throttle PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 16 of 1825

- -

GENERAL INFORMATION OA-13

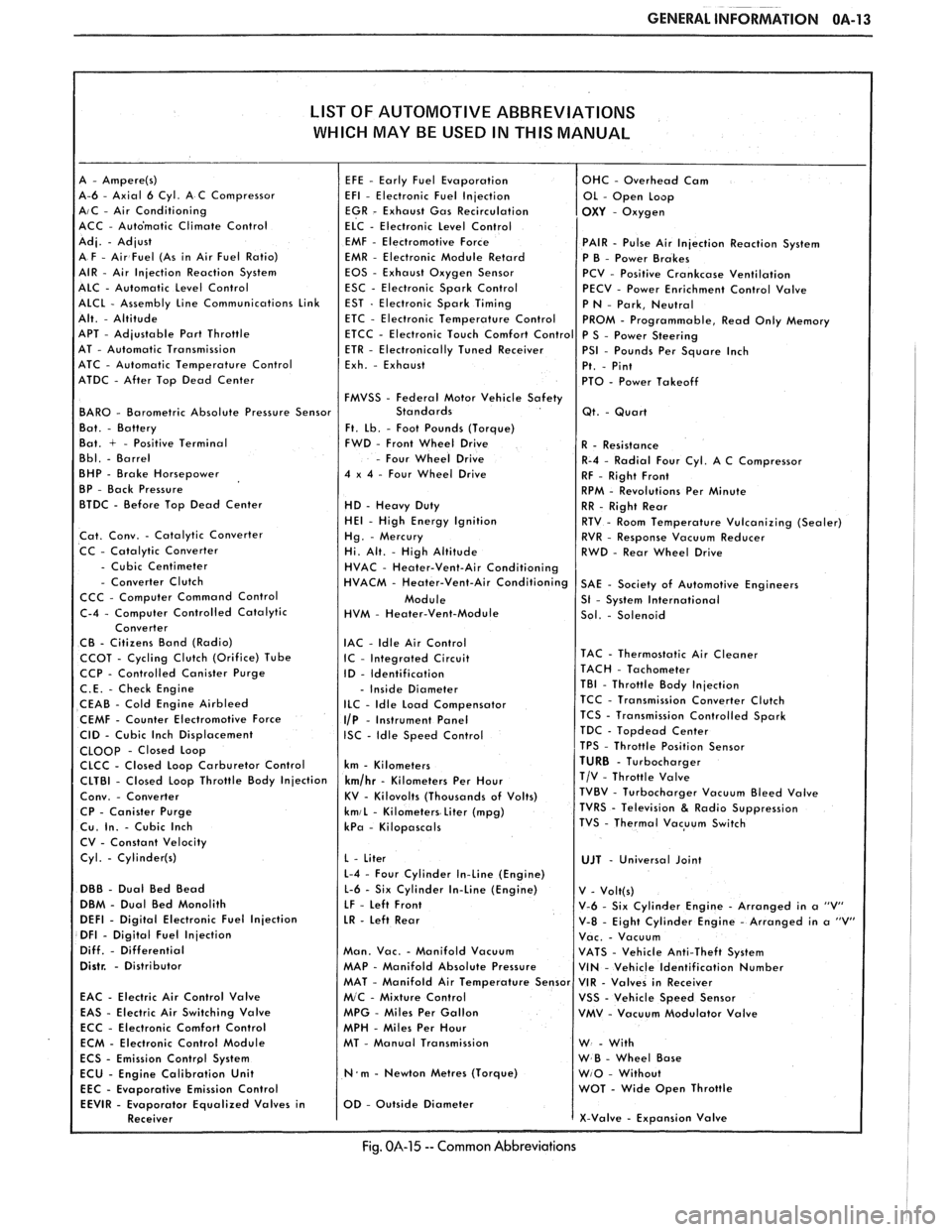

LIST OF AUTOMOTIVE ABBREVIATIONS

WHICH MAY

BE USED IN THIS MANUAL

A-6 - Axial 6 Cyl. A C Compressor AIC - Air Conditioning

ACC - Auto'matic Climate Control

EMF

- Electromotive Force PAIR - Pulse Air Injection Reaction System

EMR - Electronic Module Retard

P B - Power Brakes

EOS - Exhaust Oxygen Sensor

PCV - Positive Crankcase Ventilation

ESC - Electronic Spark Control

PECV - Power Enrichment Control Valve

APT

- Adjustable Part Throttle

AT - Automatic Transmission

ATC - Automatic Temperature Control

ATDC

- After Top Dead Center

FMVSS

- Federal Motor Vehicle Safety BAR0 - Barometric Absolute Pressure Sensor

Ft. Lb. - Foot Pounds (Torque)

Bat. + - Positive Terminal FWD - Front Wheel Drive

- Four Wheel Drive

BHP - Brake Horsepower 4 x 4 - Four Wheel Drive

BP - Back Pressure

BTDC - Before Top Dead Center

HD - Heavy Duty HE1 - High Energy Ignition

Cat. Conv. - Catalytic Converter

CC - Catalytic Converter

- Cubic Centimeter - Converter Clutch

CCC - Computer Command Control

HVM

- Heater-Vent-Module

IAC

- ldle Air Control CCOT - Cycling Clutch (Orifice) Tube IC - Integrated Circuit CCP - Controlled Canister Purge

ID - Identification

C.E. - Check Engine - Inside Diameter

CEAB - Cold Engine Airbleed ILC - Idle Load Compensator

CEMF - Counter Electromotive Force I/P - Instrument Panel

CID - Cubic Inch Displacement ISC - Idle Speed Control CLOOp - Closed Loop

CLCC - Closed Loop Carburetor Control km - Kilometers

CP

- Canister Purge kmiL - Kilometers Liter (mpg) Cu. In. - Cubic Inch kPa - Kilopascals

CV - Constant Velocity

Cyl.

- Cylinder(s)

L-4 - Four Cylinder In-Line (Engine)

DBB - Dual Bed Bead L-6 - Six Cylinder In-Line (Engine)

DBM - Dual Bed Monolith

LF - Left Front DEFl - Digital Electronic Fuel Injection LR - Left Rear DFI - Digital Fuel Injection

Diff. - Differential Man. Vac. - Manifold Vacuum Distr. - Distributor MAP - Manifold Absolute Pressure

EAC

- Electric Air Control Valve

EAS - Electric Air Switching Valve MPG - Miles Per Gallon

ECC - Electronic Comfort Control

MPH - Miles Per Hour

ECM - Electronic Control Module MT - Manual Transmission

N.m - Newton Metres (Torque)

Emission Control

Fig. 014-15 -- Common Abbreviations

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 47 of 1825

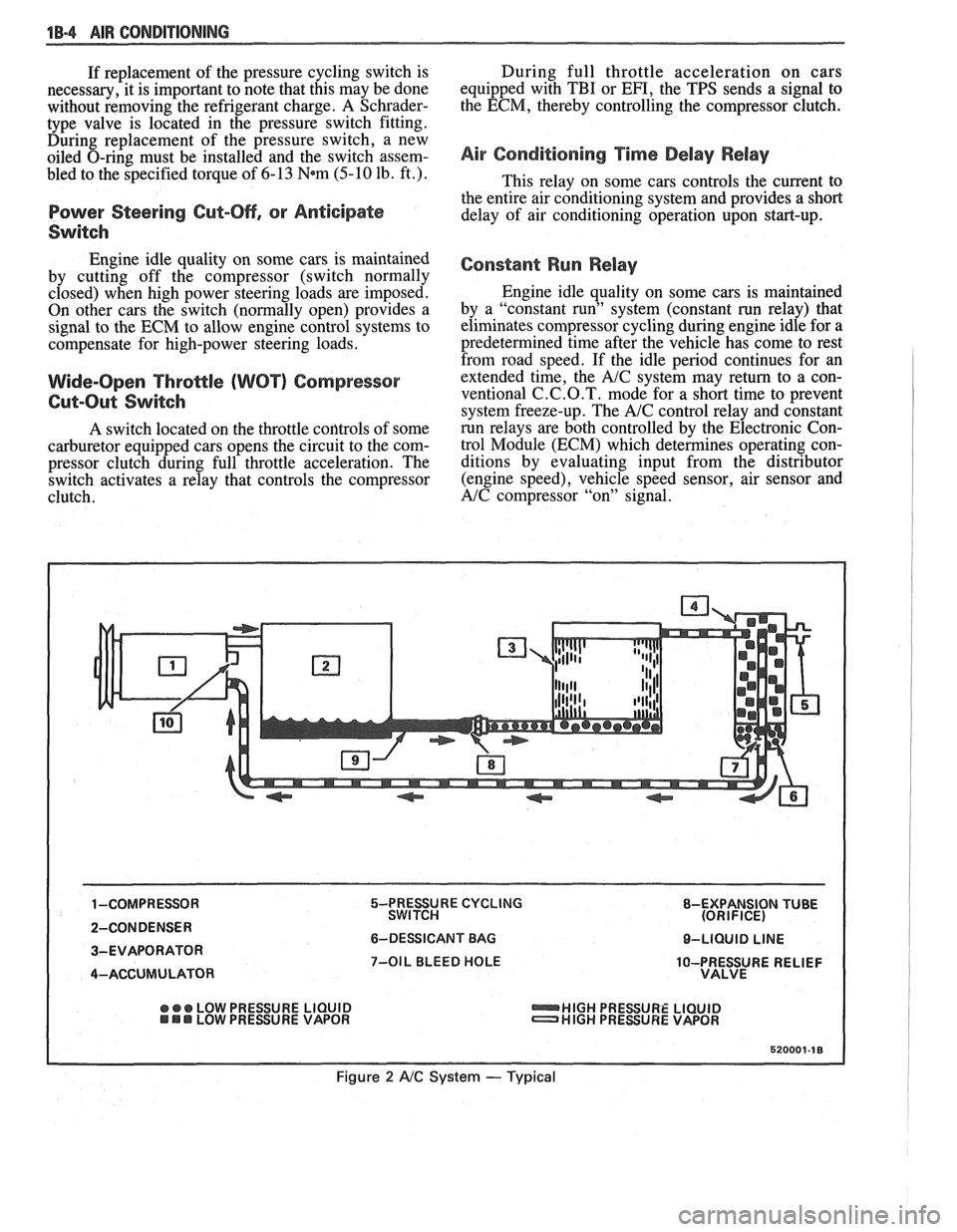

18-4 AIR CONDITIONING

If replacement of the pressure cycling switch is

necessary, it is important to note that this may be done

without removing the refrigerant charge.

A Schrader-

type valve is located in the pressure switch fitting.

During replacement of the pressure switch, a new

oiled O-ring must be installed and the switch assem-

bled to the specified torque of

6- 13 N*m (5- 10 lb. ft.).

Power Steering Gut-OH, or Anticipate

Switch

Engine idle quality on some cars is maintained

by cutting off the compressor (switch normally

closed) when high power steering loads are imposed.

On other cars the switch (normally open) provides a

signal to the ECM to allow engine control systems to

compensate for high-power steering loads.

Wide-Open Tkroale (WOT) Compressor

Cut-Out

Switch

A switch located on the throttle corltrols of some

carburetor equipped cars opens the circuit to the com-

pressor clutch during full throttle acceleration. The

switch activates a relay that controls the compressor

clutch. During full throttle acceleration

on cars

equipped with TBI or

Em, the TPS sends a signal to

the ECM, thereby controlling the compressor clutch.

Air Conditioning Time Delay Relay

This relay on some cars controls the current to

the entire air conditioning system and provides a short

delay of air conditioning operation upon start-up.

Constant Run Relay

Engine idle quality on some cars is maintained

by a "constant run" system (constant run relay) that

eliminates compressor cycling during engine idle for a

predetermined time after the vehicle has come to rest

from road speed.

If the idle period continues for an

extended time, the

A/C system may return to a con-

ventional C.C.O.T. mode for a short time to prevent

system freeze-up. The

A/C control relay and constant

run relays are both controlled by the Electronic Con-

trol Module (ECM) which determines operating con-

ditions by evaluating input from the distributor

(engine speed), vehicle speed sensor, air sensor and

A/C compressor "on" signal.

5-PRESSURE CYCLING 8-EXPANSION TUBE

SWITCH (ORIFICE)

6-DESSICANT BAG O-LIQUID LINE

7-OIL BLEED HOLE

10-PRESSURE RELIEF

VALVE

@ ee LOW PRESSURE LIQUID HIGH PRESSURE LIQUID LOW PRESURE VAPOR HIGH PRESSURE VAPOR

Figure 2 A/C System - Typical

Page 257 of 1825

481-4 REAR AXLE

Gear Noise

Gear noise (whine) is audible from 20 to 55 mph

under four driving conditions:

1. Light Acceleration - Accelerate slowly.

2. Road Load

- Car

driving load or constant speed.

3. Float - Using enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast - Throttle closed and car in gear.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

Knock At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Backlash Clunk

Excessive clunk with acceleration and deceleration

is caused by worn differential pinion gear shaft, excessive

clearance between axle shaft and side gear splines, exces-

sive clearance between side gear hub and counterbore in

case, worn pinion and side gear teeth, worn thrust washers

and excessive drive pinion and ring gear backlash. Re-

move worn parts and replace as required, selecting close

fitting parts when possible. Adjust pinion and ring gear

backlash.

DIAGNOSIS

1. Noise

is the same in "Light Acceleration" or

"Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

d. Rear axle bearing noise.

2. Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

3. Noise tone lowers as car speed is lowered.

a. Tire noise.

b. Front

wheel bearings and rear axle bearings.

c. Gear noise.

4. Similar noise is produced with car standing and

driving. a.

Engine noise.

b. Transmission noise.

c. Exhaust noise.

5. Vibration.

a. Rough rear axle bearing.

b. Unbalanced or damaged propeller shaft.

c. Tire unbalance.

d. Worn universal joint in propeller shaft.

e. Mis-indexed propeller shaft at pinion

flange.

f. Pinion flange runout too great.

6. A knock or click approximately every two

revolutions of the rear wheel.

a. A rear axle bearing.

b. Worn case.

7. Noise most pronounced on turns.

a. Rear axle side gear and pinion noise,

differential gear noise.

b. Axle bearings.

8. A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. All bearing noise.

9. Drive noise, coast noise or float noise.

a. Ring

and pinion gear noise.

b. Front

pinion bearing noise, coast or drive.

c. Axle bearing noise.

10. Clunk

on

acceleration or deceleration.

a. Worn

rear axle pinion shaft splines.

b. Side

gear hub counterbore in case worn

oversize.

c. Worn U-joints.

d. Excessive transmission backlash.

e. Worn axle shaft splines.

11. Chatter on turns.

a. Wrong

lube in rear axle.

b. Clutch

cone worn or spalled.

12. Clunk

or knock on rough road operation.

a. Worn suspension bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A carefull diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Before disassembling the rear axle, the following

checks should be made with the results recorded and

analyzed: 1) Backlash;

2) Total Assembly Preload; 3)

Tooth Contact Pattern Test; 4) Fluid Level; and 5)

Fluid Contamination.

If axle shaft end play is excessive then check

bearings, retainer, and bolts securing backing plate.

The axle bearings could be worn and need replacement.

The four bolts or nuts securing the brake backing plate

may be loose, stripped, or missing. If the inner bearing

retainer worked loose it must be replaced.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

Page 276 of 1825

REAR AXLE 4B-3

Noise which originates in other places cannot be

corrected by adjustment or replacement of parts in the

differential. It should also be remembered that rear

axle gears, like any other mechanical device, are not

absolutely quiet and should be accepted as being

commercially quiet unless some abnormal noise is

present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant.

3. Note speed and RPM at which noise occurs. Then

stop car and with automatic transmission in neutral,

run engine slowly up and down through engine speeds, corresponding to car speed at which noise

was most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure for

test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets.

Metal-to-metal contact at those points

may result in telegraphing road noise and normal axle

noise which would not be objectionable if

dampened by bushings.

AXLE NOISES

Gear Noise

After the noise has been determined as being in

the

axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

maki~~g repairs if necessary.

Gear noise (whine) is audible from 20 to

55 mph

under four driving conditions:

1. Drive - Acceleration or heavy pull.

2. Road Load - Car driving load or constant speed.

3. Float

- Using

enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast

- Throttle closed and car in gear. Gear

noise most frequently has periods where noise is

more prominent, usually 30 to 40 mph and 50 to

55 mph.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

I(noclc At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Baclclash Clunk

Excessive clunk with acceleration and

deceleration is caused by worn differential pinion shaft,

excessive clearance between axle shaft and side gear

splines, excessive clearance between side gear hub and

counterbore in case worn pinion and side gear teeth,

worn thrust washers and excessive drive pinion and

rear gear backlash. Remove worn parts and replace as

required, selecting close fitting parts when possible.

Adjust pinion and ring gear backlash.

REAR AXLE STANDARD AND LIMITED-SLIP

1. Noise is the same in "Drive" or "Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

Page 290 of 1825

REAR AXLE 48-1 7

approached. No further tightening should be

attempted until the pre-load has been checked.

7. Check pre-load by using an inch pound torque

wrench.

NOTICE: After pre-load has been checked, final

tightening should be done very carefully. For

example, if when checking, pre-load was found to

be 0.6

N-m (5 lbs. in.), any additional tightening

of the pinion nut can add many additional pound

inch of torque. Therefore, the pinion nut should be

further tightened only a little at a time and the

pre-load should be checked after each slight

amount of tightening. Exceeding pre-load

specifications will compress the collapsible spacer

too far and require the installation of a new

collapsible spacer.

While observing the preceeding note, carefully set

pre-load at 2.7 to 3.6

N-m (24 to 32 1b.in.) on new

bearings or 1.0 to 1.4

N m (8 to 12 1b.in.) on used

bearings.

8. Rotate pinion several times to assure that

bearings have been seated. Check pre-load again.

If pre-load has been reduced by rotating pinion,

reset pre-load to specifications.

Rear Axle Backlash Adjustment

1. Install rear axle case into carrier, using shims as

determined by the side bearing pre-load

adjustment.

2. Rotate rear axle case several times to seat

bearings, then mount dial indicator. Use a small

button on the indicator stem so that contact can

be made near heel end of tooth. Set dial indicator

so that stem is in line as nearly as possible with

gear rotation perpendicular to tooth angle for

accurate backlash reading.

3. Check backlash at three or four points around

ring gear. Lash must not vary over

.05mm (.002")

around ring gear. Pinion must be held stationary

when checking backlash. If variation is over

.05mm (.002") check for burrs, uneven bolting

conditions or distorted case flange and make

corrections as necessary.

4. Backlash at the point of minimum lash should be

between .13 and

.23mm (.005" and ,009") for all

new gears.

5. If backlash is not within specifications, correct by

increasing thickness of one shim and decreasing

thickness of other shim the same amount. This

will maintain correct rear axle side bearing

pre-load.

For each

.03mm (.001") change in backlash

desired, transfer

.05mm (.002") in shim

thickness. To decrease backlash

.03mm (.00lU),

decrease thickness of right shim .05mm (.002")

and increase thickness of left shim .05mm (.

002 "). To increase backlash .05mm (.002 ")

increase thickness of right shim .10mm (.004")

and decrease thickness of left shim .10mm (.

004"). 6.

When backlash is correctly adjusted, remove both

bearing caps and both shim packs.

Keep packs in their respective position, right or

left side.

Select a shim

.10mm (.004") thicker than the one

removed from the left side, then insert left side

shim pack between the spacer and the left bearing

race. Loosely install bearing cap.

7. Select a shim

.10mm (.004") thicker than the one

removed from right side and insert between the

spacer and the right bearing race. It will be

necessary to drive the right shim into position

(Fig. 614).

8. Torque to 75 Nem (55 1b.ft.).

9. Recheck backlash

and correct if necessary.

10. Install axles (See Rear Axle Installation).

11.

Use sealant 1052366 or cover gasket

only.

Install cover and torque cover bolts to 27

N-m (20 1b.ft.).

12. Fill rear axle to proper level with the specified

lubricant. Refer to specifications.

LIMITED SLIP REAR AXLE (GONE TYPE)

The cone-type limited-slip differential has several

definite operating characteristics. An understanding of

these characteristics is necessary as an aid to diagnosis.

The clutch energizing force comes from the

thrust side of the gears. Consequently, a free spinning

wheel may not have enough resistance to drive torque

to apply the clutch cones. If this occurs, apply the

parking brake a few notches which will provide enough

resistance to energize the clutch cones.

Energizing the clutch cones is independent of

acceleration; therefore, a very slow application of the

throttle on starting is recommended to provide

maximum traction by preventing "break away" of

either rear wheel.

Improper operation is generally indicated by cone

slippage or grabbing. Sometimes this produces a

chatter or whirring sound. However, these sounds do

not always indicate failure as they could be produced

from a lack of proper lubrication. For example, under

certain conditions where one wheel is on

a very slippery

surface and the other on dry pavement, wheel spin can

occur if over acceleration is attempted. Continued

spinning may cause audible noise, such as a whirring

sound, due to the cones lacking sufficient lubricant.

This does not necessarily indicate failure of the unit.

During regular operation (straight ahead driving)

when both wheels rotate at equal speeds, there is an

approximately equal driving force delivered to each

wheel. When cornering, the inside wheel delivers extra

driving force causing slippage in both clutch cones.

Consequently, the operational life of the limited slip

unit is dependent upon equal rotation of both wheels

during straight ahead operation. If wheel rotation for

both rear wheels is not equal during straight ahead

operation, the limited-slip unit will constantly be

functioning as if the vehicle were cornering. This will

impose constant slippage on the clutch cones and will

eventually lead to abnormal wear on the clutch cones.

Therefore, it is important that there be no excessive

differences in the rear wheel tire sizes, air pressures, or

Page 346 of 1825

ENGINE GENERAL INFORMATION 6-1

SECTION 6

NE GENERAL NFORMAT

Description ............................................................... 6 TBI ...................................... .. ...... 6E2 ................ Engine Mechanical Multi Port Fuel Injection (MPFI) 6E3 -

............................................... 2.8L V-6 ....................................................... 6A2 Exhaust Systems 6F

5.OL V-8 ......................................................... 6A3 ~~~~~~l ~~f~~~~ti~~ ..................................... 6-2

............................ Engine Cooling ...................................................... 6B Engine Performance Diagnosis 6-3 ............................. Engine Fuel 6C Engine Mechanical Diagnosis

6-3 ........................................................... ................................... Engine Knock Diagnosis 6-4

Engine Electrical ................................................... 6D Compression Test ...................................... ... 6-5

................... Driveability and Emission Controls ...................... 6E Oil Leak Detection .. ..................... 6-5

ALL NEW GENERAL MOTORS VEHICLES ARE CERTIFIED BY THE UNITED STATES

ENVIRONMENTAL PROTECTION AGENCY AS CONFORMING TO THE REQUIREMENTS OF

THE REGULATIONS FOR THE CONTROL OF AIR POLLUTION FROM NEW MOTOR VEHICLES.

THlS CERTIFICATION IS CONTINGENT ON CERTAIN ADJUSTMENTS BEING SET TO

FACTORY STANDARDS. IN MOST CASES, THESE ADJUSTMENT POINTS EITHER HAVE

BEEN PERMANENTLY SEALED AND/OR MADE INACCESSIBLE TO PREVENT

INDISCRIMINATE OR ROUTINE ADJUSTMENT IN THE FIELD. FOR

THlS REASON, THE

FACTORY PROCEDURE FOR TEMPORARILY REMOVING PLUGS, CAPS, ETC., FOR

PURPOSES OF SERVICING THE PRODUCT MUST BE STRICTLY FOLLOWED AND,

WHEREVER PRACTICABLE, RETURNED TO THE ORIGINAL INTENT OF THE DESIGN.

DESCRIPTION OF: SECTION 6

SECTION 6A - ENGINE MECHANICAL used for each carburetor. TBI units are described in

This section general contains information on the Section 6E.

mechanical parts of the engine, such as block,

crankshaft, pistons, valve train, and camshaft, that are

common to most engines. Overhaul procedures,

removal and replacement procedures, and

s~ecifications are also covered. Subsections furnish

detailed information on each specific engine. Service

SECTION 6D - ENG l N E ELECTRICAL

information is also given that relates to that engine's

use in each

Carline. Specific subsections are: Items

covered in this section are battery,

generator, starter, primary and secondary ignition,

6A2

- 2.8L V-6 Engine

engine wire harness, spark plugs and wires, and

6A3

- 5.OL V-8 Engine

ignition switch.

SECTION 6B - ENGINE COOLING

Engine cooling system components such as

radiator, water pump, thermostat, and cooling fan, are

covered in this section. Accessory drive belts are also

covered, along with cooling system capacities.

SECTION 6C - FUEL SYSTEM

This section contains information on all the parts

of the fuel system

except the carburetor, or Throttle

Body Injection unit (TBI) itself. Items covered are fuel

tank, fuel pump, and fuel lines. Specific subsections are

SECTION 6E - DRIVEABILITY AND EMISSIONS

This section covers emission control systems

general information, and diagnostic procedures which

will lead to repairing performance and driveability

related problems for gasoline engine equipped vehicles.

All emission components are covered, as well as all

removal and replacement procedures. Instructions on

use of special tools are also given. Specific sections are:

6E

- Driveability and Emissions

6E2

- Fuel Injection (TBI)

Page 350 of 1825

ENGINE GENERAL INFORMATION 6-5

INSTRUMENT PANEL OIL WARNING LAMP "ON" AT IDLE

1. Oil cooler, or oil or cooler line restricted. Remove 2. Oil pump pressure low. See oil pump repair

restrictions in cooler or cooler line. procedures

in Section

6A.

ENGINE COMPRESSION EST

COMPRESSION TEST

Important

e Disconnect the "BAT." terminal from the - HE1 distributor or ignition module.

To determine if the valves or pistons are at fault,

a test should be made to determine the cylinder

compression pressure. When checking cylinder

compression, the throttle and choke should be open, all

spark plugs removed, and the battery at or near full

charge. The lowest reading cylinder should not be less

than

70% of the highest and no cylinder reading

should be less than

689 kPa (100 PSI). This

should be done with four

"puffs" per

cylinder.

Normal - Compression builds up quickly and

evenly to specified compression on each cylinder.

Piston Rings - Compression low on first

stroke, tends to build up on following strokes, but does

not reach normal. Improves considerably with addition

of oil.

Valves - Low on first stroke, does not tend to

build up on following strokes. Does not improve much

with addition of oil.

Use approximately three squirts from a plunger

type oiler.

Page 359 of 1825

6A2-8 2.8 LITER V-6

6. Install new mount.

7. Lower transmission.

8. Torque nuts to specifications.

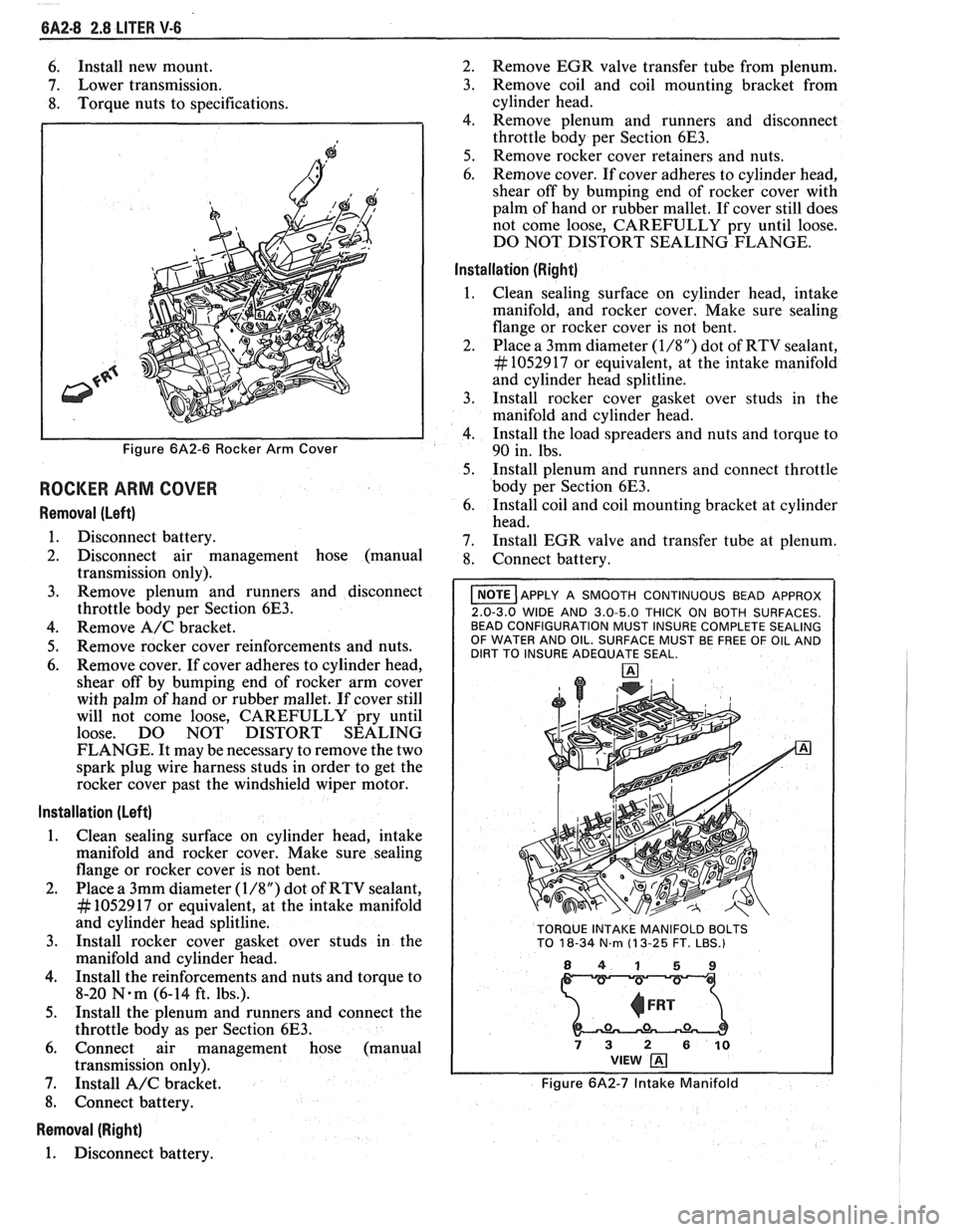

Figure 6A2-6 Rocker Arm Cover

ROCKER ARM COVER

Removal (Left)

1. Disconnect battery.

2. Disconnect air management hose (manual

transmission only).

3. Remove plenum and runners and disconnect

throttle body per Section

6E3.

4. Remove A/C bracket.

5. Remove rocker cover reinforcements and nuts.

6. Remove cover. If cover adheres to cylinder head,

shear off by bumping end of rocker arm cover

with palm of hand or rubber mallet. If cover still

will not come loose, CAREFULLY pry until

loose. DO NOT DISTORT SEALING

FLANGE. It may be necessary to remove the two

spark plug wire harness studs in order to get the

rocker cover past the windshield wiper motor.

Installation (Left)

1. Clean sealing surface on cylinder head, intake

manifold and rocker cover. Make sure sealing

flange or rocker cover is not bent.

2. Place a 3mm diameter

(1/8") dot of RTV sealant,

# 1052917 or equivalent, at the intake manifold

and cylinder head splitline.

3. Install rocker cover gasket over studs in the

manifold and cylinder head.

4. Install the reinforcements and nuts and torque to

8-20

N.m (6-14 ft. lbs.).

5. Install the plenum and runners and connect the

throttle body as per Section

6E3.

6. Connect air management hose (manual

transmission only).

7. Install

A/C bracket.

8. Connect battery.

Removal (Right)

1. Disconnect battery. 2.

Remove EGR valve transfer tube from plenum.

3. Remove coil and coil mounting bracket from

cylinder head.

4. Remove plenum and runners and disconnect

throttle body per Section

6E3.

5. Remove rocker cover retainers and nuts.

6. Remove cover. If cover adheres to cylinder head,

shear off by bumping end of rocker cover with

palm of hand or rubber mallet. If cover still does

not come loose, CAREFULLY pry until loose.

DO NOT DISTORT SEALING FLANGE.

Installation (Right)

Clean sealing surface on cylinder head, intake

manifold, and rocker cover. Make sure sealing

flange or rocker cover is not bent.

Place a 3mm diameter

(1/8") dot of RTV sealant,

# 1052917 or equivalent, at the intake manifold

and cylinder head splitline.

Install rocker cover gasket over studs in the

manifold and cylinder head.

Install the load spreaders and nuts and torque to

90 in. lbs.

Install plenum and runners and connect throttle

body per Section

6E3.

Install coil and coil mounting bracket at cylinder

head.

Install EGR valve and transfer tube at plenum.

Connect battery.

I NOTE ]APPLY A SMOOTH CONTINUOUS BEAD APPROX

2.0-3.0 WIDE AND 3.0-5.0 THICK ON BOTH SURFACES.

BEAD CONFIGURATION MUST INSURE COMPLETE SEALING

OF WATER AND OIL. SURFACE MUST BE FREE OF OIL AND

DIRT TO INSURE ADEQUATE SEAL.

TORQUE INTAKE MANIFOLD BOLTS

TO

18-34 N.m (1 3-25 FT. LBS.)

841 59

73 2 610 VIEW

Figure 6A2-7 Intake Manifold