dimensions PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 11 of 1825

08-8 GENERAL INFORMATION

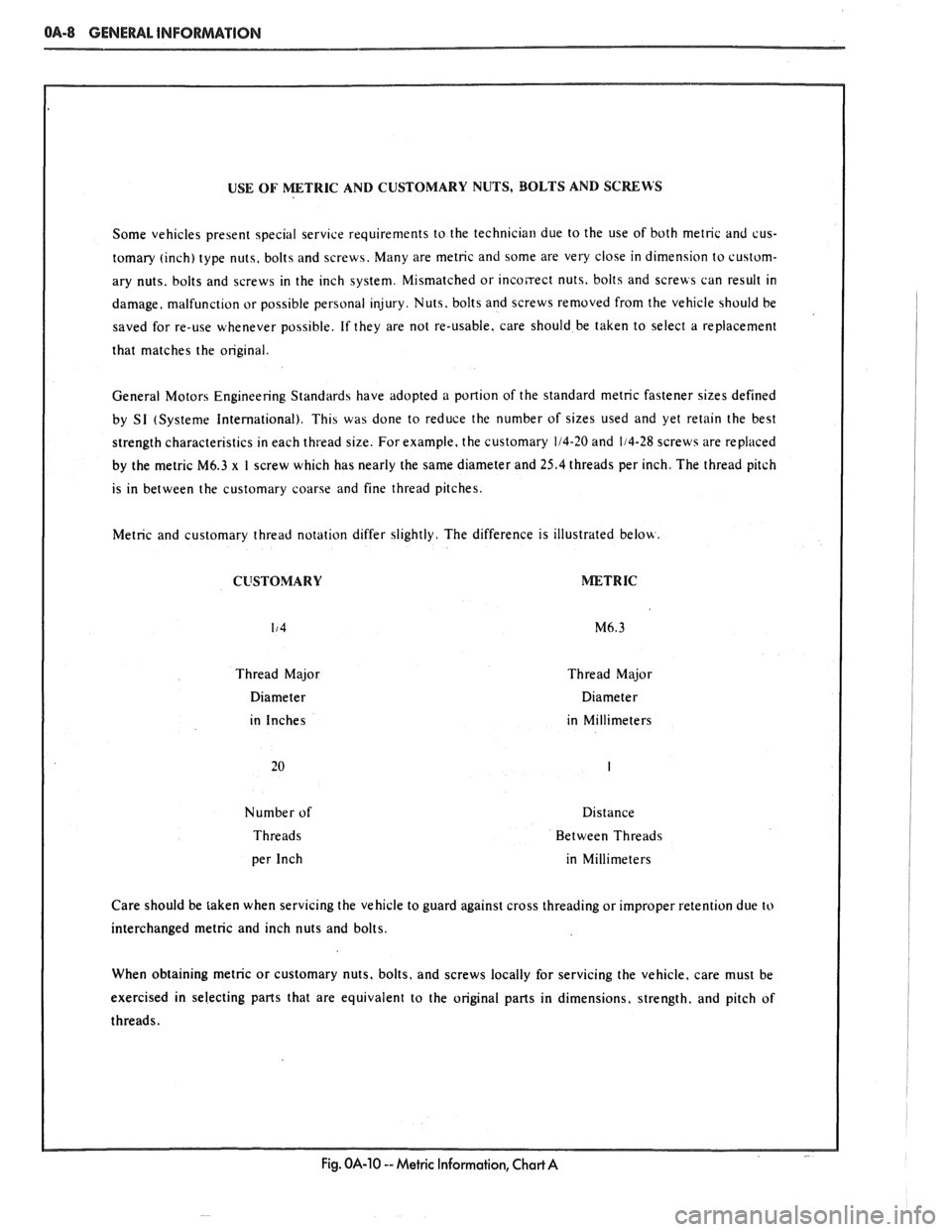

USE OF METRIC AND CUSTOMARY NUTS, BOLTS AND SCRERS

Some veh~cles present spec~al servlce requ~rements to the technrc~a~l due to the use of both metnc and cus-

tomary

(Inch) type nuts, bolt5 and screws. Many are metnc and some are very close in d~mens~on to custom-

ary nuts. bolts and screws in the

Inch system M~smatched or Incorect nut5, bolt5 and screus can result rn

damage, malfunct~on or poss~ble personal Injury Nuts. bolts and screws removed from the veh~cle 5hould be

saved for re-use

uhenever poscrble. If they are not re-usable. care should be taken to select a replacement

that matches the

ong~nal.

General Motors Eng~neenng Standards have ddopted a portion of the standard metnc fastener slzes defined

by SI (Systeme

Internatronal) Th~s was done to reduce the number of srzes used and yet retarn the best

strength

character~st~cs In each thtead size. For example. the customary 114-20 and 1/4-28 screws are replaced

by the

metrlc M6.3 x I screw wh~ch has nearly the same d~ameter and 25.4 threads per inch. The thread p~tch

IS In between the customary coarse and fine thread prtches.

Metnc and customary thread notatlon d~ffer sl~ghtly. The d~fference IS ~llustrated belou.

CUSTOMARY METRIC

Thread Major Thread Major

D~ameter D~ameter

~n inches rn M~ll~meters

Number of D~stance

Threads Between Threads

in Mill~meters

Care should be taken when servlclng the veh~cle to guard agalnst cross thread~ng or Improper retention due to

interchanged metnc and inch nuts and bolts.

When

obtarn~ng metnc or customary nuts, bolts, and screws locally for servrcing the vehicle. care must be

exerc~sed in selecting parts that are equrvalent to the ong~nal parts In dimensions. strength. and p~tch of

Fig. OA-10 -- Metric Information, Chart A

Page 146 of 1825

STEERING, SUSPENSION. TIRES AND WHEELS DIAGNOSIS 3-21

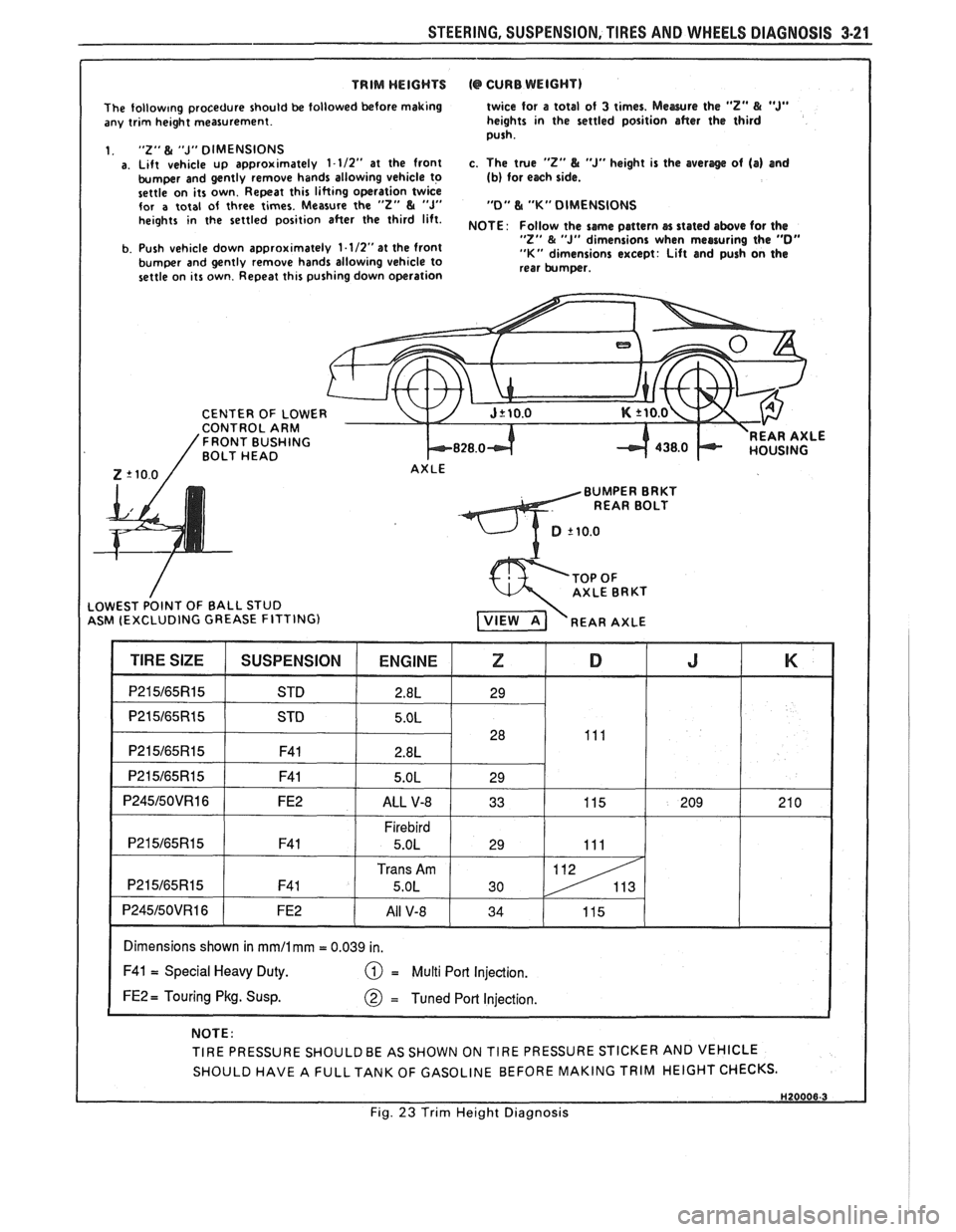

TRIM WEIGHTS (@ CURB WEIGHT) I

The follow~ng procedure should be followed before making

any trim height measurement.

1.

"2" & "J" DIMENSIONS a. Lift vehicle up approximately 1-112" at the front

bumper and gently remove hands allowing vehicle to

settle on its own. Repeat this lifting operation twice

for

a total of three times. Measure the "2" & "J" heights in the settled position after the third lift.

b. Push vehicle down approximately

1.1/2"at the front

bumper and gently remove hands allowing vehicle to

settle on its own. Repeat this pushing down operation twice for

a total

of 3 times. Mewre the "Z" & "J" heights in the settled position after the third

push.

c. The true

"2" L "J" height is the averlge of (a) and (b) for each side.

"0" L "K" DIMENSIONS

NOTE

: Follow the same pattern cn stated above for the "Z" & "J" dimensions when measuring the "0" "K" dimensions except: Lift and push on the

rear bumper.

CENTER OF

LOWE CONTROL ARM 'FRONT BUSHING BOLT HEAD k828.0-t REAR AXLE

Z '10.0 / AXLE

BUMPER BRKT

REAR BOLT

ASM (EXCLUDING GREASE FITTING)

I Dimensions shown in mmll mm = 0.039 in. I

F41 = Special Heavy Duty. = Multi Port Injection.

FE2 = Touring Pkg. Susp.

NOTE:

TIRE PRESSURE

SHOULDBE AS SHOWN ON TIRE PRESSURE STICKER AND VEHICLE

SHOULD HAVE A

FULLTANK OF GASOLINE BEFORE MAKING TRIM HEIGHT CHECKS.

I Fig. 23 Trim Height Diagnosis

Page 151 of 1825

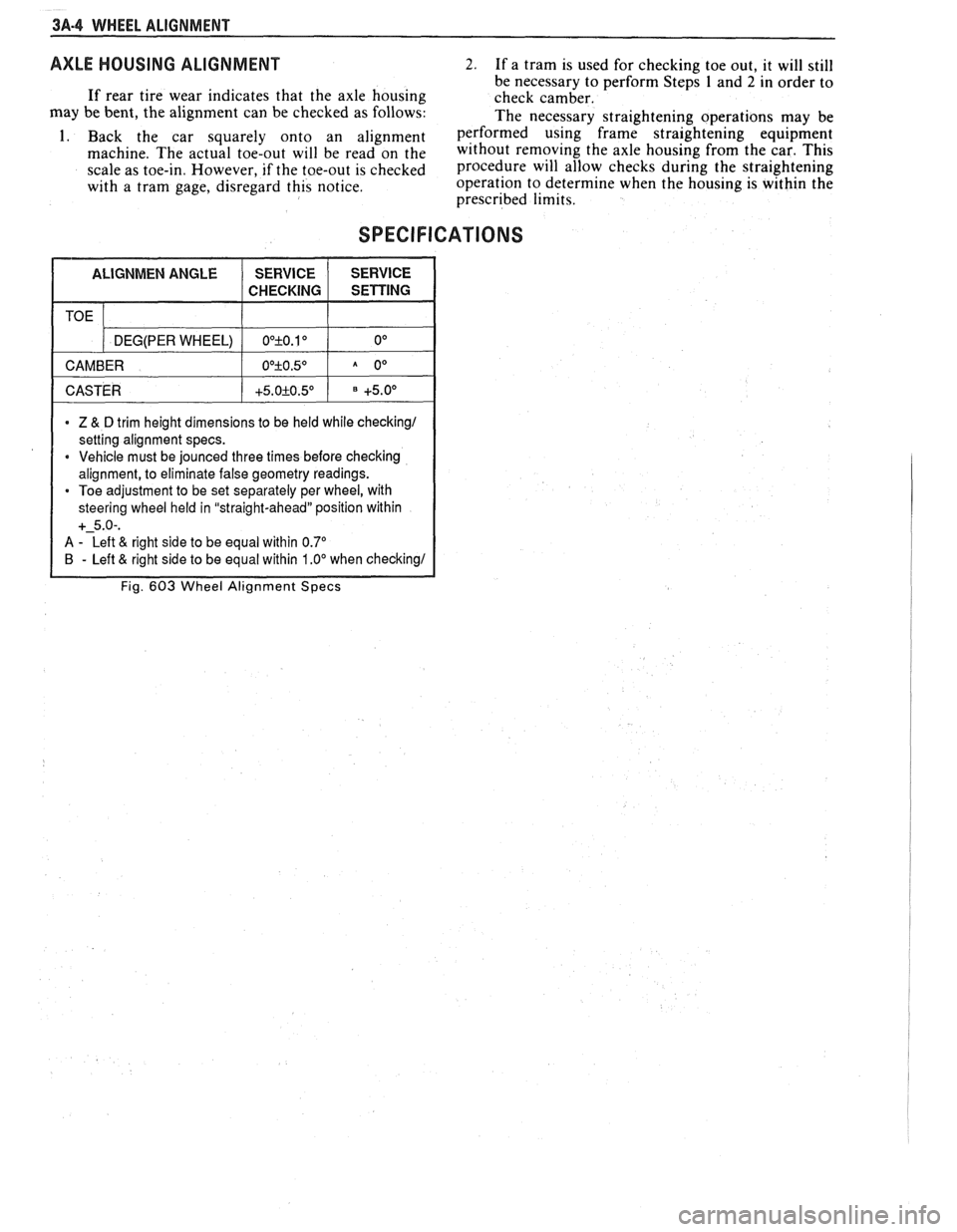

3A-4 WHEEL ALIGNMENT

AXLE HOUSING ALIGNMENT 2. If a tram is used for checking toe out, it will still

be necessary to perform Steps

1 and 2 in order to If rear tire wear indicates that the axle housing

check camber.

may be bent, the alignment can be checked as follows:

The necessary straightening operations may be

1. Back the car squarely onto an alignment performed using frame straightening equipment

machine, ~h~ actual toe-out will be read on the without removing the axle housing from the car. This

scale as toe-in. However, if the toe-out is checked procedure will allow checks during the straightening

with a tram gage, disregard this notice. operation

to determine when the housing is within the

prescribed limits.

SPECIFICATIONS

1 CASTER 1 +5.0+0.5O 1 +5.0° 1

TOE

* Z & D trim height dimensions to be held while checking1

setting alignment specs.

* Vehicle must be jounced three times before checking

alignment, to eliminate false geometry readings.

Toe adjustment to be set separately per wheel, with

steering wheel held in "straight-ahead" position within

+-5.0-.

A - Left & right side to be equal within 0.7"

B - Left & right side to be equal within 1 .OO when checking1

Fig. 603 Wheel Alignment Specs

DEG(PER WHEEL)

CAMBER OO+O.10 0°

O0+O.5O A 0°

Page 232 of 1825

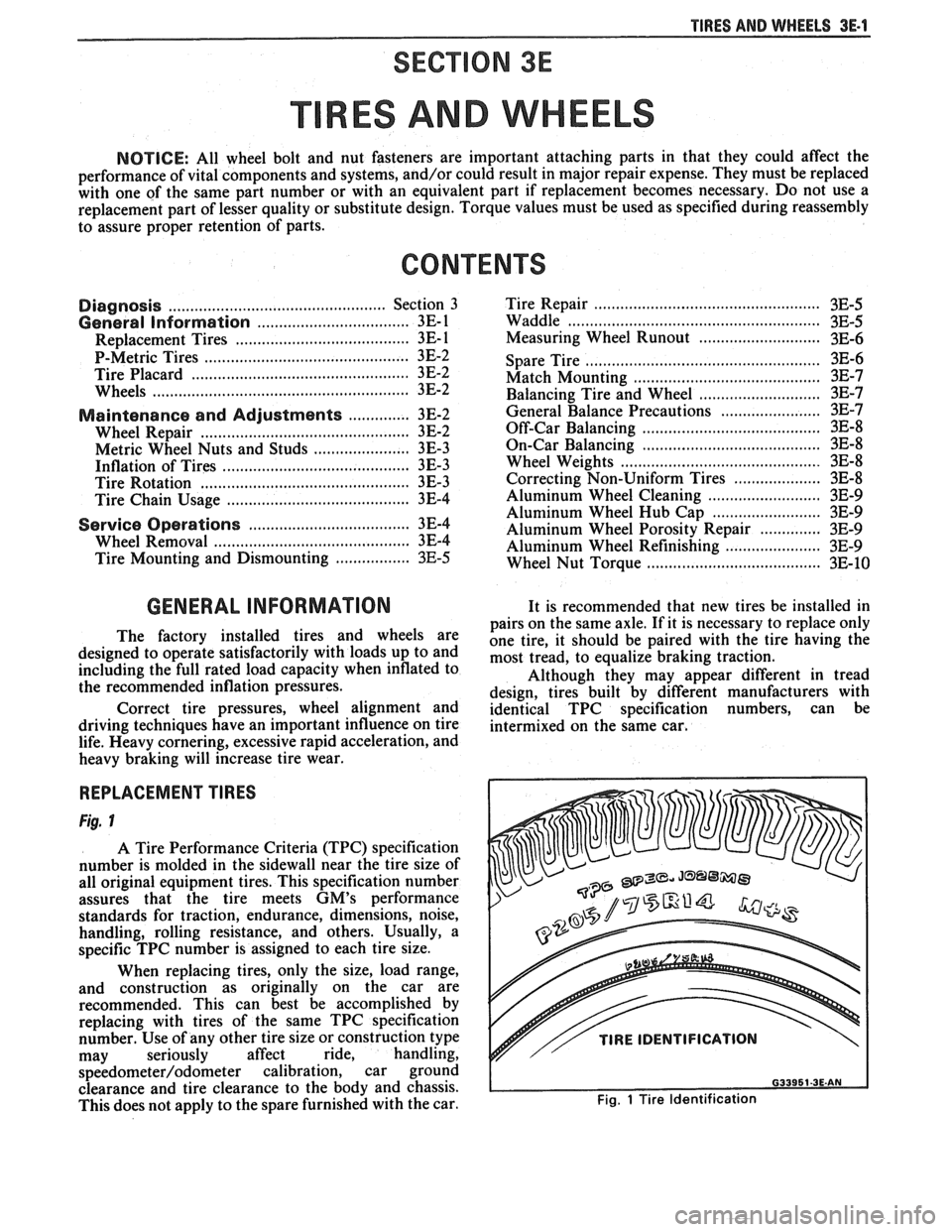

TIRES AND WHEELS 3E-1

RES AND WHEELS

NOTICE: All wheel bolt and nut fasteners are important attaching parts in that they could affect the

performance of vital components and systems, and/or could result in major repair expense. They must be replaced

with one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of parts.

CONTENTS

Diagnosis ............................................... Section 3 Tire Repair ................................................... 3E-5

General Information .......................... ..... 3E-1 Waddle ........................................................ 3E-5

........ Replacement Tires ....................... ... 3E- 1 Measuring Wheel Runout ............................ 3E-6

P-Metric Tires ...................... .. ................... 3E-2 Spare Tire ...................................................... 3E-6 ................................................ Tire Placard 3E-2 Match Mounting ......................................... 3E-7

.......................................................... Wheels 3E-2 Balancing Tire and Wheel ............................ 3E-7

....................... Maintenance and Adjustments .............. 3E-2 General Balance Precautions 3E-7 ...................................... Wheel Repair .............................................. 3E-2 Off-Car Balancing 3E-8 .............................. Metric Wheel Nuts and Studs .................... .. 3E-3 On-Car Balancing .. ...... 3E-8

......................................... Inflation of Tires ........................................ 3E-3 Wheel Weights 3E-8 .................... Tire Rotation ........................... ...... . 3E-3 Correcting Non-Uniform Tires 3E-8 .......................... Tire Chain Usage ........................................ 3E-4 Aluminum Wheel Cleaning 3E-9 Aluminum Wheel Hub Cap ......................... 3E-9 Service Operations ..................................... 3E-4 Aluminum Wheel Porosity Repair .............. 3E-9 ......................... Wheel Removal .... .......... 3E-4 Aluminum Wheel Refinishing ...................... 3E-9 Tire Mounting and Dismounting ................. 3E-5 Wheel Nut Torque 3E-10 ......................................

GENERAL INFORMATION ~t is recommended that new tires be installed in

pairs on the same axle. If it is necessary to replace only

The tires and are one tire, it should be paired with the tire having the

designed to operate satisfactorily with loads up to and

most tread, to equalize braking traction. including the full rated load capacity when inflated to

Although they may appear different in tread

the recommended inflation pressures.

design, tires built by different manufacturers with

Correct tire pressures, wheel alignment and identical TPC specification numbers, can be

driving techniques have an important influence on tire

intermixed on the same car. life. Heavy cornering, excessive rapid acceleration, and

heavy braking will increase tire wear.

REPLACEMENT TIRES

Fig. 1

A Tire Performance Criteria (TPC) specification

number is molded in the sidewall near the tire size of

all original equipment tires. This specification number

assures that the tire meets

GM's performance

standards for traction, endurance, dimensions, noise,

handling, rolling resistance, and others. Usually, a

specific TPC number is assigned to each tire size.

When replacing tires, only the size, load range,

and construction as originally on the car are

recommended. This can best be accomplished by

replacing with tires of the same TPC specification

number. Use of any other tire size or construction type

may seriously affect ride, handling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and chassis.

This does not apply to the spare furnished with the car.

v// TIRE IDENTIFICATION

Fig. 1 Tire Identification

Page 377 of 1825

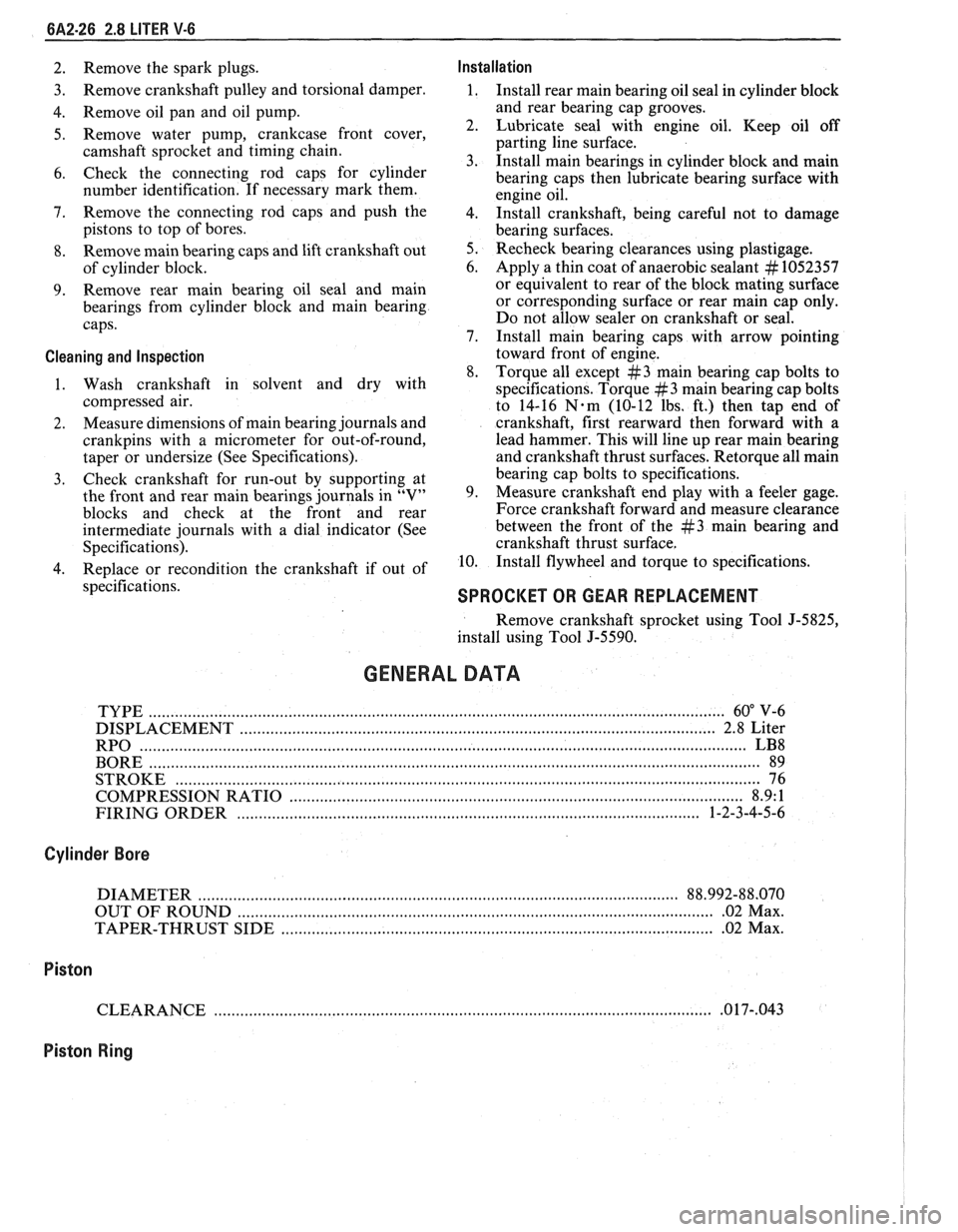

6A2-26 2.8 LITER V-6

2. Remove the spark plugs. Installation

3. Remove

crankshaft pulley and torsional damper. 1. Install rear main bearing oil seal in cylinder block

4. Remove oil pan and oil pump. and

rear bearing cap grooves.

5. Remove water pump, crankcase front cover, 2. Lubricate seal with engine oil. Keep oil off

camshaft sprocket and timing chain. parting

line surface.

3. Install main bearings in cylinder block and main

6. Check the connecting rod caps for cylinder

bearing caps then lubricate bearing surface with

number identification. If necessary mark them.

engine oil.

7. Remove the connecting rod caps and

push the

4. 1n;tall crankshaft, being careful not to damage

pistons to top of bores.

bearing surfaces.

8. Remove main bearing caps and lift crankshaft out 5. Recheck bearing clearances using plastigage.

of cylinder block. 6.

Apply a thin coat of anaerobic sealant

# 1052357

9. Remove rear

main bearing oil seal and main or

equivalent to rear of the block mating surface

bearings from cylinder block and main bearing or corresponding

surface or rear main cap only.

caps. Do

not allow sealer on crankshaft or seal.

7. Install main bearing caps with arrow pointing

Cleaning and Inspection toward front of engine.

8. Torque all except

#3 main bearing cap bolts to

1. Wash crankshaft in solvent and dry with

specifications. Torque

#3 main bearing cap bolts

compressed air. to 14-16

N-m (10-12 lbs. ft.) then tap end of

2. Measure

dimensions of main bearing journals and crankshaft, first rearward then forward with a

crankpins with a micrometer for out-of-round, lead

hammer. This will line up rear main bearing

taper or undersize (See Specifications). and crankshaft

thrust surfaces.

Retorque all main

3. Check

crankshaft for run-out by supporting at bearing

cap bolts to specifications.

the front and rear main bearings journals in "V" 9. Measure crankshaft

end play with a feeler gage.

blocks and check at the front and rear Force crankshaft forward and measure clearance

intermediate journals with a dial indicator (See between the front of the

#3 main bearing and

Specifications). crankshaft thrust surface.

4. Replace or recondition the crankshaft if out of 10.

Install flywheel and torque to specifications.

specifications.

SPROCKET OR GEAR REPLACEMENT

Remove crankshaft sprocket using Tool J-5825,

install using Tool J-5590.

GENERAL DATA

TYPE .................................................................................................................................... 60" V-6

DISPLACEMENT

............................................................................................................. 2.8 Liter

RPO

........................................................................................................................................... LB8

BORE ......................................................................................................................................... 89

STROKE

................................... .... ............................................................................................... 76

COMPRESSION RATIO

....................................................................................................... 8.9: 1

FIRING ORDER

.......................................................................................................... 1-2-3-4-5-6

Cylinder Bore

DIAMETER .............................................................................................................. 88.992-88.070

OUT OF ROUND

............................................................................................................. .02 Max.

TAPER-THRUST SIDE

................................................................................................. .02 Max.

Piston

CLEARANCE .................................................................................................................. .O 17-,043

Piston Ring

Page 407 of 1825

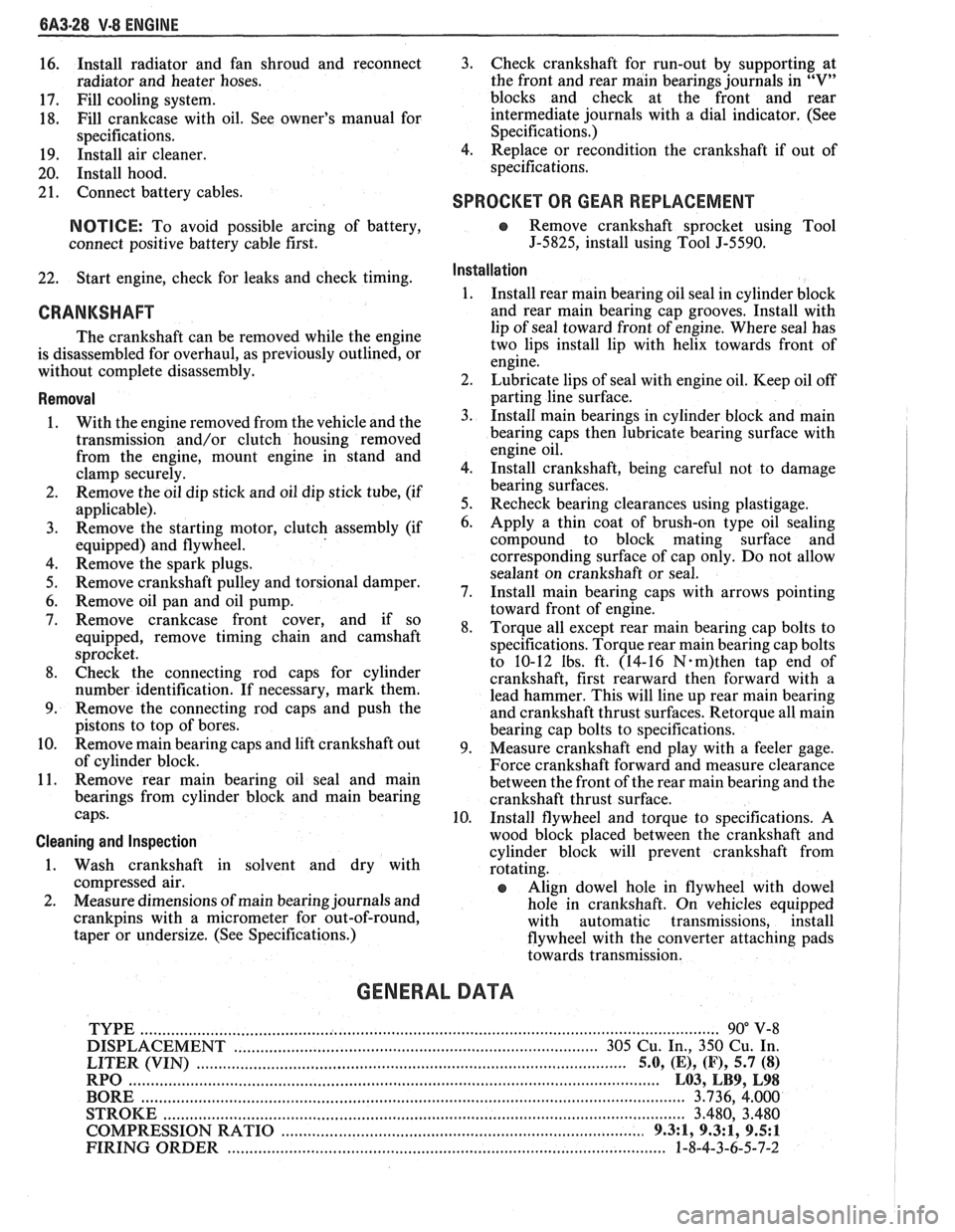

6A3-28 V-8 ENGINE

16. Install

radiator and fan shroud and reconnect

radiator and heater hoses.

17. Fill cooling system.

18. Fill

crankcase with oil. See owner's manual for

specifications.

19. Install air cleaner.

20. Install hood.

21. Connect battery cables.

NOTICE: To avoid possible arcing of battery,

connect positive battery cable first.

22. Start engine, check for leaks and check timing.

CRANKSHAFT

The crankshaft can be removed while the engine

is disassembled for overhaul, as previously outlined, or

without complete disassembly.

Removal

With the engine removed from the vehicle and the

transmission and/or clutch housing removed

from the engine, mount engine in stand and

clamp securely.

Remove the oil dip stick and oil dip stick tube, (if

applicable).

Remove the starting motor, clutch assembly (if

equipped) and flywheel.

Remove the spark plugs.

Remove crankshaft pulley and torsional damper.

Remove oil pan and oil pump.

Remove crankcase front cover, and if so

equipped, remove timing chain and camshaft

sprocket.

Check the connecting rod caps for cylinder

number identification. If necessary, mark them.

Remove the connecting rod caps and push the

pistons to top of bores.

Remove main bearing caps and lift crankshaft out

of cylinder block.

Remove rear main bearing oil seal and main

bearings from cylinder block and main bearing

caps.

Cleaning and Inspection

1. Wash crankshaft in solvent and dry with

compressed air.

2. Measure dimensions of main bearing journals and

crankpins with a micrometer for out-of-round,

taper or undersize. (See Specifications.) 3.

Check crankshaft for run-out by supporting at

the front and rear main bearings journals in

"V"

blocks and check at the front and rear

intermediate journals with a dial indicator. (See

Specifications.)

4. Replace or recondition the crankshaft if out of

specifications.

SPROCKET OR GEAR REPLACEMENT

e Remove crankshaft sprocket using Tool

5-5825, install using Tool J-5590.

Installation

1.

Install rear main bearing oil seal in cylinder block

and rear main bearing cap grooves. Install with

lip of seal toward front of engine. Where seal has

two lips install lip with helix towards front of

engine.

2. Lubricate lips of seal with engine oil. Keep oil off

parting line surface.

3. Install main bearings in cylinder block and main

bearing caps then lubricate bearing surface with

engine oil.

4. Install crankshaft, being careful not to damage

bearing surfaces.

5. Recheck bearing clearances using plastigage.

6. Apply a thin coat of brush-on type oil sealing

compound to block mating surface and

corresponding surface of cap only. Do not allow

sealant on crankshaft or seal.

7. Install main bearing caps with arrows pointing

toward front of engine.

8. Torque all except rear main bearing cap bolts to

specifications. Torque rear main bearing cap bolts

to 10-12 lbs. ft. (14-16

N.m)then tap end of

crankshaft, first rearward then forward with a

lead hammer. This will line up rear main bearing

and crankshaft thrust surfaces.

Retorque all main

bearing cap bolts to specifications.

9. Measure crankshaft end play with a feeler gage.

Force crankshaft forward and measure clearance

between the front of the rear main bearing and the

crankshaft thrust surface.

10. Install flywheel and torque to specifications. A

wood block placed between the crankshaft and

cylinder block will prevent crankshaft from

rotating.

Align dowel hole in flywheel with dowel

hole in crankshaft. On vehicles equipped

with automatic transmissions, install

flywheel with the converter attaching pads

towards transmission.

GENERAL DATA

TYPE .................................................................................................................................. 90" V-8

DISPLACEMENT

............................................................................... 305 Cu. In., 350 Cu. In.

......................................................... LITER (VIN) ................................... ...... 5.0, (E), (F), 5.7 (8)

RPO ......................................................................................................................... L03, LB9, L98

BORE ........................................................................................................................ 3.736, 4.000

STROKE

........................... .. ....................................................................................... 3.480, 3.480

COMPRESSION RATIO

................................................................................... 931, 931, 9.5:1

FIRING ORDER .................................................................................................... 1-8-4-3-6-5-7-2

Page 1072 of 1825

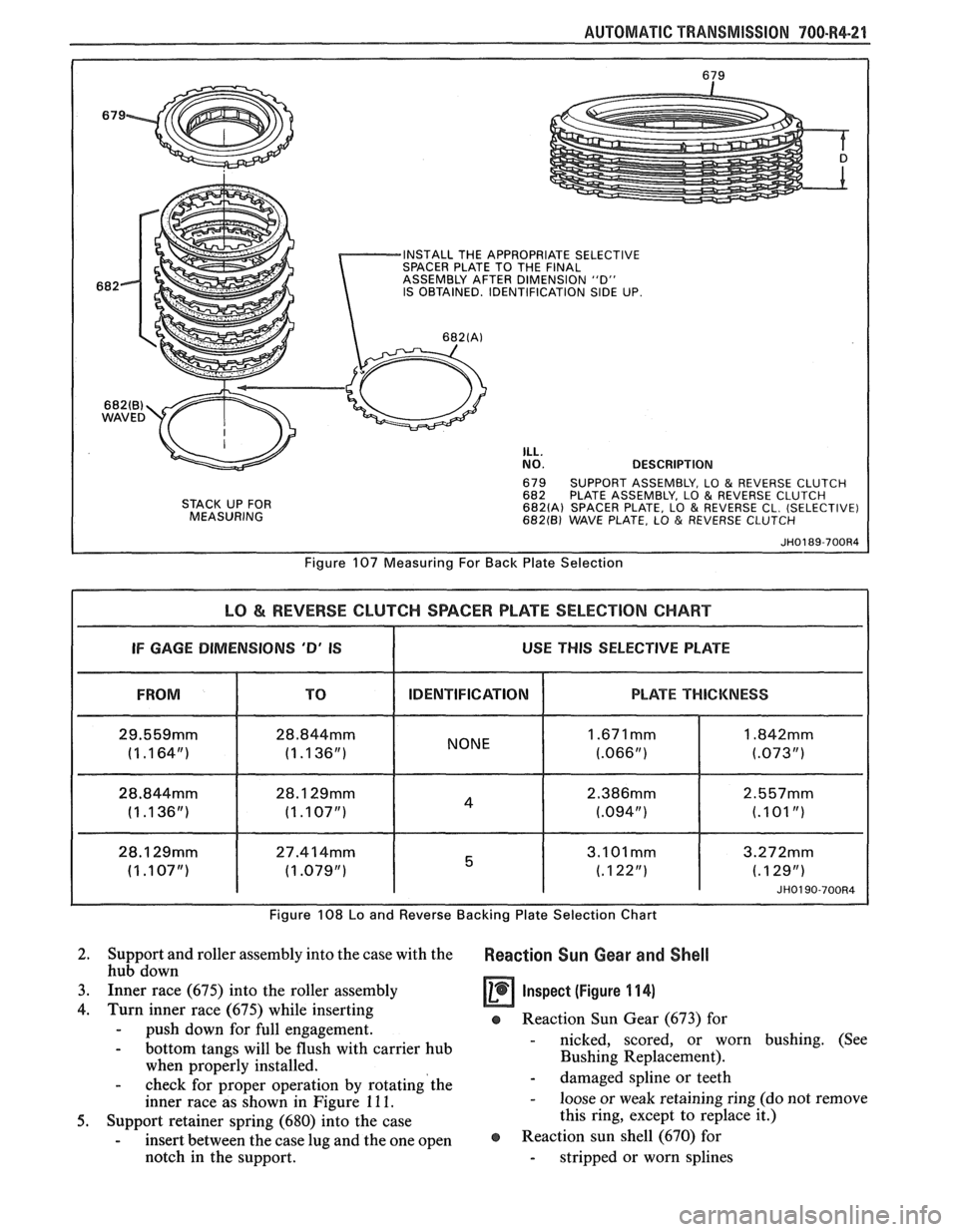

AUTOMATIC TRANSMISSION 700.R4-21

INSTALL THE APPROPRIATE SELECTIVE

SPACER PLATE TO THE FINAL

ASSEMBLY AFTER DIMENSION "D"

IS OBTAINED. IDENTIFICATION

SIDE UP.

682(B) WAVED

STACK UP FOR

MEASURING

ILL. NO. DESCRIPTION

679 SUPPORT ASSEMBLY, LO & REVERSE CLUTCH

682 PLATE ASSEMBLY, LO & REVERSE CLUTCH 682(A) SPACER PLATE, LO & REVERSE CL. (SELECTIVE) 682(B) WAVE PLATE, LO & REVERSE CLUTCH

Figure 107 Measuring For Back Plate Selection

LO & REVERSE CLUTCH SPACER PLATE SELECTION CHART

I IF GAGE DIMENSIONS 'D' IS I USE THIS SELECTIVE PLATE I

FROM IDENTIFICATION

28.844mm

(1 .I 36") I NONE

Figure 108 Lo and

Reverse Backing Plat

PLATE THICKNESS

JH0190-700R4

? Selection Chart

2. Support and roller assembly into the case with the Reaction Sun Gear and Shell hub down

3. Inner race (675) into the roller assembly

Inspect (Figure 11 4)

4. Turn inner race (675) while inserting e Reaction Sun Gear (673) for - push down for full engagement.

- bottom tangs will be flush with carrier hub - nicked, scored, or worn bushing. (See

when properly installed. Bushing Replacement).

- check for

proper operation by rotating'the - damaged spline or teeth

inner race as shown in Figure

11 1. - loose or weak retaining ring (do not remove

5. Support retainer spring (680) into the case this

ring, except to replace it.)

- insert between the case lug and the one open @ Reaction sun shell (670) for

notch in the support. - stripped or worn splines

Page 1640 of 1825

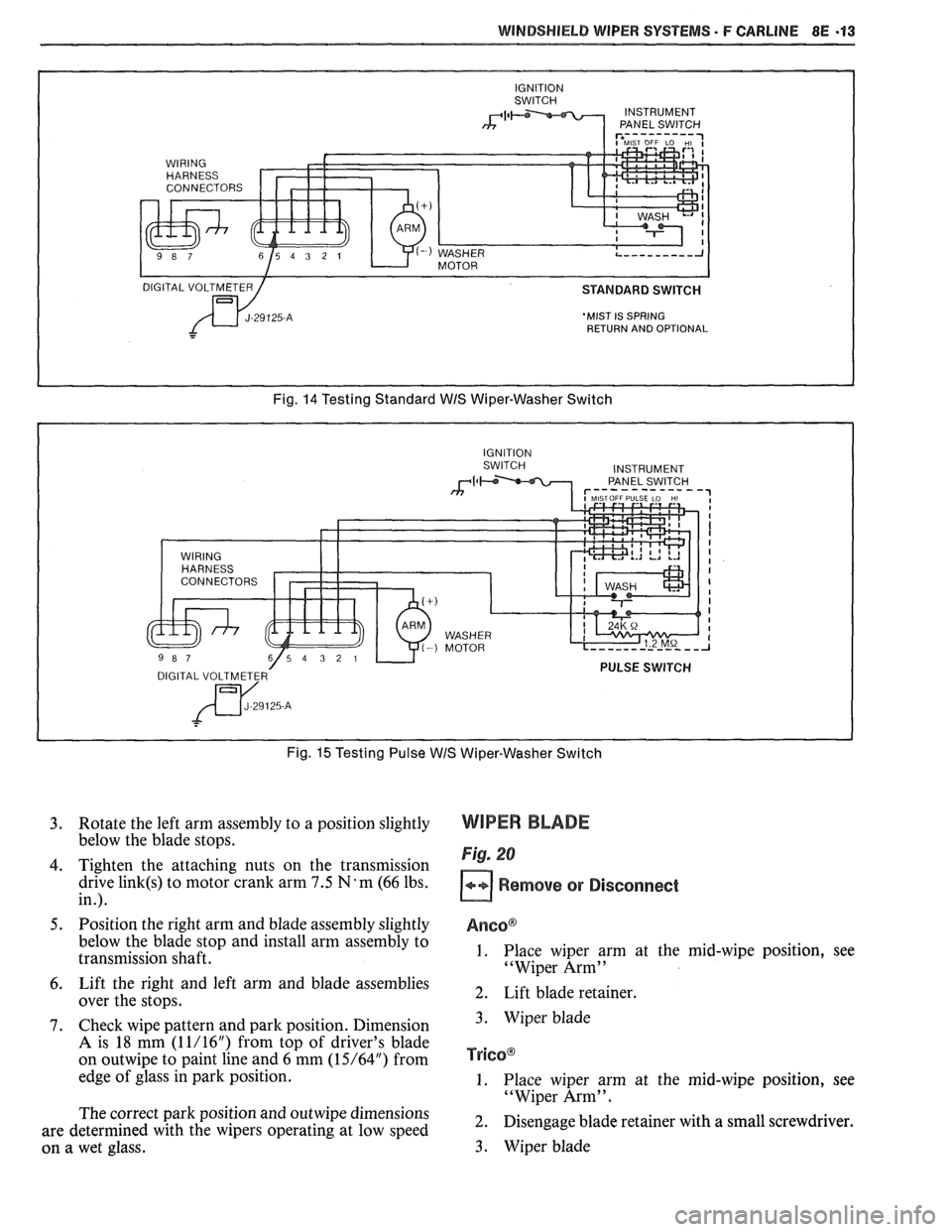

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -13

'MIST IS SPRING

RETURN AND OPTIONAL

Fig. 14 Testing Standard WIS Wiper-Washer Switch

Fig.

15 Testing Pulse WIS Wiper-Washer Switch

3. Rotate the left arm assembly to a position slightly

below the blade stops.

4. Tighten the attaching nuts on the transmission

drive

link(s) to motor crank arm 7.5 N'm (66 lbs.

in.).

5. Position the right arm and blade assembly slightly

below the blade stop and install arm assembly to

transmission shaft.

6. Lift the right and left arm and blade assemblies

over the stops.

7. Check wipe pattern and park position. Dimension

A is 18 mm (1 1/16") from top of driver's blade

on

outwipe to paint line and 6 mm (15/64") from

edge of glass in park position.

The correct park position and

outwipe dimensions

are determined with the wipers operating at low speed

on a wet glass.

WIPER BLADE

Fig. 20

Remove or Disconnect

Anso@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm"

2. Lift blade retainer.

3. Wiper blade

TY~GO@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm".

2. Disengage blade retainer with a small screwdriver.

3. Wiper blade

Page 1701 of 1825

2H-4 STATIONARY GLASS - F STYLE

7. Watertest car at once using soft spray. Use warm

or hot water if available. Do not direct hard

stream of water at fresh adhesive material. If any

leaks are found, paddle in extra adhesive at leak

point using a small disposable brush or

flat-bladed tool. Water applied on top of urethane

adhesive, either during watertest or as a separate

operation, will speed up the cure of the urethane.

8. Install windshield reveal molding.

9. Install

all other previously removed parts and

clean up.

10. On windshield installations, car must remain at

normal room temperature for six hours to

complete proper cure of adhesive.

Extended Method

It will be necessary to use extended installation

method if prior service installation was made with

butyl tape or if urethane material remaining in window

opening after window removal is damaged, or must be

removed to permit refinishing of window opening.

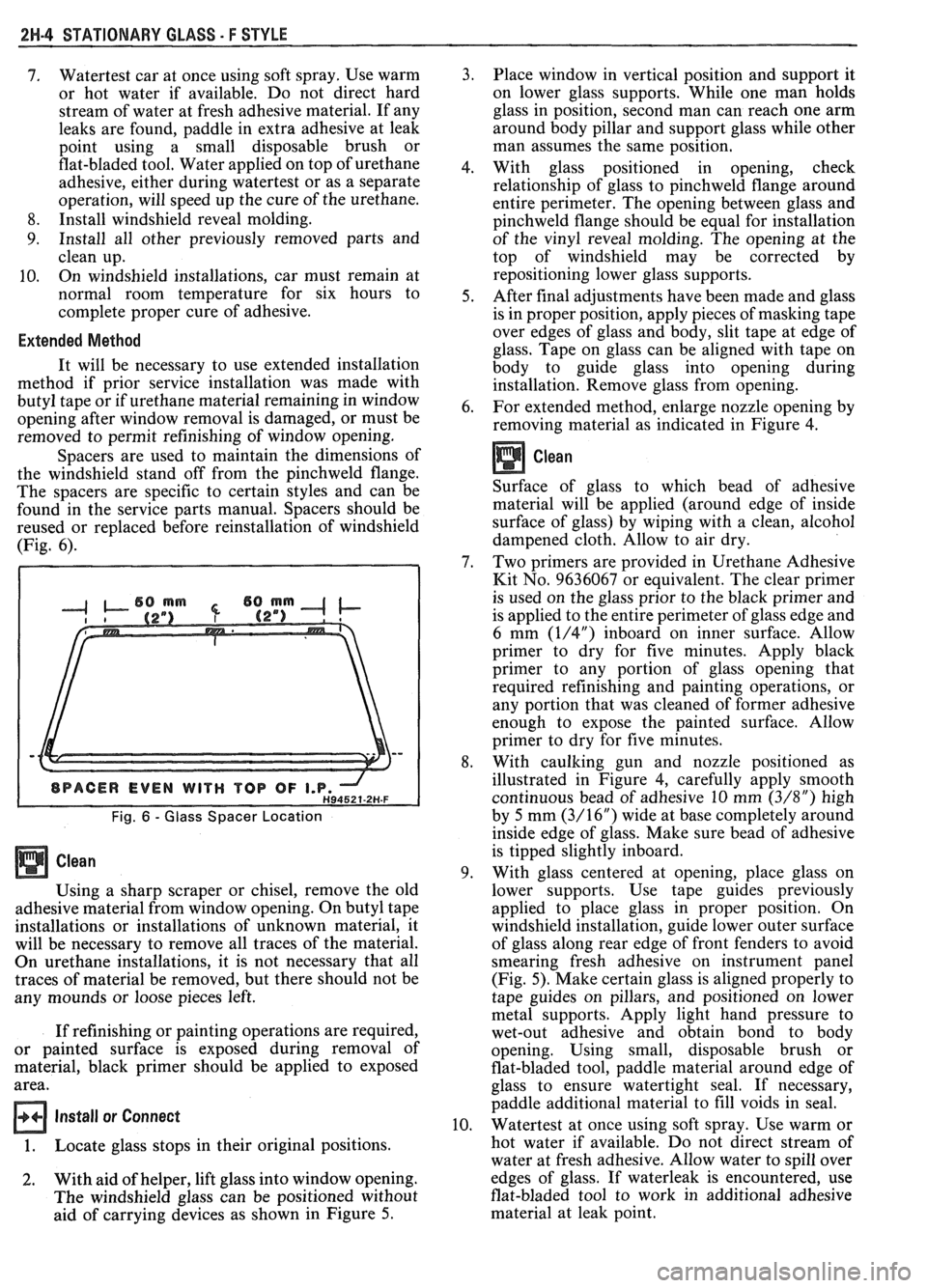

Spacers are used to maintain the dimensions of

the windshield stand off from the pinchweld flange.

The spacers are specific to certain styles and can be

found in the service parts manual. Spacers should be

reused or replaced before reinstallation of windshield

(Fig. 6).

Fig. 6 - Glass Spacer Location

Using a sharp scraper or chisel, remove the old

adhesive material from window opening. On butyl tape

installations or installations of unknown material, it

will be necessary to remove all traces of the material.

On urethane installations, it is not necessary that all

traces of material be removed, but there should not be

any mounds or loose pieces left.

If refinishing or painting operations are required,

or painted surface is exposed during removal of

material, black primer should be applied to exposed

area.

Install or Connect

1. Locate glass stops in their original positions.

2. With aid of helper, lift glass into window opening.

The windshield glass can be positioned without

aid of carrying devices as shown in Figure 5. Place window

in vertical position and support it

on lower glass supports. While one man holds

glass in position, second man can reach one arm

around body pillar and support glass while other

man assumes the same position.

With glass positioned in opening, check

relationship of glass to pinchweld flange around

entire perimeter. The opening between glass and

pinchweld flange should be equal for installation

of the vinyl reveal molding. The opening at the

top of windshield may be corrected by

repositioning lower glass supports.

After final adjustments have been made and glass

is in proper position, apply pieces of masking tape

over edges of glass and body, slit tape at edge of

glass. Tape on glass can be aligned with tape on

body to guide glass into opening during

installation. Remove glass from opening.

For extended method, enlarge nozzle opening by

removing material as indicated in Figure

4.

Clean

Surface of glass to which bead of adhesive

material will be applied (around edge of inside

surface of glass) by wiping with a clean, alcohol

dampened cloth. Allow to air dry.

Two primers are provided in Urethane Adhesive

Kit No. 9636067 or equivalent. The clear primer

is used on the glass prior to the black primer and

is applied to the entire perimeter of glass edge and

6 mm

(1/4") inboard on inner surface. Allow

primer to dry for five minutes. Apply black

primer to any portion of glass opening that

required refinishing and painting operations, or

any portion that was cleaned of former adhesive

enough to expose the painted surface. Allow

primer to dry for five minutes.

With caulking gun and nozzle positioned as

illustrated in Figure 4, carefully apply smooth

continuous bead of adhesive 10 mm

(3/8") high

by 5 mm

(3/16") wide at base completely around

inside edge of glass. Make sure bead of adhesive

is tipped slightly inboard.

With glass centered at opening, place glass on

lower supports. Use tape guides previously

applied to place glass in proper position. On

windshield installation, guide lower outer surface

of glass along rear edge of front fenders to avoid

smearing fresh adhesive on instrument panel

(Fig. 5). Make certain glass is aligned properly to

tape guides on pillars, and positioned on lower

metal supports. Apply light hand pressure to

wet-out adhesive and obtain bond to body

opening. Using small, disposable brush or

flat-bladed tool, paddle material around edge of

glass to ensure watertight seal. If necessary,

paddle additional material to fill voids in seal.

Watertest at once using soft spray. Use warm or

hot water if available. Do not direct stream of

water at fresh adhesive. Allow water to spill over

edges of glass. If waterleak is encountered, use

flat-bladed tool to work in additional adhesive

material at leak point.

Page 1706 of 1825

UNDERBODY-F STYLE 3H-1

SECTION 3H

UNDERBODY

CONTENTS

General Body Construction .......................................................................................................... 3H- 1

Alignment Checking ................................................................................................................ 3H- I

Floor Pan Insulators ...................... .. ........................................................................................ 3H- 1

Floor Carpets ................................................................................................................................. 3H-2

metric-to-English dimensional conversion data.

Dimensions to gage holes are measured to dead center

GENERAL BODY CONSTRUCTION of the holes and flush to adjacent surface metal unless

Information in this section pertains to unitized otherwise specified.

body construction which

incorporates integral front

and rear frame side rails. FLOOR PAN INSULATORS

Consideration must be given when checking

underbody dimensions. The engine front suspension

lower control arms are supported by a cross member.

The cross member, in turn, is bolted to the body at six

locations

-- three on each side of the engine front

compartment lower rails. Mounting provisions for the

front suspension system are shared by chassis

components (suspension lower control arms and cross

member) and body components (engine compartment

side panels). The suspension strut towers must be

dimensionally correct in relation to the remainder of

the underbody in order to maintain specified

suspension strut and

castedcamber angles.

Since the individual underbody components also

contribute directly to the overall strength of the body,

it is essential that proper welding techniques be

observed during service repair operations. The

underbody components should be properly sealed and

rustproofed whenever body repair operations destroy

or damage the original sealing and rustproofing. When

rustproofing critical underbody components, it is

essential that a good quality type of air dry primer be

used (such as corrosion resistant chromate or

equivalent material). It is not advisable to use

combination type primer-surfacers.

ALIGNMENT CHECKING

An accurate method of determining the

alignment of the underbody utilizes a measuring tram

gage. The tram gage set required to perform the

recommended measuring checks must include a

vertical pointer capable of reaching 914 mm (36").

Two types of measurements can be made with

a

tram gage: direct point-to-point measurements and

measurements calculated on a horizontal

vlane (datum

line) parallel to the underbody. In the

latter case, the

vertical pointers must be set as specified for each point

to be measured (Fig. 3-1).

Point-to-point measurements are generally taken

only on engine compartment components (Fig. 3-2)

and simply require the vertical pointers to be equally

set.

Figure #3-3 describes the alphabetically

identified points of measurement. Figure 3-4 provides Floor

pan insulators have been designed for the

higher floor pan temperatures that result from the use

of the catalytic converter in the exhaust system.

Therefore, when servicing a vehicle in the field, it is

essential that any insulators that may have been

disturbed or removed be reinstalled in the original

sequence and location. Also, if it becomes necessary to

replace an insulator, the material specified for that

particular location on the floor pan must be used. The

types of materials are listed below. Items 1 and

2 are

rolled stock and are ordered by linear foot and cut to

fit.

1. Insulator floor pan

(cerra blanket thermal) -

consists of 10 mm (3/8") thick aluminum silica

(type 1).

2. Insulator floor pan (amberlite) - consists of 10

mm

(3/8") thick resinated fibers (type 2).

3. Insulator floor pan sheet (phenolic bonded fiber

glass)

305 mm x 457 mm (12" x 18") cut to size,

(type 3).

All of the above materials must meet

Motor Vehicle Safety Standard No. 302 for

flammability.

When servicing or replacing interior insulators,

the following instructions must be observed:

1. Insulators must be installed in the original

position and sequence. Pieces should be butted

together in order to avoid gapping or

overlapping.

2. If it is necessary to replace an insulator, the

specified material must be used.

3. Use original

part to determine the amount of

replacement material required and as a template

for cutting and fitting the new piece to the floor

pan.

4. When installing insulator, do not enlarge cutouts

or holes that are used for the attachment of

interior components such as seats or seat belts.

5. Cross body harnesses for interior components

such as power seats, lap belt warning light and

buzzer or rear speakers must be routed over the

floor pan insulators in the original location and

clipped in place.