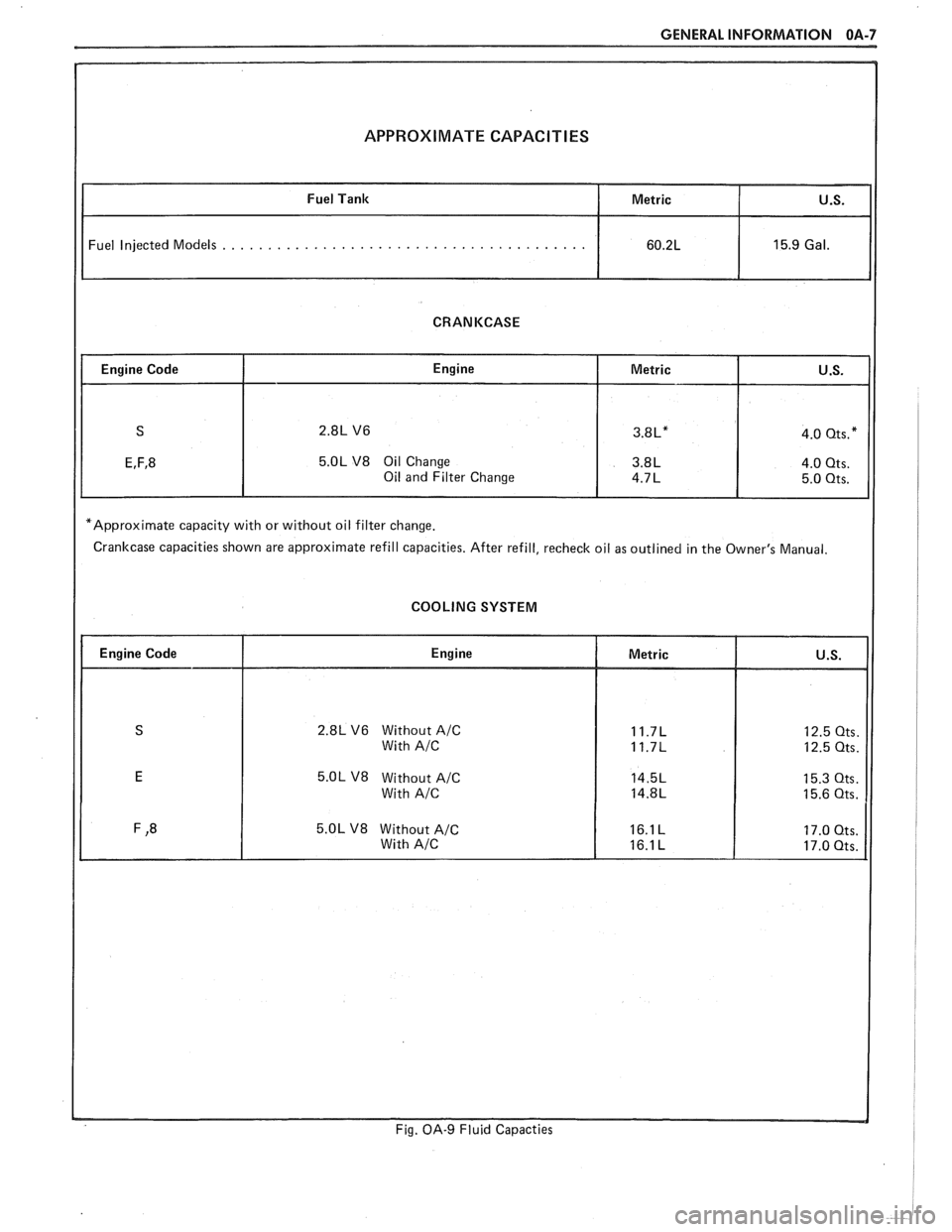

APPROXIMATE CAPACITIES

Fuel Injected Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKCASE

5.OL V8 Oil Change

*Approximate capacity with or without oil filter change.

Crankcase capacities shown are approximate refill capacities. After refill, recheck oil as outlined in the Owner's Manual.

COOLING SYSTEM

2.8L V6 Without A/C

5.OL V8 Without A/C

Fig. OA-9 Fluid Capacties

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 36 of 1825

HEATING AND VENTILATION 1.4-1 3

ON-VEHICLE SERVICE

HEATER ELECTRICAL WIRING

The heater wiring diagrams are shown in

Electrical Diagnosis, Section

8A, and should be

referred to for diagnosis of electrical problems in the

heater system.

HEATER CONTROL ASSEMBLY AND BLOWER

SWITCH

Remove or Disconnect

1. Negative battery cable.

2.

Control/radio console trim plate.

3. Three

(3) controller retaining screws and pull

controller out from console.

4. Control cables and electrical connections.

5. Blower switch from controller if either switch or

controller requires replacement. If controller is

being replaced, transfer blower switch to new

controller.

Install or Connect

1. When installing controller, install lower right

screw first to properly align controller in console.

2. Blower switch to controller.

3. Control cables and electrical connections.

4. Three (3) controller retaining screws and

controller to console.

5. Control/radio console trim plate.

6. Negative battery cable.

TEMPERATURE CONTROL, POWER VENT,

HEATER DEFROST CABLE

Remove or Disconnect

1. Hush panel(s) (see Section 8C):

a. Temperature

cable - R.H. hush panel.

b.

Heateddefrost cable - R.H. hush panel.

c. Vent

cable

- L.H. hush panel.

2.

Control/radio console trim plate.

3. Three (3) controller retaining screws and pull

controller out from console.

4. Control cable requiring replacement at control

end.

5. Cable at mode control end (temperature cable:

remove cable link cover at crank location).

Install or Connect

1. When installing controller, install right lower

screw first to align control in console.

2. Cable

at mode control end (temperature cable:

install cable link cover at crank location).

3. Control cable at control end.

4. Three (3) controller retaining screws and

contoller in console.

5. Control/radio console trim plate.

6. Hush panel(s) (see Section 8C).

7. Fully cycle controls to adjust cables and check for

proper operation.

HEATER CORE

Remove or Disconnect

Battery ground cable.

Drain cooling system.

Heater inlet and outlet hoses from heater core.

Right lower hush panel (see Section

8C).

ECM attaching screw and move aside.

Right lower I.P. trim panel (see Section

8C).

Lower right I.P. carrier-to-cowl screw.

Four (4) heater case cover screws. Upper left screw

may be reached with a long socket extension through

the I.P. openings exposed by removal of the lower

right I.P. trim panel. Carefully lift the lower right

corner of the I.P. to align socket extension.

Heater case cover.

Core support plate and baffle screws.

Heater core, support plate and baffle from case.

Install or Connect

1. Heater core, support plate and baffle to case.

2. Core support

plate and baffle screws.

3. Heater case cover.

4. Four (4) heater case cover screws.

5. Lower right I.P. carrier-to-cowl screw.

6. Right lower I.P. trim panel (see Section 8C).

7. ECM.

8. Right lower hush panel (see Section

8C).

9. Heater inlet and outlet hoses to heater core.

10. Refill cooling system and check for leaks.

11. Battery ground cable.

VENT CONTROL CABLE (RAM VENT)

Remove or Disconnect 1

1. Hush panel(s) (see Section 8C). R.H. cable

replacement will require removal of both L.H.

and R.H. hush panels.

2. Two

(2) retaining screws and individual vent

control.

3. Unclip

cable control clamp at vent duct and

disengage formed end of cable from door lever.

1 Install or Connect

1. Cable control clamp at vent duct and install

formed end of cable on door lever.

2, Two (2) retaining screws and individual vent

control.

3. Hush

panel@) (see Section 8C).

4. Cycle

control fully and check for proper

operation.

HEATER CONTROL WIRING I

Remove or Disconnect

1. Negative battery cable.

Page 37 of 1825

1A-14 HEATING AND VENTILATION

2. Control/radio console trim plate and hush

panels.

3. Three (3) screws holding controller in console

and pull controller out far enough to disconnect

electrical connectors.

4. Blower motor and blower resistor electrical

connections.

5. Carefully pull cowl grommet from cowl and pull

wiring harness through cowl hole into engine

compartment.

Install or Connect

1. When reinstalling controller, install lower right

screw first to align controller.

2. Cowl grommet on cowl and wiring harness.

3. Blower motor and blower resistor electrical

connections.

4. Three (3) screws holding controller in console

and connect electrical connectors.

5. Control/radio console trim plate and hush

panels.

6. Negative battery cable.

HEATER/VENTILATION/DEFROSTER DUCTS

See section 8C for removal.

LOWER (FLOOR) HEATER OUTLET

Remove or Disconnect

1. Console (see Section 8C).

2. L.H. and R.H. hush panels. (see Section 8C).

3. Two (2) floor outlet retaining screws.

4. Floor outlet from core case.

Install or Connect

1. Floor outlet to core case.

2. Two (2) floor outlet retaining screws.

3. L.H. and R.H. hush panels.

4. Console.

BLOWER MOTOR

Remove or Disconnect

1. Negative battery cable.

2. Electrical connections at blower motor and

blower resistor.

3. Blower motor cooling tube.

4. Blower motor retaining screws and remove

motor/cage assembly from case.

5. Holding blower motor cage, remove cage

retaining screw and slide cage from motor shaft.

Install or Connect

1. Blower motor cage and retaining screw.

2. Blower

motor retaining screws and

motor/cage

assembly in case.

3. Blower motor cooling tube.

4. Electrical connections at blower motor and

blower resistor.

5. Negative battery cable.

6. Reinstall radio capacitor in proper location, if so

equipped.

Page 44 of 1825

AIR CONDITIONING 1B-1

SECTION 1B

R COND

When performing air conditioning diagnosis on vehicles equipped with a catalytic converter, it will be necessary to

WARM the engine to a NORMAL operating temperature BEFORE attempting to idle the engine for periods greater

than five

(5) minutes. Once the engine attains normal idle, diagnosis and adjustments can be made.

CONTENTS

.................. General Description .................................. 1B-1 Accumulator Assembly Service .1B-19

.......................... C.C.O.T. A!C System ................................ 1B-1 On-Vehicle Sewice ..... 1B-20

....................................... System Components - Functional ................. 1B-2 Blower Motor .1B-20

..................................... System Components - Control ..................... 1B-3 Hi-Blower Relay 1B-20

...................................... Relays and Switches ................................... 1B-3 Blower Resistor 1B-20

Diagnosis ................................................. 1B-5 Controller, Blower Switch or Vacuum

................................................ Testing the Refrigerant System ...................... 1B-5 Valve .lB-20

Insufficient Cooling "Quick-Check Temperature Control Cable ....................... .1B-20

.................................... Procedure.. ............................................. 1B-5 Vacuum

Harness .lB-20

C.C.O.T. A/C System Diagnostic Control Wiring Harness ........................... .1B-20

..... ................................. Procedure.. ............................................. 1B-8 Heater

Core .. .lB-21

................................ Leak Testing ........................................... 1B-12 Lower Heater Outlet 1B-21

............................... Service Procedures ................................. .1B-12 Heater Module Case .lB-21

.......................... O-Ring Replacement ................................ .1B- 12 Pressure Cycling Switch .1B-21

....................................... Handling Refrigerant- 12 ............................ .1B- 13 Vacuum Tank .lB-21

Discharging, Adding Oil, Evacuating Liquid Line .......................................... .1B-23

and

Charging Procedures - AIC Accumulator ......................................... .1B-23

.................................... Systems .............................................. .1B-14 Evaporator Core .1B-24

In-Line Air Conditioning Evaporator Case .................................... .1B-24

.......................................... Filter

Installation.. .................................. .1B- 18 Compressor .lB-24

.............................................

................ Expansion Tube (Orifice) Service .1 B- 19 Condenser IB-24

GENERAL DESCRIPTION

All engines are equipped with a fixed displace- evaporator temperature. The pressure cycling switch

ment (R-4) air conditioning compressor. This

com- is the freeze protection device in the system and

pressor may cycle on and off under normal air

senses refrigerant pressure on the suction side of the

conditioning demand. system. This switch is located on a standard

Schrader- -

All air conditioning systems that use the fixed

displacement R-4 compressor are referred to as

C. C.O.T. (Cycling Clutch, Orifice Tube) type sys-

tems. This is the same system that has been used on

all General Motors vehicles in the past several years.

The C.C.O.T. NG System

The Cycling Clutch Orifice Tube (C.C.O.T.)

refrigeration system is designed to cycle a compressor

on and off to maintain desired cooling and to prevent

evaporator freeze. Passenger compartment comfort is

maintained by the temperature lever on the controller.

Control of the refrigeration cycle (on and off

operation of the compressor) is done with a switch

which senses low-side pressure as an indicator of type

valve low-side fitting. During air temperatures

over 10°C

(50°F), the equalized pressures within the

charged

A/C system will close the contacts of the

pressure switch. When an air conditioning mode

(max, norm, bi-level, defrost) is selected, electrical

energy is supplied to the compressor clutch coil. AS

the compressor reduces the evaporator pressure

to

approximately 175 kPa (25 psi), the pressure switch

will open, de-energizing the compressor clutch.

As

the system equalizes and the pressure reaches approxl-

mately 315 kPa (46 psi), the pressure switch contacts

close, re-energizing the clutch coil. This cycling

coy

tinues and maintains average evaporator discharge air

temperature at approximately 1°C (33°F). Because of

this cycling, some slight increases and decreases of

engine speedlpower may be noticed under certain con-

ditions. This is normal as the system is designed

to

cycle to maintain desired cooling, thus preventing

evaporator freeze-up.

Page 45 of 1825

18-2 AIR CONDITIONING

SYSTEM GONIPONENE - FFUNCnIONAL

Compressor

All compressors are belt driven from the engine

crankshaft through the compressor clutch pulley. The

compressor pulley rotates without driving the com-

pressor shaft until an electromagnetic clutch coil is

energized. When voltage is applied to energize the

clutch coil, the clutch plate and hub assembly is

drawn rearward toward the pulley. The magnetic

force locks the clutch plate and pulley together as one

unit to drive the compressor shaft.

As the compressor shaft is driven, it compresses

the low-pressure refrigerant vapor from the evaporator

into a high-pressure, high-temperature vapor. Carried

with the refrigerant is the refrigerant oil which is used

to lubricate the compressor. Complete compressor

overhaul procedures can be found in Section

ID of the

General Service Manual.

Pressure Relief Valve

The compressor is equipped with a pressure

relief valve which is placed in the system as a safety

factor. Under certain conditions, the refrigerant on the

discharge side may exceed the designed operating

pressure. To prevent system damage, the valve is

designed to open automatically at approximately

3036

kPa (440 psi). Conditions that might cause this valve

to open (defective high pressure cut-off switch, inop-

erative electric cooling fan, etc.) should be corrected,

and the refrigerant oil and refrigerant should be

replaced as necessary.

A muffler is used on some refrigerant systems to

reduce compressor noises from high or low pressure

vibrations.

Condenser Gore

The condenser assembly in front of the radiator

is made up of coils which carry the refrigerant TO

cooling fins to provide rapid transfer of heat. The air

passing through the condenser cools the high-pressure

refrigerant vapor causing it to condense to a liquid.

Expansion (Orifice) Tube

The plastic expansion tube, with its mesh screen

and orifice, is located in the evaporator inlet pipe at

the liquid line connection. It provides a restriction to

the high-pressure liquid refrigerant in the liquid line,

metering the flow of refrigerant to the evaporator as a

low-pressure liquid. The expansion tube and orifice

are protected from contamination by filter screens on

both inlet and outlet sides. The tube is serviced only

as a replacement assembly.

When the engine is turned "OFF" with the

A/C

system operating, the refrigerant in the system will

flow from the high-pressure side of the expansion tube (orifice) to the low-pressure side until the pressure

is

equalized. This may be detected as a faint sound of

liquid flowing (hissing) for 30 to

60 seconds and is a

normal condition.

Evaporator Gore

The evaporator is a device which cools and

dehumidifies the air before it enters the car. High-

pressure liquid refrigerant flows through the expan-

sion tube (orifice) into the low-pressure area of the

evaporator. The heat in the air passing through the

evaporator core is transferred to the cooler surface of

the core, thereby cooling the air. As the process of

heat transfer from the air to the evaporator core sur-

face is taking place, any moisture (humidity) in the air

condenses on the outside surface of the evaporator

core and is drained off as water.

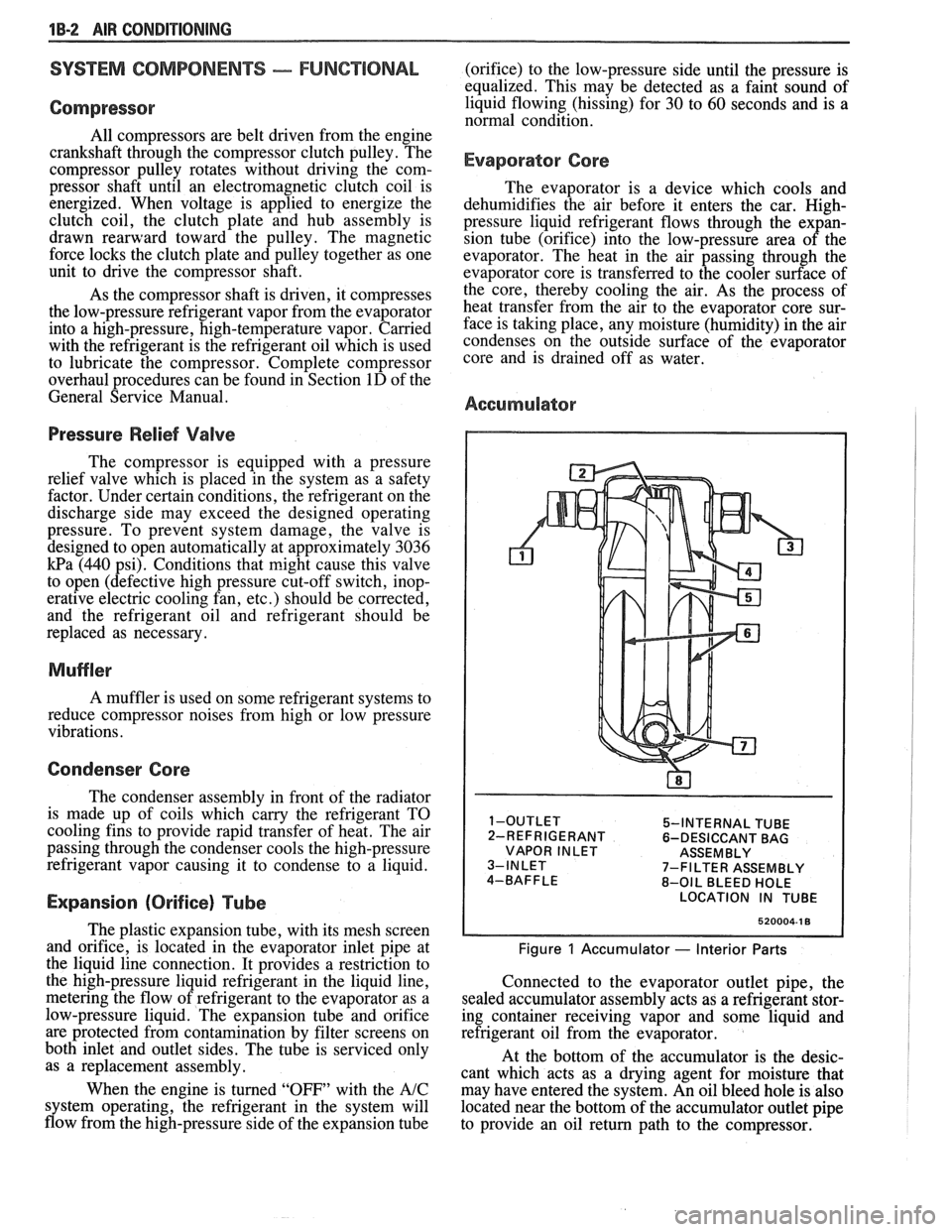

Accumulator

5-INTERNAL TUBE

2-REFRIGERANT 6-DESICCANT BAG

VAPOR INLET ASSEMBLY

7-FILTER ASSEMBLY

8-OIL BLEED HOLE

LOCATION IN TUBE

520004-1 8

Figure 1 Accumulator - Interior Parts

Connected to the evaporator outlet pipe, the

sealed accumulator assembly acts as a refrigerant stor-

ing container receiving vapor and some liquid and

refrigerant oil from the evaporator.

At the bottom of the accumulator is the desic-

cant which acts as a drying agent for moisture that

may have entered the system. An oil bleed hole is also

located near the bottom of the accumulator outlet pipe

to provide an oil return path to the compressor.

Page 46 of 1825

AIR CONDITIONING 1 B-3

A low-side pressure Schrader valve service fit-

ting is located near the top of the accumulator. A

similar Schrader fitting may be provided for mounting

the pressure cycling switch. It is not necessary to dis-

charge the system to replace the switch. The accumu-

lator is serviced only as a replacement assembly.

Heater Core

The heater core heats the air before it enters the

car. Engine coolant is circulated through the core to

heat the outside air passing over the fins of the core.

The core is functional at all times (no water valve) and

may be used to temper conditioned air in

A/C mode,

as well as heat or vent mode.

SYSTEM COMPONENTS --- CON"FOL

Controller

The operation of the A/C system is controlled by

the switches and the lever on the control head. The

compressor clutch and blower are connected electri-

cally to the control head by a wiring harness. The

blower circuit is open in the off mode and air flow is

provided by the four blower speeds available in the

remaining modes. Cooled and dehumidified air is

available in the max, normal, bi-level and defrost

modes.

Temperature is controlled by the position of the

temperature lever on the control head. A cable con-

nects this lever to the temperature door which controls

air flow through the heater core. As the temperature

lever is moved through its range of travel, a sliding

clip on the cable at the temperature valve connection

should assume a position assuring that the temperature

door will seat in both extreme positions. Temperature

door position is independent of mode selection. The

temperature cable attaches to the right side of the air

conditioning module. The temperature door on some

models is controlled electrically, thereby eliminating

the need for the temperature cable.

The electric engine cooling fan on some cars is

not part of the

A/C system; however, the fan is

operational any time the

A/C control is in Max.,

Norm, or Bi-Level modes. Some models provide for

engine cooling fan operation when the controller is in

the defrost mode. This added feature is part of the

A/C

controller function and is aimed at preventing exces-

sive compressor head temperatures. It also allows the

A/C system to function more efficiently. On some

models during road speed (above

35 mph) conditions

when air flow through the condenser coil is adequate

for efficient cooling, the engine cooling fan will be

turned off. The operation of the cooling fan is con-

trolled by the ECM through the cooling fan relay.

Complete wiring diagrams and diagnosis for the

AIC Electrical System are in Section 8A. Section 8A

also contains additional diagnostic information

regarding air flows and vacuum logic.

Vacuum Lines

Vacuum lines are molded to a connector which

is attached to a vacuum control switch on the control

head assembly.

In case of leakage or hose collapse, it will not be

necessary to replace the entire harness assembly.

Replacement can be made by cutting the hose and

inserting a plastic connector. If an entire hose must be

replaced, cut all hoses off at the connector and then

attach hoses directly to the control head vacuum

switch. (NOTE: The Fiero uses an electric motor to

control mode selection. Therefore, it will not have a

vacuum harness.

)

Vacuum Tank

During heavy acceleration, the vacuum supply

from the carburetor drops. A check valve in the vac-

uum tank maintains vacuum so that, under load condi-

tions, vacuum will be available for continuous use.

REWVS AND SWITCHES

High-Pressure Compresssr Gut-OFF Switch

The high-side, high-pressure cut-off switch in

the rear head of the compressor is a protective device

intended to prevent excessive compressor head pres-

sures and reduce the chance of refrigerant escape

through a safety relief valve. Normally closed, this

switch will open the circuit at a high-side pressure of

approximately 2700

kPa (430 psi 9 20 psi) and

reclose the circuit at approximately 1379 kPa (200 psi

9 50 psi).

Lsw-Pressure Cut-On Switch

Compressor protection is provided on some cars

by a low-pressure cut-off switch which will open in

the event of a low-charge condition. This switch can

be located in the liquid line or in the rear head of the

compressor. This switch will also keep the compres-

sor from running during cold weather.

Pressure eyesing Switch

The refrigeration cycle (on and off operation of

the compressor) is controlled by a switch which

senses the low-side pressure as an indicator of evapo-

rator temperature. The pressure cycling switch is the

freeze protection device in the system and senses

refrigerant pressure on the suction side of the system.

This switch is located on a standard Schrader-type

valve low-side fitting. This switch also provides com-

pressor cut-off during cold weather.

Additional compressor protection results from

the operating characteristics of the low-side pressure

cycling system. If a massive discharge occurs or the

orifice tube becomes plugged, low-side pressures

could be insufficient to close the contacts of the pres-

sure switch. In the event of a low charge, insufficient

cooling accompanied by rapid compressor clutch

cycling will be noticed at high air temperatures.