set clock PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 60 of 1825

AIR CONDITIONING 1B-17

If prescribed vacuum cannot be reached, close

vacuum control valve, shut off pump and look

for a leak at connections or pump.

3. When gauge reaches prescribed vacuum, the

system is fully evacuated. Close the high-side

gauge set valve and turn off the vacuum pump.

4. Watch low-side gauge to be sure vacuum holds

for five (5) minutes. If vacuum is held, discon-

nect vacuum hose at gauge set and then proceed

to charging.

5. If vacuum does not hold for five (5) minutes,

charge system with

420ml(1/2 pound) Refriger-

ant-12 and leak check. Discharge system again

and repair leak as necessary. Repeat evacuation

procedure.

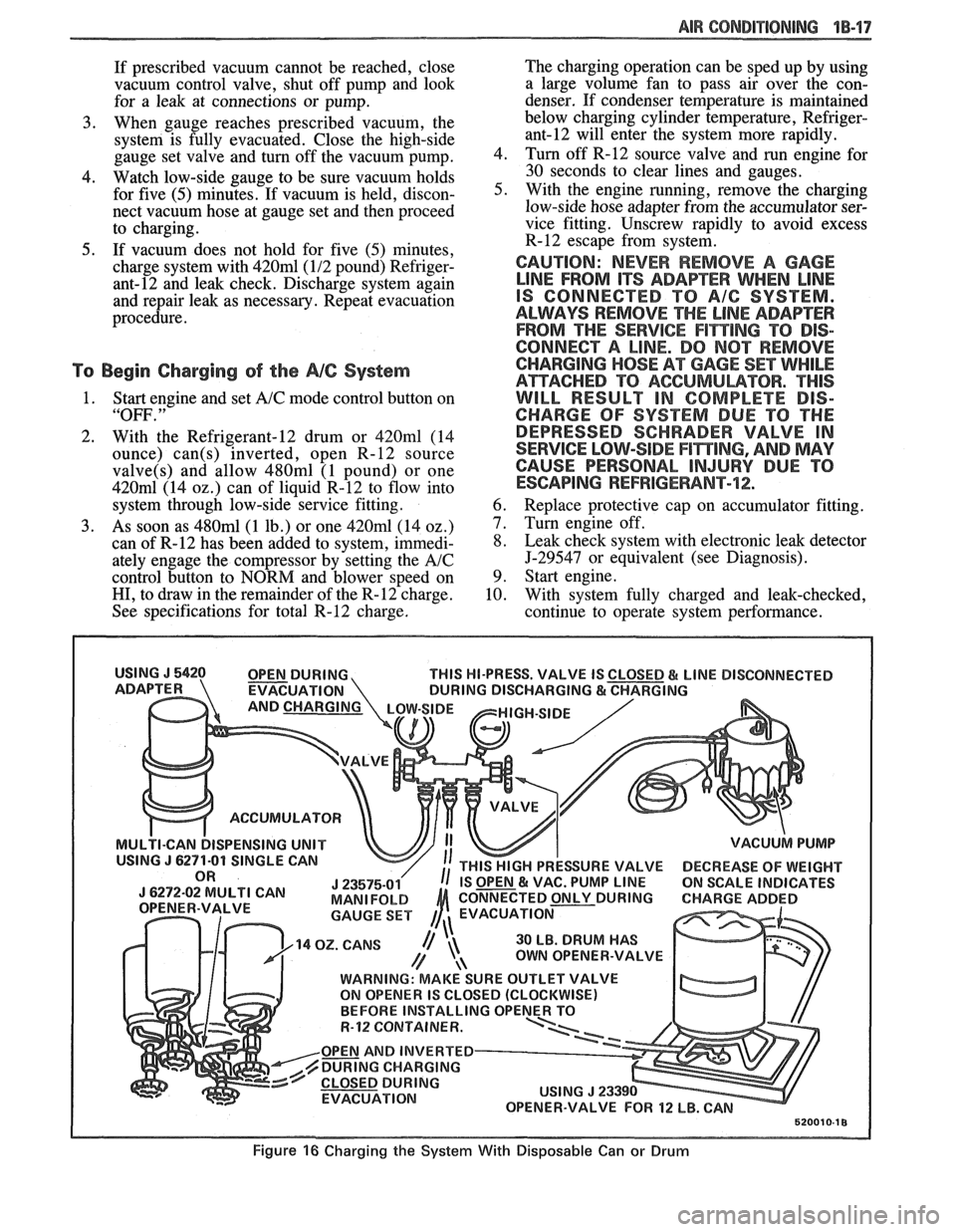

To Begin Charging of the NC System

1. Start engine and set A/C mode control button on

"OFF. "

2. With the Refrigerant-12 drum or 420ml (14

ounce)

can(s) inverted, open R-12 source

valve(s) and allow 480ml (1 pound) or one

420m1 (14 02.) can of liquid R-12 to flow into

system through low-side service fitting.

3. As soon as 480ml (1 lb.) or one 420ml (14 oz.)

can of R-12 has been added to system, immedi-

ately engage the compressor by setting the

A/C

control button to NORM and blower speed on

HI, to draw in the remainder of the R-12 charge.

See specifications for total R-12 charge. The

charging operation can be sped up by using

a large volume fan to pass air over the con-

denser. If condenser temperature is maintained

below charging cylinder temperature,

Refriger-

ant-12 will enter the system more rapidly.

4. Turn off

R-12 source valve and run engine for

30 seconds to clear lines and gauges.

5. With the engine running, remove the charging

low-side hose adapter from the accumulator ser-

vice fitting. Unscrew rapidly to avoid excess

R-12 escape from system.

CAUTION: NEVER REMOVE A GAGE

LINE FROM ITS ADAPEER WHEN LINE

IS CONNECTED TO A/G SYSTEM.

ALWAYS REMOVE

THE LINE ADAPTER

FROM THE

SERVICE F1miNG TO DIS-

CONNECT A LINE. DO

NOT REMOVE

CHARGING

HOSE AT GAGE SET WHILE

ATTACHED TO ACGUMULBTOR. "THIS

WILL RESULT IN COMPLETE DIS-

CHARGE OF SYSTEM DUE TO THE

DEPRESSED SCHRADER VALVE IN

SERVICE LOW-SIDE

F17$TING, AND MAY

CAUSE PERSONAL

INJURY DUE TO

ESCAPING REFRIGERANT-72;.

6. Replace protective cap on accumulator fitting.

7. Turn engine off.

8. Leak check system with electronic leak detector

5-29547 or equivalent (see Diagnosis).

9. Start engine.

10. With system fully charged and leak-checked,

continue to operate system performance.

THIS HI-PRESS. VALVE IS

EVACUATION

ACCUMULATOR

ISPENSING UNIT

30 LB. DRUM HAS

OWN OPENER-VALVE

WARNING: MAKE SURE OUTLET VALVE

ON OPENER IS CLOSED (CLOCKWISE)

R-12 CQNTAINER.

OPEN AND INVERTED

DURING CHARGING

EVACUATION

Figure 16 Charging the System With Disposable Can or Drum

Page 152 of 1825

STEERING WHEELS AND COLUMNS 385.1

SECTION 3B5

STEER NG WHEELS AND COLUMNS

NOTICE: All steering wheel and column fasteners are important attaching parts in that they could affect

the performance of vital parts and systems, and/or could result in major repair expense. They

must be replaced

with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. 'Torque values must be used as specified during reassembly

to assure proper retention of all parts. There is to be no welding as

it may result in extensive damage and weakening

of the metal.

For prevailing torque

nut(s) and bolts(s), refer to the "Reuse of Prevailing Torque Nut(<) and Bolt(s) " chart

in Section OA.

CONTENTS

..................... ................................................................... GENERAL DESCRIPTION .. 3B5-1 ............................................. ........................ MAINTENANCE AND ADJUSTMENTS .. 3B5-1 ON-CAR SERVICE ........................................................................................................ 3B5-2

Steering Column ............................................................................................................ 3B5-2 ......................................................................................................... Intermediateshaft 3B5-3

Park Lock Cable .................................................................... 3B54 ......................................................................................... Checking For Accident Damage 3B5-5 ............................................................................ Unit Repair Intermediate Shaft Assembly 3B5-6

..................................................................................... Standard Column @lanual Trans) 3B5-7 ......................................................... ....................... Standard Column (Auto Trans) .. 3B5-13 Tilt Column (Manual Trans) ............................................................................................. 3B5-19

Tilt Column (Auto Trans). ................................................................................................ 3B5-27

................ .................... TORQUE SPECIFICATIONS .. .. 3B5-35

SPECIAL TOOLS .......................................................................................................... 3B5-35

GENERAL DESCRIPTION

STEERING COLUMN

The function locking energy absorbing steering

column includes three important features in addition

to the steering function:

1. 'The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of an injury to the driver of the car.

2. The ignition switch and lock are mounted

conveniently on this column.

3. With the column mounted lock, the ignition and

steering operations can be locked to inhibit theft

of the car.

The turn signal lever provides for control of

headlight beams, windshield washer and wipers.

The column may be easily

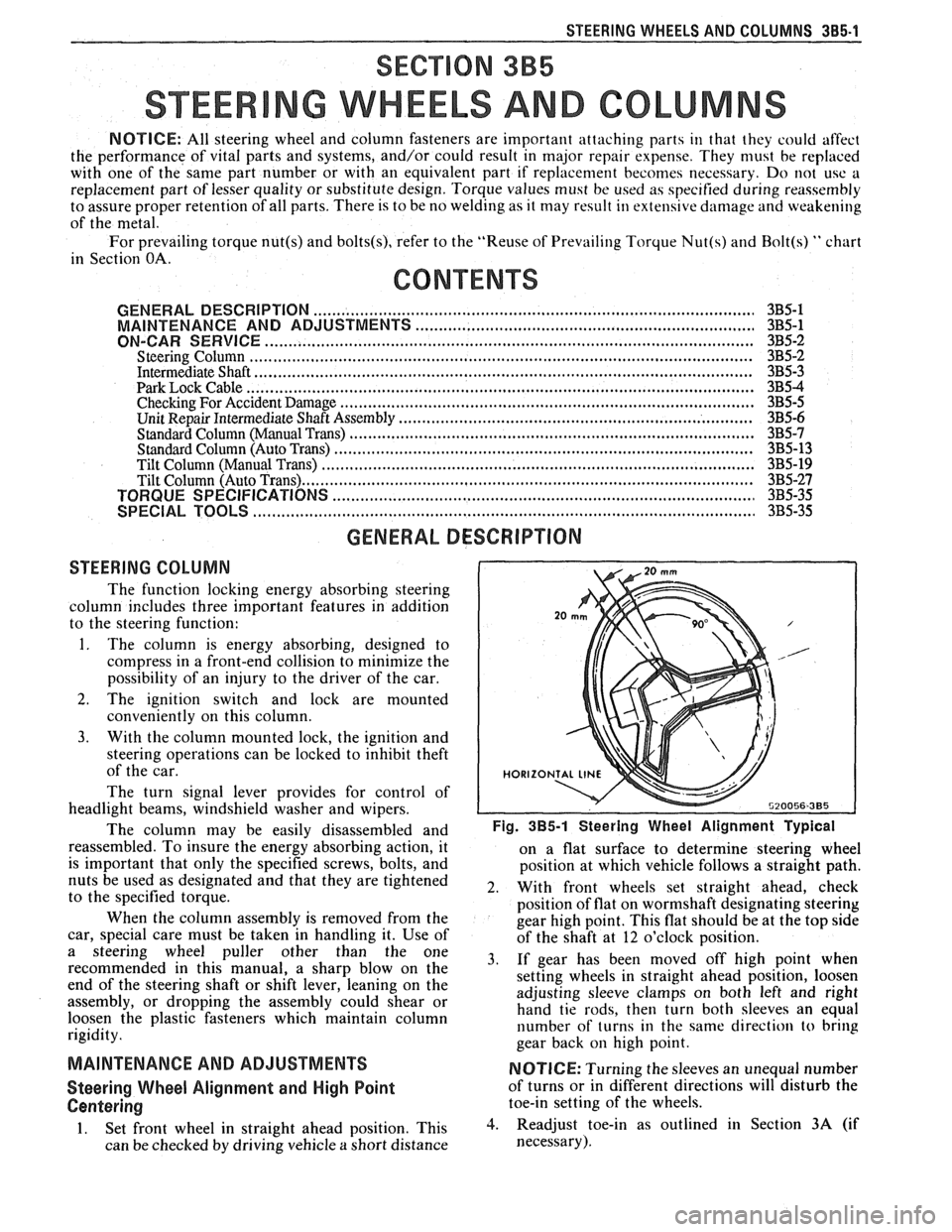

disassembled and Fig. 385-1 Steering Wheel Alignment ~ypical

reassembled. To insure the energy absorbing action, it

on a flat surface to determine steering wheel

is important that only the specified screws, bolts, and

position at which vehicle follows a straight path.

nuts be used as designated and that they are tightened

2. With front wheels set straight ahead, check to the specified torque.

position of flat on wormshaft designating steering

When the column assembly is removed from the

gear high point. This flat should be at the top side

car, special care must be taken in handling it. Use of

of the shaft at 12 o'clock position.

a steering puller other than the One 3, if gear has been moved off high when recommended in this manual, a sharp blow on the

setting wheels in straight ahead position, loosen

end of the steering shaft or shift lever, leaning on the

assembly, or dropping the assembly could shear or adjusting

sleeve clamps on both left and right

hand tie rods, then turn both sleeves an equal

loosen the plastic fasteners which maintain column

rigidity. number

of turns in the same direction

to bring

gear back

on high point.

MAINTENANCE AND ADJUSTMENTS NOTICE: Turning the sleeves an unequal number

Steering Wheel Alignment and High Point of turns or in different directions will disturb the

Centering toe-in setting of the wheels.

1. Set front wheel in straight ahead position, This 3. Readjust toe-in as outlined in Section 3A (if

can be checked by driving vehicle

a short distance necessary).

Page 161 of 1825

385.10 STEERING WHEELS AND COLUMNS

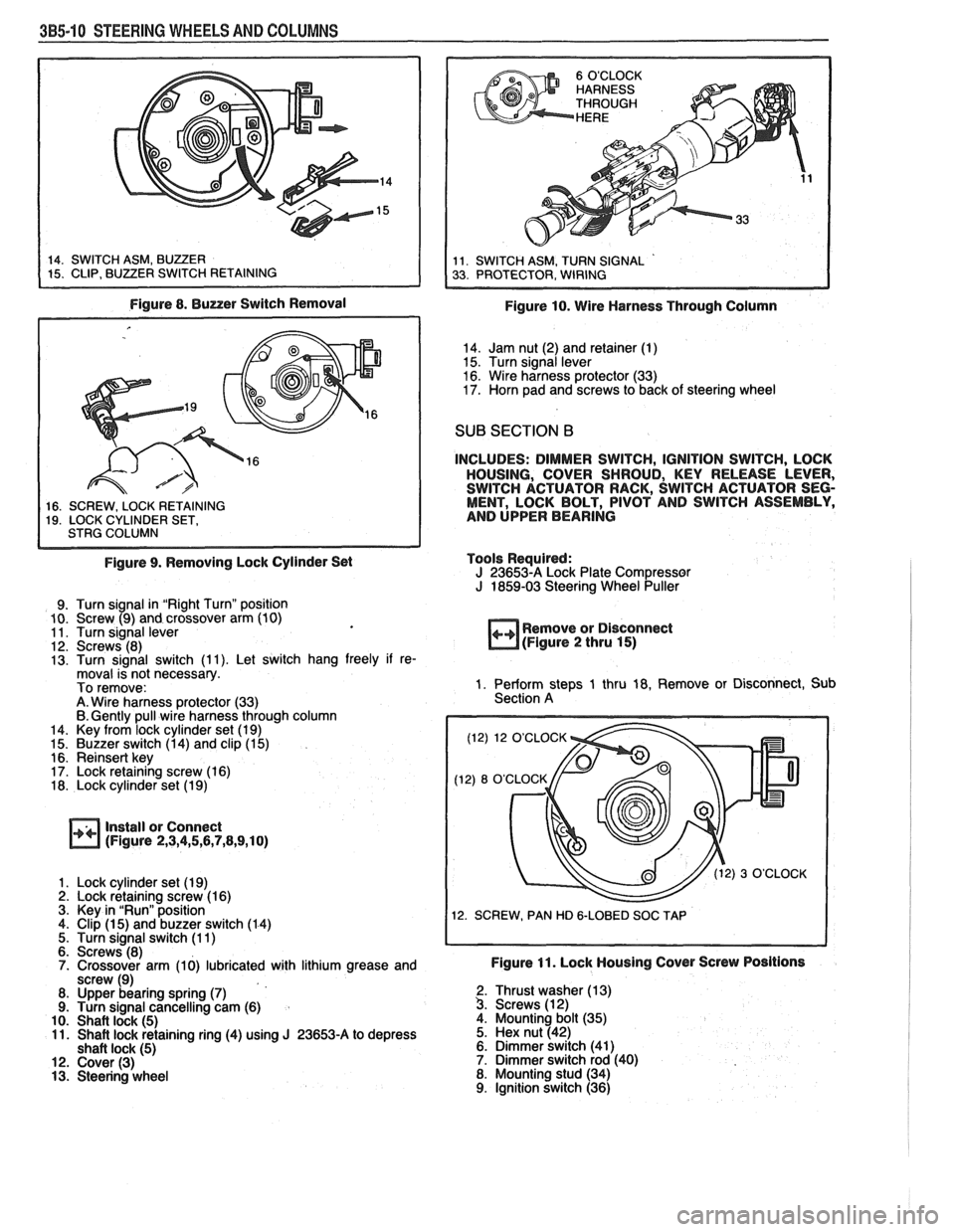

Figure 8. Buzzer Switch Removal

1 16. SCREW. LOCK RETAINING I 19. LOCK CYLINDER SET, I STRG COLUMN I

Figure 9. Removing Lock Cylinder Set

9. Turn signal in "Right Turn" position

10. Screw (9) and crossover arm (10)

11. Turn signal lever

12. Screws (8)

13. Turn signal switch (1 1). Let switch hang freely if re-

moval is not necessary.

To remove:

A. Wire harness protector (33)

6. Gently pull wire harness through column

14. Key from lock cylinder set (1 9)

15. Buzzer switch (1 4) and clip (1 5)

16. Reinsert key

17. Lock retaining screw (1 6)

18. Lock cylinder set (1 9)

Install or Connect

(Figure 2,3,4,5,6,7,8,9,10)

1. Lock cylinder set (1 9) 2. Lock retaining screw (1 6)

3. Key in "Run" position

4. Clip

(1 5) and buzzer switch (1 4)

5. Turn signal switch (1 1)

6. Screws (8)

7. Crossover arm (10) lubricated with lithium grease and

screw (9)

8. Upper bearing spring

(7) 9. Turn signal cancelling cam (6)

10. Shaft lock (5) 11. Shaft lock retaining ring (4) using J 23653-A to depress

shaft lock (5) 12. Cover (3) 13. Steering wheel

Figure 10. Wire Harness Through Column

14. Jam nut (2) and retainer (1)

15. Turn signal lever

16. Wire harness protector (33)

17. Horn pad and screws to back of steering wheel

SUB SECTION B

INCLUDES: DIMMER SWITCH, IGNITION SWITCH, LOCK

HOUSING, COVER SHROUD, KEY RELEASE LEVER,

SWITCH ACTUATOR RACK, SWITCH ACTUATOR SEG-

MENT, LOCK BOLT, PIVOT AND SWITCH ASSEMBLY,

AND UPPER BEARING

Tools Required:

J 23653-A Lock Plate Compressor J 1859-03 Steering Wheel Puller

++ Remove or Disconnect

(Figure 2 thru 15)

1. Perform steps 1 thru 18, Remove or Disconnect, Sub

Section A

(12) 12 O'CLOCK

12. SCREW, PAN HD

&LOBED SOC TAP

Figure 11. Lock Housing Cover Screw Positions

2. Thrust washer (1 3) 3. Screws (1 2)

4. Mounting bolt (35)

5. Hex nut (42)

6. Dimmer switch (41)

7. Dimmer switch rod (40)

8. Mounting stud (34)

9. Ignition switch (36)

Page 287 of 1825

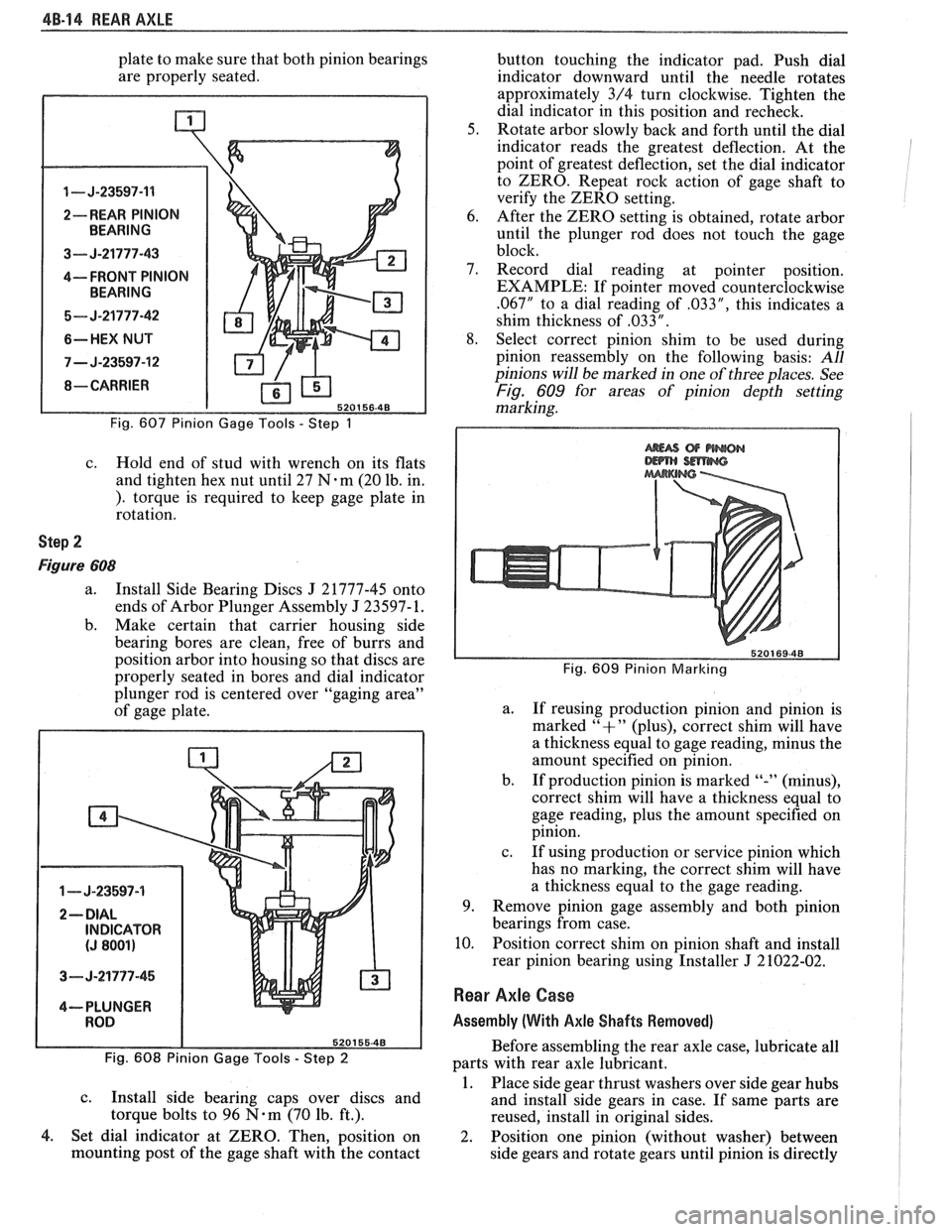

4B-14 REAR AXLE

plate to make sure that both pinion bearings

are properly seated.

1 - J-23597-11

2-- REAR PINION

3--- J-21777-43

4---- FRONT PINION

5- J-21777-42

6-HEX NUT

7 - J-23597-12

Fig. 607 Pinion Gage Tools - Step 1

c. Hold end of stud with wrench on its flats

and tighten hex nut until 27

N.m (20 lb. in.

). torque is required to keep gage plate in

rotation.

Step 2

Figure 608

a. Install Side Bearing Discs J 21777-45 onto

ends of Arbor Plunger Assembly

J 23597- 1.

b. Make certain that carrier housing side

bearing bores are clean, free of burrs and

position arbor into housing so that discs are

properly seated in bores and dial indicator

plunger rod is centered over "gaging area"

of gage plate.

1 - J-23597-4

3- J-21777-45

4--- PLUNGER

Fig. 608 Pinion Gage Tools

- Step 2

c.

Install side bearing caps over discs and

torque bolts to 96

N-m (70 lb. ft.).

4. Set dial indicator at ZERO. Then, position on

mounting post of the gage shaft with the contact button

touching the indicator pad. Push dial

indicator downward until the needle rotates

approximately 3/4 turn clockwise. Tighten the

dial indicator in this position and recheck.

5. Rotate arbor slowly back and forth until the dial

indicator reads the greatest deflection. At the

point of greatest deflection, set the dial indicator

to ZERO. Repeat rock action of gage shaft to

verify the ZERO setting.

6. After the ZERO setting is obtained, rotate arbor

until the plunger rod does not touch the gage

block.

7. Record dial reading at pointer position.

EXAMPLE: If pointer moved counterclockwise

.067" to a dial reading of .033", this indicates a

shim thickness of

,033 " .

8. Select correct pinion shim to be used during

pinion reassembly on the following basis:

All

pinions will be marked in one of three places. See

Fig. 609 for areas of pinion depth setting

marking.

Fig. 609 Pinion Marlcing

a.

If reusing production pinion and pinion is

marked

"+" (plus), correct shim will have

a thickness equal to gage reading, minus the

amount specified on pinion.

b. If production pinion is marked

"-" (minus),

correct shim will have

a thickness equal to

gage reading, plus the amount specified on

pinion.

c. If using production or service pinion which

has no marking, the correct shim will have

a thickness equal to the gage reading.

9. Remove pinion gage assembly and both pinion

bearings from case.

10. Position correct shim on pinion shaft and install

rear pinion bearing using Installer

J 21022-02.

Rear Axle Case

Assembly (With Axle Shafts Removed)

Before assembling the rear axle case, lubricate all

parts with rear axle lubricant.

1. Place side gear thrust washers over side gear hubs

and install side gears in case. If same parts are

reused, install in original sides.

2. Position one pinion (without washer) between

side gears and rotate gears until pinion is directly

Page 368 of 1825

2.8 LITER V-6 6A2-17

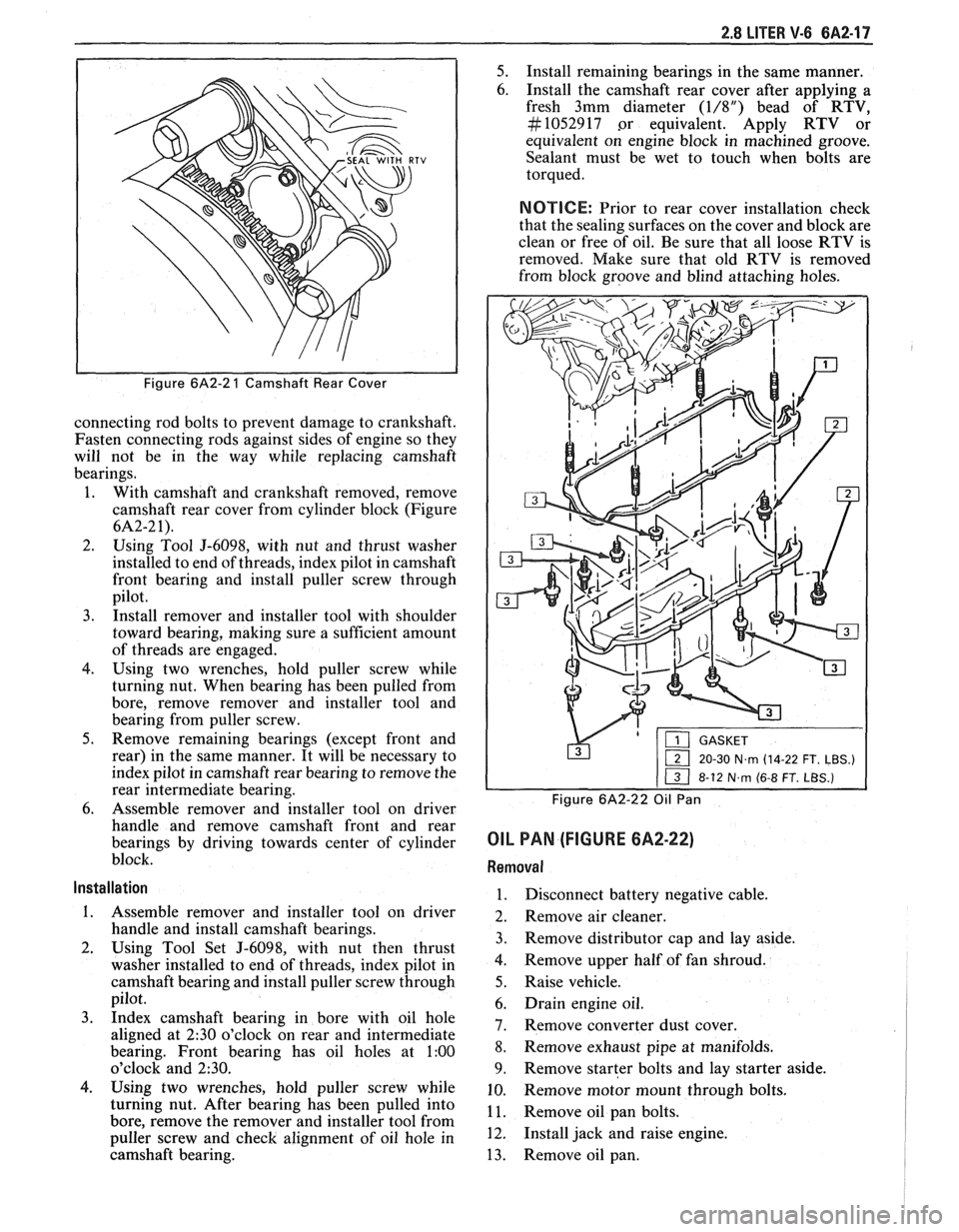

Figure 6A2-2 1 Camshaft Rear Cover

connecting rod bolts to prevent damage to crankshaft.

Fasten connecting rods against sides of engine so they

will not be in the way while replacing camshaft

bearings.

1. With camshaft and crankshaft removed, remove

camshaft rear cover from cylinder block (Figure

6A2-2 1).

2. Using Tool J-6098, with nut and thrust washer

installed to end of threads, index pilot in camshaft

front bearing and install puller screw through

pilot.

3. Install remover and installer tool with shoulder

toward bearing, making sure a sufficient amount

of threads are engaged.

4. Using two wrenches, hold puller screw while

turning nut. When bearing has been pulled from

bore, remove remover and installer tool and

bearing from puller screw.

5. Remove remaining bearings (except front and

rear) in the same manner. It will be necessary to

index pilot in camshaft rear bearing to remove the

rear intermediate bearing.

6. Assemble remover and installer tool on driver

handle and remove camshaft front and rear

bearings by driving towards center of cylinder

block.

Installation

1. Assemble remover and installer tool on driver

handle and install camshaft bearings.

2. Using Tool Set J-6098, with nut then thrust

washer installed to end of threads, index pilot in

camshaft bearing and install puller screw through

pilot.

3. Index camshaft bearing in bore with oil hole

aligned at

2:30 o'clock on rear and intermediate

bearing. Front bearing has oil holes at

1:00

o'clock and 230.

4. Using two wrenches, hold puller screw while

turning nut. After bearing has been pulled into

bore, remove the remover and installer tool from

puller screw and check alignment of oil hole in

camshaft bearing.

5. Install remaining bearings in the same manner.

6. Install the camshaft rear cover after applying a

fresh 3mm diameter

(1/8") bead of RTV,

#I052917 .or equivalent. Apply RTV or

equivalent on engine block in machined groove.

Sealant must be wet to touch when bolts are

torqued.

NOTICE: Prior to rear cover installation check

that the sealing surfaces on the cover and block are

clean or free of oil. Be sure that all loose RTV is

removed. Make sure that old RTV is removed

from block groove and blind attaching holes.

&'p-x&F--

1 20-30 N~rn (14-22 FT. LBS.)

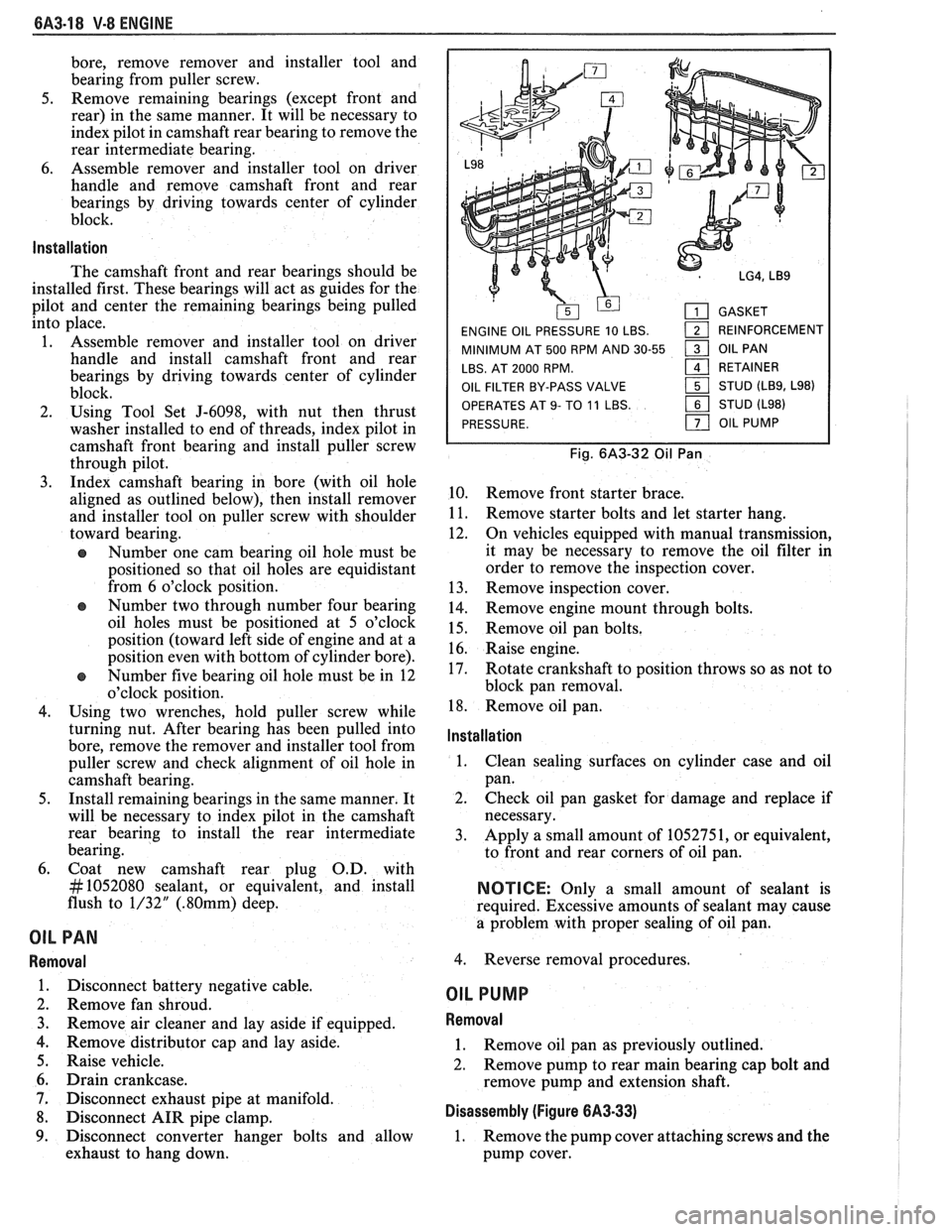

Figure 6A2-22 Oil Pan

OIL PAN (FIGURE 6A2-22)

Removal

1. Disconnect battery negative cable.

2. Remove air cleaner.

3. Remove distributor cap and lay aside.

4. Remove upper half of fan shroud.

5. Raise vehicle.

6. Drain engine oil.

7. Remove converter dust cover.

8. Remove exhaust

pipe at manifolds.

9. Remove starter bolts and lay starter aside.

10. Remove

motor mount through bolts.

1 1. Remove oil pan bolts.

12. Install jack and raise engine.

13. Remove oil pan.

Page 397 of 1825

6A3-18 V-8 ENGINE

bore, remove remover and installer tool and

bearing from puller screw.

5. Remove remaining bearings (except front and

rear) in the same manner. It will be necessary to

index pilot in camshaft rear bearing to remove the

rear intermediate bearing.

6. Assemble remover

and installer tool on driver

handle and remove camshaft front and rear

bearings by driving towards center of cylinder

block.

lnstallation

The camshaft front and rear bearings should be

installed first. These bearings will act as guides for the

pilot and center the remaining bearings being pulled

into place.

1. Assemble remover

and installer tool on driver

handle and install camshaft front and rear

bearings by driving towards center of cylinder

block.

2. Using Tool Set J-6098, with nut then thrust

washer installed to end of threads, index pilot in

camshaft front bearing and install puller screw

through pilot.

3. Index camshaft bearing in bore (with oil hole

aligned as outlined below), then install remover

and installer tool on puller screw with shoulder

toward bearing.

e Number one cam bearing oil hole must be

positioned so that oil holes are equidistant

from 6 o'clock position.

e Number two through number four bearing

oil holes must be positioned at 5 o'clock

position (toward left side of engine and at a

position even with bottom of cylinder bore).

e Number five bearing oil hole must be in 12

o'clock position.

4. Using two wrenches, hold puller screw while

turning nut. After bearing has been pulled into

bore, remove the remover and installer tool from

puller screw and check alignment of oil hole in

camshaft bearing.

5. Install remaining bearings in the same manner. It

will be necessary to index pilot in the camshaft

rear bearing to install the rear intermediate

bearing.

6. Coat new camshaft rear plug O.D. with

# 1052080 sealant, or equivalent, and install

flush to 1/32"

(.80mm) deep.

OIL PAN

Removal

1. Disconnect battery negative cable.

2. Remove fan shroud.

3. Remove air cleaner and lay aside if equipped.

4. Remove distributor cap and lay aside.

5. Raise vehicle.

6. Drain crankcase.

7. Disconnect exhaust pipe at manifold.

8. Disconnect AIR pipe clamp.

9. Disconnect converter hanger bolts and allow

exhaust to hang down.

GASKET

ENGINE OIL PRESSURE 10 LBS.

1 REINFORCEMENT

MINIMUM AT 500 RPM AND 30-55

1 OIL PAN

LBS. AT 2000 RPM.

161 RETAINER

OIL FILTER BY-PASS VALVE STUD

(LB9, L98)

OPERATES

AT 9- TO 11 LBS. STUD (L98)

PRESSURE.

OIL PUMP

Fig. 6A3-32 Oil Pan

10. Remove front starter brace.

11. Remove starter bolts and let starter hang.

12. On vehicles equipped with manual transmission,

it may be necessary to remove the oil filter in

order to remove the inspection cover.

13. Remove inspection cover.

14. Remove engine mount through bolts.

15. Remove oil pan bolts.

16. Raise engine.

17. Rotate crankshaft to position throws so as not to

block pan removal.

18. Remove oil pan.

lnstallation

1.

Clean sealing surfaces on cylinder case and oil

pan.

2. Check oil pan gasket for damage and replace if

necessary.

3. Apply a small amount of 1052751, or equivalent,

to front and rear corners of oil pan.

NOTICE: Only a small amount of sealant is

required. Excessive amounts of sealant may cause

a problem with proper sealing of oil pan.

4. Reverse removal procedures.

OIL PUMP

Removal

1. Remove oil pan as previously outlined.

2. Remove pump to rear main bearing cap bolt and

remove pump and extension shaft.

Disassembly (Figure 6A3-33)

1. Remove the pump cover attaching screws and the

pump cover.

Page 418 of 1825

ENGINE COOLING BB-7

NOTICE: If recommended quality antifreeze is

used, supplemental inhibitors or additives claiming

to provide increased cooling capability are not

necessary. They may be detrimental to the efficient

operation of the system, and represent an

unnecessary operating expense.

Every 12 months or 15,000 miles, the cooling

system should be serviced as follows;

1. Wash radiator cap and filler neck with clean

water.

2. Check coolant for proper level and freeze

protection.

3. Pressure test system and radiator cap for proper

pressure holding capacity, 103

kPa (15 psi). If

replacement of cap is required, use the proper cap

specified for car model.

4. Tighten hose clamps and inspect all hoses. Replace

hoses whenever cracked, swollen or otherwise

deteriorated.

5. Clean frontal area of radiator core and air

conditioning condenser.

DRAINING AND REFILLING THE COOLING

SYSTEM

Replace hoses every 24 months or 30,000 miles or

earlier if cracked, swollen or otherwise deteriorated.

Every two years or 30,000 miles, whichever first

occurs, the cooling system should be flushed and

refilled using the following recommended procedure:

1. Remove radiator cap, or thermostat housing cap

(VIN

0, J, R and U), when engine is cool by:

a. Slowly

rotating cap counterclockwise to

detent. (Do not press down while rotating.)

b. Wait until any

residual pressure (indicated

by a hissing sound) is relieved.

c. After all hissing ceases, press down on cap

while continuing to rotate

counterclockwise.

CAUTION: To avoid the danger of

being burned, do not remove radiator

cap while engine and radiator are still

hot. Scalding fluid and steam may be

blown out under pressure.

2. Remove the thermostat by using the wire handle

to lift it out of the housing (VIN

0, J, R and U).

3. With the thermostat removed, reinstall the

thermostat housing cap (VIN

0, J, R and U).

4. Open radiator drain valve and block drain plugs

to drain coolant. On VIN R and

9 (P series)

engines, open coolant pipe plugs.

5. Close valve. Reinstall drain plugs, and add

sufficient water to fill system.

6. Run engine, drain and refill the system, as

described in steps

4 and 5 a sufficient number of

times, until the drained liquid is nearly colorless.

Important

BLOCK DRIVE WHEELS, place

transmission in PARK (automatic

transmission) or NEUTRAL (manual

transmission) and set the parking brake. 7.

Allow system to drain completely. Then close

radiator drain valve tightly, and reinstall block

drain plugs.

8. Remove recovery cap leaving hoses in place.

Remove coolant recovery tank and empty of

fluid. Flush tank with clean water, drain and

reinstall.

9. Add sufficient ethylene glycol coolant, meeting

GM specification 1825-M, to provide the

required freezing and corrosion protection

- at

least 50 percent solution -37°C (-34°F). Fill

radiator to the base of the radiator fill neck and

add sufficient coolant to the recovery tank to

raise level to the "FULL" mark. Reinstall

recovery tank cap.

10. Run engine, with radiator cap or thermostat

housing cap removed, until normal operating

temperature is reached. (Radiator upper hose

becomes hot.)

11. With engine idling, add coolant until level

reaches bottom of filler neck and reinstall cap,

making certain arrows line up with overflow tube.

CAUTION: Under some conditions, the

ethylene glycol in engine coolant is

flammable. To help avoid being

burned when adding coolant, DO NOT

spill

it on the exhaust system or hat

engine parts.

It is the owner's responsibility to keep the freeze

protection at a level appropriate to the

temperatures which may occur in the area of

vehicle operation.

a. Maintain

cooling system freeze protection

at

-37°C (-34"F), to ensure protection

against corrosion and loss of coolant from

boiling, even though freezing temperatures

are not expected.

b. Add ethylene glycol base coolant that meets

GM Specification 1825-M, when coolant

additions are required because of coolant

loss, or to provide additional protection

against

freezing at temperatures lower than

-37°C (-34°F).

NOTICE: Alcohol or methanol base coolants, or

plain water, are not recommended at any time.

DRlVE BELT

NOTICE: Routine inspection of the belt may

reveal cracks in the belt ribs. These cracks will

not impair belt performance and therefore should

not be considered a problem requiring belt

replacement. However, the belt should be

replaced if belt slip occurs or if sections of the

belt ribs are missing.

A single (serpentine) belt is used to drive all

engine accessories formerly driven by multiple drive

belts. All belt driven accessories are ridgedly mounted

with belt tension maintained by a spring loaded

tensioner.

The drive belt tensioner has the ability to control

belt tension over a fairly broad range of belt lengths.

Page 473 of 1825

684.4 IGNITION SYSTEM

a spark plug wire from a spark plug, twist the 4. Do not wipe grease from module, or distributor

boot on the spark plug and pull

on the boot to base,

if same module is to be replaced.

remove the wire, or use a special tool designed to

remove spark plug boots.

Install or Connect

Remove or Disconnect

1. Ignition switch battery feed wire and tachometer

lead (if equipped) from distributor cap. Also

release the coil connectors from the cap. (DO

NOT use a screwdriver or tool to release the

locking tabs.)

2. Distributor cap by turning four screws

counterclockwise. Move cap out of the way.

3. Four-terminal ECM harness from distributor.

4. If necessary, remove secondary wires from cap,

release wiring harness latches and remove wiring

harness retainer. The spark plug wire numbers

are indicated on the retainer.

5. Distributor clamp screw and hold-down clamp.

6. Note position of rotor, then pull distributor up

until rotor just stops turning counterclockwise

and again note position of rotor.

To insure correct timing of the distributor,

the distributor must be INSTALLED with

the rotor correctly positioned as noted.

If the engine was accidentally cranked after the

distributor was removed, the following procedure can

be used for installing:

1. Remove No. 1 spark plug.

2. Place finger over No. 1 spark plug hole and crank

engine slowly until compression is felt.

3. Align timing mark on pulley to "0" on engine

timing indicator.

4. Turn rotor to point between No. 1 and No. 8

spark plug towers on distributor cap on V8

engines, between No. 1 and No. 6 on V6 engines,

and No.

1 and No. 4 on 4 cylinder engines.

5. Install distributor and connect ignition feed wire.

6. Install distributor cap and spark plug wires.

7. Check engine timing (see Set Ignition Timing).

Install or Connect

1. Insert distributor, positioning rotor as removed.

2. Distributor hold-down clamp and screw.

3. Wiring harness retainer and secondary wires, if

removed.

4. ECM harness connector.

5. Distributor cap.

6. Coil connectors.

7. Battery wire and tachometer lead, if equipped.

Module

It is not necessary to remove the distributor from

car.

Remove or Disconnect

1. Distributor cap and rotor.

2. Two module attaching screws, and lift module

UP. 3. Leads from module. (Observe color code on leads

as these cannot be interchanged.)

NOTICE: If a new module is to be installed, a

package of silicone grease will be included with it.

Spread the grease on the metal face of the module

and on the distributor base where the module

seats. This grease is necessary for module cooling.

1. Module.

2. Module leads (observe color code).

3. Attaching screws to module.

4. Rotor.

5. Cap.

Pick-Up Coil

1. Remove distributor from car and follow

instructions in Unit Repair, as applicable.

Rotor

Fig. 1

1. Remove distributor cap.

2. The rotor is retained by two screws and is

provided with a slot which fits over a square lug,

,

so that the rotor can be installed in only one

position.

Integral Ignition Coil

Fig. I

Remove or Disconnect

1. Distributor cap.

2. Three coil cover attaching screws, and lift off

cover.

3. Coil attaching screws and lift ignition coil and

leads from cap.

Install or Connect I

1. Coil and attaching screws.

2. Coil leads.

3. Coil cover and attaching screws.

Capacitor

Fig. 1

The capacitor is part of the coil wire harness

assembly. Since the capacitor is used only for radio

noise suppression, it will seldom need replacement.

Remove or Disconnect I

1. Distributor cap and rotor.

2. Capacitor attaching screw and unplug connector

from module. It may help to loosen the module.

Install or Connect I

1. Plug into module.

2. Capacitor and hold-down screw (be sure ground

lead is under screw).

Page 750 of 1825

DRIVEABILITY AND EMISSIONS 2.8L (VIN S) 6E3-CZ-15

NOTICE: Before instal ling new idle air control valve

assembly, the position of its pintle

MUST

be checked. If pintle is extended too far,

damage to the assembly may occur.

Measure

@ Distance from gasket mounting surface of IAC

valve assembly

(70) to tip of pintle, Dimension

"A" in Figure

C2-19.

Adjust

If distance is greater that 28 mm (1 118 in.), reduce -

it as follows:

a. If

IAC valve assembly has

a "collar" around

electrical connector end, use firm hand pressure

on pintle to retract it. (A slight side-to-side motion

may help.)

b. If IAC valve assembly has "no collar", compress

pintle-retaining spring toward body of the IAC

and try to turn pintle clockwise.

@ If pintle will turn, continue turning until

28mm

(1 118 in.) is reached. Return spring to

original position, with straight part of spring

end lined up with flat surface under the pintle

head.

@ If pintle will not turn, use firm hand pressure

to retract it.

Install or Connect

1. New IAC valve assembly gasket (71) on IAC valve

assembly

(70).

2. IAC valve assembly in idle airlvacuum signal

housing assembly

(60).

Tighten

IAC valve assembly to 18N.m (13 ft. Ibs.), with

wrench on hex surface only.

3. Electrical connector at IAC valve assembly (70).

Important

No physical adjustment is made to the IAC

assembly after installation.

IAC resetting occurs

after reinstallation on the vehicle, and is reset

after the engine is started and then the ignition

turned off.

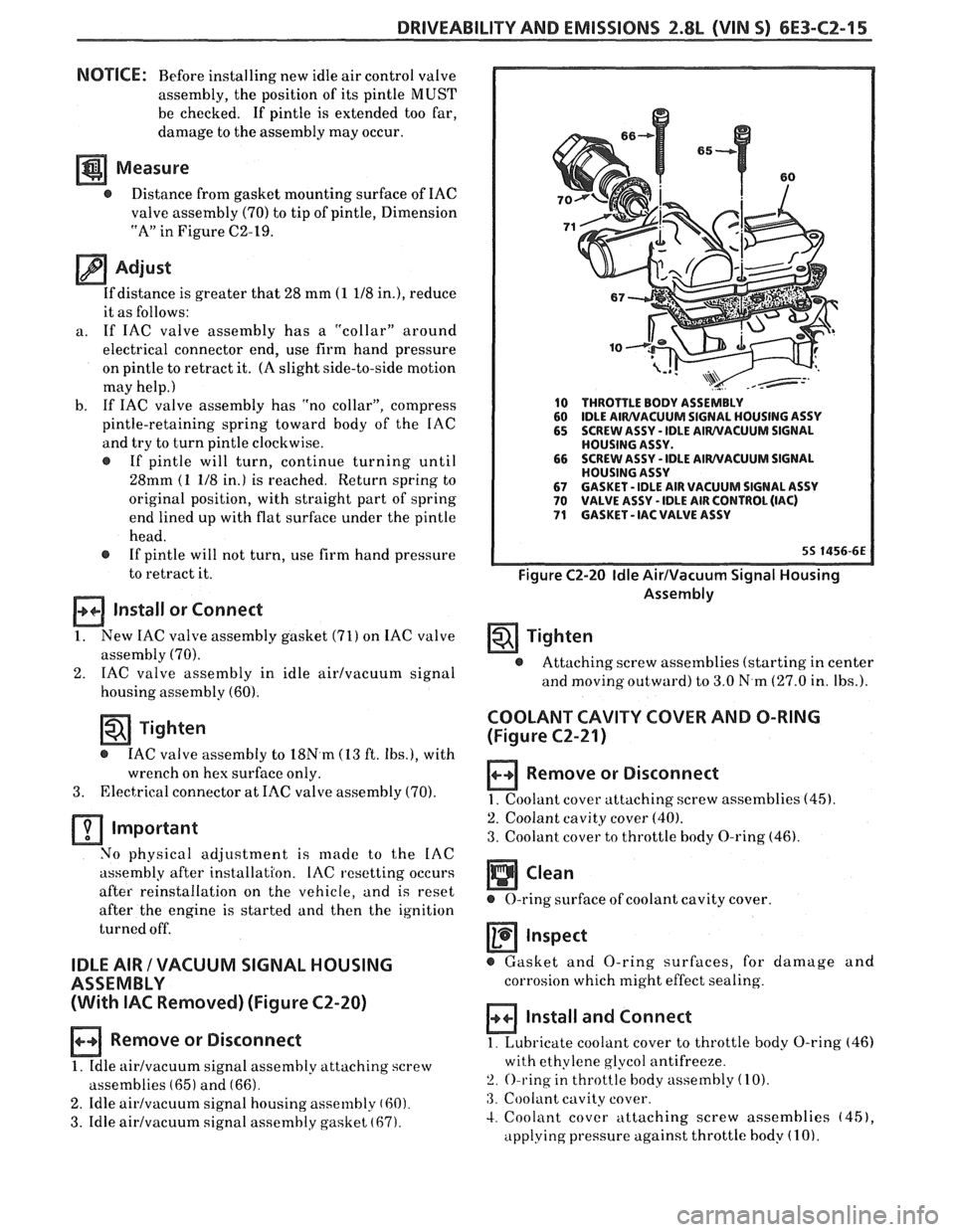

IDLE AIR / VACUUM SIGNAL HOUSING

ASSEMBLY

(With

IAC Removed) (Figure C2-20)

Remove or Disconnect

1. Idle airlvacuurn signal assembly attaching screw

assemblies

(65) and (66).

2. Idle airlvacuum signal housing assembly (60).

3. Idle airlvacuum signal assembly gasket (67).

10 THROTTLE BODY ASSEMBLY

60 IDLE AIWVACUUM SIGNAL

HOUSING ASSY

65 SCREW ASSY - IDLE AIWVACUUM SIGNAL

HOUSING ASSY.

66 SCREW

ASSY

- IDLE AIWVACUUM SIGNAL

HOUSING ASSY

67 GASKET - IDLE AIR VACUUM SIGNAL ASSY 70 VALVE ASSY - IDLE AIR CONTROL (IAC) 71 GASKET - IAC VALVE ASSY

Figure C2-20 Idle AirIVacuum Signal Housing

Assembly

Tighten

@ Attaching screw assemblies (starting in center

and

moving outward) to 3.0 N.m (27.0 in. Ibs.).

COOLANT CAVITY COVER AND O-RING

(Figure

C2-21)

Remove or Disconnect

1. Coolant cover attaching. screw assemblies (45).

2. Coolant cavity cover (40).

3. Coolant cover to throttle body O-ring (46).

Inspect

@ Gasket and O-ring surfaces, for damage and

corrosion which might effect sealing.

Install and Connect

1. Lubricate coolant cover to throttle body O-ring (46)

with ethylene glycol antifreeze.

2. O-ring in throttle body assembly (10).

:3. Coolant cavity cover.

4. Coolant cover attaching screw assemblies (451,

applying pressure against throttle body (1 0).

Page 900 of 1825

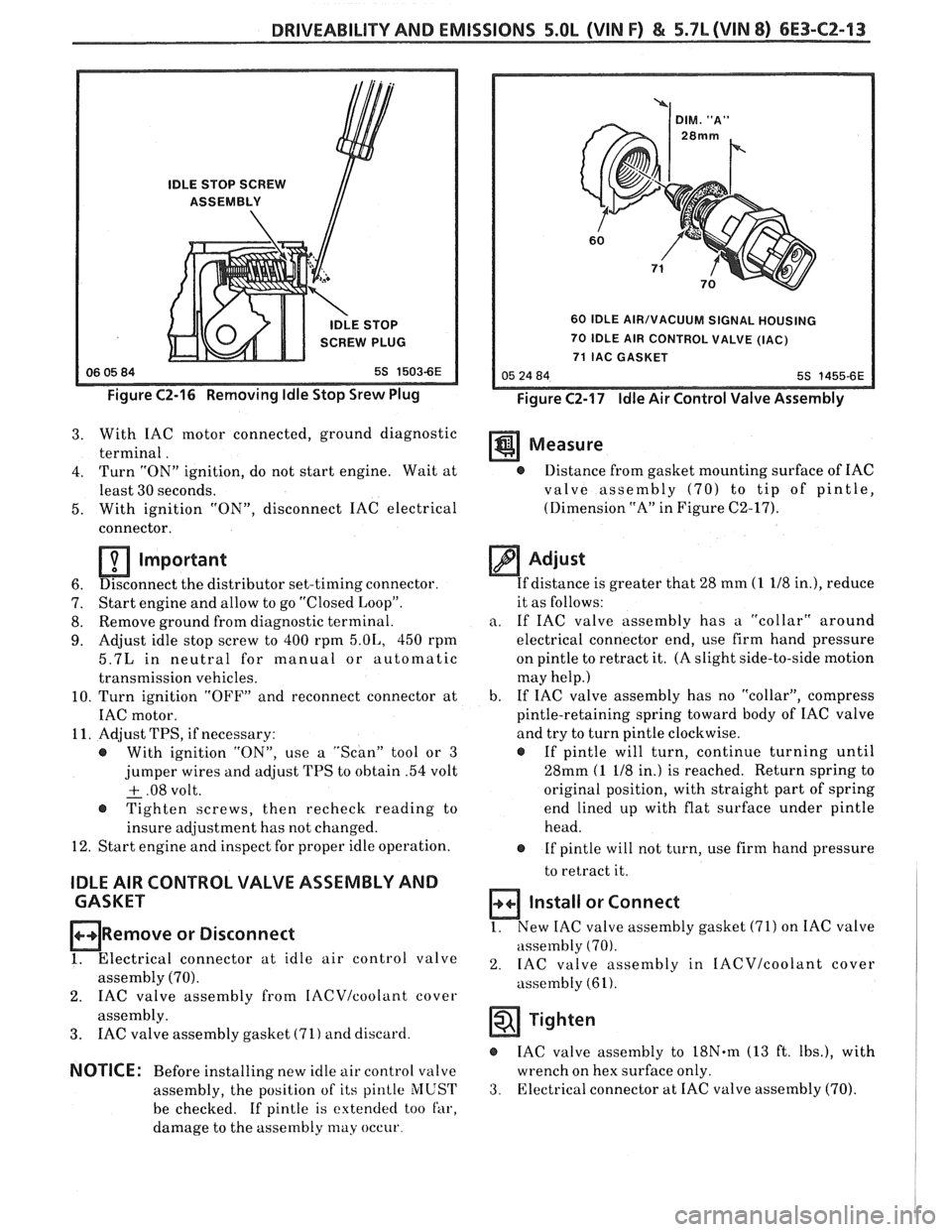

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7b (VIN 8) 6E3-CZ-13

IDLE STOP SCREW

ASSEMBLY

IDLE STOP

SCREW PLUG

Figure C2-16 Removing Idle Stop Srew Plug

60 IDLE AIR/VACUUM SIGNAL HOUSING

70 IDLE AIR CONTROL VALVE (IAC)

71 IAC GASKET

Figure C2-17 Idle Air Control Valve Assembly

3. With IAC motor connected, ground diagnostic

terminal. Measure

4. Turn "ON" ignition, do not start engine. Wait at @ Distance from gasket mounting surface of IAC

least 30 seconds. valve assembly

(70) to tip of pintle,

5. With ignition

"ON", disconnect IAC electrical (Dimension

"A" in Figure C2-17).

connector.

Important

6. Disconnect

the distributor set-timing connector.

7. Start

engine and allow to go "Closed Loop".

8. Remove

ground from diagnostic terminal.

9. Adjust idle stop screw to 400 rpm 5.01,, 450 rpm

5.7L in neutral for manual or automatic

transmission vehicles.

10. Turn ignition "OFF" and reconnect connector at

IAC motor.

11. Adjust TPS, if necessary:

@ With ignition "ON", use a "Scan" tool or 3

jumper wires and adjust TPS to obtain .54 volt

+ .08 volt. - @ Tighten screws, then recheck reading to

insure adjustment has not changed.

12. Start engine and inspect for proper idle operation.

IDLE AIR CONTROL VALVE ASSEMBLY AND

CASKET

ORemove or Disconnect

1. Electrical connector at idle air control valve

assembly (70).

2. IAC valve assembly from IACVIcoolant cover

assembly.

3. IAC valve assembly gasket (71) and discard.

NOTICE: Before installing new idle air control valve

assembly, the position of its

pinlle MUST

be checked. If pintle is extended too far,

damage to the assembly

may occur

Adjust

If distance is greater that 28 mm (1 118 in.), reduce

it as follows:

a. If IAC valve assembly has a "collar" around

electrical connector end, use firm hand pressure

on pintle to retract it. (A slight side-to-side motion

may help.)

b. If

IAC valve assembly has no "collar", compress

pintle-retaining spring toward body of IAC valve

and try to turn pintle clockwise.

@ If pintle will turn, continue turning until

28mm

(1 118 in.) is reached. Return spring to

original position, with straight part of spring

end lined up with flat surface under pintle

head.

@ If pintle will not turn, use firm hand pressure

to retract it.

Install or Connect

1. New IAC valve assembly gasket (71) on IAC valve

assembly

(70).

2. IAC valve assembly in IACVIcoolant cover

assembly (61).

Tighten

IAC valve assembly to 18N.m (13 ft. Ibs.), with

wrench on hex surface only.

3. Electrical connector at IAC valve assembly (70).