wheel size PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 232 of 1825

TIRES AND WHEELS 3E-1

RES AND WHEELS

NOTICE: All wheel bolt and nut fasteners are important attaching parts in that they could affect the

performance of vital components and systems, and/or could result in major repair expense. They must be replaced

with one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of parts.

CONTENTS

Diagnosis ............................................... Section 3 Tire Repair ................................................... 3E-5

General Information .......................... ..... 3E-1 Waddle ........................................................ 3E-5

........ Replacement Tires ....................... ... 3E- 1 Measuring Wheel Runout ............................ 3E-6

P-Metric Tires ...................... .. ................... 3E-2 Spare Tire ...................................................... 3E-6 ................................................ Tire Placard 3E-2 Match Mounting ......................................... 3E-7

.......................................................... Wheels 3E-2 Balancing Tire and Wheel ............................ 3E-7

....................... Maintenance and Adjustments .............. 3E-2 General Balance Precautions 3E-7 ...................................... Wheel Repair .............................................. 3E-2 Off-Car Balancing 3E-8 .............................. Metric Wheel Nuts and Studs .................... .. 3E-3 On-Car Balancing .. ...... 3E-8

......................................... Inflation of Tires ........................................ 3E-3 Wheel Weights 3E-8 .................... Tire Rotation ........................... ...... . 3E-3 Correcting Non-Uniform Tires 3E-8 .......................... Tire Chain Usage ........................................ 3E-4 Aluminum Wheel Cleaning 3E-9 Aluminum Wheel Hub Cap ......................... 3E-9 Service Operations ..................................... 3E-4 Aluminum Wheel Porosity Repair .............. 3E-9 ......................... Wheel Removal .... .......... 3E-4 Aluminum Wheel Refinishing ...................... 3E-9 Tire Mounting and Dismounting ................. 3E-5 Wheel Nut Torque 3E-10 ......................................

GENERAL INFORMATION ~t is recommended that new tires be installed in

pairs on the same axle. If it is necessary to replace only

The tires and are one tire, it should be paired with the tire having the

designed to operate satisfactorily with loads up to and

most tread, to equalize braking traction. including the full rated load capacity when inflated to

Although they may appear different in tread

the recommended inflation pressures.

design, tires built by different manufacturers with

Correct tire pressures, wheel alignment and identical TPC specification numbers, can be

driving techniques have an important influence on tire

intermixed on the same car. life. Heavy cornering, excessive rapid acceleration, and

heavy braking will increase tire wear.

REPLACEMENT TIRES

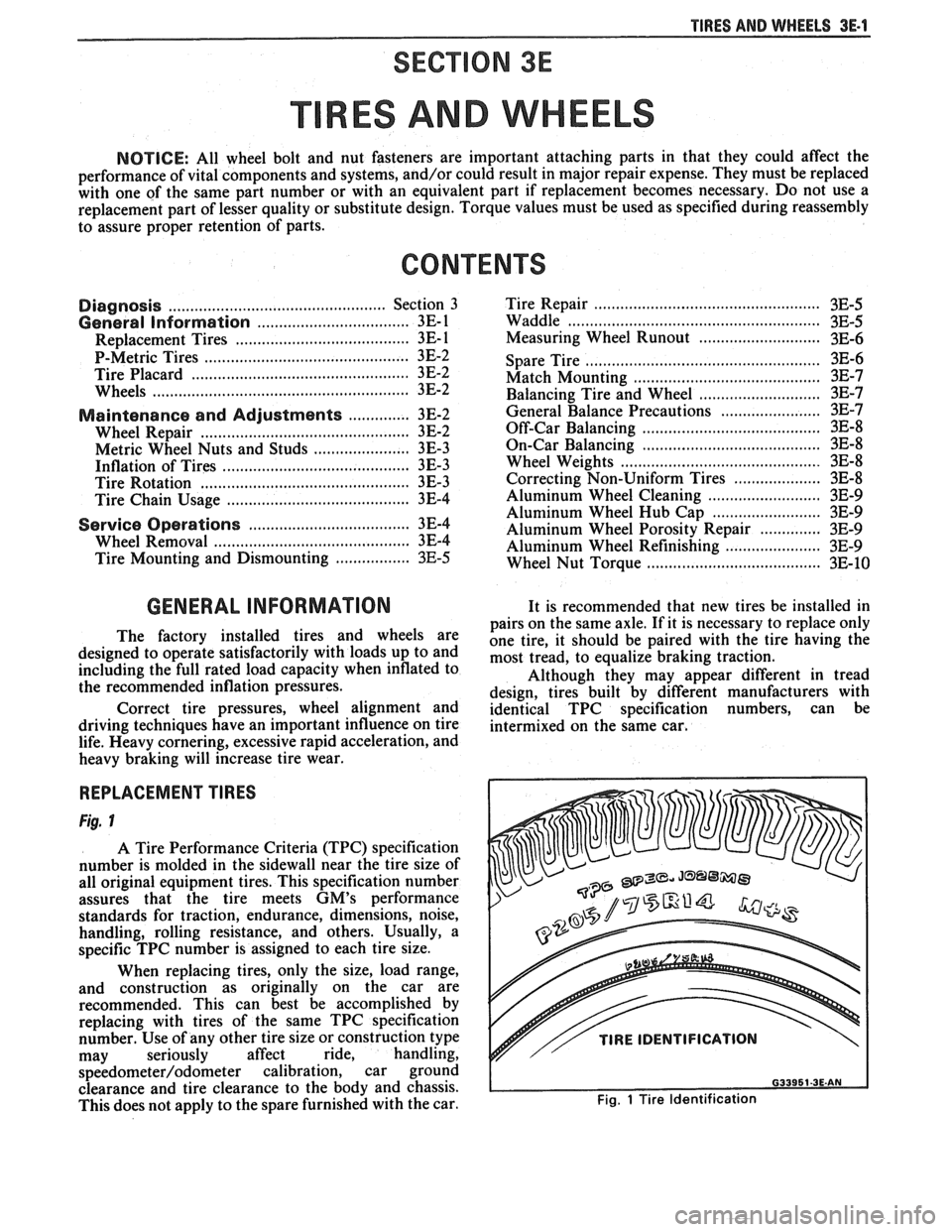

Fig. 1

A Tire Performance Criteria (TPC) specification

number is molded in the sidewall near the tire size of

all original equipment tires. This specification number

assures that the tire meets

GM's performance

standards for traction, endurance, dimensions, noise,

handling, rolling resistance, and others. Usually, a

specific TPC number is assigned to each tire size.

When replacing tires, only the size, load range,

and construction as originally on the car are

recommended. This can best be accomplished by

replacing with tires of the same TPC specification

number. Use of any other tire size or construction type

may seriously affect ride, handling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and chassis.

This does not apply to the spare furnished with the car.

v// TIRE IDENTIFICATION

Fig. 1 Tire Identification

Page 233 of 1825

3E.2 TIRES AND WHEELS

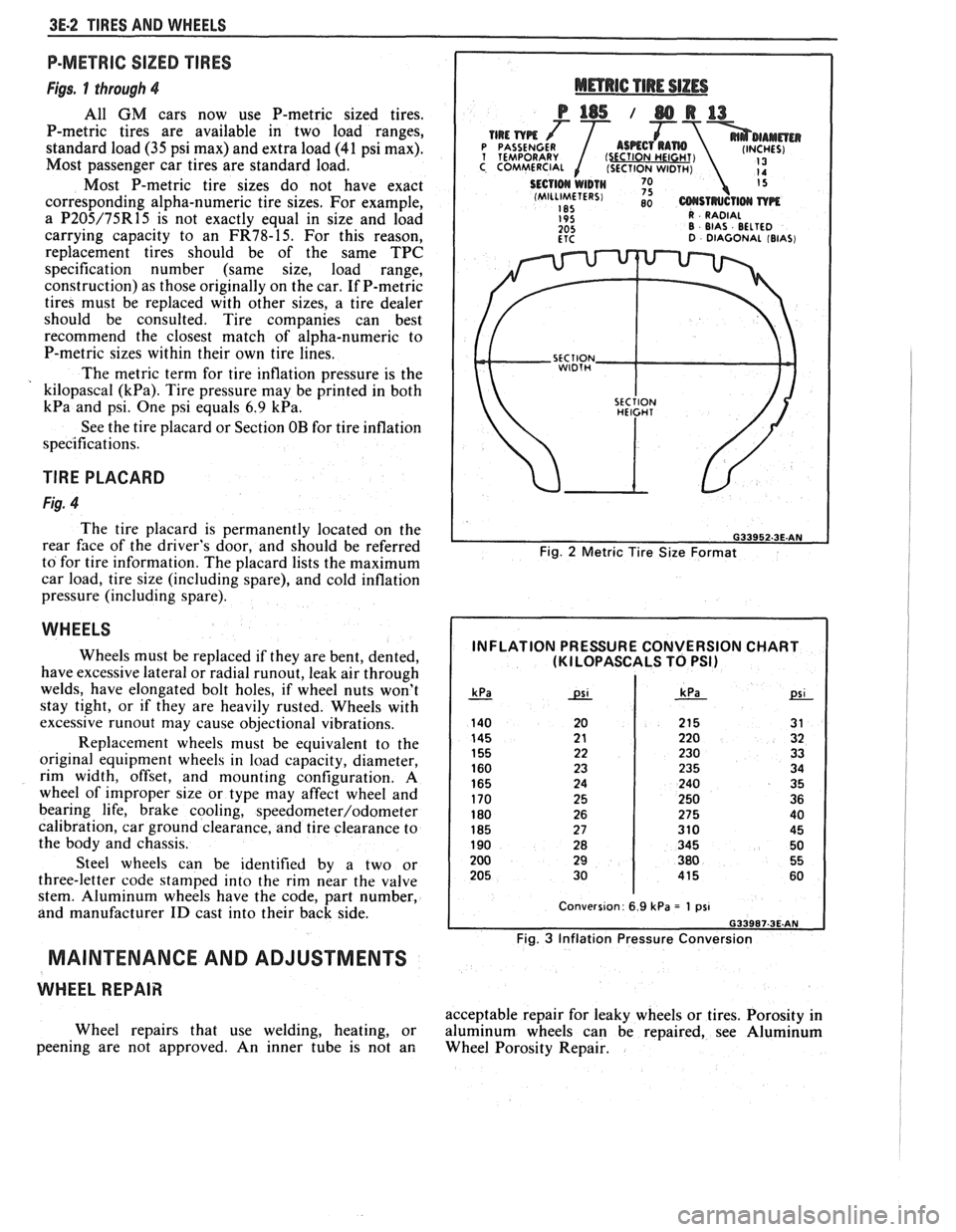

P-METRIC SIZED TIRES

Figs. 1 through 4

All GM cars now use P-metric sized tires.

P-metric tires are available in two load ranges,

standard load

(35 psi max) and extra load (41 psi max).

Most passenger car tires are standard load.

Most P-metric tire sizes do not have exact

corresponding alpha-numeric tire sizes. For example,

a

P205/75R15 is not exactly equal in size and load

carrying capacity to an

FR78-15. For this reason,

replacement tires should be of the same TPC

specification number (same size, load range,

construction) as those originally on the car. If P-metric

tires must be replaced with other sizes, a tire dealer

should be consulted. Tire companies can best

recommend the closest match of alpha-numeric to

P-metric sizes within their own tire lines.

The metric term for tire inflation pressure is the

kilopascal

(kPa). Tire pressure may be printed in both

kPa and psi. One psi equals 6.9 kPa.

See the tire placard or Section OB for tire inflation

specifications.

TlRE PLACARD

Fig. 4

The tire placard is permanently located on the

rear

face of the driver's door, and should be referred

to for tire information. The placard lists the maximum

car load, tire size (including spare), and cold inflation

pressure (including spare).

WHEELS

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial

runout, leak air through

welds, have elongated bolt holes, if wheel nuts won't

stay tight, or if they are heavily rusted. Wheels with

excessive

runout may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity, diameter,

rim width, offset, and mounting configuration.

A

wheel of improper size or type may affect wheel and

bearing life, brake cooling,

speedometer/odometer

calibration, car ground clearance, and tire clearance to

the body and chassis.

Steel wheels can be identified by a two or

three-letter code stamped into the rim near the valve

stem. Aluminum wheels have the code, part number,

and manufacturer

ID cast into their back side.

MAINTENANCE AND ADJUSTMENTS

WHEEL REPAIR

Wheel repairs that use welding, heating, or

peening are not approved. An inner tube is not an

Fig. 2 Metric Tire Size Format

INFLATION PRESSURE CONVERSION CHART (KI LOPASCALS TO PSI)

Fig. 3 Inflation Pressure Conversion

acceptable repair for leaky wheels or tires. Porosity in

aluminum wheels can be repaired, see Aluminum

Wheel Porosity Repair.

Page 234 of 1825

TIRES AND WHEELS 3E-3

METRIC WHEEL NUTS AND STUDS

Some models use metric wheel nuts and wheel

studs. The nut will have the word "metric" stamped on

its face and the stud will have the letter

"M" stamped

into the threaded end. The word "metric" is stamped

on its head.

The thread size of the metric wheel nuts and

wheel studs are

"MI2 x 1.5". These stand for:

M = Metric

12

= Diameter in millimeters

1.5

= Millimeters per thread

If a broken stud is found, see Section 3C (Front

Suspension) or Section 3D (Rear Suspension) for

replacement procedure.

INFLATION OF TIRES

The pressure recommended for any model is

carefully calculated to give a satisfactory ride,

handling, tread life and load carrying capacity.

Tire pressure, with tires cold, (after car has set for

three hours or more, or driven less than one mile)

should be checked monthly or before any extended trip

and set to the specifications on the tire placard located

on rear face of driver's door. Tire inflation pressure is

also given in Section OB.

Valve caps or extensions should be on the valves

to keep dust and water out.

1. For sustained driving at speeds up to 85

mph (140 km/h), in countries where such

speeds are allowed by law, your tires should be set

at the pressures recommended on your tire

placard.

Sustained driving at speeds

faster than

85 mph (140 km/h), where

permitted

by law, is not advised unless

your car has special high speed tires available

from many tire dealers.

2. Tire pressures may increase as much as 6 psi

when hot.

3. Higher

than recommended pressure can cause:

o Hard ride

o Tire bruising or carcass damage

Rapid tread wear at center of tire

4. Lower

than

recommended pressure can cause:

@ Tire squeal on turns

@ Hard steering

o Rapid and uneven wear on the edges of the

tread

Tire rim bruises and rupture

e Tire cord breakage

o High tire temperatures

o Reduced handling

High fuel consumption

5. Unequal pressure on same axle can cause:

Uneven braking

o Steering lead

o Reduced handling

e Swerve on acceleration

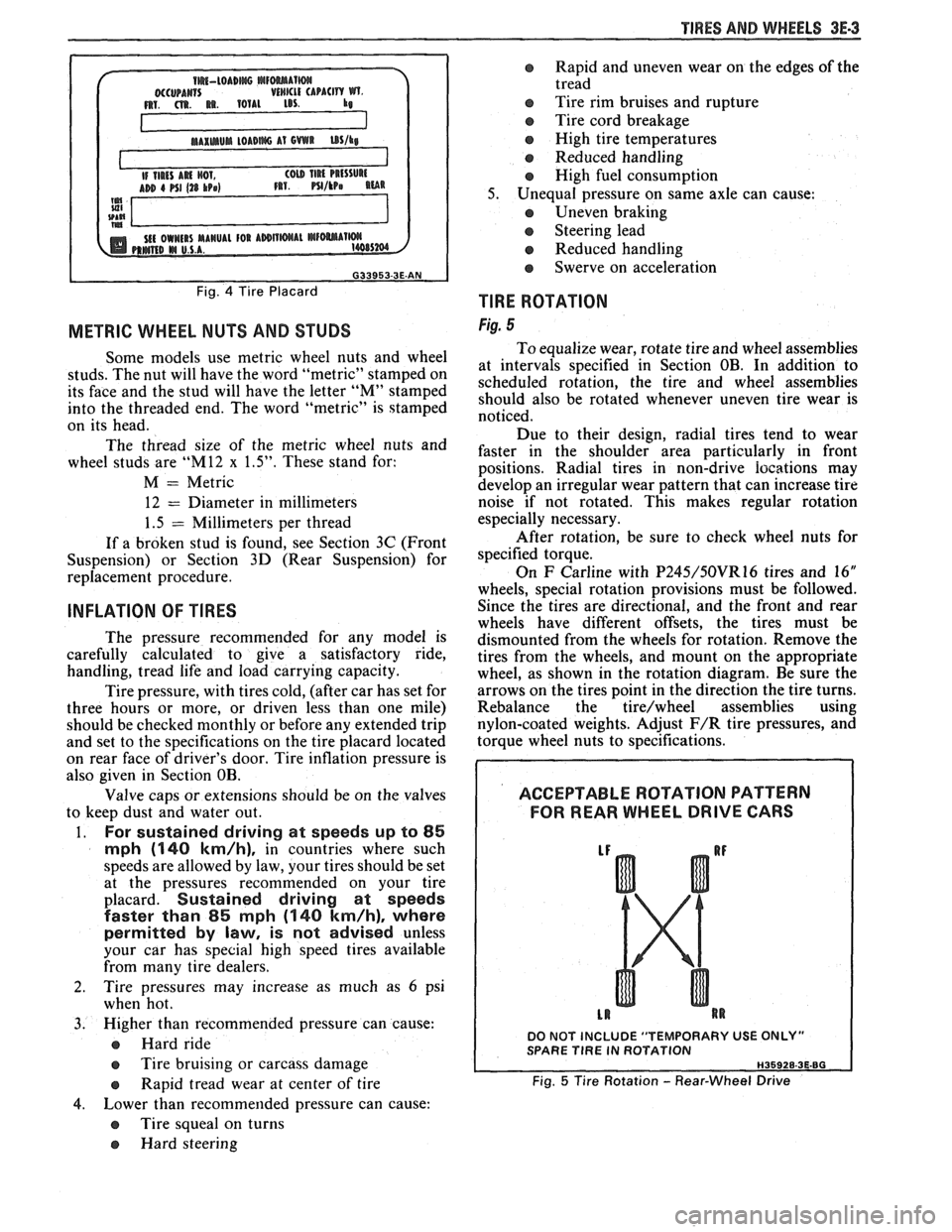

TlRE ROTATION

Fig. 5

To equalize wear, rotate tire and wheel assemblies

at intervals specified in Section OB. In addition to

scheduled rotation, the tire and wheel assemblies

should also be rotated whenever uneven tire wear is

noticed.

Due to their design, radial tires tend to wear

faster in the shoulder area particularly in front

positions. Radial

tires in non-drive

iocations may

develop an irregular wear pattern that can increase tire

noise if not rotated. This makes regular rotation

especially necessary.

After rotation, be sure to check wheel nuts for

specified torque.

On

F Carline with P245/50VR16 tires and 16"

wheels, special rotation provisions must be followed.

Since the tires are directional, and the front and rear

wheels have different offsets, the tires must be

dismounted from the wheels for rotation. Remove the

tires from the wheels, and mount on the appropriate

wheel, as shown in the rotation diagram. Be sure the

arrows on the tires point in the direction the tire turns.

Rebalance the

tire/wheel assemblies using

nylon-coated weights. Adjust

F/R tire pressures, and

torque wheel nuts to specifications.

ACCEPTABLE ROTATION PATTERN

FOR REAR WHEEL

DRIVE GARS

DO NOT INCLUDE "TEMPORARY USE ONLY" SPARE TlRE IN ROTATION

Fig. 5 Tire Rotation - Rear-Wheel Drive

Page 235 of 1825

3E.4 TIRES AND WHEELS

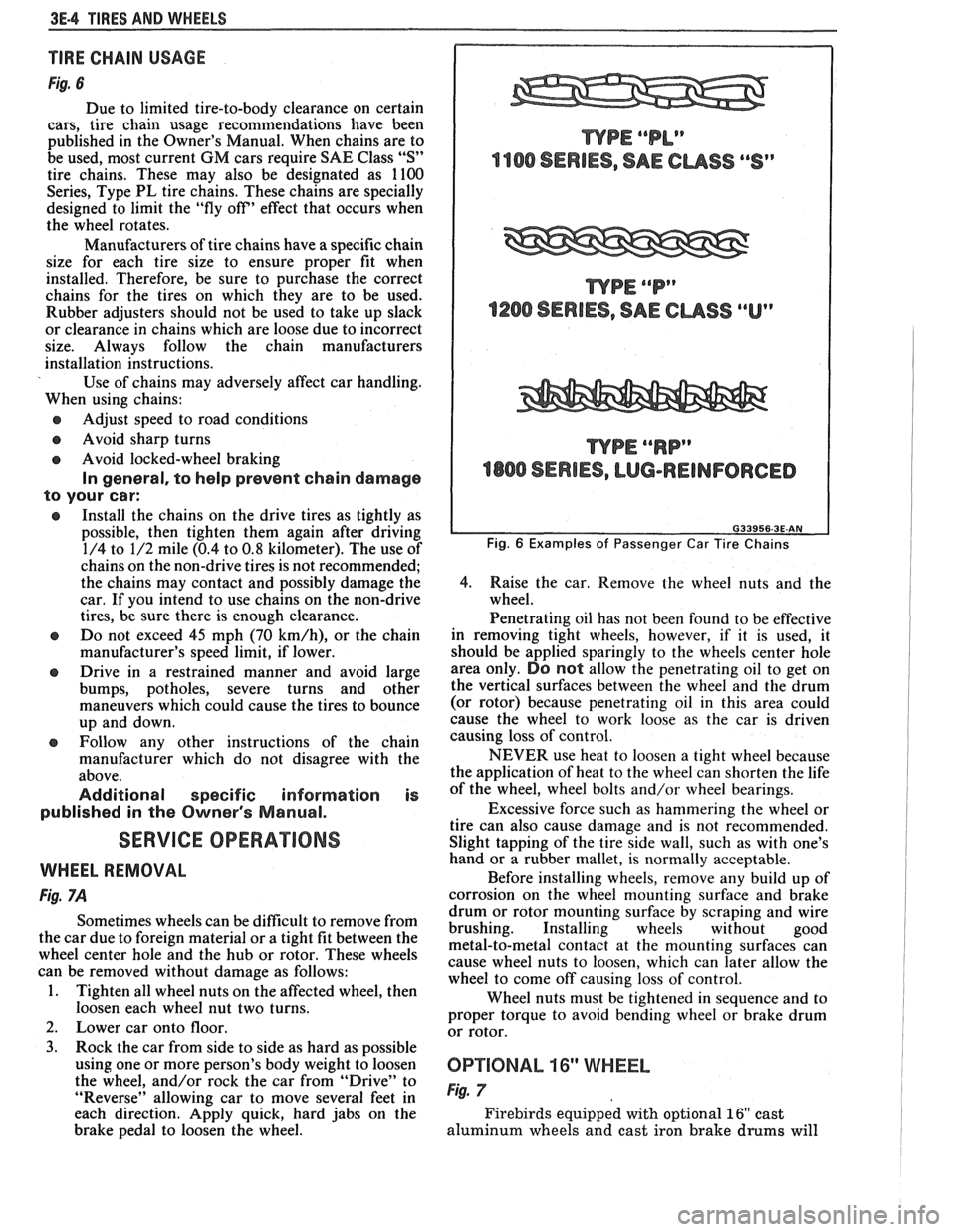

TIRE CHAIN USAGE

Fig. 6

Due to limited tire-to-body clearance on certain

cars, tire chain usage recommendations have been

published in the Owner's Manual. When chains are to

be used, most current

GM cars require SAE Class "S"

tire chains. These may also be designated as 1100

Series, Type PL tire chains. These chains are specially

designed to limit the "fly off' effect that occurs when

the wheel rotates.

Manufacturers of tire chains have a specific chain

size for each tire size to ensure proper fit when

installed. Therefore, be sure to purchase the correct

chains for the tires on which they are to be used.

Rubber adjusters should not be used to take up slack

or clearance in chains which are loose due to incorrect

size. Always follow the chain manufacturers

installation instructions.

Use of chains may adversely affect car handling.

When using chains:

@ Adjust speed to road conditions

@ Avoid sharp turns

@ Avoid locked-wheel braking

In general, to help prevent chain damage

to your car:

@ Install the chains on the drive tires as tightly as

possible, then tighten them again after driving

1/4 to 1/2 mile (0.4 to

0.8 kilometer). The use of

chains on the non-drive tires is not recommended;

the chains may contact and possibly damage the

car. If you intend to use chains on the non-drive

tires, be sure there is enough clearance.

e Do not exceed 45 mph (70 km/h), or the chain

manufacturer's speed limit, if lower.

@ Drive in a restrained manner and avoid large

bumps, potholes, severe turns and other

maneuvers which could cause the tires to bounce

up and down.

e Follow any other instructions of the chain

manufacturer which do not disagree with the

above.

Additional specific information is

published in the Owner's Manual.

SERVICE OPERATIONS

WHEEL REMOVAL

Fig. 7A

Sometimes wheels can be difficult to remove from

the car due to foreign material or a tight fit between the

wheel center hole and the hub or rotor. These wheels

can be removed without damage as follows:

1. Tighten all wheel nuts on the affected wheel, then

loosen each wheel nut two turns.

2. Lower car onto floor.

3. Rock the car from side to side as hard as possible

using one or more person's body weight to loosen

the wheel, and/or rock the car from

"Drive" to

"Reverse" allowing car to move several feet in

each direction. Apply quick, hard jabs on the

brake pedal to loosen the wheel.

WPE ""P"

1200 SERIES, SAE CUSS ""Up

WPE ""RP"

4800 SERIES, LUG-REINFORCED

Fig. 6 Examples of Passenger Car Tire Chains

4.

Raise the car. Remove the wheel nuts and the

wheel.

Penetrating oil has not been found to be effective

in removing tight wheels, however,

if it is used, it

should be applied sparingly to the wheels center hole

area only.

DO not allow the penetrating oil to get on

the vertical surfaces between the wheel and the drum

(or rotor) because penetrating oil in this area could

cause the wheel to work loose as the car is driven

causing loss of control.

NEVER use heat to loosen a tight wheel because

the application of heat to the wheel can shorten the life

of the wheel, wheel bolts and/or wheel bearings.

Excessive force such as hammering the wheel or

tire can also cause damage and is not recommended.

Slight tapping of the tire side wall, such as with one's

hand or a rubber mallet, is normally acceptable.

Before installing wheels, remove any build up of

corrosion on the wheel mounting surface and brake

drum or rotor mounting surface by scraping and wire

brushing. Installing wheels without good

metal-to-metal contact at the mounting surfaces can

cause wheel nuts to loosen, which can later allow the

wheel to come off causing loss of control.

Wheel nuts must be tightened in sequence and to

proper torque to avoid bending wheel or brake drum

or rotor.

0P"FIONAL 16" WHEEL

Fig. 7

Firebirds equipped with optional 16" cast

aluminum wheels and cast iron brake

drums will

Page 257 of 1825

481-4 REAR AXLE

Gear Noise

Gear noise (whine) is audible from 20 to 55 mph

under four driving conditions:

1. Light Acceleration - Accelerate slowly.

2. Road Load

- Car

driving load or constant speed.

3. Float - Using enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast - Throttle closed and car in gear.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

Knock At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Backlash Clunk

Excessive clunk with acceleration and deceleration

is caused by worn differential pinion gear shaft, excessive

clearance between axle shaft and side gear splines, exces-

sive clearance between side gear hub and counterbore in

case, worn pinion and side gear teeth, worn thrust washers

and excessive drive pinion and ring gear backlash. Re-

move worn parts and replace as required, selecting close

fitting parts when possible. Adjust pinion and ring gear

backlash.

DIAGNOSIS

1. Noise

is the same in "Light Acceleration" or

"Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

d. Rear axle bearing noise.

2. Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

3. Noise tone lowers as car speed is lowered.

a. Tire noise.

b. Front

wheel bearings and rear axle bearings.

c. Gear noise.

4. Similar noise is produced with car standing and

driving. a.

Engine noise.

b. Transmission noise.

c. Exhaust noise.

5. Vibration.

a. Rough rear axle bearing.

b. Unbalanced or damaged propeller shaft.

c. Tire unbalance.

d. Worn universal joint in propeller shaft.

e. Mis-indexed propeller shaft at pinion

flange.

f. Pinion flange runout too great.

6. A knock or click approximately every two

revolutions of the rear wheel.

a. A rear axle bearing.

b. Worn case.

7. Noise most pronounced on turns.

a. Rear axle side gear and pinion noise,

differential gear noise.

b. Axle bearings.

8. A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. All bearing noise.

9. Drive noise, coast noise or float noise.

a. Ring

and pinion gear noise.

b. Front

pinion bearing noise, coast or drive.

c. Axle bearing noise.

10. Clunk

on

acceleration or deceleration.

a. Worn

rear axle pinion shaft splines.

b. Side

gear hub counterbore in case worn

oversize.

c. Worn U-joints.

d. Excessive transmission backlash.

e. Worn axle shaft splines.

11. Chatter on turns.

a. Wrong

lube in rear axle.

b. Clutch

cone worn or spalled.

12. Clunk

or knock on rough road operation.

a. Worn suspension bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A carefull diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Before disassembling the rear axle, the following

checks should be made with the results recorded and

analyzed: 1) Backlash;

2) Total Assembly Preload; 3)

Tooth Contact Pattern Test; 4) Fluid Level; and 5)

Fluid Contamination.

If axle shaft end play is excessive then check

bearings, retainer, and bolts securing backing plate.

The axle bearings could be worn and need replacement.

The four bolts or nuts securing the brake backing plate

may be loose, stripped, or missing. If the inner bearing

retainer worked loose it must be replaced.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

Page 264 of 1825

REAR AXLE 4Bl-I I

Fig. 11 Installing Wheel Bolt

Loosen parking brake cable adjuster nut and

remove two parking brake cables from adjuster

and body clips.

Shock absorbers from axle.

Track bar from rear axle and body.

Stabilizer bar links from axle and bushings.

Mark propeller shaft and companion flange, then

disconnect and remove propeller shaft.

Brake line junction block bolt at axle housing,

then disconnect brake lines at wheel cylinders.

Brake lines from clips.

Lower rear axle and remove springs.

Torque arm from rear axle.

Lower control arms from rear axle.

Lower hoist and remove rear axle assembly from

vehicle.

Install or Connect

Raise hoist and rear axle assembly.

Lower control arms to rear axle.

Torque arm to rear axle.

Springs and raise rear axle assembly.

Brake lines to clips.

Brake line junction block bolt at axle housing,

then connect brake lines at wheel cylinders or

calipers.

Align drive shaft and pinion flange, then install

drive shaft and connect.

Stabilizer bushings and links to axle.

Track bar to body and rear axle.

Shock absorbers to axle.

Parking brake cables to body clips and cable

adjuster, then tighten parking brake cable

adjuster nut.

Wheels and tighten lug nuts.

Frame supports and lower hoist.

NOTICE: Lubricant level is to the bottom of the

filler plug hole. Use only the specified lubricant.

(Refer to Specifications).

Before attempting any service procedures the

technician must know what type rear axle is to be

serviced. Refer to chart (Rear Axle Codes And

Identification) to identify codes, ring gear size, and ratios.

Remember that all ring gear bolts have

L.H.

threads.

Most rear axle service repairs can be made by

supporting the car by the frame with the axle housing

supported and lowered to its lowest travel. On some

models it may be necessary to disconnect shock

absorbers to obtain additional clearance. When doing

this, do not allow the rear brake hose to become

kinked

or stretched.

Lubricant may be drained by backing out all

cover bolts and breaking cover loose at the bottom.

If the rear axle housing is removed for any reason,

rear axle service can be performed on the bench.

When a new ring gear and pinion is installed, the

owner should be advised not to accelerate rapidly or

exceed 50 mph for the first 50 miles of driving.

It is necessary to perform a service diagnosis

before disassembly of the rear axle. Check all fasteners

with torque wrench for correct torque. Check level and

condition of fluid.

If fluid is contaminated the rear axle

will require disassembly and a complete inspection and

cleaning. The bearing preloads should be checked with

a torque wrench. A dial indicator reading should be

made for run out of ring gear and backlash between

ring and pinion gear. Use specifications from chart

below to perform suggested diagnostic checks. Roll

gears and paint to read out pattern.

DRAIN REAR AXLE ASSEMBLY

1. Loosen cover and pry cover away from carrier.

2. Let axle fluids drain from carrier.

3. Remove cover bolts and cover from carrier.

4. Scrape off gasket and sealer from cover and

carrier.

Remove or Disconnect

Differential Assembly

1. Bearing caps and bolts. Identify bearing caps with

paint. The bearing caps are not interchangeable.

2. The differential assembly is worked out of the

carrier by putting a box wrench on ring gear bolt.

The box wrench contacts back of housing when

companion

tlange is rotated with tool 3-8614-01.

When the differential assembly rotates out of the

carrier from pinion rotation the shims will also

come out. The shims and bearing caps location,

left or right, must be identified for reassembly.

(Fig. 12).

3. Differential assembly from carrier.

Remove or Disconnect

Hypoid Pinion and Pinion Bearings

1. Pinion nut and companion flange from pinion

with companion flange tool 5-8614-01. (Fig. 8).

2. Drive pinion gear through rear of carrier with

soft face hammer.

Page 270 of 1825

REAR AXLE 4B1-17

e. Assemble oiled oil seal, companion

flange, and new nut on pinion and tighten

nut to specified rotational torque while

rotating pinion forwards to seat bearing

correctly.

Important

NOTICE: If after tightening pinion nut, the

preload is excessive then the collapsible spacer

must be replaced and procedure (d) and (e)

repeated.

OPERATION OF LIMITED SLIP REAR AXLE

(CONE TYPE)

The cone-type limited-slip differential has several

definite operating characteristics. An understanding of

these characteristics is necessary as an aid to diagnosis.

During regular operation (straight ahead driving)

when both wheels rotate at equal speeds, there is an

approximately equal driving force delivered to each

wheel. When cornering, the inside wheel delivers extra

driving force causing slippage in both clutch cones.

Consequently, the operational life of the limited slip

unit is dependent upon equal rotation of both wheels

during straight ahead operation. If wheel rotation for

both rear wheels is not equal during straight ahead

operation, the limited-slip unit will constantly be

functioning as if the vehicle were cornering. This will

impose constant slippage on the clutch cones and will

eventually lead to abnormal wear on the clutch cones.

Therefore, it is important that there be no excessive differences in

the rear wheel tire sizes, air pressures, or

tire wear patterns. One indication of this condition is

"swerving on acceleration." If swerving on

acceleration is encountered, check the rear wheels for

different tire size, air pressure, or excessively different

wear patterns, and tread depths, before proceeding into

an overhaul operation.

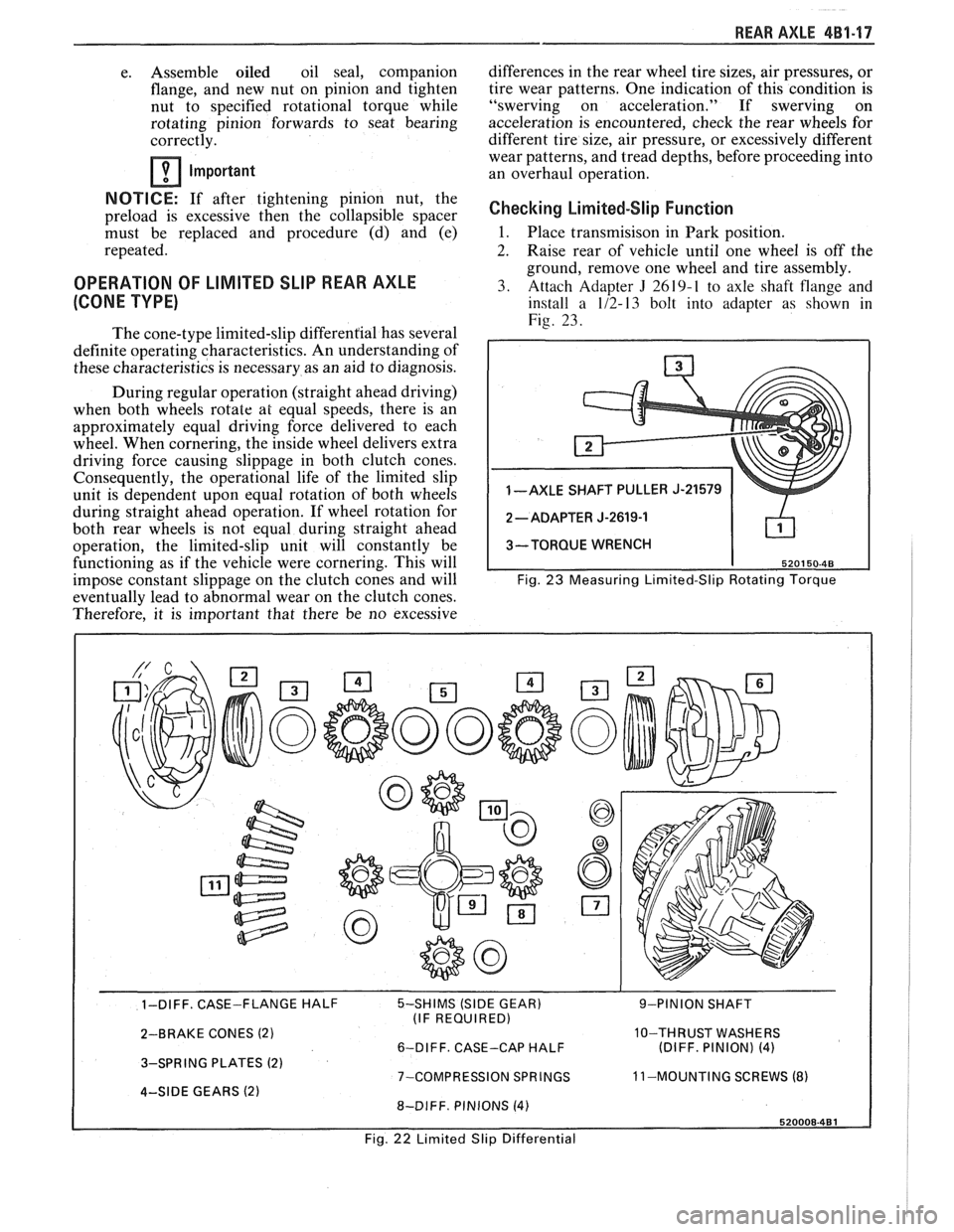

Checking Limited-Slip Function

1. Place transmisison in Park position.

2. Raise rear of vehicle until one wheel is off the

ground, remove one wheel and tire assembly.

3. Attach Adapter

J 2619-1 to axle shaft flange and

install a 1/2-13 bolt into adapter as shown in

Fig. 23.

1 -AXLE SHAFT PULLER J-21579

3-TORQUE WRENCH

Fig.

23 Measuring Limited-Slip Rotating Torque

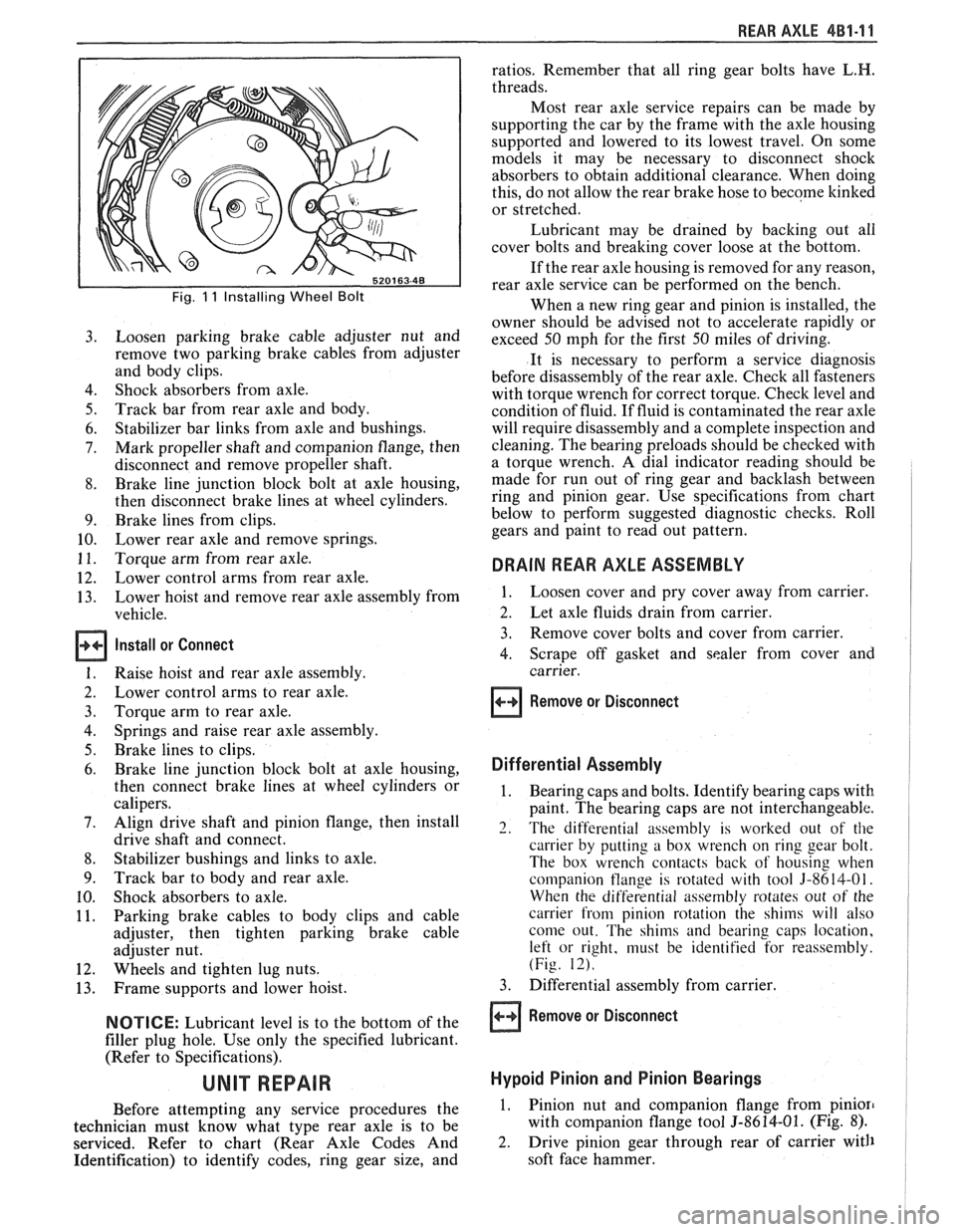

- - 1-DIFF. CASE-FLANGE HALF 5-SHIMS (SIDE GEAR) 9-PINION SHAFT

(IF REQUIRED)

2-BRAKE CONES

(2) 10-THRUST WASHERS

6-DIFF. CASE-CAP HALF (DIFF. PINION) (4)

3-SPRING PLATES (2) 7-COMPRESSION SPRINGS 11

-MOUNTING SCREWS (8) 4-SIDE GEARS (2) 8-DIFF. PINIONS (4)

Fig. 22 Limited Slip Differential

Page 271 of 1825

484-18 REAR AXLE

4. With transmission in park and both wheels and

tires clear of ground, (wheels will r~tate in opp-

osite directions), measure torque required to

rotateaxle shafts with a torque

wrenchattached

to J 2619-1. If the torque reading is less than

48 N.m (35 1b.ft.) the unit should be disassembled

and repaired as required.

5. Reinstall wheel and tire assembly.

Disassemble

Limited Slip Differential.

1. Remove ring gear bolts.

NOTICE: Left hand threaded ring gear bolts.

2. Tap

ring gear off differential housing with soft

face hammer.

NOTICE: Mark differential case halves with

alignment mark before disassembly because they

could be assembled

180" off from original position.

3. Remove 8 screws holding differential housing

halves together and separate halves. 4.

Remove pinion shaft, 4 differential pinions,

thrust washers side gears, side gear shims

(if

required), spring plates, and compression springs

from housing. Discard compression springs. New

springs are required for assembly.

5. Mark each cone during disassembly to ensure

that the same brake cone will be assembled with

the same case as originally assembled. If shims

are used they must be marked so that they will be

assembled in original case half.

6. If differential bearings are damaged remove with

tool J-22888-D. (Fig. 15).

Inspect

Disassemble

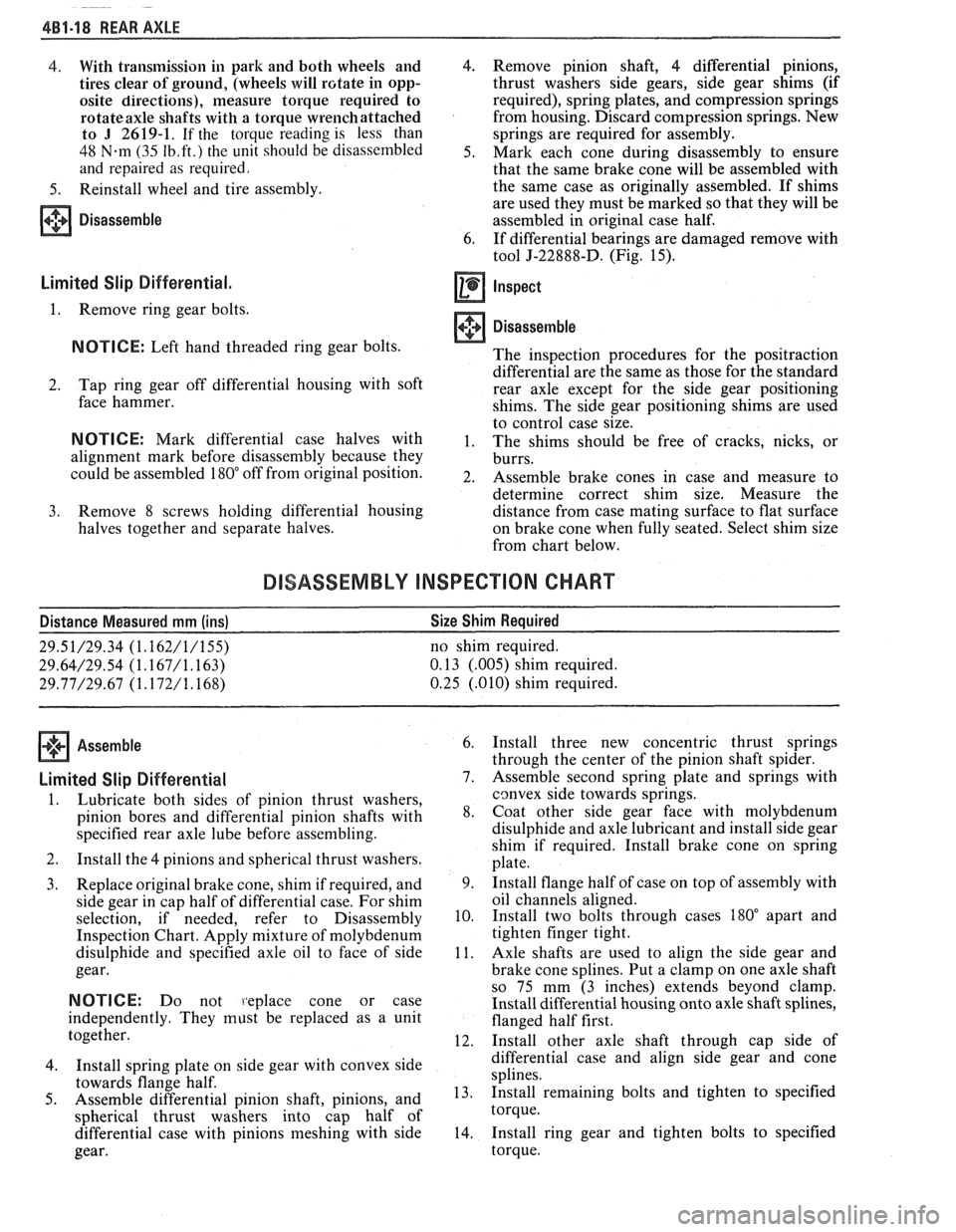

The inspection procedures for the positraction

differential are the same as those for the standard

rear axle except for the side gear positioning

shims. The side gear positioning shims are used

to control case size.

1. The shims should be free of cracks, nicks, or

burrs.

2. Assemble brake cones in case and measure to

determine correct shim size. Measure the

distance from case mating surface to flat surface

on brake cone when fully seated. Select shim size

from chart below.

DISASSEMBLY INSPECTION CHART

Distance Measured mm (ins) Size

Shim Required

29.51/29.34 (1.162/1/155) no shim required.

29.64/29.54 (1.167/1.163) 0.13 (.005) shim required.

29.77D9.67 (1.172/1.168) 0.25 (.010) shim required.

Assemble

Limited Slip Differential

1.

Lubricate both sides of pinion thrust washers,

pinion bores and differential pinion shafts with

specified rear axle lube before assembling.

2. Install the 4 pinions and spherical thrust washers.

3. Replace original brake cone, shim if required, and

side gear in cap half of differential case. For shim

selection, if needed, refer to Disassembly

Inspection Chart. Apply mixture of molybdenum

disulphide and specified axle oil to face of side

gear.

NOTICE: Do not 1.eplace cone or case

independently. They must be replaced as a unit

together.

4. Install spring

plate on side gear with convex side

towards flange half.

5. Assemble differential pinion shaft, pinions, and

spherical thrust washers into cap half of

differential case with pinions meshing with side

gear. 6.

Install three new concentric thrust springs

through the center of the pinion shaft spider.

7. Assemble second spring plate and springs with

cgnvex side towards springs.

8. Coat other side gear face with molybdenum

disulphide and axle lubricant and install side gear

shim if required. Install brake cone on spring

plate.

9. Install

flange half of case on top of assembly with

oil channels aligned.

10. Install

two bolts through cases

180" apart and

tighten finger tight.

11. Axle shafts are used to align the side gear and

brake cone splines. Put a clamp on one axle shaft

so 75 mm (3 inches) extends beyond clamp.

Install differential housing onto axle shaft splines,

flanged half first.

12. Install other axle shaft through cap side of

differential case and align side gear and cone

splines.

13. Install remaining

bolts and tighten to specified

torque.

14. Install

ring gear and tighten bolts to specified

torque.

Page 276 of 1825

REAR AXLE 4B-3

Noise which originates in other places cannot be

corrected by adjustment or replacement of parts in the

differential. It should also be remembered that rear

axle gears, like any other mechanical device, are not

absolutely quiet and should be accepted as being

commercially quiet unless some abnormal noise is

present.

To make a systematic check for axle noise under

standard conditions, observe the following:

1. Select a level smooth asphalt road to reduce tire

noise and body drumming.

2. Check rear axle lubricant to assure correct level,

then drive car far enough to thoroughly warm up

rear axle lubricant.

3. Note speed and RPM at which noise occurs. Then

stop car and with automatic transmission in neutral,

run engine slowly up and down through engine speeds, corresponding to car speed at which noise

was most pronounced, to determine if it is caused by

exhaust, muffler roar or other engine conditions.

4. Tire noise changes with different road surfaces,

but rear axle noise does not. Temporarily

inflating all tires to approximately 50 pounds

pressure for

test purposes only will materially

alter noise caused by tires, but will not affect noise

caused by rear axle. Rear axle noise usually stops

when coasting at speeds under 30 miles per hour;

however, tire noise continues, but with lower

tone, as car speed is reduced. Rear axle noise

usually changes when comparing acceleration

and coast, but tire noise remains about the same.

Distinguish between tire noise and rear axle noise

by noting if noise varies with various speeds or

sudden acceleration and deceleration; exhaust

and axle noise show variations under these

conditions while tire noise remains constant and

is more pronounced at speeds of 20 to 30 miles

per hour. Further check for tire noise by driving

car over smooth pavements or dirt roads (not

gravel) with tires at normal pressure. If noise is

caused by tires, it will noticeably change or

disappear and reappear with changes in road

surface.

5. Loose or rough front wheel bearings will cause

noise which may be confused with rear axle

noises; however, front wheel bearing noise does

not change when comparing drive and coast.

Light application of brakes while holding car

speed steady will often cause wheel bearing noise

to diminish, as this takes some weight off the

bearing. Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that no metallic

contact exists between the spring and spring

opening in frame or between upper and lower

control arm bushings and frame or axle housing

brackets.

Metal-to-metal contact at those points

may result in telegraphing road noise and normal axle

noise which would not be objectionable if

dampened by bushings.

AXLE NOISES

Gear Noise

After the noise has been determined as being in

the

axle by following the above appraisal procedure,

the type of axle noise should be determined to aid in

maki~~g repairs if necessary.

Gear noise (whine) is audible from 20 to

55 mph

under four driving conditions:

1. Drive - Acceleration or heavy pull.

2. Road Load - Car driving load or constant speed.

3. Float

- Using

enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast

- Throttle closed and car in gear. Gear

noise most frequently has periods where noise is

more prominent, usually 30 to 40 mph and 50 to

55 mph.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

I(noclc At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Baclclash Clunk

Excessive clunk with acceleration and

deceleration is caused by worn differential pinion shaft,

excessive clearance between axle shaft and side gear

splines, excessive clearance between side gear hub and

counterbore in case worn pinion and side gear teeth,

worn thrust washers and excessive drive pinion and

rear gear backlash. Remove worn parts and replace as

required, selecting close fitting parts when possible.

Adjust pinion and ring gear backlash.

REAR AXLE STANDARD AND LIMITED-SLIP

1. Noise is the same in "Drive" or "Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

Page 277 of 1825

4B-4 REAR AXLE

d. Incorrect driveline angle.

Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

Noise tone lowers as car speed is lowered.

a. Tire noise.

Similar noise is produced with car standing and

driving.

a. Engine noise.

b. Transmission noise.

Vibration. a. Rough rear wheel bearing.

b. Unbalanced

or damaged propeller shaft.

c. Tire unbalance.

d. Worn

universal joint in propeller shaft.

e. Incorrect driveline angle.

f. Mis-indexed propeller shaft at pinion

flange.

g. Pinion

flange

runout too great.

A knock or click approximately every two

revolutions of the rear wheel.

a. A rear wheel bearing.

Noise most pronounced on turns.

a. Rear

axle side gear and pinion noise.

A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. Pinion bearing noise.

Drive noise, coast noise or float noise.

a. Ring and

pinion gear noise.

Clunk on acceleration or deceleration.

a. Worn rear

axle pinion shaft in case or side

gear hub counterbore in case worn oversize.

b. Insufficient

lubrication on propeller shaft

slip yoke.

c. Worn U-joints on

propeller shaft. Front or

rear.

Groan in "Forward" or "Reverse".

a. Wrong

or contaminated lube in rear axle.

b. Worn bushings.

Chatter on turns.

a. Wrong

or contaminated lube in rear axle.

b. Clutch

cone worn and/or

spring(s) worn.

Clunk or knock on rough road operation.

a. Excessive end play of axle shafts to

differential cross shaft.

b. Worn bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A careful1 diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Therefore, before removing the rear axle from the

housing, the following checks should be made with the

results recorded and analyzed:

1) Backlash; 2) Total Assembly

Preload; 3) Tooth Contact Pattern Test;

4)

Fluid Level; and 5) Fluid Contamination.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

The pinion and ring gear must be completely

assembled, installed and all pre-load and backlash

adjustments completed prior to the start of this method

of pinion depth setting. The following procedure can

be used in place of the gage method of pinion depth

setting.

Gear Tooth Nomenclature

The side of the ring gear tooth which curves

outward, or is convex, is referred to as the "drive" side.

The concave side is the "coast" side. The end of the

tooth nearest center of ring gear is referred to as the

"toe" end. The end of the tooth farthest away from the

center is the "heel" end. Toe end of tooth is smaller

than heel end.

It is very important that tooth contact be tested

before the rear axle carrier assembly is disassembled.

Variations in the carrier or pinion rear bearing may

cause the pinion to be too far away from, or close to,

the ring gear. Thus, the tooth contact must be tested

and corrected, if necessary, or the gears may be noisy.

Tooth Contact Pattern Test

1. Wipe oil out of carrier and carefully clean each

tooth of ring gear.

2. Use gear marking compound part number

1052351 or equivalent and apply this mixture

sparingly to all ring gear teeth, using a medium

stiff brush. When properly used, the area of

pinion tooth contact will be visible when hand

load is applied.

3. Tighten bearing cap bolts to 75

N.m (55 lb. ft.).

4. Expand

brake shoes using parking brake cables

until a torque of 54 to

70 N-m (40-50 lb. ft.) is

required to turn the pinion.

A test made without loading the gears will not

give a satisfactory pattern. Turn pinion flange

with wrench so that ring gear rotates one full

revolution, then reverse rotation so that ring gear

rotates one revolution in opposite direction.

5. Observe

pattern on ring gear teeth and compare

with Fig. 3.

Effects of Increasing Load on Teeth Contact

Pattern

When "load" on ring and pinion gear is

increased, such as when car is accelerated forward

from standstill or from normal drive, the tooth contact

will tend to spread out and, under very heavy load, will

extend from near toe to near heel on the drive side. The

entire contact also tends to shift toward heel under

increasingly heavier loads and will become somewhat

broader with respect to tops and bottoms of teeth. The

patterns obtained by this tooth contact pattern test

approximate a light load and, for this reason, they will

extend only about halfway.