lights PORSCHE BOXSTER 2005 2.G Workshop Manual

[x] Cancel search | Manufacturer: PORSCHE, Model Year: 2005, Model line: BOXSTER, Model: PORSCHE BOXSTER 2005 2.GPages: 276, PDF Size: 4.05 MB

Page 232 of 276

232

Practical Tips, Emergency Service

Putting vehicle into operationAfter the battery is connected or after an exhaus-

tively discharged battery is charged, the multi-

functional PSM light lights up on the instrument

panel and a message appears on the on-board

computer to indicate a fault.

This fault can be remedied with a few simple

steps:

1. Start the engine.

2. With the vehicle stationary, perform a few

steering movements to the left and right and

then drive a short distance in a straight line

until the multifunctinal PSM light goes out and

the message on the on-board computer

disappears.

3. If the warnings do not disappear, then:

Drive carefully to the nearest qualified

specialist workshop.

Have the fault remedied.

4. After the warnings disappear, stop the vehicle

in a suitable place.

5. Perform adaptation of the power windows:

Please observe the chapter “STORING END

POSITION OF THE WINDOWS” on Page 29.Ignition key/ignition lock

fDo not insert the ignition key into the ignition

lock if the vehicle battery is discharged.

The ignition key can no longer be removed.

The key cannot be removed until the vehicle elec-

trical system is supplied with power again.

fPlease observe the chapter “EMERGENCY UN-

LOCKING OF THE FRONT LUGGAGE COMPART-

MENT LID” on Page 228.

6. Please observe the chapter “JUMP LEAD

STARTING” on Page 236.

Page 237 of 276

Practical Tips, Emergency Service

237

3. Run the engine of the donor car at a higher

speed.

4. Start the engine.

An attempted start using jump leads should

not last more than 15 seconds. Then allow a

waiting period of at least one minute.

5.Note

Before disconnecting the jump leads, electrical

loads such as the heated rear window and the

heating fan blower should be switched on (the

vehicle’s lights must not be switched on). This

reduces voltage peaks which may occur when

disconnecting the jump leads.

With the engine running, remove both jump

leads in reverse order.

Page 238 of 276

238

Practical Tips, Emergency Service

Replacing bulbs

Warning!

Risk of short circuit.

fAlways switch off the relevant load when

changing bulbs.

Risk of injury. The Bi-Xenon headlights are

under high voltage when installed.

fExercise extreme caution when working in the

area of the Bi-Xenon headlights.

Risk of damage. Bulbs of a higher wattage

can damage the lamp housing.

fOnly use the bulbs specified in the bulb chart.

fBulbs must be clean and free from grease.

fNever touch bulbs with your bare hands. Use a

cloth or soft paper when replacing bulbs.

fAlways carry spare bulbs with you.

In certain countries, the carrying of spare

bulbs is mandatory.

Caution!

Risk of damage to headlights due to exces-

sive temperatures and abrasion.

fAttach no coverings (e.g. films, “stone

guards”) in the area of the headlights.

fUse soapy water only to clean light lenses and

plastic headlight lenses.

In no case may chemical cleaners or other vol-

atile cleaning fluids be used.

fTo prevent scratches, do not rub with a dry or merely moist cloth, tissue or insect sponges.

Page 240 of 276

240

Practical Tips, Emergency Service

Warning!

Risk of short circuit.

fAlways switch off the relevant load when

changing bulbs.

Risk of injury. The Bi-Xenon headlights are

under high voltage when installed.

fExercise extreme caution when working in the

area of the Bi-Xenon headlights.

Risk of damage. Bulbs of a higher wattage

can damage the lamp housing.

fOnly use the bulbs specified in the bulb chart.

fBulbs must be clean and free from grease.

fNever touch bulbs with your bare hands. Use a

cloth or soft paper when replacing bulbs.

fAlways carry spare bulbs with you.

In certain countries, the carrying of spare

bulbs is mandatory.

Caution!

Risk of damage to headlights due to exces-

sive temperatures and abrasion.

fAttach no coverings (e.g. films, “stone

guards”) in the area of the headlights.

fUse soapy water only to clean light lenses and

plastic headlight lenses.

In no case may chemical cleaners or other vol-

atile cleaning fluids be used.

fTo prevent scratches, do not rub with a dry or merely moist cloth, tissue or insect sponges.

Page 241 of 276

Practical Tips, Emergency Service

241

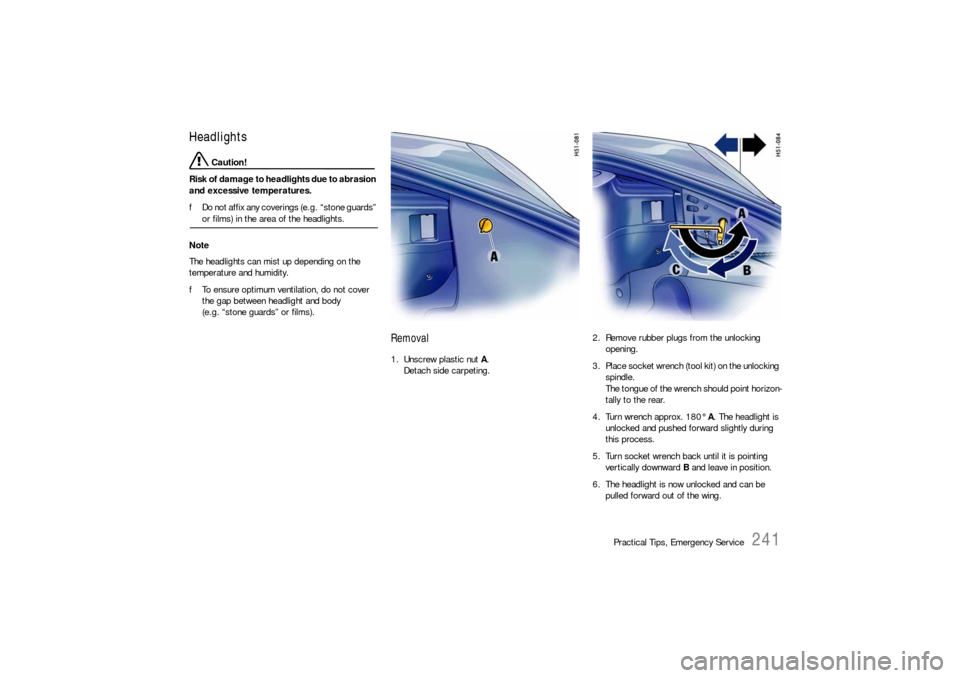

Headlights

Caution!

Risk of damage to headlights due to abrasion

and excessive temperatures.

fDo not affix any coverings (e.g. “stone guards” or films) in the area of the headlights.

Note

The headlights can mist up depending on the

temperature and humidity.

fTo ensure optimum ventilation, do not cover

the gap between headlight and body

(e.g. “stone guards” or films).

Removal1. Unscrew plastic nut A.

Detach side carpeting.2. Remove rubber plugs from the unlocking

opening.

3. Place socket wrench (tool kit) on the unlocking

spindle.

The tongue of the wrench should point horizon-

tally to the rear.

4. Turn wrench approx. 180° A. The headlight is

unlocked and pushed forward slightly during

this process.

5. Turn socket wrench back until it is pointing

vertically downward B and leave in position.

6. The headlight is now unlocked and can be

pulled forward out of the wing.

Page 242 of 276

242

Practical Tips, Emergency Service

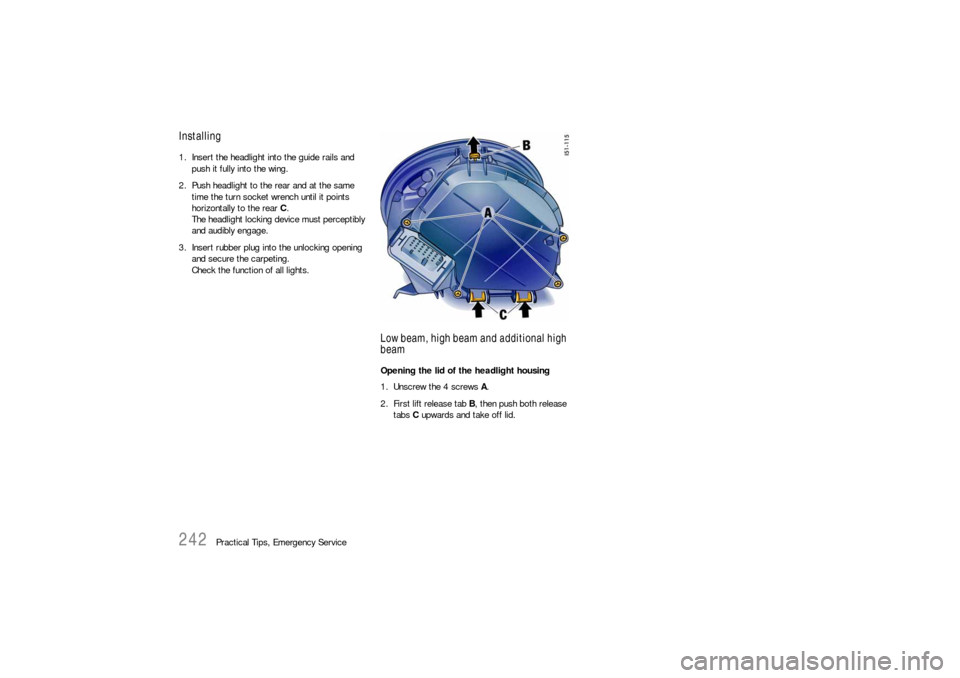

Installing1. Insert the headlight into the guide rails and

push it fully into the wing.

2. Push headlight to the rear and at the same

time the turn socket wrench until it points

horizontally to the rear C.

The headlight locking device must perceptibly

and audibly engage.

3. Insert rubber plug into the unlocking opening

and secure the carpeting.

Check the function of all lights.

Low beam, high beam and additional high

beamOpening the lid of the headlight housing

1. Unscrew the 4 screws A.

2. First lift release tab B, then push both release

tabs C upwards and take off lid.

Page 243 of 276

Practical Tips, Emergency Service

243

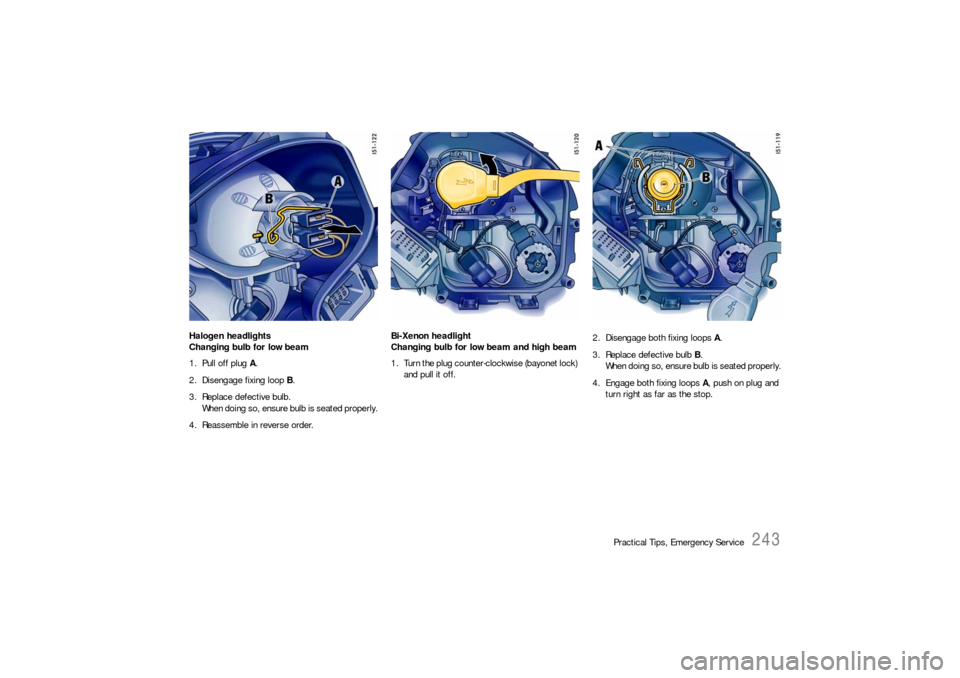

Halogen headlights

Changing bulb for low beam

1. Pull off plug A.

2. Disengage fixing loop B.

3. Replace defective bulb.

When doing so, ensure bulb is seated properly.

4. Reassemble in reverse order.Bi-Xenon headlight

Changing bulb for low beam and high beam

1. Turn the plug counter-clockwise (bayonet lock)

and pull it off.2. Disengage both fixing loops A.

3. Replace defective bulb B.

When doing so, ensure bulb is seated properly.

4. Engage both fixing loops A, push on plug and

turn right as far as the stop.

Page 249 of 276

Practical Tips, Emergency Service

249

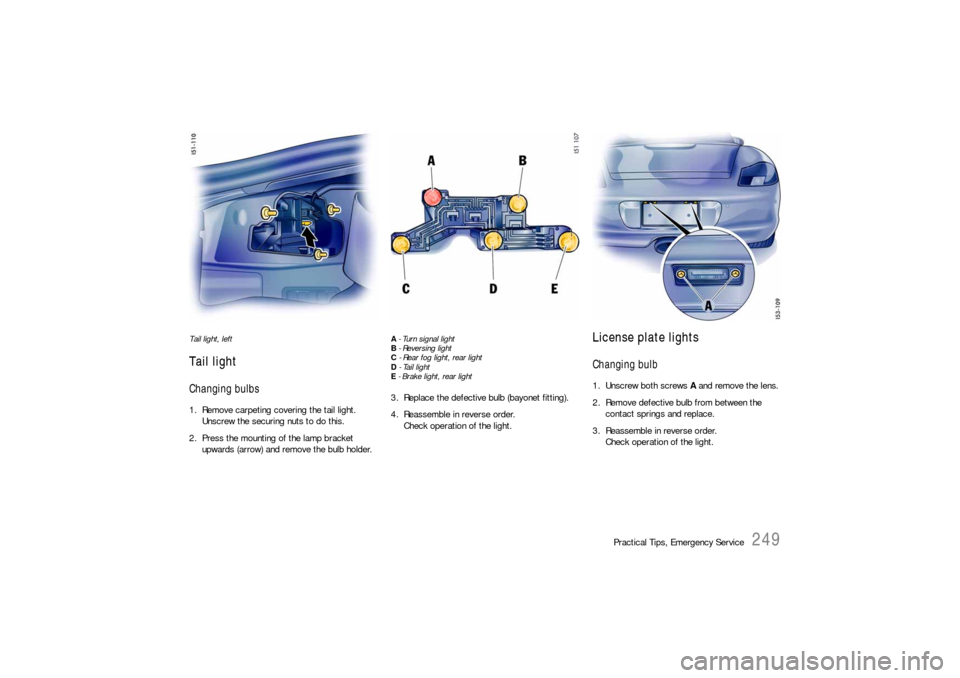

Tail light, leftTail lightChanging bulbs1. Remove carpeting covering the tail light.

Unscrew the securing nuts to do this.

2. Press the mounting of the lamp bracket

upwards (arrow) and remove the bulb holder.

A - Turn signal light

B - Reversing light

C - Rear fog light, rear light

D - Tail light

E - Brake light, rear light3. Replace the defective bulb (bayonet fitting).

4. Reassemble in reverse order.

Check operation of the light.

License plate lightsChanging bulb 1. Unscrew both screws A and remove the lens.

2. Remove defective bulb from between the

contact springs and replace.

3. Reassemble in reverse order.

Check operation of the light.

Page 250 of 276

250

Practical Tips, Emergency Service

Additional brake lightThe light-emitting diodes of the additional brake

light cannot be replaced individually.

fHave the defective brake light replaced in a

qualified specialist workshop.

We recommend a Porsche partner for this

work as they have trained workshop personnel

and the necessary parts and tools.

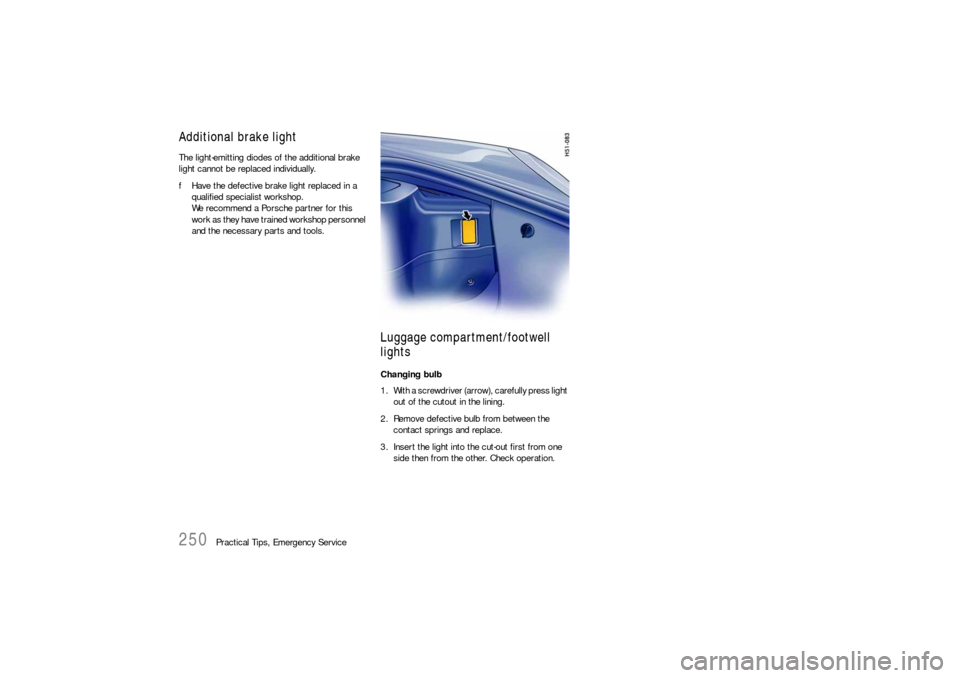

Luggage compartment/footwell

lightsChanging bulb

1. With a screwdriver (arrow), carefully press light

out of the cutout in the lining.

2. Remove defective bulb from between the

contact springs and replace.

3. Insert the light into the cut-out first from one

side then from the other. Check operation.

Page 252 of 276

252

Practical Tips, Emergency Service

Adjusting Headlights fPlease observe the chapter “REPLACING BUL-

BS” on Page 238.

Adjustment

The adjustment is made with the vehicle ready to

drive and the fuel tank completely filled.

The driver’s seat must be loaded by a person or a

165 lbs. (75 kg) weight and the tire pressures

must meet the prescribed values.

After being loaded, the car must be rolled a few

meters so that the suspension can settle.

For checking the headlight adjustment, the verti-

cal position of the cutoff of the lowbeam (see fig.)

has to be projected on a vertical screen (wall) in

distance of 24.6 ft. (7.5 m) from the front lens of

the headlamp.

The correct position of the cutoff is 2.0 in. (5 cm)

at 24.6 ft. or 7.5 m (0.4°) below a horizontal line,

x cm from ground to the center of the headlamp

lens. Lateral adjustment of the headlights should be

carried out at a specialist workshop with an optical

adjustment unit.

Distance

Visual aim shall be performed at not less than

24.6 ft. (7.5) m (this value is a rounded down con-

version from the 25-foot distance typical of field

aim using a screen). The 24.6 ft. (7.5 m) distance

is measured from the headlamp lens to the view-

ing screen.