change wheel Ram 1500 2015 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2015, Model line: 1500, Model: Ram 1500 2015Pages: 871, PDF Size: 24.83 MB

Page 631 of 871

•Seasonal temperature changes will affect tire pressure,

and the TPMS will monitor the actual tire pressure in

the tire.

Premium System

The Tire Pressure Monitor System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors mounted to each

wheel as part of the valve stem transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the

tire pressure in all of the tires on your vehicle monthly

and to maintain the proper pressure.

The TPMS consists of the following components:

•Receiver module

•Four TPM sensors

•Various TPMS messages, which display in the Elec-

tronic Vehicle Information Center (EVIC)/Driver In-

formation Display (DID)

•TPM Telltale Light

The matching full size spare wheel and tire assembly (if

equipped) has a TPM sensor. The full size spare can be

used in place of any of the four road tires. A spare with a

pressure below the low-pressure limit will not cause the

“Tire Pressure Monitoring Telltale Light” to illuminate or

the chime to sound while it is stored in the spare tire

location.

Tire Pressure Monitoring Low Pressure Warnings

The “Tire Pressure Monitoring Telltale Light” will

illuminate in the instrument cluster and a chime

will sound when tire pressure is low in one or more of the

four active road tires. In addition, the EVIC/DID will

display a “LOW TIRE” message and a graphic showing

5

STARTING AND OPERATING 629

Page 665 of 871

sliding the manual brake control lever will display the

GAIN setting for 10 seconds and the “Trailer Brake Status

Indicator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.

GAIN Adjustment Buttons (+/-)

Pressing these buttons will adjust the brake control

power output to the trailer brakes in 0.5 increments. The

GAIN setting can be increased to a maximum of 10 or

decreased to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control

for the specific towing condition and should be changed

as towing conditions change. Changes to towing condi-

tions include trailer load, vehicle load, road conditions

and weather.

Adjusting GAIN

NOTE:This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working

condition, functioning normally and properly ad-

justed. See your trailer dealer if necessary.

2.Hook up the trailer and make the electrical connections

according to the trailer manufacturer’s instructions.

3. When a trailer with electric/EOH brakes is plugged

in, the trailer connected message should appear in the

EVIC/DID (if the connection is not recognized by the

ITBM, braking functions will not be available), the

GAIN setting will illuminate and the correct type of

trailer must be selected from the EVIC/DID options.

4. Press the UP or DOWN button on the steering wheel

until “TRAILER TOW” appears on the screen.

5

STARTING AND OPERATING 663

Page 666 of 871

5. Press the RIGHT arrow on the steering wheel to enter

“TRAILER TOW”.

6. Press the UP or DOWN buttons until Trailer Brake

Type appears on the screen.

7. Press the RIGHT arrow and then press the UP or

DOWN buttons until the proper Trailer Brake Type

appears on the screen.

8.In a traffic-free environment, tow the trailer on a dry,

level surface at a speed of 20–25 mph (30–40 km/h) and

squeeze the manual brake control lever completely.

9. If the trailer wheels lockup (indicated by squealing

tires), reduce the GAIN setting; if the trailer wheels

turn freely, increase the GAIN setting.

Repeat steps 8 and 9 until the GAIN setting is at a point

just below trailer wheel lockup. If towing a heavier

trailer, trailer wheel lockup may not be attainable even

with the maximum GAIN setting of 10.

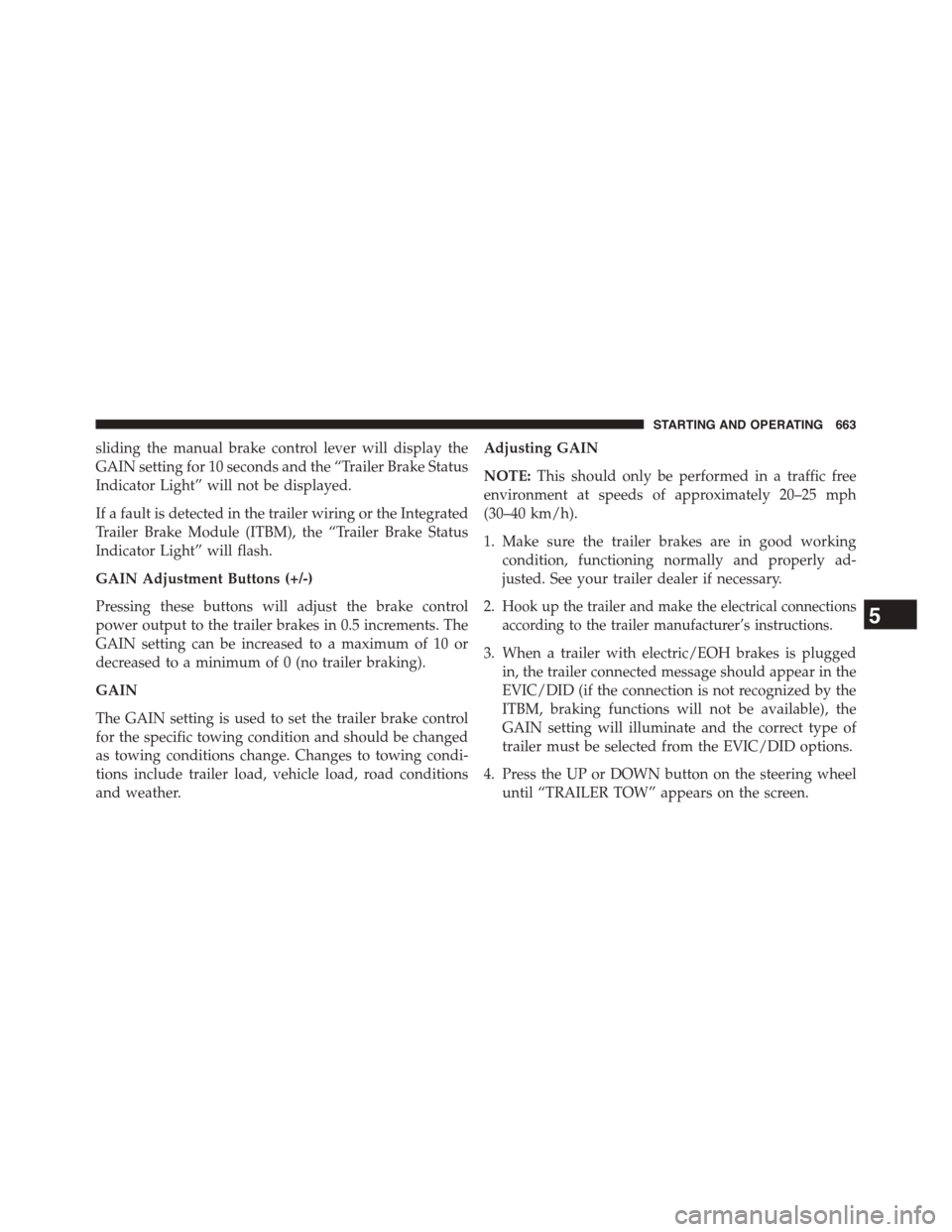

Light Electric Heavy Electric Light EOHHeavy EOH

Type of Trailer BrakesElectric Trailer Brakes Electric Trailer Brakes Electric over Hydrau-

lic Trailer Brakes

Electric over Hydrau-

lic Trailer Brakes

Load*Under 10,000 lbs *Above 10,000 lbs *Under 10,000 lbs *Above 10,000 lbs

* The suggested selection depends and may change

depending on the customer preferences for braking per-

formance. Condition of the trailer brakes, driving and

road state may also affect the selection.

664 STARTING AND OPERATING

Page 690 of 871

After 25 miles (40 km) check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated

against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

JACKING AND TIRE CHANGING

Jacking And Tire Changing 1500 Series Trucks

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

(Continued)

4 And 5 Lug Nuts/Bolts Torque Pattern

688 WHAT TO DO IN EMERGENCIES

Page 698 of 871

Preparations

1. Park the vehicle on a firm, level surface. Avoid ice or

slippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK. On four-wheel drive

vehicles, shift the transfer case to the 4L position.

5. Turn the ignition OFF.

Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

NOTE:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

696 WHAT TO DO IN EMERGENCIES

Page 699 of 871

Jack Instructions (1500 Series)

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

•Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to

be raised.

•Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

•Never start or run the engine with the vehicle on a

jack.

(Continued)

WARNING!(Continued)

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

•Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

•If working on or near a roadway, be extremely

careful of motor traffic.

•To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

6

WHAT TO DO IN EMERGENCIES 697

Page 710 of 871

WARNING!(Continued)

you may experience abrupt stopping, rapid accelera-

tion or sharp turns. A loose jack, tools, bracket or

other objects in the vehicle may move around with

force, resulting in serious injury.

Jacking And Tire Changing 2500 And 3500 Series

Trucks

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

(Continued)

WARNING!(Continued)

•Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

•Never start or run the engine while the vehicle is

on a jack.

•The jack is designed to be used as a tool for

changing tires only. The jack should not be used to

lift the vehicle for service purposes. The vehicle

should be jacked on a firm level surface only.

Avoid ice or slippery areas.

708 WHAT TO DO IN EMERGENCIES

Page 717 of 871

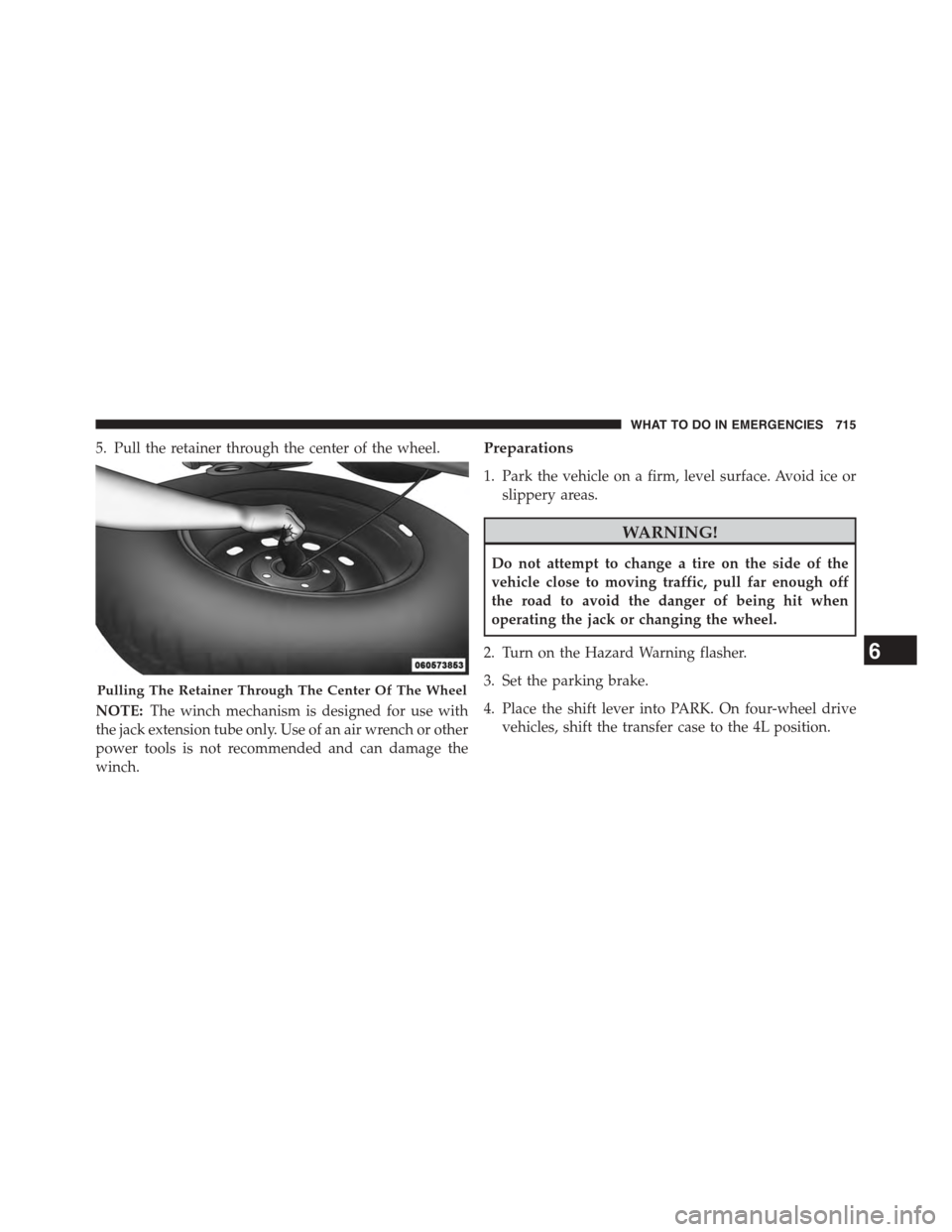

5. Pull the retainer through the center of the wheel.

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Preparations

1. Park the vehicle on a firm, level surface. Avoid ice or

slippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK. On four-wheel drive

vehicles, shift the transfer case to the 4L position.

Pulling The Retainer Through The Center Of The Wheel

6

WHAT TO DO IN EMERGENCIES 715

Page 718 of 871

5. Turn the ignition OFF.

Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

NOTE:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

Jack Instructions (2500, 3500 Series)

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

(Continued)

WARNING!(Continued)

•Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

•Turn on the Hazard Warning flasher.

•Block the wheel diagonally opposite the wheel to

be raised.

•Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

•Never start or run the engine with the vehicle on a

jack.

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

(Continued)

716 WHAT TO DO IN EMERGENCIES

Page 768 of 871

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air condi-

tioning components. Such damage is not covered by

the New Vehicle Limited Warranty.

Refrigerant Recovery And Recycling R134a — If

Equipped

R-134a Air Conditioning Refrigerant is a hydrofluoro-

carbon (HFC) that is endorsed by the Environmental

Protection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by authorized dealer or other

service facilities using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system

PAG compressor oil and refrigerants.

Refrigerant Recovery And Recycling HFO 1234yf —

If Equipped

HFO 1234yf Air Conditioning Refrigerant is a hydro-

fluorocarbon (HFC) that is endorsed by the Environmen-

tal Protection Agency and is an ozone-saving product

with a low GWP (Global Warming Potential). However,

the manufacturer recommends that air conditioning ser-

vice be performed by authorized dealer or other service

facilities using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system

PAG compressor oil and refrigerants.

Front Driveshaft Lubrication — 2500/3500

(Four-Wheel Drive Models Only)

Lubricate the front driveshaft grease fitting at each oil

change. Refer to the “Maintenance Schedule” for the

proper maintenance intervals. Use MOPAR® Type MS-

6560 (lithium-based grease), or equivalent.

766 MAINTAINING YOUR VEHICLE