eco Ram 1500 2016 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 1500, Model: Ram 1500 2016Pages: 916, PDF Size: 7.55 MB

Page 602 of 916

•Always wear leather gloves and do not allow the wire

rope to slip through your hands when handling the

rope.

•Only the operator should handle the wire rope and

remote control.

•Think safety at all times.

Vehicle Recovery Using The Winch

CAUTION!

•Always Know Your Winch: Take the time to fully

read and understand the included Installation and

Operations Guide, and Basic Guide to Winching

Techniques, in order to understand your winch and

the winching operation.

(Continued)

CAUTION!(Continued)

•Always inspect winch installation and wire rope

condition before operating the winch. Frayed,

kinked or damaged wire rope must be replaced

immediately. Loose or damaged winch installation

must be corrected immediately.

•Always be sure any element which can interfere

with safe winching operations is removed prior to

initiating winching.

•Always keep remote control lead clear of the drum,

wire rope and rigging.

•Inspect for cracks, pinches, frayed wires, or loose

connections. Replace if damaged.

•Be careful not to pull the Winch Cable Collar

through the rollers. Watch and listen to Winch for

proper snugness.

600 STARTING AND OPERATING

Page 604 of 916

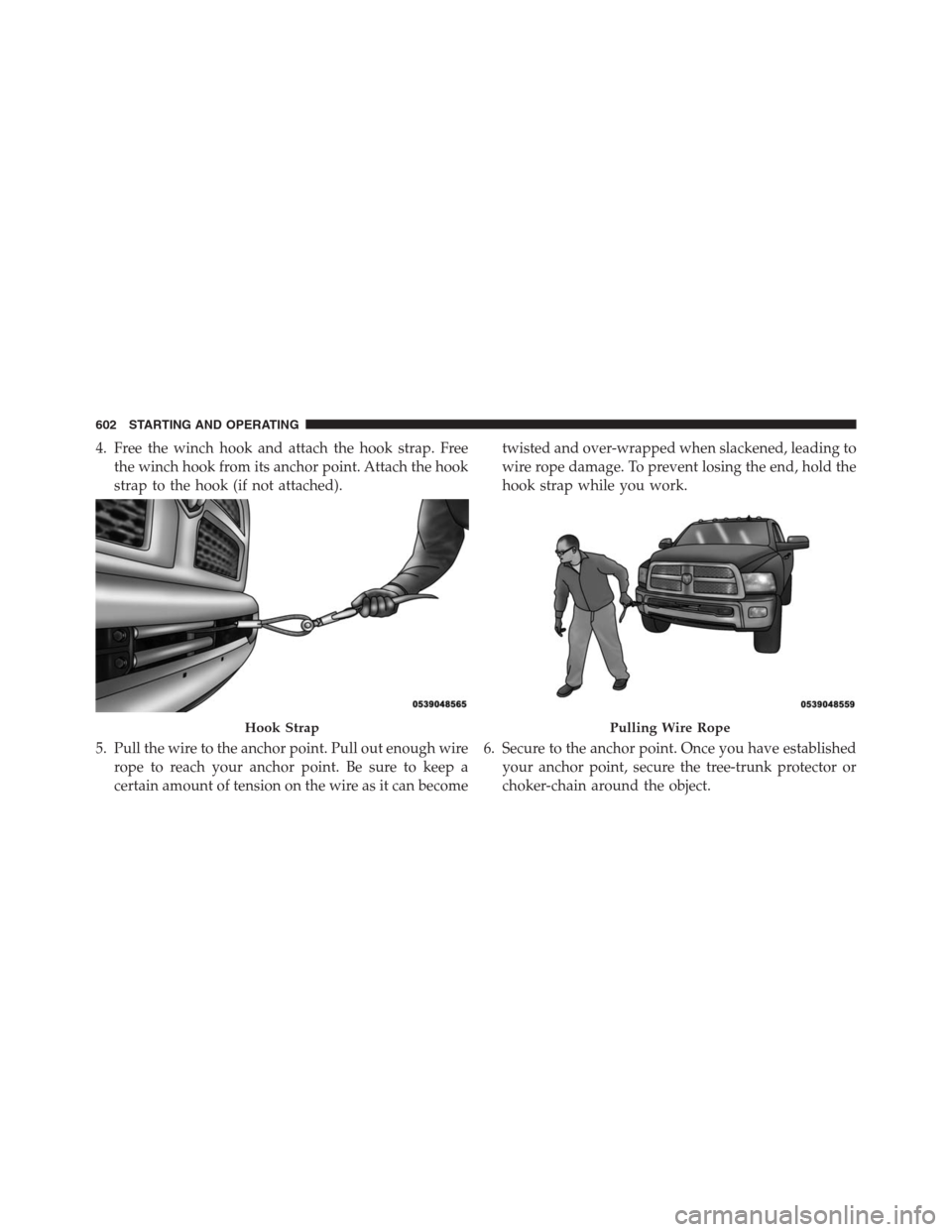

4. Free the winch hook and attach the hook strap. Free

the winch hook from its anchor point. Attach the hook

strap to the hook (if not attached).

5. Pull the wire to the anchor point. Pull out enough wire

rope to reach your anchor point. Be sure to keep a

certain amount of tension on the wire as it can becometwisted and over-wrapped when slackened, leading to

wire rope damage. To prevent losing the end, hold the

hook strap while you work.

6. Secure to the anchor point. Once you have established

your anchor point, secure the tree-trunk protector or

choker-chain around the object.

Hook StrapPulling Wire Rope

602 STARTING AND OPERATING

Page 605 of 916

CAUTION!

Always be certain the anchor you select will with-

stand the load.NOTE: How to choose an anchor point:A secure anchor

is critical to winching operations. An anchor must be

strong enough to hold while winching. Natural anchors

include trees, stumps and rocks. Hook the cable as low as

possible. If no natural anchors are available when recov-

ering another vehicle, your vehicle becomes the anchor

point. In this case, be sure to put the transmission in

NEUTRAL, apply the hand brake and block its wheels to

prevent your vehicle from moving. Ideally, you’ll want

an anchor point that will enable you to pull straight in the

direction the vehicle will move. This allows the wire rope

to wind tightly and evenly onto the spooling drum. An

anchor point as far away as possible will provide the

winch with its greatest pulling power.

7. Attach the Clevis/D-shackle and Tree Trunk Protector.

Attach the shackle to the two ends of the strap or chain

and through the hook loop, being careful not to over

tighten (tighten and back-off 1/2 turn).

Tree Trunk Protector

5

STARTING AND OPERATING 603

Page 610 of 916

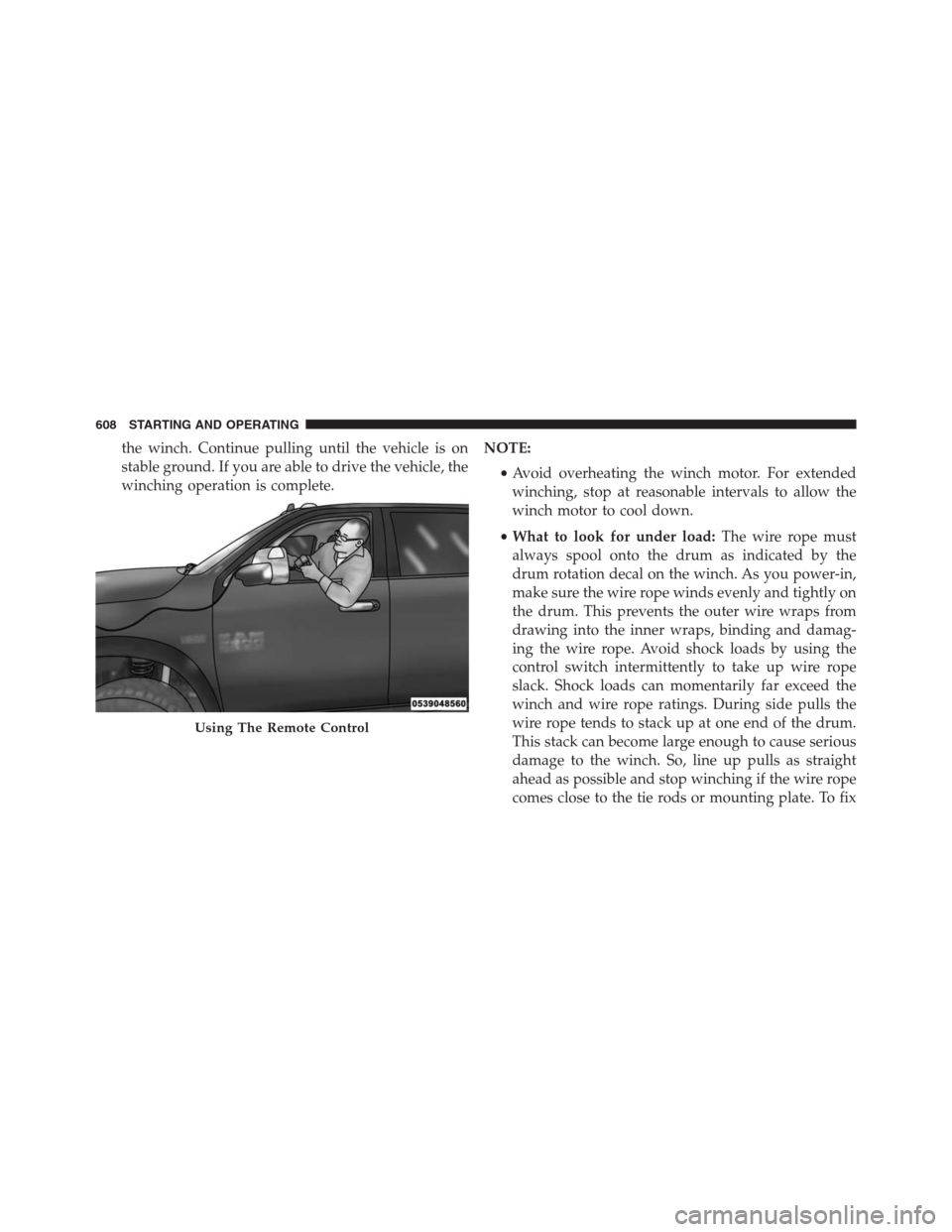

the winch. Continue pulling until the vehicle is on

stable ground. If you are able to drive the vehicle, the

winching operation is complete.NOTE:

•Avoid overheating the winch motor. For extended

winching, stop at reasonable intervals to allow the

winch motor to cool down.

•What to look for under load:The wire rope must

always spool onto the drum as indicated by the

drum rotation decal on the winch. As you power-in,

make sure the wire rope winds evenly and tightly on

the drum. This prevents the outer wire wraps from

drawing into the inner wraps, binding and damag-

ing the wire rope. Avoid shock loads by using the

control switch intermittently to take up wire rope

slack. Shock loads can momentarily far exceed the

winch and wire rope ratings. During side pulls the

wire rope tends to stack up at one end of the drum.

This stack can become large enough to cause serious

damage to the winch. So, line up pulls as straight

ahead as possible and stop winching if the wire rope

comes close to the tie rods or mounting plate. To fix

Using The Remote Control

608 STARTING AND OPERATING

Page 611 of 916

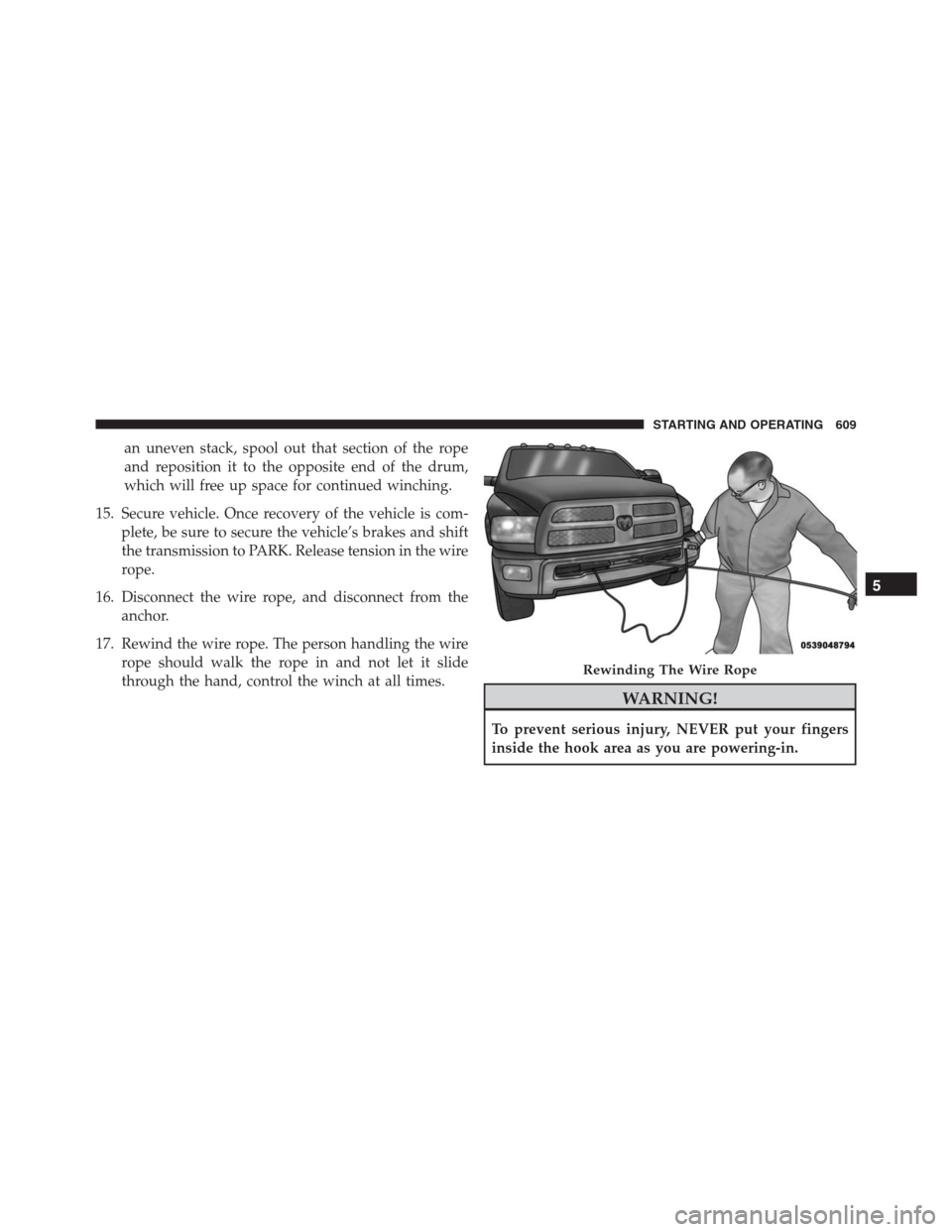

an uneven stack, spool out that section of the rope

and reposition it to the opposite end of the drum,

which will free up space for continued winching.

15. Secure vehicle. Once recovery of the vehicle is com-

plete, be sure to secure the vehicle’s brakes and shift

the transmission to PARK. Release tension in the wire

rope.

16. Disconnect the wire rope, and disconnect from the

anchor.

17. Rewind the wire rope. The person handling the wire

rope should walk the rope in and not let it slide

through the hand, control the winch at all times.

WARNING!

To prevent serious injury, NEVER put your fingers

inside the hook area as you are powering-in.

Rewinding The Wire Rope

5

STARTING AND OPERATING 609

Page 617 of 916

system. This noise should be considered normal, and it

does not in any way damage the steering system.

CAUTION!

Prolonged operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and it should be avoided when

possible. Damage to the power steering pump may

occur.

Power Steering Fluid Check — 2500/3500 Models

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through an autho-

rized dealer.

CAUTION!

Do not use chemical flushes in your power steering

system as the chemicals can damage your power

steering components. Such damage is not covered by

the New Vehicle Limited Warranty.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to ensure accurate fluid level reading. Do

not overfill. Use only manufacturer’s recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to “Fluids, Lubricants, And Genuine

Parts” in “Maintaining Your Vehicle” for further informa-

tion.

5

STARTING AND OPERATING 615

Page 618 of 916

FUEL SAVER TECHNOLOGY 5.7L/6.4L ENGINES

ONLY — IF EQUIPPED

This feature offers improved fuel economy by shutting

off four of the engine’s eight cylinders during light load

and cruise conditions. The system is automatic with no

driver inputs or additional driving skills required.

NOTE:This system may take some time to return to full

functionality after a battery disconnect.

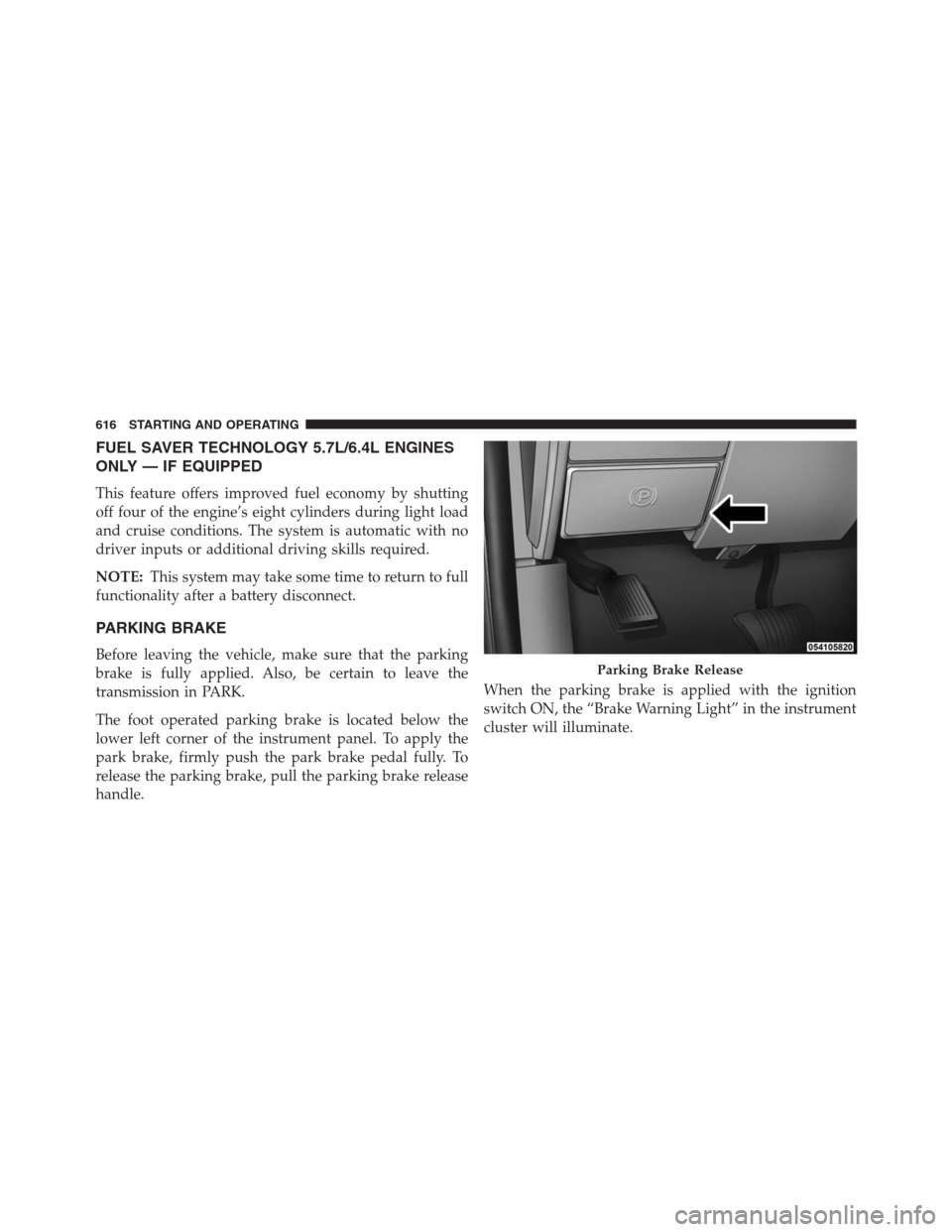

PARKING BRAKE

Before leaving the vehicle, make sure that the parking

brake is fully applied. Also, be certain to leave the

transmission in PARK.

The foot operated parking brake is located below the

lower left corner of the instrument panel. To apply the

park brake, firmly push the park brake pedal fully. To

release the parking brake, pull the parking brake release

handle.When the parking brake is applied with the ignition

switch ON, the “Brake Warning Light” in the instrument

cluster will illuminate.Parking Brake Release

616 STARTING AND OPERATING

Page 621 of 916

system. You may experience some clicking or hissing

noises from the hydro-boost system during hard braking

conditions.

NOTE:Under cold temperatures, pedal effort will be

higher than normal until the power steering fluid reaches

operating temperature.

ELECTRONIC BRAKE CONTROL SYSTEM

Your vehicle is equipped with an advanced Electronic

Brake Control system (EBC). This system includes Elec-

tronic Brake Force Distribution (EBD), Anti-Lock Brake

System (ABS), Brake Assist System (BAS), Hill Start

Assist (HSA), Traction Control System (TCS), Electronic

Stability Control (ESC), and Electronic Roll Mitigation

(ERM). These systems work together to enhance both

vehicle stability and control in various driving condi-

tions.Your vehicle may also be equipped with Trailer Sway

Control (TSC) and Hill Descent Control (HDC).

Electronic Brake Force Distribution (EBD)

This function manages the distribution of the braking

torque between the front and rear axles by limiting

braking pressure to the rear axle. This is done to prevent

overslip of the rear wheels to avoid vehicle instability,

and to prevent the rear axle from entering ABS before the

front axle.

Brake System Warning Light

The red “Brake System Warning Light” will turn on when

the ignition switch is turned to the ON position and may

stay on for as long as four seconds.

If the “Brake System Warning Light” remains on or

comes on while driving, it indicates that the brake system

is not functioning properly and that immediate service is

required. If the “Brake System Warning Light” does not

5

STARTING AND OPERATING 619

Page 623 of 916

WARNING!(Continued)

can cause possible loss of anti-lock braking capa-

bility. Installation of such equipment should be

performed by qualified professionals.

•Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to a collision.

Pumping makes the stopping distance longer. Just

press firmly on your brake pedal when you need to

slow down or stop.

•The ABS cannot prevent the natural laws of phys-

ics from acting on the vehicle, nor can it increase

braking or steering efficiency beyond that afforded

by the condition of the vehicle brakes and tires or

the traction afforded.

•The ABS cannot prevent collisions, including those

resulting from excessive speed in turns, following

another vehicle too closely, or hydroplaning.

(Continued)

WARNING!(Continued)

•The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner that could jeopardize the user ’s safety or

the safety of others.

ABS is designed to function with the OEM tires. Modifi-

cation may result in degraded ABS performance.

Anti-Lock Brake Warning Light

The amber “Anti-Lock Brake Warning Light” will turn on

when the ignition switch is turned to the ON position

and may stay on for as long as four seconds.

If the “Anti-Lock Brake Warning Light” remains on or

comes on while driving, it indicates that the anti-lock

portion of the brake system is not functioning and that

service is required. However, the conventional brake

system will continue to operate normally if the “Brake

System Warning Light” is not on.

5

STARTING AND OPERATING 621

Page 627 of 916

Center (EVIC)” or “Driver Information Display (DID)”

in “Understanding Your Instrument Panel” for further

information.

•If disabling HSA using Uconnect Settings, refer to

“Uconnect Settings” in “Understanding Your Instru-

ment Panel” for further information.

For vehicles not equipped with the EVIC/DID, perform

the following steps:

1. Center the steering wheel (front wheels pointing

straight forward).

2. Shift the transmission into PARK.

3. Apply the parking brake.

4. Start the engine.

5. Rotate the steering wheel slightly more than one-half

turn to the left.6. Push the “ESC Off” button located in the lower switch

bank below the climate control four times within

twenty seconds. The “ESC Off Indicator Light” should

turn on and turn off two times.

7. Rotate the steering wheel back to center and then an

additional slighty more than one-half turn to the right.

8. Turn the ignition switch to the OFF position and then

back to the ON position. If the sequence was com-

pleted properly, the “ESC Off Indicator Light” will

blink several times to confirm HSA is disabled.

9. Repeat these steps if you want to return this feature to

its previous setting.

Traction Control System (TCS)

This system monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, the TCS may

apply brake pressure to the spinning wheel(s) and/or

reduce engine power to provide enhanced acceleration

5

STARTING AND OPERATING 625