PORSCHE 911 CARRERA 2010 5.G Owners Manual

911 CARRERA 2010 5.G

PORSCHE

PORSCHE

https://www.carmanualsonline.info/img/22/7747/w960_7747-0.png

PORSCHE 911 CARRERA 2010 5.G Owners Manual

Trending: phone, AUX, oil type, reset, isofix, low oil pressure, oil level

Page 271 of 310

Practical Tips, Emergency Service

269

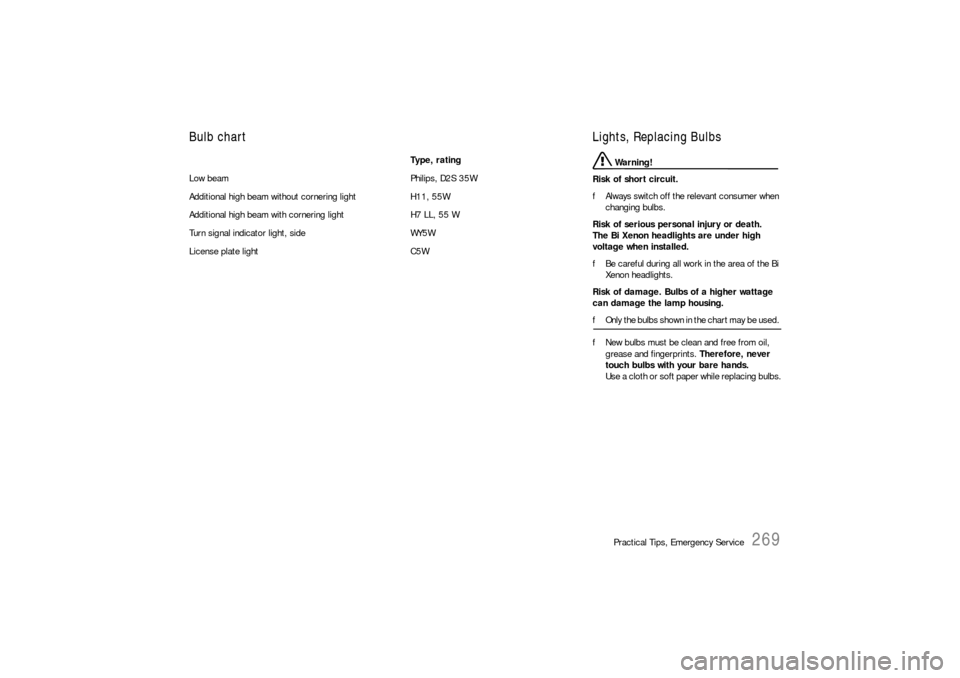

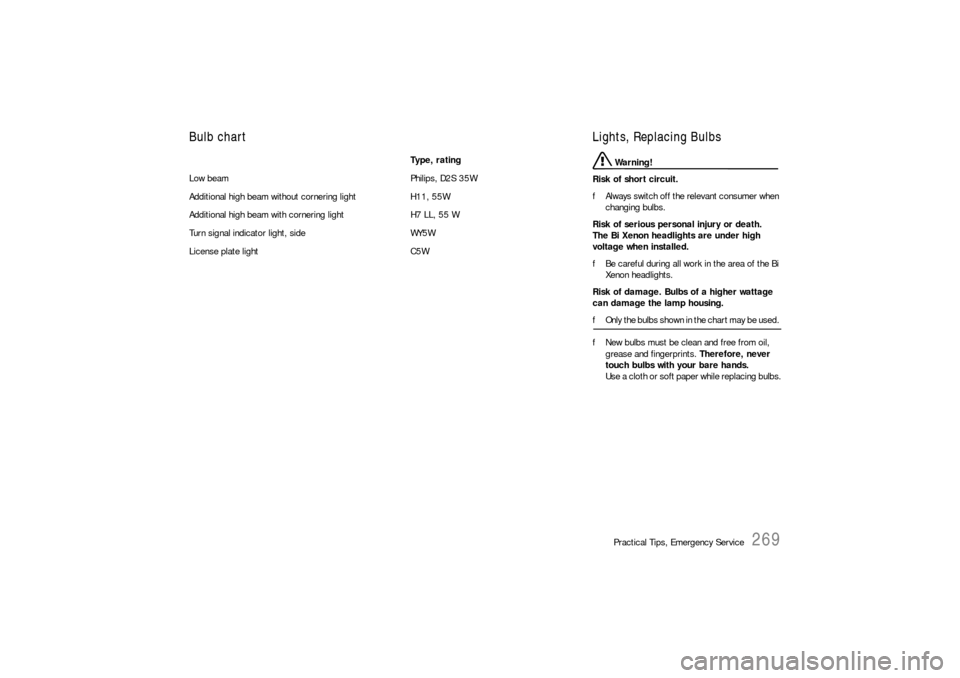

Bulb chart

Ty p e , r a t i n g

Low beam Philips, D2S 35W

Additional high beam without cornering light H11, 55W

Additional high beam with cornering light H7 LL, 55 W

Turn signal indicator light, side WY5W

License plate light C5W

Lights, Replacing Bulbs

Warning!

Risk of short circuit.

fAlways switch off the relevant consumer when

changing bulbs.

Risk of serious personal injury or death.

The Bi Xenon headlights are under high

voltage when installed.

fBe careful during all work in the area of the Bi

Xenon headlights.

Risk of damage. Bulbs of a higher wattage

can damage the lamp housing.

fOnly the bulbs shown in the chart may be used.

fNew bulbs must be clean and free from oil,

grease and fingerprints. Therefore, never

touch bulbs with your bare hands.

Use a cloth or soft paper while replacing bulbs.

Page 272 of 310

270

Practical Tips, Emergency Service

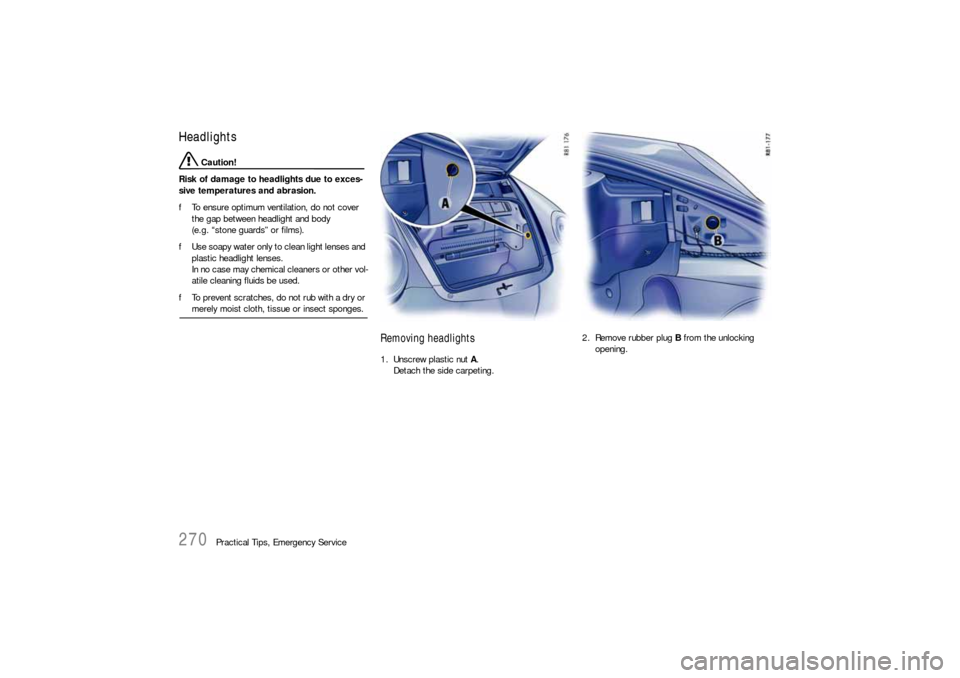

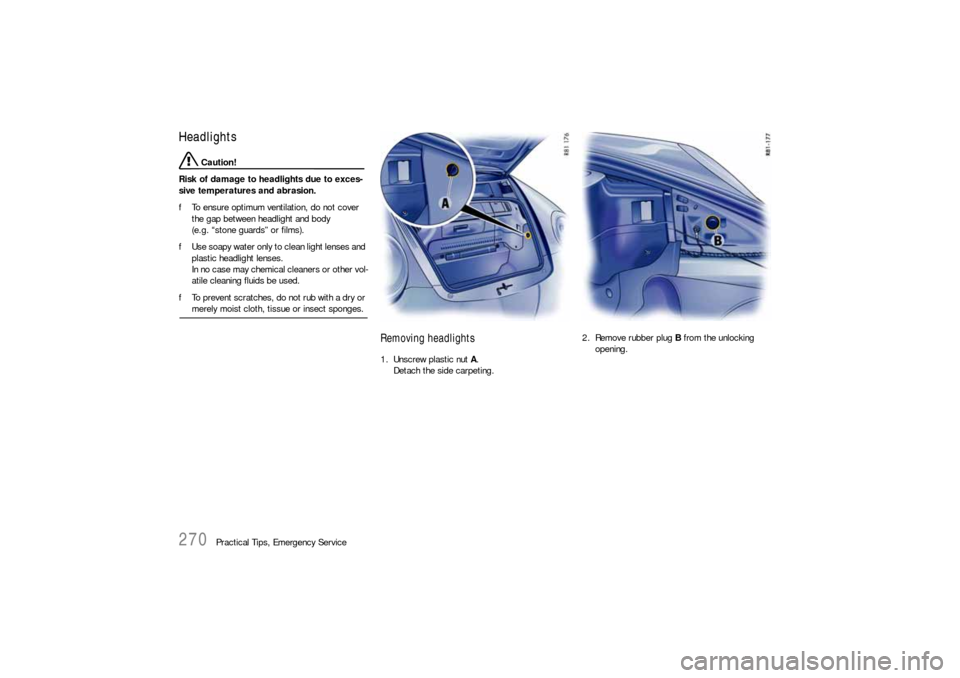

Headlights

Caution!

Risk of damage to headlights due to exces-

sive temperatures and abrasion.

fTo ensure optimum ventilation, do not cover

the gap between headlight and body

(e.g. “stone guards” or films).

fUse soapy water only to clean light lenses and

plastic headlight lenses.

In no case may chemical cleaners or other vol-

atile cleaning fluids be used.

fTo prevent scratches, do not rub with a dry or merely moist cloth, tissue or insect sponges.

Removing headlights1. Unscrew plastic nut A.

Detach the side carpeting.2. Remove rubber plug B from the unlocking

opening.

Page 273 of 310

Practical Tips, Emergency Service

271

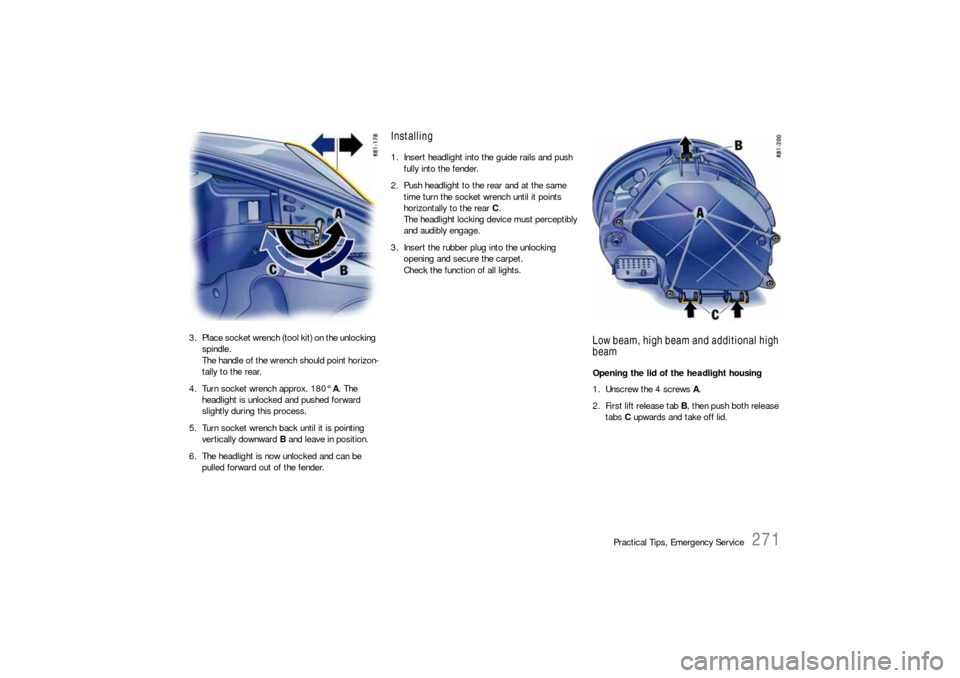

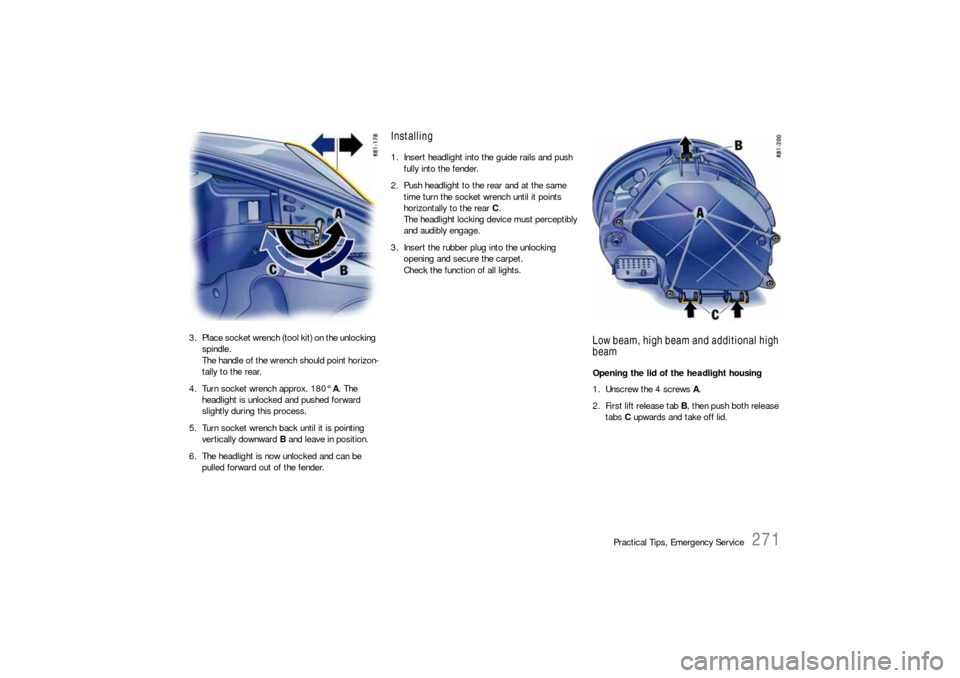

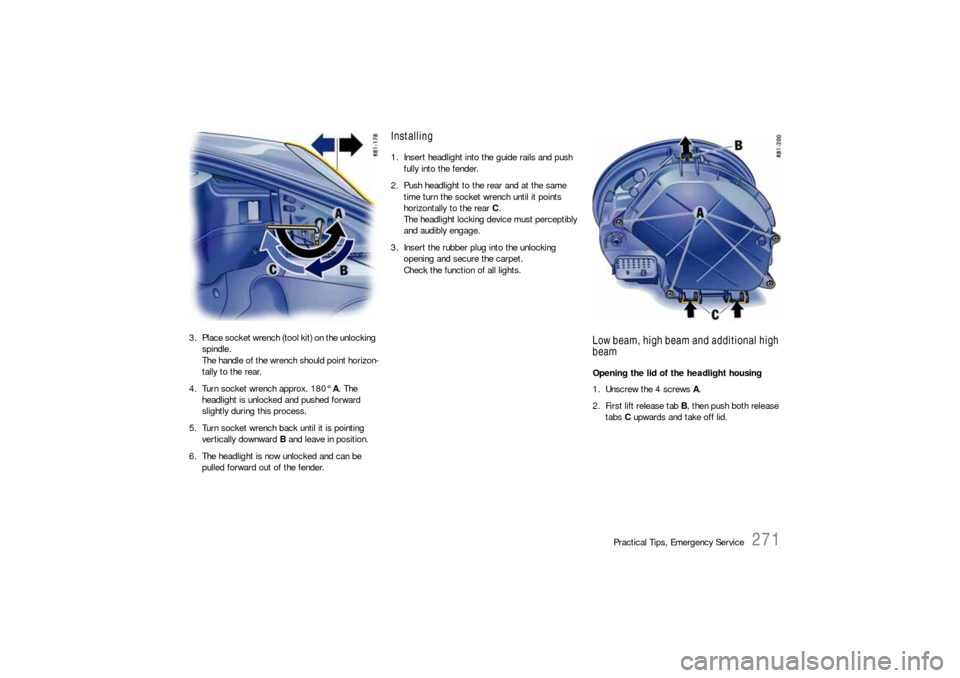

3. Place socket wrench (tool kit) on the unlocking

spindle.

The handle of the wrench should point horizon-

tally to the rear.

4. Turn socket wrench approx. 180° A. The

headlight is unlocked and pushed forward

slightly during this process.

5. Turn socket wrench back until it is pointing

vertically downward B and leave in position.

6. The headlight is now unlocked and can be

pulled forward out of the fender.

Installing1. Insert headlight into the guide rails and push

fully into the fender.

2. Push headlight to the rear and at the same

time turn the socket wrench until it points

horizontally to the rear C.

The headlight locking device must perceptibly

and audibly engage.

3. Insert the rubber plug into the unlocking

opening and secure the carpet.

Check the function of all lights.

Low beam, high beam and additional high

beamOpening the lid of the headlight housing

1. Unscrew the 4 screws A.

2. First lift release tab B, then push both release

tabs C upwards and take off lid.

Page 274 of 310

272

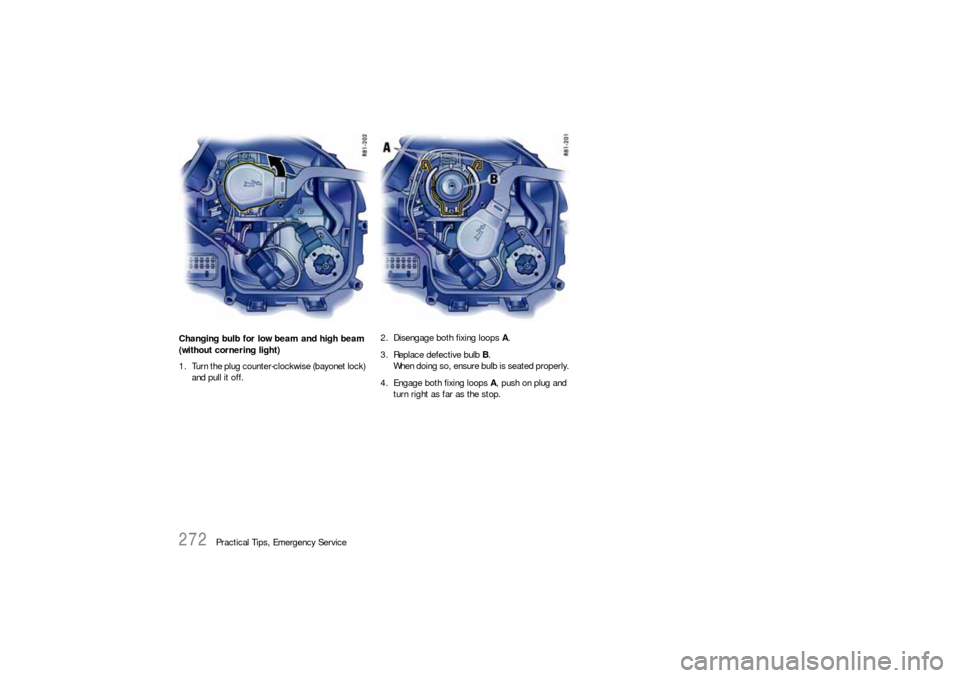

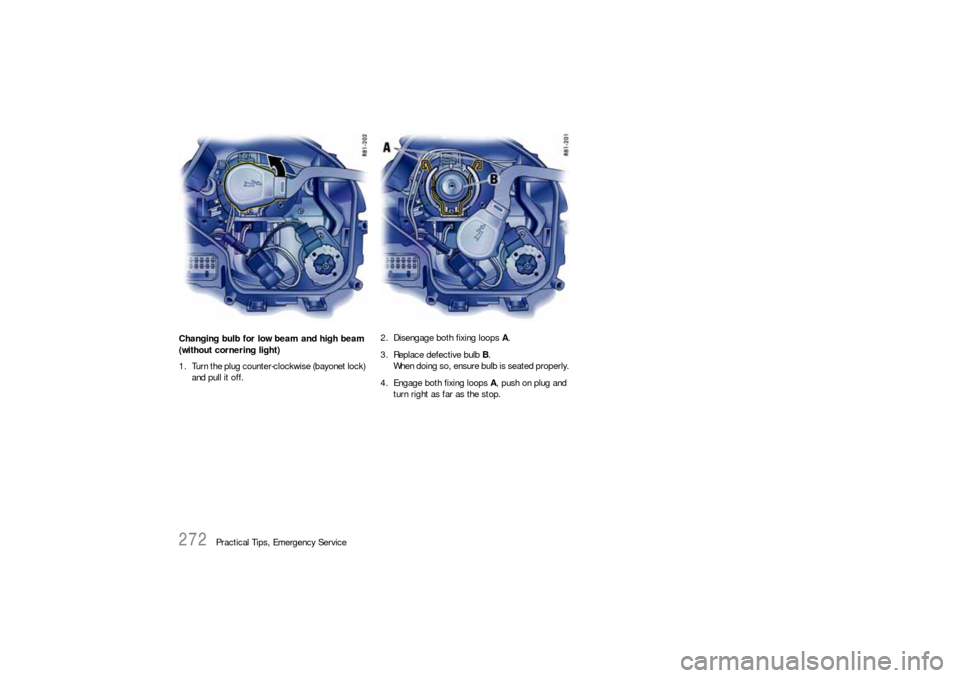

Practical Tips, Emergency Service Changing bulb for low beam and high beam

(without cornering light)

1. Turn the plug counter-clockwise (bayonet lock)

and pull it off.2. Disengage both fixing loops A.

3. Replace defective bulb B.

When doing so, ensure bulb is seated properly.

4. Engage both fixing loops A, push on plug and

turn right as far as the stop.

Page 275 of 310

Practical Tips, Emergency Service

273

Changing bulb for additional high beam

(without cornering light

1. Turn the bulb holder.

Turn it counter-clockwise on the left headlight

and clockwise on the right headlight.

Take bulb holder out of the headlight housing.2. Pull both plug release tabs apart.

Pull plug out of the bulb holder.

3. Replace the defective bulb with bulb holder.

4. Reassemble in reverse order.Closing lid of headlight housing

1. Push on lid until it perceptibly engages.

2. Fasten lid with the 4 screws.

Page 276 of 310

274

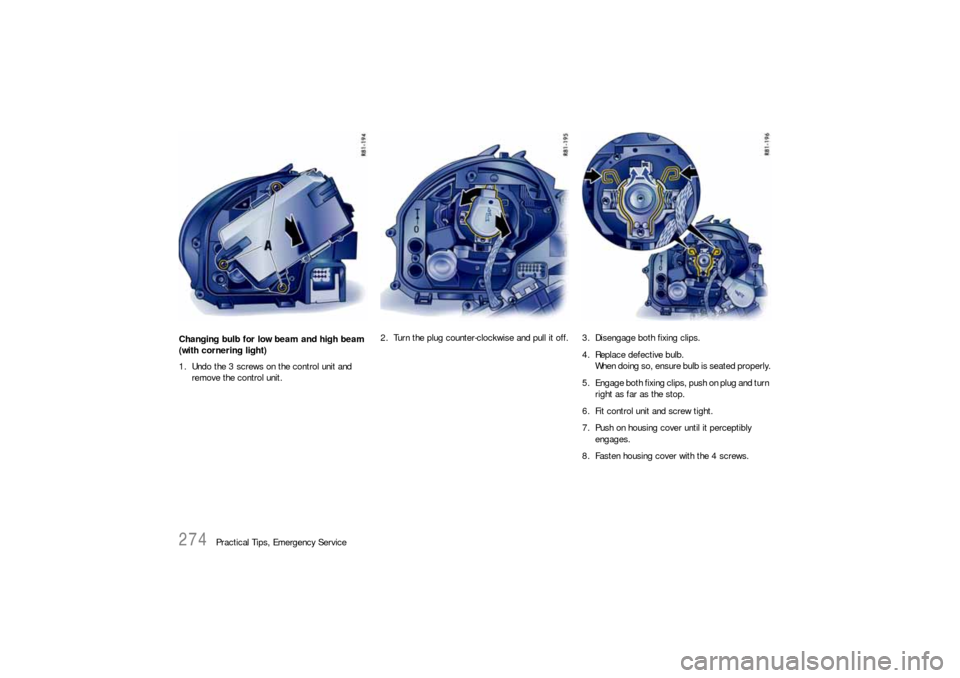

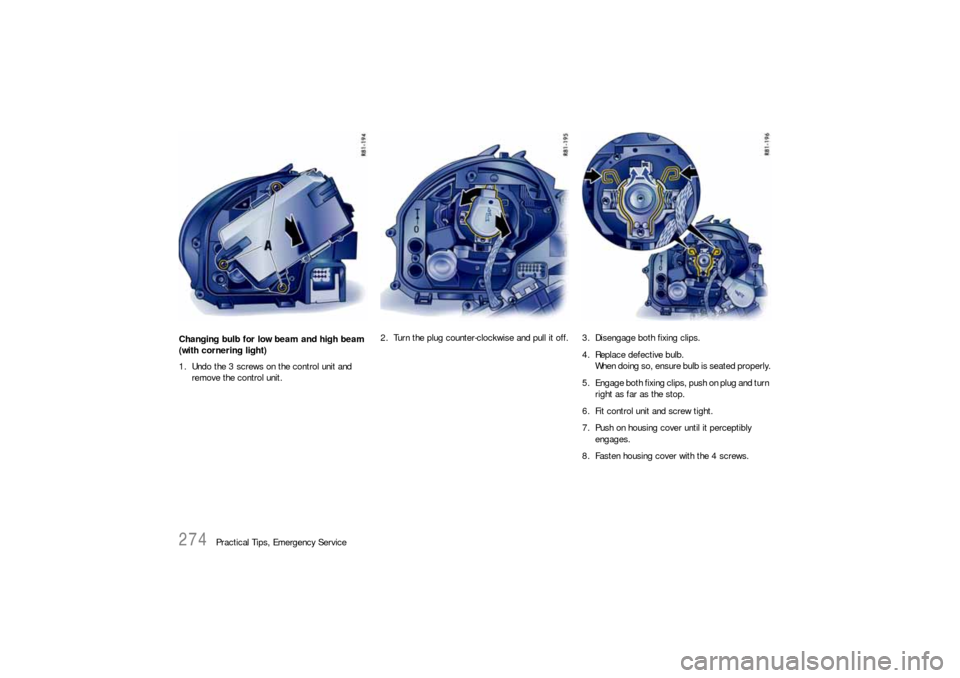

Practical Tips, Emergency Service Changing bulb for low beam and high beam

(with cornering light)

1. Undo the 3 screws on the control unit and

remove the control unit.2. Turn the plug counter-clockwise and pull it off. 3. Disengage both fixing clips.

4. Replace defective bulb.

When doing so, ensure bulb is seated properly.

5. Engage both fixing clips, push on plug and turn

right as far as the stop.

6. Fit control unit and screw tight.

7. Push on housing cover until it perceptibly

engages.

8. Fasten housing cover with the 4 screws.

Page 277 of 310

Practical Tips, Emergency Service

275

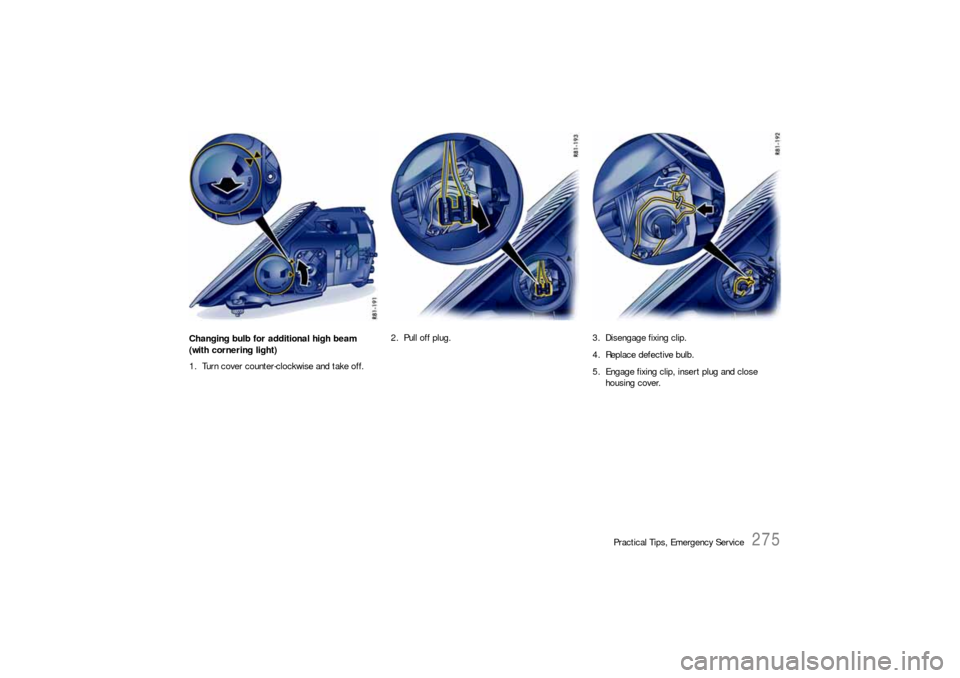

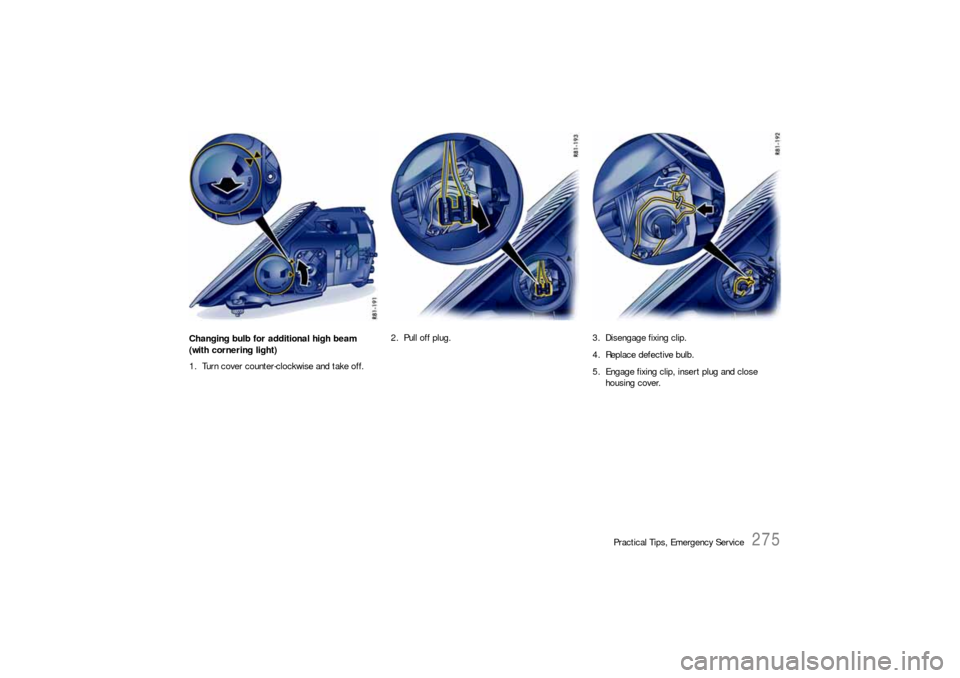

Changing bulb for additional high beam

(with cornering light)

1. Turn cover counter-clockwise and take off.2. Pull off plug. 3. Disengage fixing clip.

4. Replace defective bulb.

5. Engage fixing clip, insert plug and close

housing cover.

Page 278 of 310

276

Practical Tips, Emergency Service

Changing bulb for side marker light1. Remove the cap in the wheel housing liner with

a screwdriver.

2. Insert the screwdriver into the opening in the

wheel housing liner parallel to the turn signal

housing (in direction of travel).

By pressing with the screwdriver, disengage

the securing spring of the turn signal housing.3. Swivel out the indicator light and undo bulb

holder (bayonet lock).

4. Remove the bulb from the holder and replace

it. Insert holder.

Check operation of the light.

5. Insert the turn signal’s retaining lugs A into the

side section at the front.

Push in turn signal until the securing spring B

is felt to engage.

6. Press the cap into the wheel housing liner.

Page 279 of 310

Practical Tips, Emergency Service

277

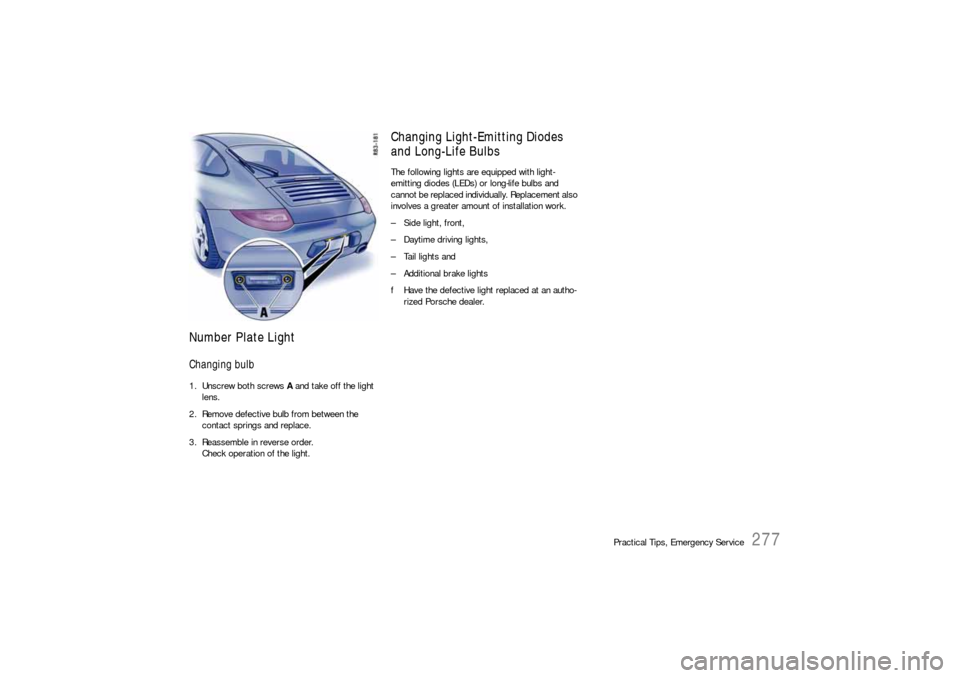

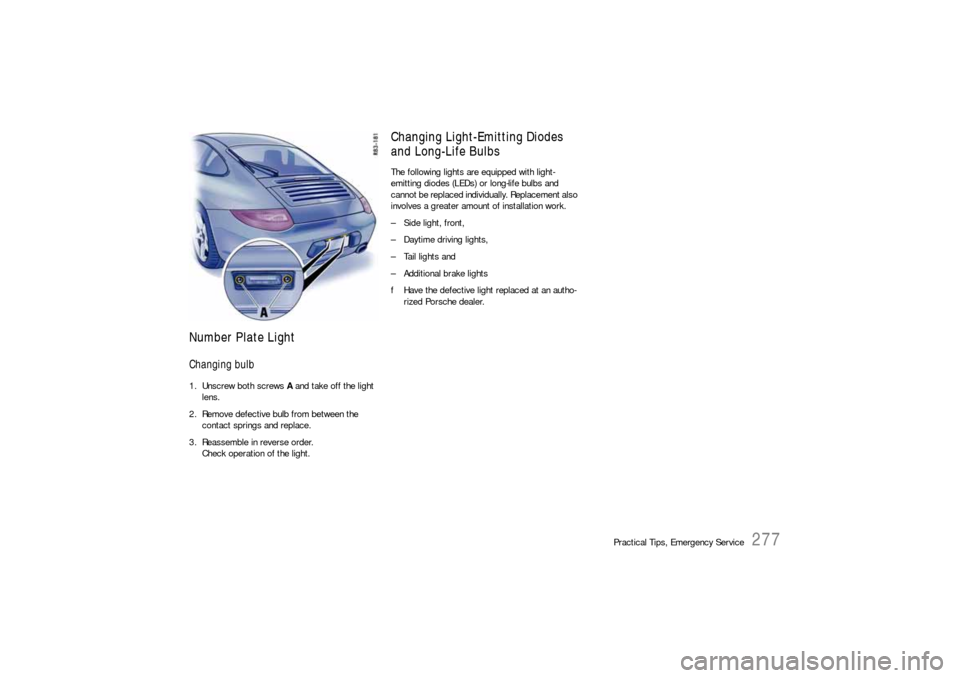

Number Plate LightChanging bulb1. Unscrew both screws A and take off the light

lens.

2. Remove defective bulb from between the

contact springs and replace.

3. Reassemble in reverse order.

Check operation of the light.

Changing Light-Emitting Diodes

and Long-Life BulbsThe following lights are equipped with light-

emitting diodes (LEDs) or long-life bulbs and

cannot be replaced individually. Replacement also

involves a greater amount of installation work.

– Side light, front,

– Daytime driving lights,

– Tail lights and

– Additional brake lights

fHave the defective light replaced at an autho-

rized Porsche dealer.

Page 280 of 310

278

Practical Tips, Emergency Service

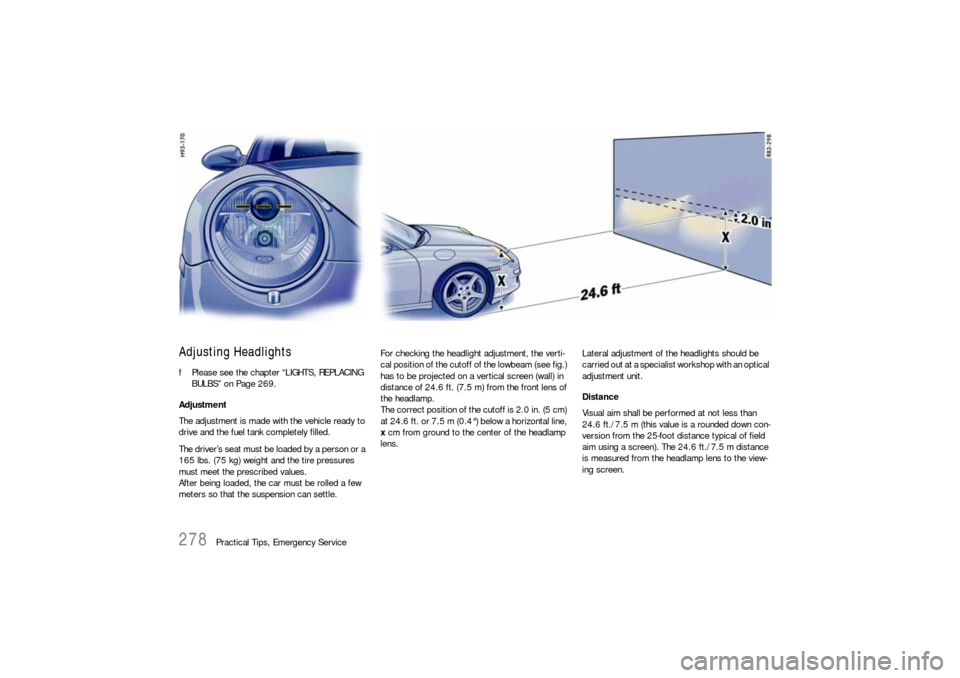

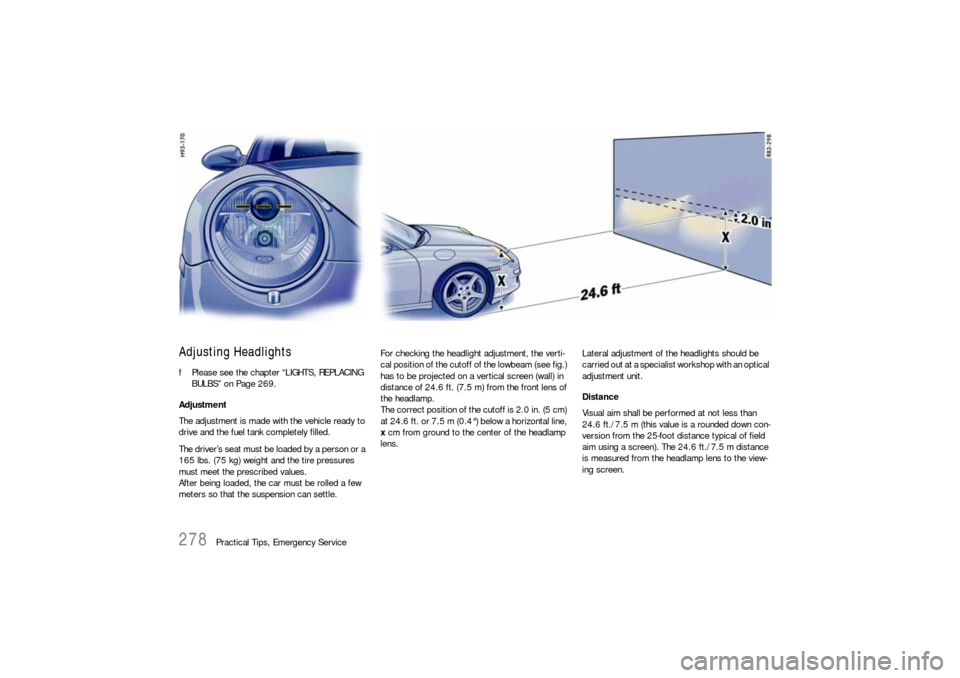

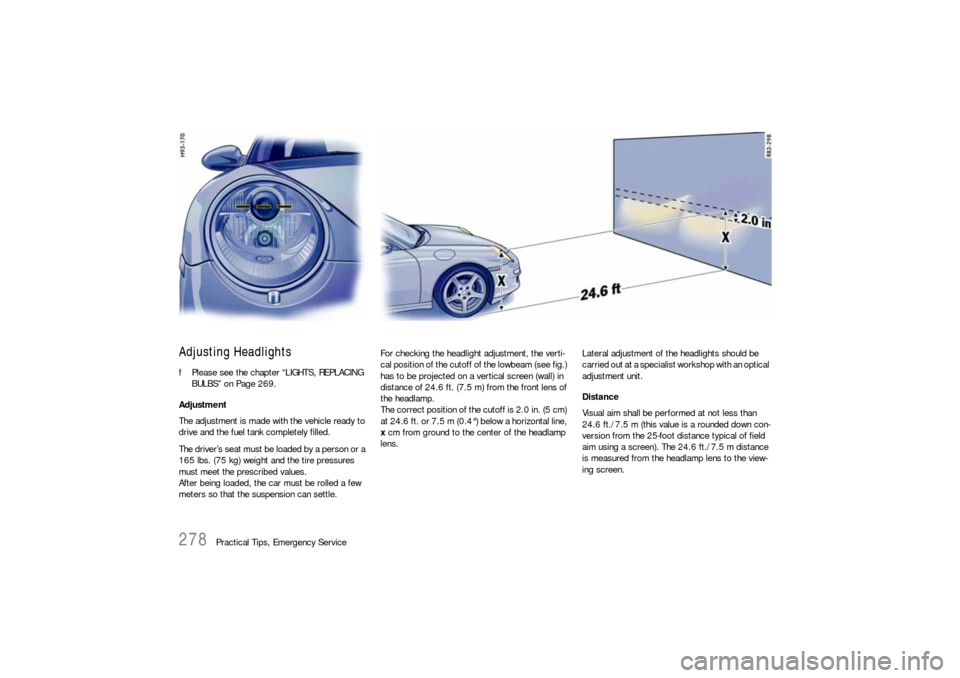

Adjusting HeadlightsfPlease see the chapter “LIGHTS, REPLACING

BULBS” on Page 269.

Adjustment

The adjustment is made with the vehicle ready to

drive and the fuel tank completely filled.

The driver’s seat must be loaded by a person or a

165 lbs. (75 kg) weight and the tire pressures

must meet the prescribed values.

After being loaded, the car must be rolled a few

meters so that the suspension can settle.

For checking the headlight adjustment, the verti-

cal position of the cutoff of the lowbeam (see fig.)

has to be projected on a vertical screen (wall) in

distance of 24.6 ft. (7.5 m) from the front lens of

the headlamp.

The correct position of the cutoff is 2.0 in. (5 cm)

at 24.6 ft. or 7.5 m (0.4°) below a horizontal line,

x cm from ground to the center of the headlamp

lens.Lateral adjustment of the headlights should be

carried out at a specialist workshop with an optical

adjustment unit.

Distance

Visual aim shall be performed at not less than

24.6 ft./7.5 m (this value is a rounded down con-

version from the 25-foot distance typical of field

aim using a screen). The 24.6 ft./7.5 m distance

is measured from the headlamp lens to the view-

ing screen.

Trending: oil type, wiper fluid, key fob battery, charging, washer fluid, dashboard, check transmission fluid