trailer PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 19 of 1825

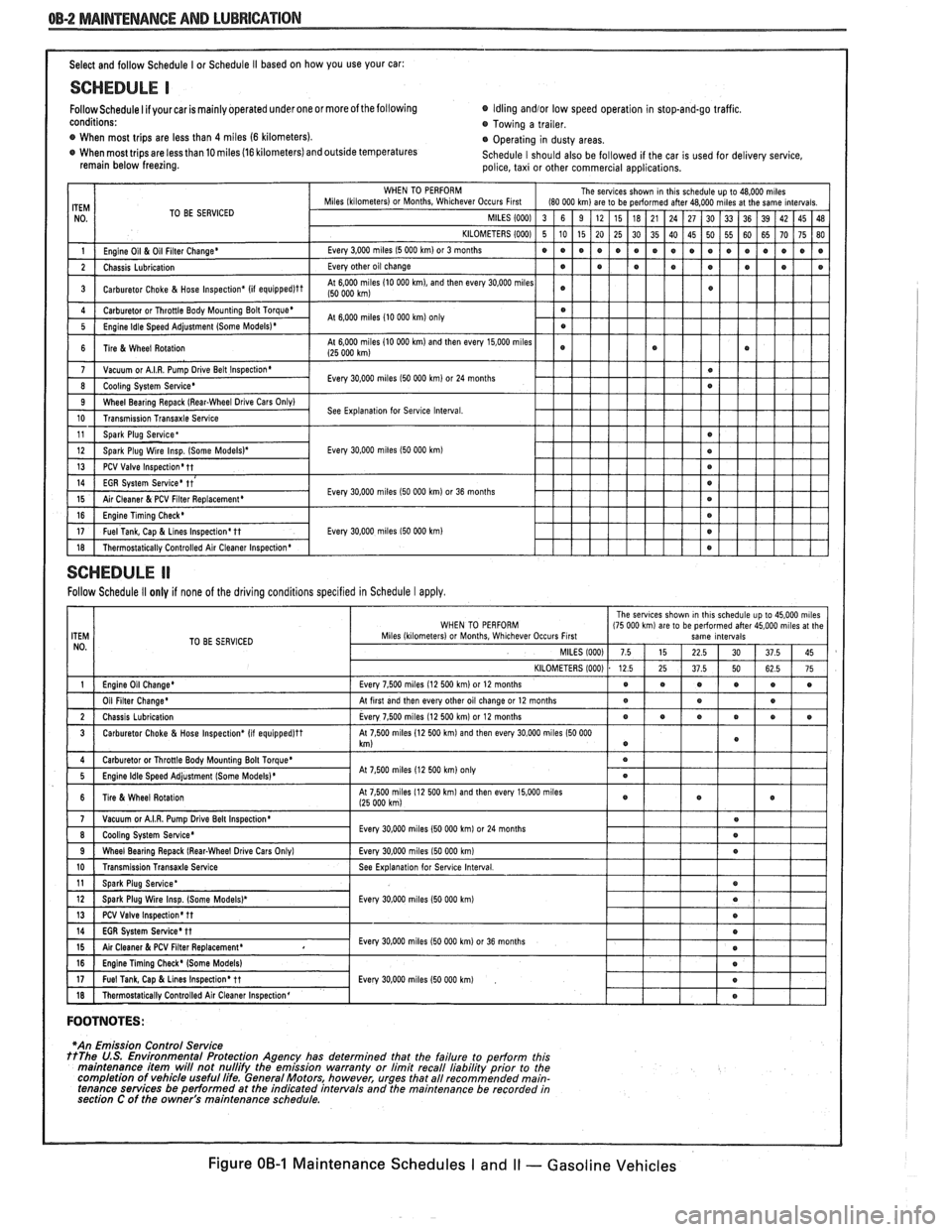

OB-2 MAINTENANCE AND LUBRICATION

Select and follow Schedule I or Schedule I1 based on how you use your car:

SCHEDULE I

Follow Schedule I if your car is mainly operated under one or moreof the following Idling andlor low

speed operation in stop-and-go traffic.

conditions: Towing a trailer.

@ When most trips are less than 4 miles (6 kilometers).

Operating in dusty areas.

When most trips are less than 10 miles (16 kilometers) and outside temperatures

Schedule I should also be followed if the car is used for delivery service,

remain below freezing.

police, taxi or other commercial applications.

TO BE SERVICED

Every

30.000 miles I50 000 km)

Every 30,000 miles I50 000 km) or 36 months

Every

30,000 miles 150 000 km)

SCHEDULE ll

Follow Schedule II only if none of the driving conditions specified in Schedule I apply.

TO BE SERVICED

At

7 500 miles 12 500 km on1

FOOTNOTES:

I

*An Emission Control Service ttThe U.S. Environmental Protection Agency has determined that the failure to perform this

maintenance item will not nullifv the emission warrantv or limit recall liabilitv orior to the

completion of vehicle useful life. General Motors, however, urges that all recommended main-

tenance services be performed at the indicated intervals and the maintenance be recorded in

section C of the owner's

ma~ntenance schedule.

Figure OB-1 Maintenance Schedules I and I1 - Gasoline Vehicles

Page 20 of 1825

F CARLINE

ITEM 10

TransmissionRransaxle Service

The manual transmission or transaxle fluid does not

require changing. (Corvette only.) Change fluid in over-

drive unit every 30,000 miles (50 000 km).

For automatic transmissions or transaxles, change

both the fluid and filter every 15,000 miles (25 000 km) if

the car is mainly driven under one or more of these

conditions:

@ In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

@ In hilly or mountainous terrain.

@ Frequent trailer pulling.

@ Uses such as found in taxi, police car or delivery

service.

If you do not use your car under any of these condi-

tions, change both the fluid and filter every 100,000 miles

(160 000 km). See you Owner's Manual for further

details.

ITEM 11

Spark Plug Service*

Replace spark plugs with type listed in your Owner's

Manual.

ITEM 12

Spark Plug Wire Inspection*

Clean wires and inspect for burns, cracks or other dam-

age. Check the wire boot fit at distributor and at spark plugs.

Replace wires as needed.

ITEM 13

Positive Crankcase Ventilation (PCV) Valve

Inspection*

Inspect valve for proper function. Replace valve if

necessary as well as any worn, plugged or collapsed

hoses.

ITEM 14

EGR System Service*

Conduct EGR System Service as referenced in the

EGR System Chart shown in the appropriate 6E Section.

Also, refer to your GM maintenance schedule booklet for

specific applications.

ITEM 15

Air Cleaner and PCV Filter Replacement*

On 1.6 and 2.0 liter engines, replace every 50,000

miles (80 000 km). On all other engines, replace every

30,000 miles (50 000 km). Replace more often under

dusty conditions. Ask your dealer for the proper replace-

ment interval for your driving conditions.

MAINTENANCE AND LUBRICATION 08-3

ITEM 16

Engine Timing Check*

Adjust timing to underhood label specifications. If

no specifications are shown, no adjustment is needed.

ITEM 17

Fuel Tank, Cap and Lines Inspection*

Inspect fuel tank, cap and lines (including fuel rails

and injection assembly, if so equipped) for damage or

leaks. Inspect fuel cap gasket for an even filler neck

imprint or any damage. Replace parts as needed.

ITEM 18

Thermostatically Controlled Air Cleaner

Inspection*

If your car is equipped, inspect all hoses and ducts

for proper hookup. Make sure valve works properly.

OWNER INSPECTIONS AND SERVICES

Listed below are inspections and services which

should be made by either you or a qualified technician at

the intervals shown to help ensure proper safety, emission

performance and dependability of your car. Take any

problems promptly to your dealer or another qualified

technician for service advice. Whenever repairs are neces-

sary, have them completed at once. For your safety and

that of others, any safety-related parts that could have

been damaged in an accident should be inspected and all

needed repairs should be done before operating your car.

Be sure to use the proper fluids and lubricants as shown in

Figure OB-2.

WHILE OPERATING YOUR VEHICLE

Automatic transmissionltransaxle shift indi-

cator operation - Make sure the indicator points to the

gear chosen.

Horn operation - Blow the horn occasionally to

make sure it works. Check all button locations.

I

Brake system operation -- Be alert to abnormal

sounds, increased brake pedal travel or repeated pulling to

one side when braking. Also, if a brake warning light

comes on or flashes, or the anti-lock warning light (if

equipped) comes on or remains on, something may be

wrong with part of the brake system. Have it inspected and

repaired at once.

Exhaust system operation - Be alert to any

changes in the sound of the system or any smell of fumes.

These are signs the system may be leaking or overheating.

.

Have it inspected and repaired at once. Also see "Engine

Exhaust Gas Caution (Carbon Monoxide)" and "Catalytic

Converter" in your Owner's Manual.

*An Emission Control Service

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 348 of 1825

ENGINE GENERAL INFORMATION 6-3

B, Section 6E2 - Fuel Injection (TBI)

B, Section 6E3 - Fuel Injection (Ported)

ENGINE MECHANICAL DIAGNOSIS

The following diagnostic information covers common problems and possible causes. When

the proper diagnosis is made, the problem should be corrected by adjustment, repair or part

replacement as required. Refer to the appropriate section of the manual for these procedures.

EXCESSIVE OIL LOSS

B, External oil leaks. Tighten bolts and/or replace o Continuous high speed driving, and/or severe

gaskets and seals as necessary. usage

such as trailer hauling, will normally cause

decreased oil mileage.

e Improper reading of dipstick. Check oil with car PCV system malfunctioning. on a level surface and allow adequate drain-down Valve guides and/or valve stem seals worn, or time.

seals omitted. Ream guides and install oversize

service valves and/or new valve stem seals.

Improper Use S.A'E' Piston rings broken, worn, or not seateded. Allow viscosity for prevailing temperatures. See

adequate time for rings to seat. Replace broken

Owner's Manual for proper specifications.

or worn rings, as necessary.

Piston improperly installed or misfitted.

LOW OIL PRESSURE

Slow idle speed. Set idle speed to correct

specification, if not ECM controlled.

Incorrect, or malfunctioning, oil pressure switch.

Incorrect, or malfunctioning, oil pressure gage.

Replace with proper gage.

.*

Improper oil viscosity, or diluted oil. install oil of

proper viscosity for expected temperature, or

install new oil if diluted with moisture or

unburned fuel mixtures.

o Oil pump worn or dirty.

e Plugged oil filter.

e Oil pickup screen loose or plugged.

B, Hole in oil pickup tube.

e Excessive bearing clearance. Replace if necessary.

o Cracked, porous or plugged oil galleys. Repair or

replace block.

o Galley plugs missing or misinstalled. Install

plugs, or repair as necessary.

VALVE TRAIN NOISE

e Low oil pressure. Repair as necessary. (See o Broken valve spring.

preceding diagnosis for low oil pressure.)

o Sticking valves.

o Loose rocker arm attachments. Inspect and B, Lifters worn, dirty, or defective. Clean, inspect,

test and replace as necessary.

repair as necessary.

o Camshaft worn, or poor machining. Replace

o Worn rocker arm and/or pushrod. camshaft.

B, Worn valve guides.

ENGINE KNOCK DIAGNOSIS

KNOCKS COLD AND CONTINUES FOR TWO TO THREE MINUTES

INCREASES

WITH TORQUE

o Vacuum operated EFE engines may have valve o Excessive piston to bore clearance. Replace

knock. Replace EFE valve. piston.

e Flywheel contacting splash shield. Reposition

splash shield.

e Loose or broken balancer or drive pulleys.

Tighten, or replace as necessary. Cold engine piston knock usually

disappears when the cylinder is grounded

out. Cold engine piston knock which

disappears in 1.5 minutes should be

considered acceptable.

Page 415 of 1825

BB.4 ENGINE COOLING

ENGINE COOLING SYSTEM COMPLAINT

TO AVOID NEEDLESS

TIME AND COST IN DIAGNOSING COOLING SYSTEM COMPLAINTS, THE CUSTOMER

SHOULD BE QUESTIONED ABOUT DRIVING CONDITIONS THAT PLACE ABNORMAL LOADS ON THE COOLING

SYSTEM.

1. DOES OVERHEATING OCCUR WHILE PULLING A TRAILER?

IF ANSWER IS "YES'- HOW HEAVY IS TRAILER? IF TRAILER WEIGHT IS GREATER THAN 1,000 LBS. & CAR IS EQUIPPED

WITH NORMAL DUTY COOLING SYSTEM, A HEAVY DUTY COOLING PACKAGE IS REQUIRED (PER MFR'S TRAILER HAULING

SPECS.). FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

2. IS CAR EQUIPPED WlTH ADD-ON OR AFTER MARKET AIR CONDITIONING SYSTEM?

IF ANSWER IS "YES"- WAS HEAVY DUTY RADIATOR INSTALLED WITH THE SYSTEM? IF NOT, INSTALL HEAVY DUTY AIR

CONDITIONING RADIATOR FOR THE CAR MODEL INVOLVED (PER MANUFACTURER'S SPECS.). FURTHER DlAGNOSTlC

CHECKS SHOULD NOT BE REQUIRED.

3. IS OVERHEATING OCCURRING AFTER PROLONGED IDLE, IN GEAR, AIC SYSTEM OPERATING?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING SUCH AS: a, IDLE IN NEUTRAL AS MUCH AS POSSIBLE - INCREASE ENGINE R.P.M. TO GET HIGHER AIR FLOW & WATER

FLOW THROUGH RADIATOR.

b. TURN A/C SYSTEM OFF DURING EXTENDED IDLES IF OVERHEATING IS INDICATED BY HOT LIGHT OR TEMP. GAGE.

FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

4. IS OVERHEATING OCCURRING AFTER PROLONGED DRIVING IN SLOW CITY TRAFFIC, TRAFFIC JAMS,

GARAGES, ETC.?

IF ANSWER IS "YES - INSTRUCT OWNER ON DRIVING TECHNIQUES THAT WOULD AVOID OVERHEATING - SAME AS

FOR PROLONGED IDLES - NO. 3 FURTHER DIAGNOSTIC CHECKS SHOULD NOT BE REQUIRED.

IF NONE OF THE ABOVE APPLY, GO TO DIAGNOSTIC CHART

TO EFFECTIVELY USE THlS CHART, QUESTION THE OWNER TO DETERMINE WHICH OF THE FOLLOWING

(3) CATEGORIES APPLIES TO THE COMPLAINT:

1. HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE 2. BOILING 3. COOLANT LOSS

1. IF COMPLAINT IS HOT LlGHT OR HOT INDICATION ON TEMPERATURE GAGE -

WAS HOT LlGHT ACCOMPANIED BY BOILING? IF ANSWER IS "YES", GO TO BOILING ON CHART

IF ANSWER IS "NO, GO TO HOT LlGHT ON CHART

2. IF COMPLAINT IS BOILING - GO TO BOILING ON CHART

IF PROBLEM REMAINS, GO TO COOLING

FAN DIAGNOSIS SECTION 8 (IF SO EQUIPPED).

I 3. IF COMPLAINT IS COOLANT LOSS -

DETERMINE IF CUSTOMER IS OVERFILLING THE SYSTEM, THlS WOULD NORMALLY RESULT IN SMALL AMOUNTS OF

I COOLANT LOSS THROUGH THE OVERFLOW TUBE. IF THlS IS THE CASE, INSTRUCT THE CUSTOMER ON PROPER FILL LEVEL & NO FURTHER DIAGNOSTIC CHECKS SHOULD BE REQUIRED.

I IF OVERFILLING IS NOT THE PROBLEM, GO TO COOLANT LOSS ON CHART.

NOTICE:

ANYTIME COOLING SYSTEM IS OBVIOUSLY CONTAMINATED, THE SYSTEM SHOULD BE

DRAINED AND FLUSHED.

1 CAUTION - THE COOLING SYSTEM IS DESIGNED TO OPERATE AT 15 P.S.I. PRESSURE & TEMPERATURES

EXCEEDING 200°F. CAUTION SHOULD BE EXERCISED WHEN REMOVING PRESSURE CAP OR

I SERVICING THE SYSTEM.

Fig. 4 Cooling System Diagnosis Chart (I of 3)

Page 991 of 1825

700-R4-2 HYDRAULIC DIAGNOSIS

R - Reverse allows the vehicle to be operated in

a rearward direction.

N - Neutral allows the engine to be started and

operated without driving the vehicle. If necessary this

position may be selected if the engine must be restarted

with the vehicle moving.

D - Overdrive is used for all normal driving

conditions. It provides four gear ratios plus converter

clutch operation. Downshifts are available for safe

passing by depressing the accelerator.

D - Drive position is used for city traffic, hilly

terrain, and trailer towing. It provides three gear

ranges. Again, downshifts are available by depressing

the accelerator.

2 - Manual second is used to provide acceleration

and engine braking. This range may be selected at any

vehicle speed.

1 - Manual Lo is used to provide maximum

engine

brlking. This range may also be selected at any

vehicle speed.

DIAGNOSIS INFORMATION

ROAD TEST PROCEDURE

e Perform the road test following the sequence

given

e MPH (KPH) shift points will vary with actual

throttle position and driver habits

e Compare the results of the test with speed shift

chart information. Use these results with the

diagnosis information contained in this

Automatic Transmission Hydraulic Diagnosis

Section to evaluate the transmission.

e This test should only be performed when traffic

and road conditions permit

e Observe all traffic safety regulations

Drive and Reverse Engagement Shift Check

1. Start engine

2. Depress brake pedal

3. Move gear selector:

- "Park" (P) to "Reverse" (R)

- "Reverse" (R) to "Neutral"

(N) to "Drive" (D)

Gear selections should be immediate and

not harsh.

Upshifts and Torque Converter Clutch (TCC)

Apply (Figure

2)

With gear selector in "Overdrive" (D)

1. Accelerate using a steady increasing throttle

pressure

2. Note the shift speed point gear engagements for:

- 2nd gear

- 3rd gear

- Overdrive

3. Note the speed shift point for TCC apply. This

should occur while in third gear or overdrive. If

the apply is not noticed, refer to the Preliminary

Torque Converter Clutch Diagnosis information

contained in this section of the Service Manual.

Important

The torque converter clutch will not engage if

engine coolant has not reached a minimum

operating temperature of approximately 54°C

(1 30°F).

Part Throttle Downshift

At vehicle speeds of 40-55 MPH (64-88

KPH) quickly depressed the accelerator to

a half open position and observe:

- TCC releases

- Transmission downshift to 3rd gear

immediately

Full Throttle (Detent) Downshift

At vehicle speeds of 48-55 MPH (77-88

KPH) quickly depress the accelerator to a

wide open position and observe:

- TCC releases

- Transmission downshifts to 2nd gear

immediately

Manual Downshift

1. At vehicle speeds of 40-55 MPH (64 to 88 KPH)

release the accelerator pedal while moving the

gear selector to "Third" gear (D) and observe:

- TCC release

- Transmission downshift to 3rd gear should

be immediate

- Engine should slow vehicle down

2. Move gear selector to "Overdrive" and accelerate

to 40-45 MPH (64-72 KPH). Release the

accelerator pedal while moving the gear selector

to "Second" gear (2) and observe.

- TCC release

- Downshift to second gear should be

immediate

- Engine should slow vehicle down

3. Move gear selector to "Overdrive" (D) and

accelerate to 25 MPH (40 KPH). Release the

accelerator pedal while moving the gear selector

to "First" gear (1) and observe:

- TCC release

- Transmission downshift to 1st gear should

be immediate

- Engine should slow vehicle down

Coastdown Downshift

1. With the gear selector in "Overdrive" (D)

accelerate to 4th gear with TCC applied.

2. Release the accelerator pedal and lightly apply

the brakes to observe:

- TCC release

- Shift points for downshifts.

Manual Gear Range Selection

MANUAL THIRD (D)

1. With vehicle stopped, place gear selector in

"Third" (D) and accelerate to observe:

Page 1117 of 1825

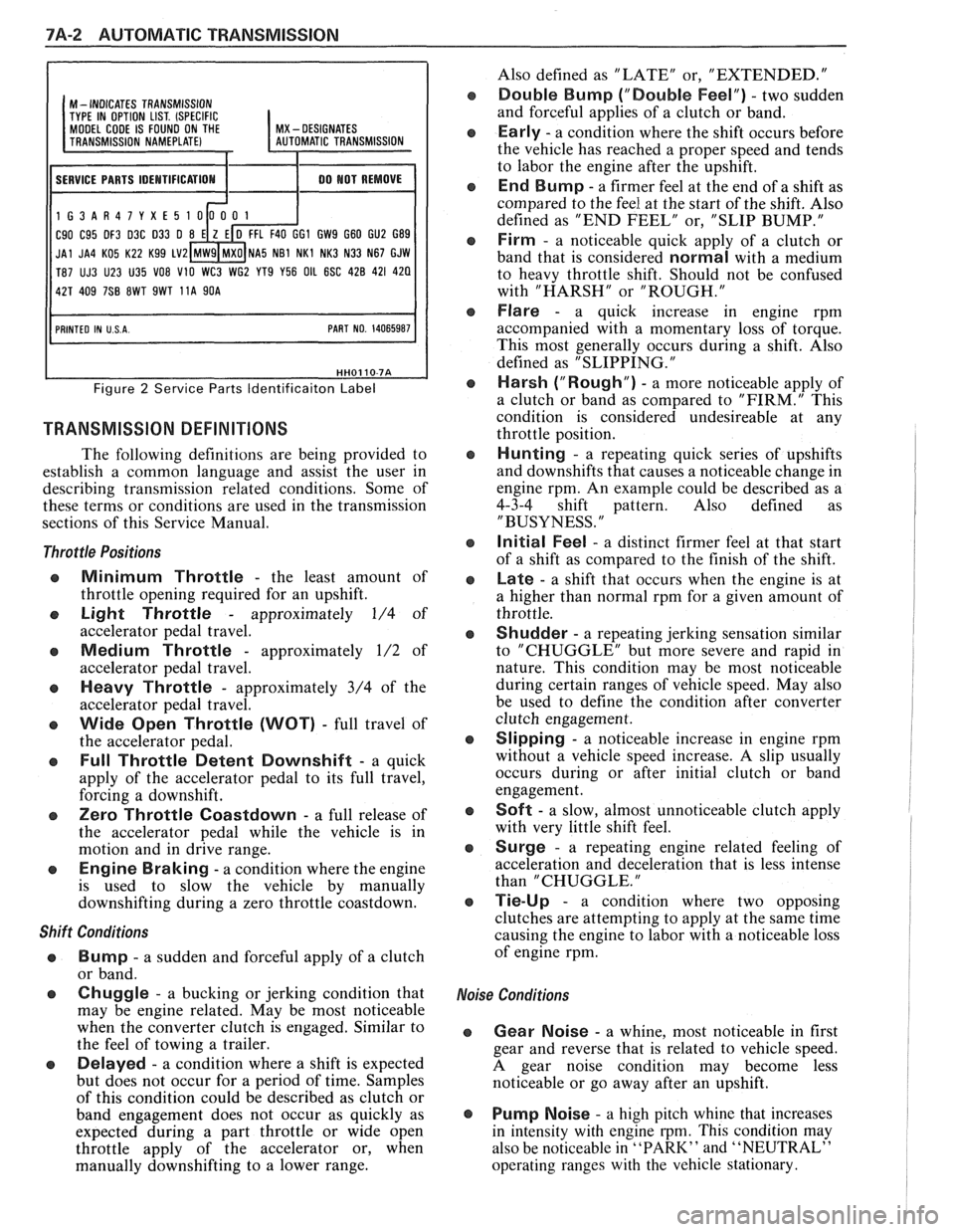

7A-2 AUTOMATIC TRANSMISSION

I I

M - INDICATES TRANSMISSION

TYPE IN OPTION LIST. (SPECIFIC MODEL CODE IS FOUND ON THE I MX - DESIGNATES

11 SERVICE PARTS IDEMTIFICATIOM I 1 00 MOT REMOVE I

1G3AR47YXE5

C90 C95 DF3 D3C 033 0 GI GW9 G60 GU2 G89

JAl JA4 KO5 K22 Kg9 LV2 NA5 NB1 NKl NK3 N33 N67 GJW

T87 UJ3 U23 U35

VO8 V10 WC3 WG2 YT9 Y56 OIL 6SC 428 421 420

Figure 2 Service Parts ldentificaiton Label

TRANSMISSION DEFINITIONS

The following definitions are being provided to

establish a common language and assist the user in

describing transmission related conditions. Some of

these terms or conditions are used in the transmission

sections of this Service Manual.

Throttle Positions

Minimum Throttle - the least amount of

throttle opening required for an upshift.

Light Throttle - approximately 1/4 of

accelerator pedal travel.

Medium Throttle - approximately 1/2 of

accelerator pedal travel.

Heavy Throttle - approximately 3/4 of the

accelerator pedal travel.

Wide Open Throttle (WOT) - full travel of

the accelerator pedal.

Full Throttle Detent Downshift - a quick

apply of the accelerator pedal to its full travel,

forcing a downshift.

Zero Throttle Coastdown - a full release of

the accelerator pedal while the vehicle is in

motion and in drive range.

Engine Braking - a condition where the engine

is used to slow the vehicle by manually

downshifting during a zero throttle coastdown.

Shift Conditions

'a Bump - a sudden and forceful apply of a clutch

or band.

Q Chuggle - a bucking or jerking condition that

may be engine related. May be most noticeable

when the converter clutch is engaged. Similar to

the feel of towing a trailer.

e Delayed - a condition where a shift is expected

but does not occur for a period of time. Samples

of this condition could be described as clutch or

band engagement does not occur as quickly as

expected during a part throttle or wide open

throttle apply of the accelerator or, when

manually downshifting to a lower range. Also

defined as "LATE" or, "EXTENDED."

Double Bump ("Double Feel") - two sudden

and forceful applies of a clutch or band.

Early - a condition where the shift occurs before

the vehicle has reached a proper speed and tends

to labor the engine after the upshift.

End Bump - a firmer feel at the end of a shift as

compared to the feel at the start of the shift. Also

defined as "END FEEL" or, "SLIP BUMP."

Firm - a noticeable quick apply of a clutch or

band that is considered

normal with a medium

to heavy throttle shift. Should not be confused

with "HARSH" or "ROUGH."

Flare - a quick increase in engine rpm

accompanied with a momentary loss of torque.

This most generally occurs during a shift. Also

defined as "SLIPPING.

"

Harsh ("Rough") - a more noticeable apply of

a clutch or band as compared to "FIRM." This

condition is considered undesireable at any

throttle position.

Hunting - a repeating quick series of upshifts

and downshifts that causes a noticeable change in

engine rpm. An example could be described as a

4-3-4 shift pattern. Also defined as

"BUSYNESS.

"

Initial Feel - a distinct firmer feel at that start

of a shift as compared to the finish of the shift.

Late - a shift that occurs when the engine is at

a higher than normal rpm for a given amount of

throttle.

Shudder - a repeating jerking sensation similar

to "CHUGGLE" but more severe and rapid in

nature. This condition may be most noticeable

during certain ranges of vehicle speed. May also

be used to define the condition after converter

clutch engagement.

Slipping - a noticeable increase in engine rpm

without a vehicle speed increase.

A slip usually

occurs during or after initial clutch or band

engagement.

Soft - a slow, almost unnoticeable clutch apply

with very little shift feel.

Surge - a repeating engine related feeling of

acceleration and deceleration that is less intense

than "CHUGGLE.

"

Tie-Up - a condition where two opposing

clutches are attempting to apply at the same time

causing the engine to labor with a noticeable loss

of engine rpm.

,e Conditions

Gear Noise - a whine, most noticeable in first

gear and reverse that is related to vehicle speed.

A gear noise condition may become less

noticeable or go away after an upshift.

Pump Noise - a high pitch whine that increases

in intensity with engine

rpm. This condition may

also be noticeable in

"PARK" and "NEUTRAL"

operating ranges with the vehicle stationary.