jack Ram 1500 2013 Service Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2013, Model line: 1500, Model: Ram 1500 2013Pages: 734, PDF Size: 5.47 MB

Page 606 of 734

1. Turn the wheel so that the valve stem is facing theground and toward the rear of the vehicle for conve-

nience in checking the spare tire inflation. Slide the

wheel retainer through the center of the wheel.

2. Lift the spare tire with one hand to give clearance to tilt the retainer at the end of the cable and position it

properly across the wheel opening. 3. Attach the wheel wrench to the jack extension tube

with the curved angle facing away from the vehicle.

Insert the tube through the access hole between the

lower tailgate and the top of the bumper and into the

winch mechanism tube.

604 WHAT TO DO IN EMERGENCIES

Page 607 of 734

4. Rotate the lug wrench handle clockwise until thewheel is drawn into place against the underside of the

vehicle. Continue to rotate until you feel the winch

mechanism slip, or click three or four times. It cannot

be overtightened. Push against the tire several times to

ensure it is firmly in place. NOTE:

The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

6

WHAT TO DO IN EMERGENCIES 605

Page 608 of 734

Reinstalling The Jack And Tools (2500 And 3500

Series)

1. Tighten the jack all the way down by turning the jackturn-screw counterclockwise until the jack is snug.

2. Position the jack and tools into bracket assembly. Make sure the lug wrench is under the jack near the

jack turn-screw. Snap tools into bracket assembly clips.

Install the jack into bracket assembly and turn the

jack-turn-screw clockwise until jack is snug into

bracket assembly.

3. Place the jack and tool bracket assembly in the storageposition holding the jack by the jack turn-screw, slip

the jack and tools under the seat so that the bottom slot

engages into the fastener on the floor.

Jack And Tools Bracket Assembly

606 WHAT TO DO IN EMERGENCIES

Page 609 of 734

NOTE:Ensure that the jack and tool bracket assembly

slides into the front hold down location.

4. Turn the wing bolt clockwise to secure to the floor pan. Reinstall the plastic cover.Hub Caps/Wheel Covers — If Equipped

The hub caps must be removed before raising the vehicle

off the ground.

Jack Hold Down FastenerJack And Tools (2500/3500 Series)6

WHAT TO DO IN EMERGENCIES 607

Page 610 of 734

CAUTION!

Use extreme caution when removing the front and

rear center caps. Damage can occur to the center cap

and/or the wheel if screwdriver type tools are used. A

pulling motion, not a pry off motion, is recom-

mended to remove the caps.

For single rear wheel (SRW) models, use the blade on the

end of the lug wrench to pry the hub cap off. Insert the

blade end into the pry off notch and carefully pop off the

hub cap with a back and forth motion.

On 3500 models with dual rear wheels (DRW), you must

first remove the hub caps. The jack handle driver has a

hook at one end that will fit in the pry off notch of the

rear hub caps. Position the hook and pull out on the

ratchet firmly. The hub cap should pop off. The wheel

skins can now be removed. For the front hub cap on models use the blade on the end of the lug wrench to pry

the caps off. The wheel skin can now be removed.

CAUTION!

•

Use a back and forth motion to remove the hub cap.

Do not use a twisting motion when removing the

hub cap, damage to the hub cap; finish may occur.

• The rear hub caps on the dual rear wheel has two

pry off notches. Make sure that the hook of the jack

handle driver is located squarely in the cap notch

before attempting to pull off.

You must use the flat end of the lug wrench to pry off the

wheel skins. Insert the flat tip completely and using a

back and forth motion, loosen the wheel skin. Repeat this

procedure around the tire until the skin pops off.

Replace the wheel skins first using a rubber mallet. When

replacing the hub caps, tilt the cap retainer over the lug

608 WHAT TO DO IN EMERGENCIES

Page 613 of 734

These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the numbered sequence to asnug fit.

2. Retighten the wheel nuts in the same sequence to the torques listed in the table. Go through the sequence a second time to verify that specific torque has been

achieved. Retighten to specifications at 100 miles

(160 km) and after 500 miles (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts of the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

Tightening Pattern

6

WHAT TO DO IN EMERGENCIES 611

Page 723 of 734

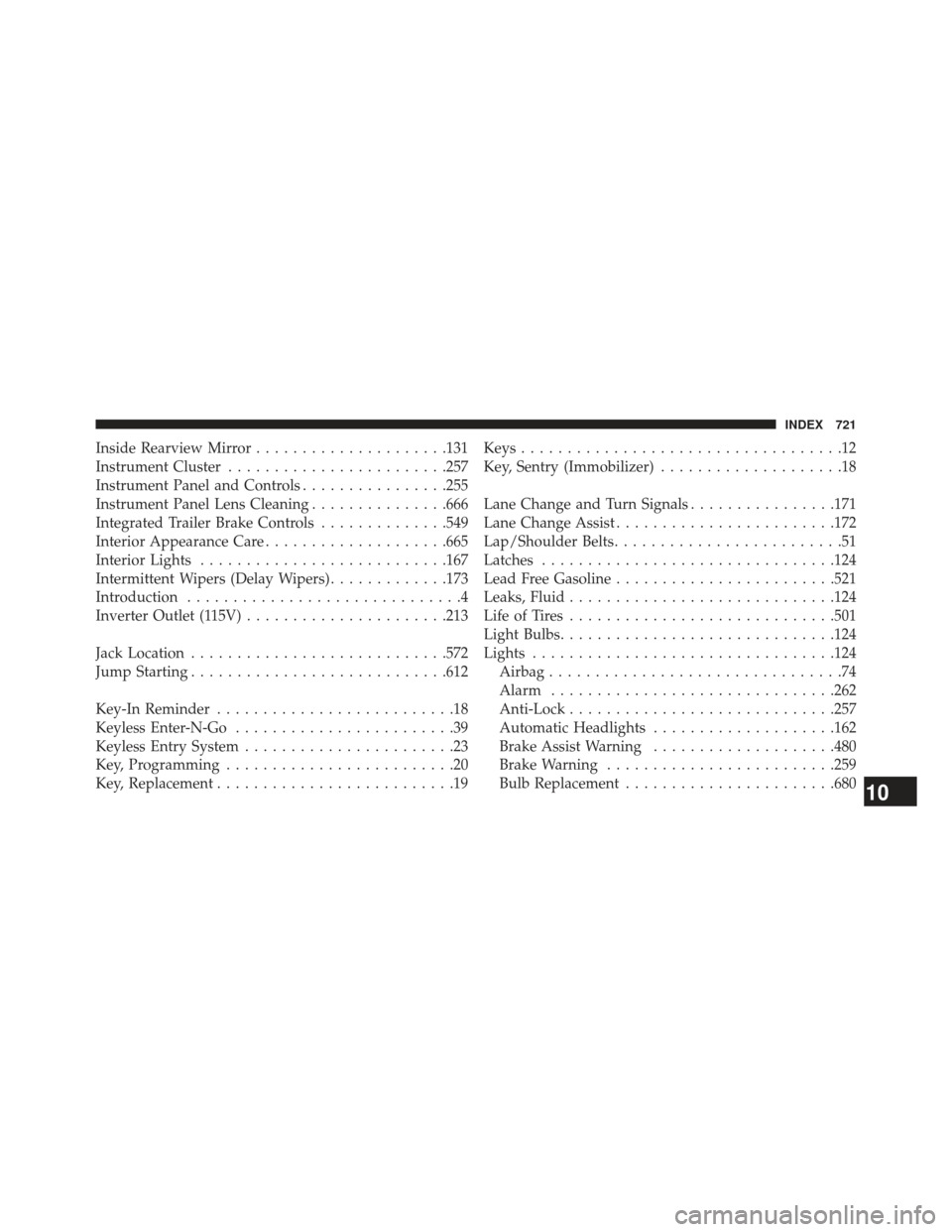

Inside Rearview Mirror.....................131

Instrument Cluster ....................... .257

Instrument Panel and Controls ................255

Instrument Panel Lens Cleaning ...............666

Integrated Trailer Brake Controls ..............549

Interior Appearance Care ....................665

Interior Lights .......................... .167

Intermittent Wipers (Delay Wipers) .............173

Introduction ..............................4

Inverter Outlet (115V) ..................... .213

Jack Location ........................... .572

Jump Starting ........................... .612

Key-In Reminder ..........................18

Keyless Enter-N-Go ........................39

Keyless Entry System .......................23

Key, Programming .........................20

Key, Replacement ..........................19 Keys

...................................12

Key, Sentry (Immobilizer) ....................18

Lane Change and Turn Signals ................171

Lane Change Assist ....................... .172

Lap/Shoulder Belts .........................51

Latches ............................... .124

Lead Free Gasoline ....................... .521

Leaks, Fluid ............................ .124

Life of Tires ............................ .501

Light Bulbs ............................. .124

Lights ................................ .124

Airbag ................................74

Alarm .............................. .262

Anti-Lock ............................ .257

Automatic Headlights ....................162

Brake Assist Warning ....................480

Brake Warning ........................ .259

Bulb Replacement ...................... .680

10

INDEX 721