torque PONTIAC GTO 2005 Owners Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 2005, Model line: GTO, Model: PONTIAC GTO 2005Pages: 318, PDF Size: 2.06 MB

Page 83 of 318

Torque Lock (Automatic Transmission)

If you are parking on a hill and you do not shift your

transmission into PARK (P) properly, the weight of the

vehicle may put too much force on the parking pawl

in the transmission. You may find it difficult to move

the shift lever out of PARK (P). This is called torque lock.

To prevent torque lock, set the parking brake and

then shift into PARK (P) properly before you leave the

driver’s seat. To find out how, seeShifting Into Park (P)

(Automatic Transmission) on page 2-24.

When you are ready to drive, move the shift lever out of

PARK (P) before you release the parking brake.

If torque lock does occur, you may need to have another

vehicle push your vehicle uphill. This should take some of

the pressure from the parking pawl in the transmission,

so you can move the shift lever out of PARK (P).

Shifting Out of Park (P)

(Automatic Transmission)

Your vehicle has an automatic transmission shift lock

control system. You must fully apply your regular brakes

before you can press the button on the shift lever to

shift from PARK (P) while the ignition is ON. See

Automatic Transmission Operation on page 2-18.If you cannot shift out of PARK (P), ease pressure on

the shift lever by pushing it all the way into PARK (P)

while keeping the brake pedal down. Release the

shift lever button. Then move the shift lever out of

PARK (P), being sure to press the shift lever button.

Shift Lock Release

If you ever hold the brake pedal down but still cannot

shift out of PARK (P), try this:

1. Turn the ignition to LOCK to remove the key.

2. Remove the front console rubber insert, located in

front of the shift lever, by lifting upwards.

3. Remove the screw slightly to the right of the

front center.

4. Open the console storage compartment and pry

the console cover assembly from the console.

The cover is attached in six places.

5. Insert a tool into the opening in front of the shift

lever and move the yellow release lever forward.

6. Press the button on the shift lever to move lever out

of park.

7. Replace the console cap.

8. Have the vehicle fixed as soon as possible.

2-25

Page 224 of 318

Brake Wear

Your vehicle has four-wheel disc brakes.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque specifications.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a moderate brake stop, your disc

brakes adjust for wear. If you rarely make a moderate

or heavier stop, then your brakes might not adjust

correctly. If you drive in that way, then — very

carefully — make a few moderate brake stops about

every 1,000 miles (1 600 km), so your brakes will

adjust properly.

Replacing Brake System Parts

The braking system on a vehicle is complex. Its many

parts have to be of top quality and work well together if

the vehicle is to have really good braking. Your

vehicle was designed and tested with top-quality

GM brake parts. When you replace parts of your braking

system — for example, when your brake linings wear

down and you need new ones put in — be sure you get

new approved GM replacement parts. If you do not,

your brakes may no longer work properly. For example,

if someone puts in brake linings that are wrong for

your vehicle, the balance between your front and rear

brakes can change — for the worse. The braking

performance you have come to expect can change in

many other ways if someone puts in the wrong

replacement brake parts.

5-38

Page 249 of 318

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Tire and

Loading Information label. Make certain that all wheel

nuts are properly tightened. See “Wheel Nut Torque”

underCapacities and Specifications on page 5-90.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get all

the rust or dirt off. SeeChanging a Flat Tire on

page 5-68.

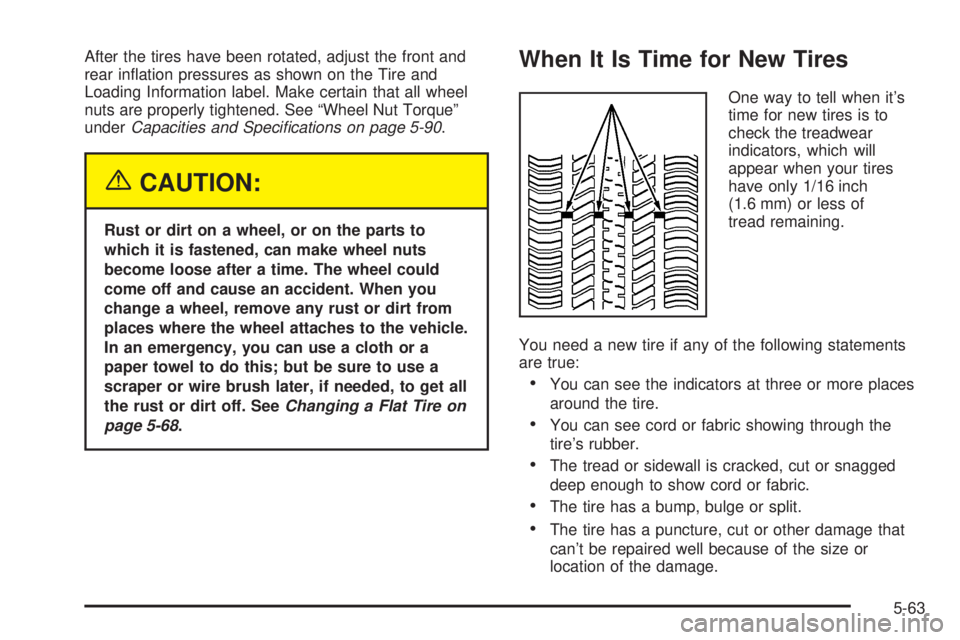

When It Is Time for New Tires

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of

tread remaining.

You need a new tire if any of the following statements

are true:

•You can see the indicators at three or more places

around the tire.

•You can see cord or fabric showing through the

tire’s rubber.

•The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

•The tire has a bump, bulge or split.

•The tire has a puncture, cut or other damage that

can’t be repaired well because of the size or

location of the damage.

5-63

Page 260 of 318

12. Lower the vehicle by turning the wheel wrench

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci�cation. SeeCapacities

and Specifications on page 5-90for wheel nut

torque speci�cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 5-90for the wheel nut

torque speci�cation.13. Tighten the wheel nuts

firmly in a crisscross

sequence, as shown.

Notice:Wheel covers will not �t on your compact

spare. If you try to put a wheel cover on the compact

spare, you could damage the cover or the spare.

Do not try to put a wheel cover on your compact spare

tire. It will not fit. Store a wheel cover in the trunk

until you have the flat tire repaired or replaced.

5-74

Page 276 of 318

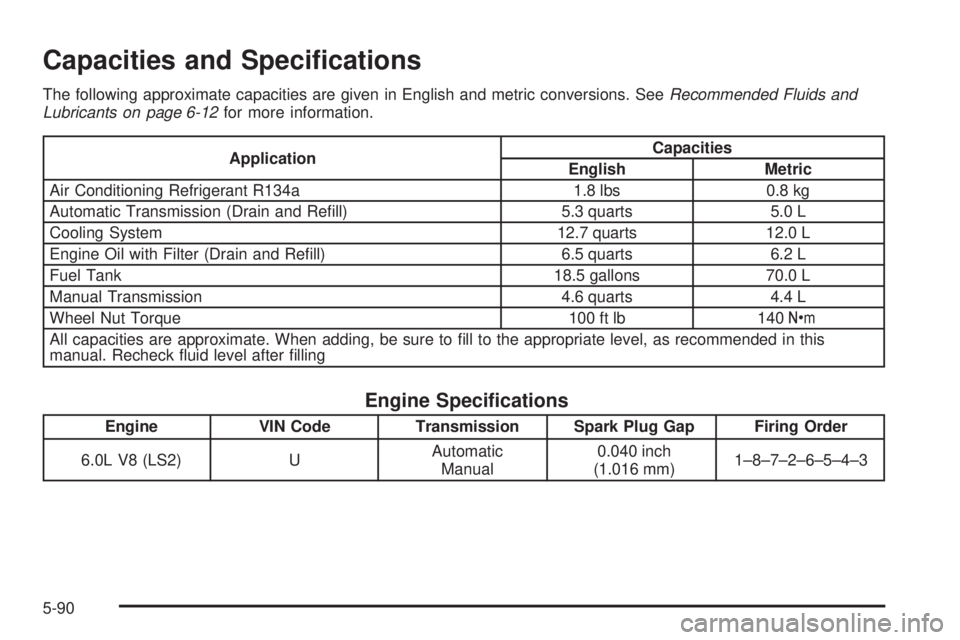

Capacities and Speci�cations

The following approximate capacities are given in English and metric conversions. SeeRecommended Fluids and

Lubricants on page 6-12for more information.

ApplicationCapacities

English Metric

Air Conditioning Refrigerant R134a 1.8 lbs 0.8 kg

Automatic Transmission (Drain and Refill) 5.3 quarts 5.0 L

Cooling System 12.7 quarts 12.0 L

Engine Oil with Filter (Drain and Refill) 6.5 quarts 6.2 L

Fuel Tank 18.5 gallons 70.0 L

Manual Transmission 4.6 quarts 4.4 L

Wheel Nut Torque 100 ft lb 140Y

All capacities are approximate. When adding, be sure to fill to the appropriate level, as recommended in this

manual. Recheck fluid level after filling

Engine Speci�cations

Engine VIN Code Transmission Spark Plug Gap Firing Order

6.0L V8 (LS2) UAutomatic

Manual0.040 inch

(1.016 mm)1–8–7–2–6–5–4–3

5-90