PORSCHE CAYNNE S 2006 1.G Owners Manual

Manufacturer: PORSCHE, Model Year: 2006, Model line: CAYENNE S, Model: PORSCHE CAYENNE S 2006 1.GPages: 420, PDF Size: 3.81 MB

Page 321 of 420

Practical Tips, Minor Repairs

321

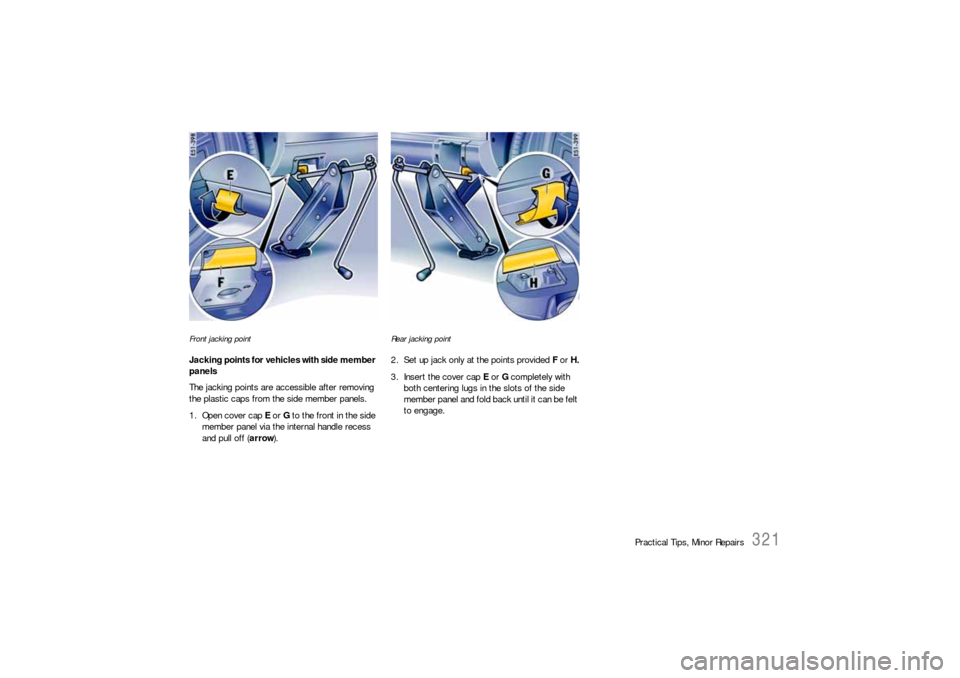

Front jacking pointJacking points for vehicles with side member

panels

The jacking points are accessible after removing

the plastic caps from the side member panels.

1. Open cover cap E or G to the front in the side

member panel via the internal handle recess

and pull off (arrow).

Rear jacking point2. Set up jack only at the points provided F or H.

3. Insert the cover cap E or G completely with

both centering lugs in the slots of the side

member panel and fold back until it can be felt

to engage.

Page 322 of 420

322

Practical Tips, Minor Repairs

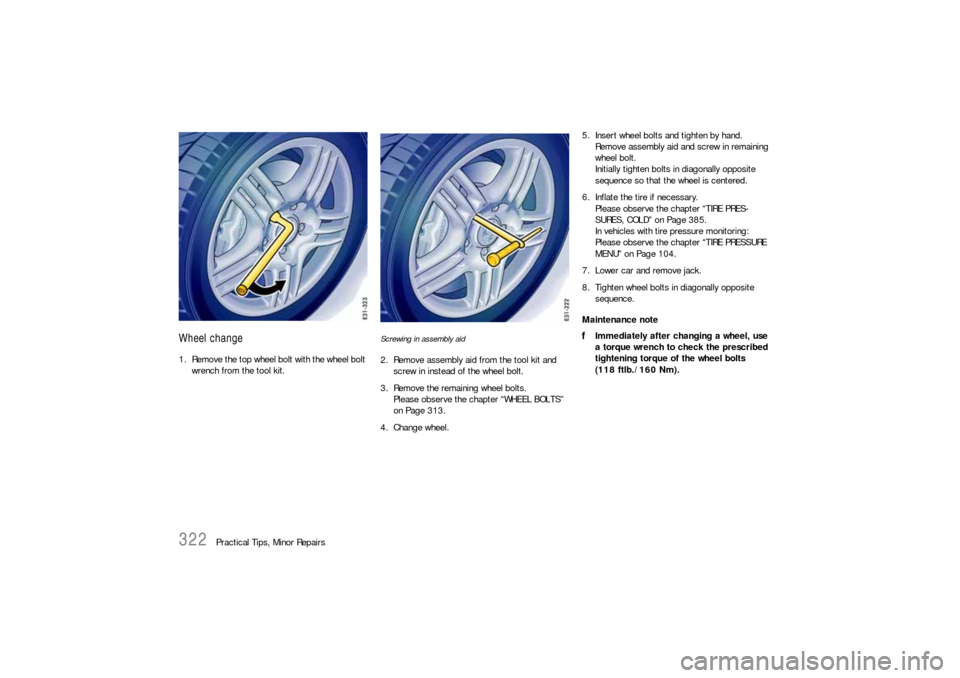

Wheel change1. Remove the top wheel bolt with the wheel bolt

wrench from the tool kit.

Screwing in assembly aid 2. Remove assembly aid from the tool kit and

screw in instead of the wheel bolt.

3. Remove the remaining wheel bolts.

Please observe the chapter “WHEEL BOLTS”

on Page 313.

4. Change wheel.5. Insert wheel bolts and tighten by hand.

Remove assembly aid and screw in remaining

wheel bolt.

Initially tighten bolts in diagonally opposite

sequence so that the wheel is centered.

6. Inflate the tire if necessary.

Please observe the chapter “TIRE PRES-

SURES, COLD” on Page 385.

In vehicles with tire pressure monitoring:

Please observe the chapter “TIRE PRESSURE

MENU” on Page 104.

7. Lower car and remove jack.

8. Tighten wheel bolts in diagonally opposite

sequence.

Maintenance note

fImmediately after changing a wheel, use

a torque wrench to check the prescribed

tightening torque of the wheel bolts

(118 ftlb./160 Nm).

Page 323 of 420

Practical Tips, Minor Repairs

323

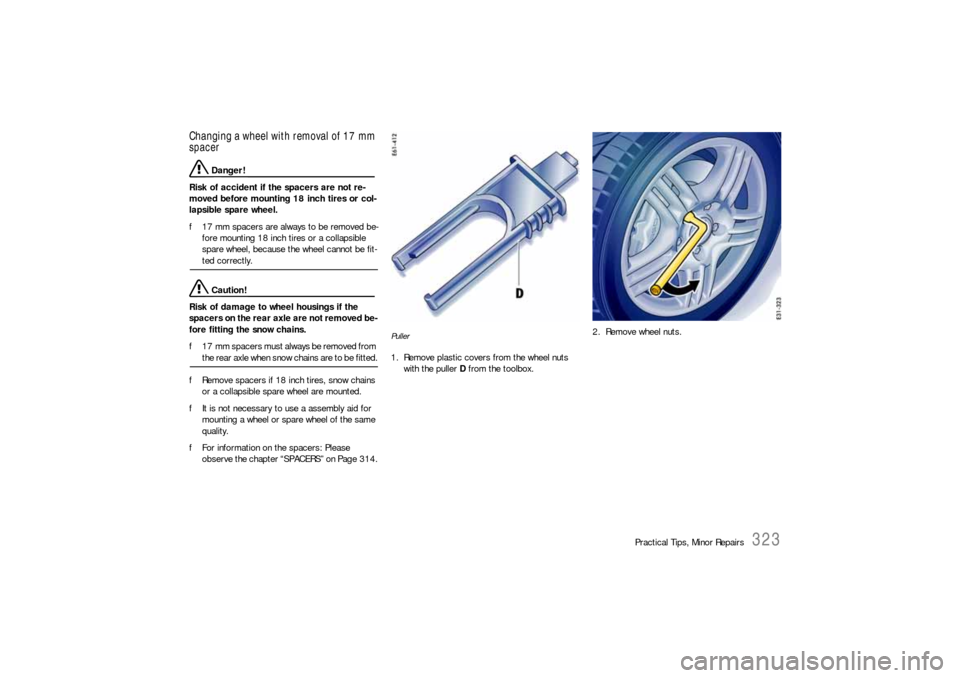

Changing a wheel with removal of 17 mm

spacer

Danger!

Risk of accident if the spacers are not re-

moved before mounting 18 inch tires or col-

lapsible spare wheel.

f17 mm spacers are always to be removed be-

fore mounting 18 inch tires or a collapsible

spare wheel, because the wheel cannot be fit-ted correctly. Caution!

Risk of damage to wheel housings if the

spacers on the rear axle are not removed be-

fore fitting the snow chains.

f17 mm spacers must always be removed from the rear axle when snow chains are to be fitted.

fRemove spacers if 18 inch tires, snow chains

or a collapsible spare wheel are mounted.

fIt is not necessary to use a assembly aid for

mounting a wheel or spare wheel of the same

quality.

fFor information on the spacers: Please

observe the chapter “SPACERS” on Page 314.

Puller1. Remove plastic covers from the wheel nuts

with the puller D from the toolbox.2. Remove wheel nuts.

Page 324 of 420

324

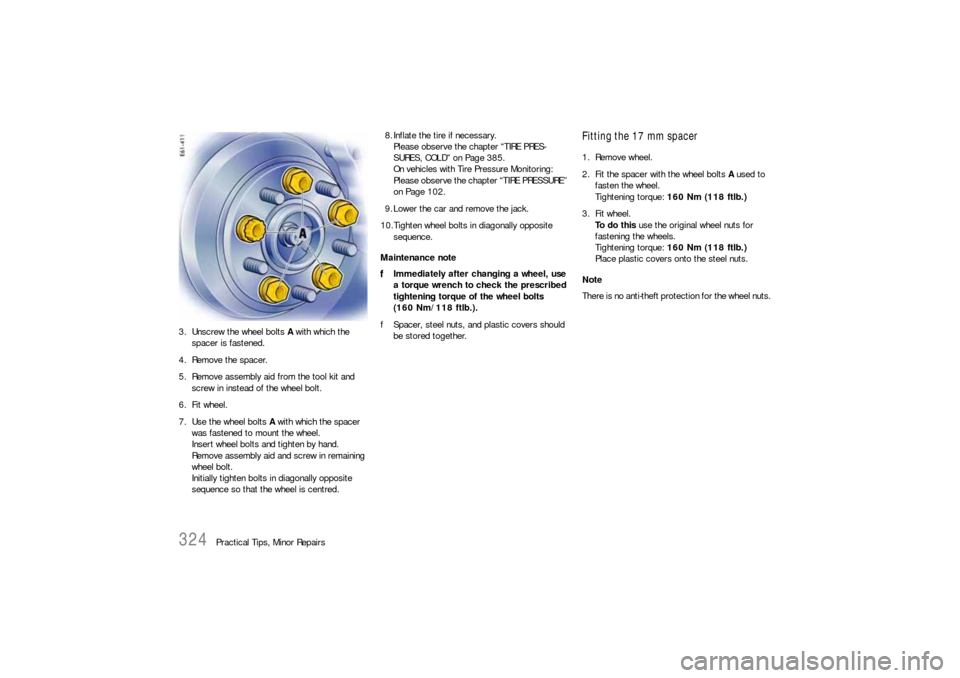

Practical Tips, Minor Repairs 3. Unscrew the wheel bolts A with which the

spacer is fastened.

4. Remove the spacer.

5. Remove assembly aid from the tool kit and

screw in instead of the wheel bolt.

6. Fit wheel.

7. Use the wheel bolts A with which the spacer

was fastened to mount the wheel.

Insert wheel bolts and tighten by hand.

Remove assembly aid and screw in remaining

wheel bolt.

Initially tighten bolts in diagonally opposite

sequence so that the wheel is centred.8. Inflate the tire if necessary.

Please observe the chapter “TIRE PRES-

SURES, COLD” on Page 385.

On vehicles with Tire Pressure Monitoring:

Please observe the chapter “TIRE PRESSURE”

on Page 102.

9. Lower the car and remove the jack.

10.Tighten wheel bolts in diagonally opposite

sequence.

Maintenance note

fImmediately after changing a wheel, use

a torque wrench to check the prescribed

tightening torque of the wheel bolts

(160 Nm/118 ftlb.).

fSpacer, steel nuts, and plastic covers should

be stored together.

Fitting the 17 mm spacer1. Remove wheel.

2. Fit the spacer with the wheel bolts A used to

fasten the wheel.

Tightening torque: 160 Nm (118 ftlb.)

3. Fit wheel.

To d o t h i s use the original wheel nuts for

fastening the wheels.

Tightening torque: 160 Nm (118 ftlb.)

Place plastic covers onto the steel nuts.

Note

There is no anti-theft protection for the wheel nuts.

Page 325 of 420

Practical Tips, Minor Repairs

325

Collapsible spare wheelThe collapsible spare wheel is fastened under the

floor in the luggage compartment.

On vehicles with 17 mm spacers:

fBefore fitting a collapsible spare wheel on the

rear axle always remove the corresponding

spacer.

For information on the spacers: Please

observe the chapter “SPACERS” on Page 314.

For information about removing the spacers:

Please observe the chapter “CHANGING A

WHEEL WITH REMOVAL OF 17 MM SPACER”

on Page 323.

1. Take out rotary knob A and put it on bolt B.

2. Unscrew the screw and take out the collapsible

spare wheel.

3. Mount the collapsible spare wheel on the vehi-

cle before inflating it. Leave the car jacked up.

Please observe the chapter “LIFTING THE

VEHICLE WITH A JACK” on Page 319.

4. Inflate the tire.

Please observe the chapter “TIRE PRES-

SURES, COLD” on Page 385.

Warning!

Risk of accident.

fThe collapsible spare wheel must be used only

over short distances in cases of emergency.

For safety reasons, replace the tires before

the wear indicators appear (webs in the tire

grooves, 1/16 in. (1.6 mm) high).

fNever deactivate the Porsche Stability Man-

agement (PSM) system.

fAvoid hard acceleration and high cornering

speeds.

The maximum permitted speed is 50 mph

(80 km/h) and must not be exceeded

because of altered driving characteristics and

for reasons of wear.

The tread depth of the spare wheel is subject

to the same laws as the original tires.

fDo not use a collapsible spare wheel from a

different vehicle type.

fDo not mount the collapsible spare wheel from

your car on a different vehicle.

fOnly fit one collapsible spare wheel on the

vehicle at a time.

fOn vehicles with air suspension, use the tire fill-

ing connection A only to inflate the collapsible

spare wheel.

fTo avoid damage, do not use automatic car washes when the spare wheel is installed.

Page 326 of 420

326

Practical Tips, Minor Repairs After using the collapsible spare wheel

fRelease air by unscrewing the valve insert.

Notes on operation

The tire will revert to its original shape only after

several hours. Only then can it be stowed in the

spare wheel recess in the luggage compartment.

There is a plastic sheet in the tool box to store the

damaged wheel.Maintenance note

The collapsible spare wheel must be repaired only

by the manufacturer.

fPlease consult your authorized Porsche dealer

if the collapsible spare wheel is defective.

Page 327 of 420

Practical Tips, Minor Repairs

327

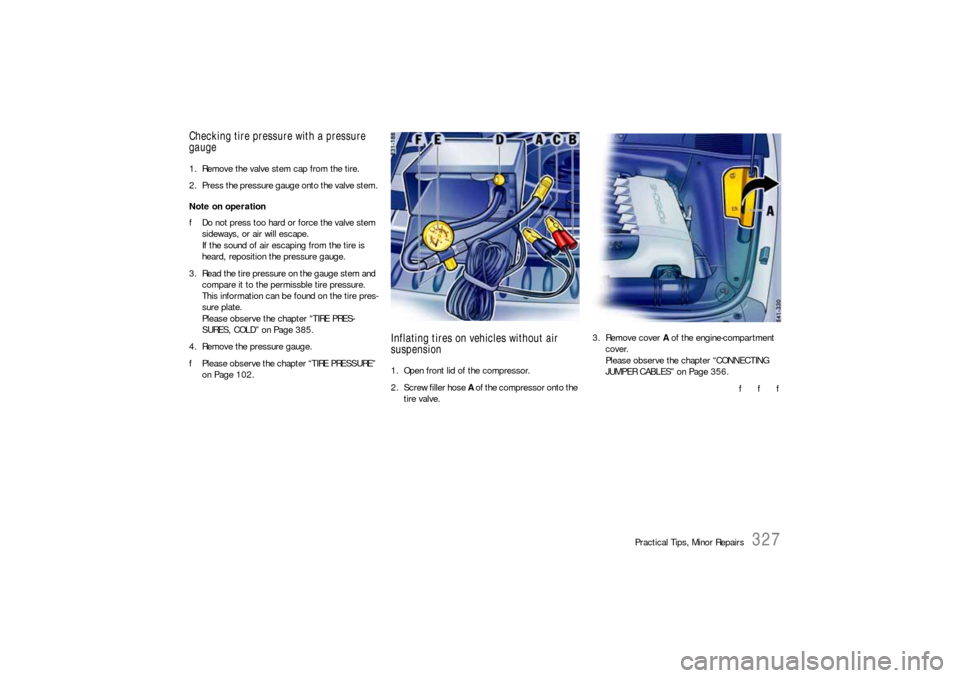

Checking tire pressure with a pressure

gauge1. Remove the valve stem cap from the tire.

2. Press the pressure gauge onto the valve stem.

Note on operation

fDo not press too hard or force the valve stem

sideways, or air will escape.

If the sound of air escaping from the tire is

heard, reposition the pressure gauge.

3. Read the tire pressure on the gauge stem and

compare it to the permissble tire pressure.

This information can be found on the tire pres-

sure plate.

Please observe the chapter “TIRE PRES-

SURES, COLD” on Page 385.

4. Remove the pressure gauge.

fPlease observe the chapter “TIRE PRESSURE”

on Page 102.

Inflating tires on vehicles without air

suspension1. Open front lid of the compressor.

2. Screw filler hose A of the compressor onto the

tire valve.3. Remove cover A of the engine-compartment

cover.

Please observe the chapter “CONNECTING

JUMPER CABLES” on Page 356.

f f f

Page 328 of 420

328

Practical Tips, Minor Repairs

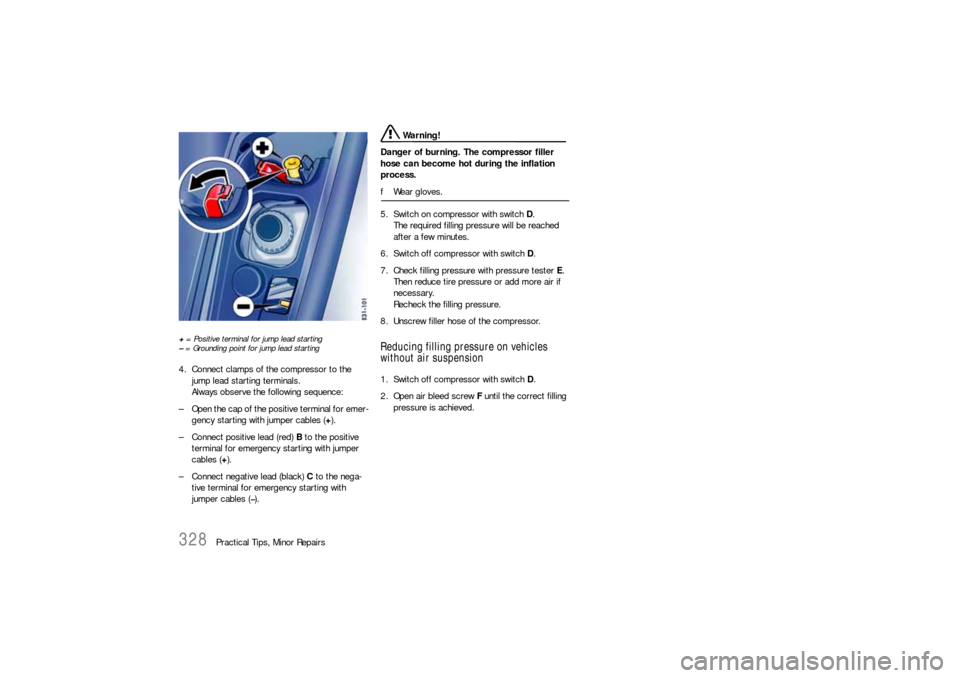

+ = Positive terminal for jump lead starting

– = Grounding point for jump lead starting4. Connect clamps of the compressor to the

jump lead starting terminals.

Always observe the following sequence:

– Open the cap of the positive terminal for emer-

gency starting with jumper cables (+).

– Connect positive lead (red) B to the positive

terminal for emergency starting with jumper

cables (+).

– Connect negative lead (black) C to the nega-

tive terminal for emergency starting with

jumper cables (

–).

Warning!

Danger of burning. The compressor filler

hose can become hot during the inflation

process.

fWear gloves.

5. Switch on compressor with switch D.

The required filling pressure will be reached

after a few minutes.

6. Switch off compressor with switch D.

7. Check filling pressure with pressure tester E.

Then reduce tire pressure or add more air if

necessary.

Recheck the filling pressure.

8. Unscrew filler hose of the compressor.Reducing filling pressure on vehicles

without air suspension1. Switch off compressor with switch D.

2. Open air bleed screw F until the correct filling

pressure is achieved.

Page 329 of 420

Practical Tips, Minor Repairs

329

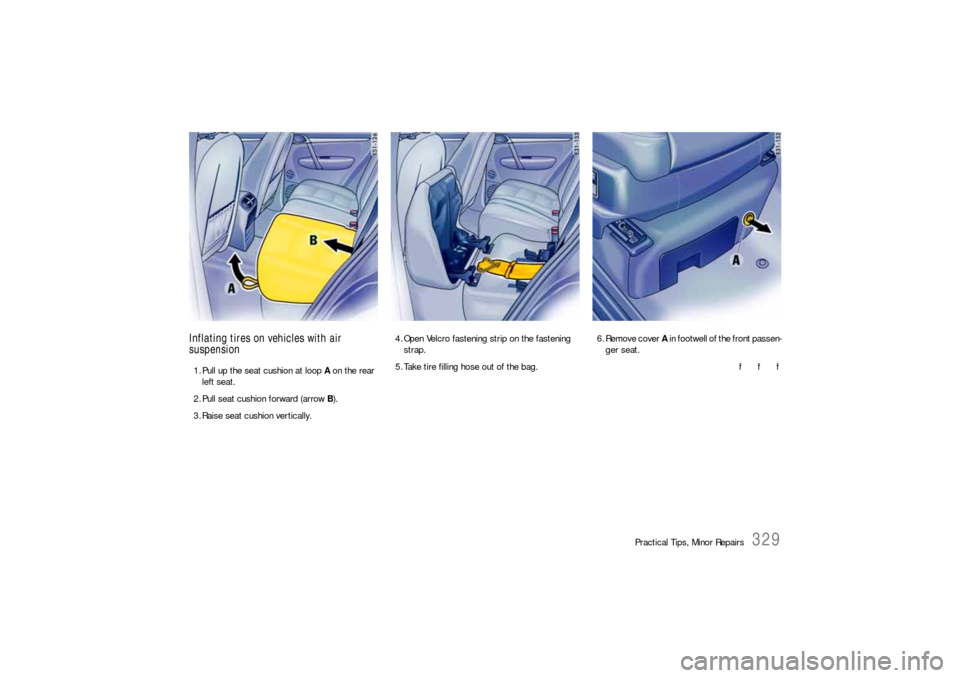

Inflating tires on vehicles with air

suspension1. Pull up the seat cushion at loop A on the rear

left seat.

2. Pull seat cushion forward (arrow B).

3. Raise seat cushion vertically.4. Open Velcro fastening strip on the fastening

strap.

5. Take tire filling hose out of the bag.6. Remove cover A in footwell of the front passen-

ger seat.

f f f

Page 330 of 420

330

Practical Tips, Minor Repairs

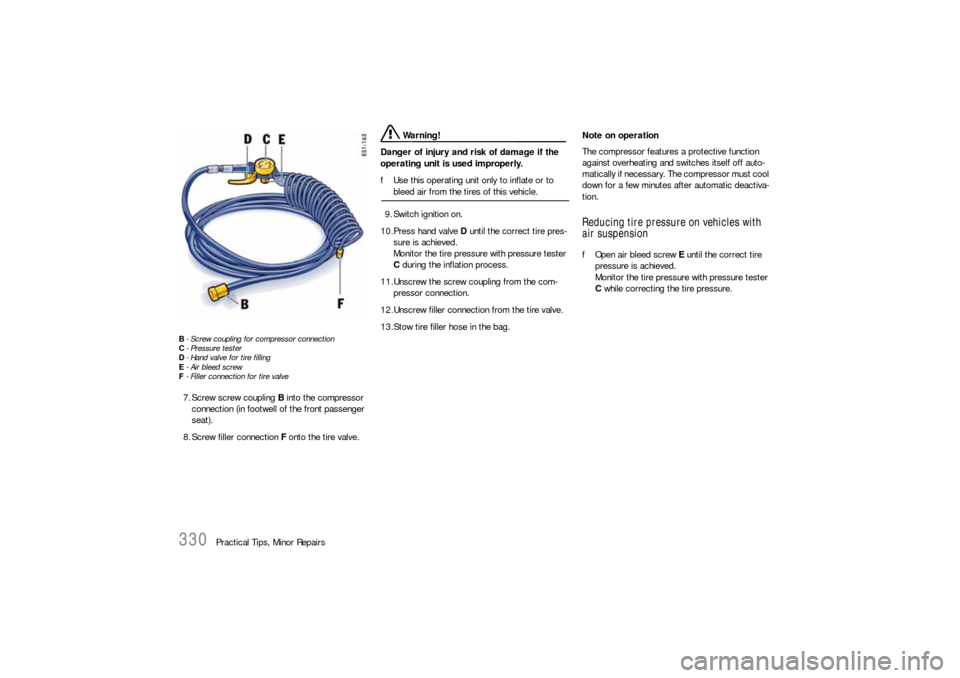

B- Screw coupling for compressor connection

C- Pressure tester

D- Hand valve for tire filling

E- Air bleed screw

F- Filler connection for tire valve7. Screw screw coupling B into the compressor

connection (in footwell of the front passenger

seat).

8. Screw filler connection F onto the tire valve.

Warning!

Danger of injury and risk of damage if the

operating unit is used improperly.

fUse this operating unit only to inflate or to bleed air from the tires of this vehicle.

9. Switch ignition on.

10.Press hand valve D until the correct tire pres-

sure is achieved.

Monitor the tire pressure with pressure tester

C during the inflation process.

11.Unscrew the screw coupling from the com-

pressor connection.

12.Unscrew filler connection from the tire valve.

13.Stow tire filler hose in the bag.Note on operation

The compressor features a protective function

against overheating and switches itself off auto-

matically if necessary. The compressor must cool

down for a few minutes after automatic deactiva-

tion.

Reducing tire pressure on vehicles with

air suspensionfOpen air bleed screw E until the correct tire

pressure is achieved.

Monitor the tire pressure with pressure tester

C while correcting the tire pressure.