lights Ram 1500 2018 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 1500, Model: Ram 1500 2018Pages: 372, PDF Size: 7.1 MB

Page 86 of 372

– 4WD AUTO Indicator Light — If

Equipped

This light alerts the driver that the vehicle is

in the four-wheel drive auto mode, and the

front axle is engaged, but the vehicle's power

is sent to the rear wheels. Four-wheel drive

will be automatically engaged when the ve-

hicle senses a loss of traction.

For further information on four-wheel drive

operation and proper use, refer to “Four-

Wheel Drive Operation — If Equipped” in

“Starting And Operating.”

White Indicator Lights

— Cruise Control Ready Indicator

This light will turn on when the speed control

is ready, but not set.

— Speed Control SET Indicator Light

— If Equipped

This light will turn on when the speed control

is set. Refer to “Speed Control — If

Equipped” in “Starting And Operating” for

further information.

— Hill Descent Control (HDC) Indicator

Light — If Equipped

This indicator shows when the Hill Descent

Control (HDC) feature is turned on. The lamp

will be on solid when HDC is armed. HDC can

only be armed when the transfer case is in the

“4WD LOW” position and the vehicle speed

is less then 30 mph (48 km/h). If these

conditions are not met while attempting to

use the HDC feature, the HDC indicator light

will flash on/off.

Blue Indicator Lights

— High Beam Indicator Light

This indicator shows that the high beam

headlights are on. With the low beams acti-

vated, push the multifunction lever forward

(toward the front of the vehicle) to turn on the

high beams. Pull the multifunction lever rear-

ward (toward the rear of the vehicle) to turn

off the high beams. If the high beams are off,

pull the lever toward you for a temporary high

beam on, "flash to pass" scenario.

ONBOARD DIAGNOSTIC SYSTEM —

OBD II

Your vehicle is equipped with a sophisticated

Onboard Diagnostic system called OBD II.

This system monitors the performance of the

emissions, engine, and transmission control

systems. When these systems are operating

properly, your vehicle will provide excellent

performance and fuel economy, as well as

engine emissions well within current govern-

ment regulations.

If any of these systems require service, the

OBD II system will turn on the Malfunction

Indicator Light (MIL). It will also store diag-

nostic codes and other information to assist

your service technician in making repairs.

Although your vehicle will usually be drivable

and not need towing, see your authorized

dealer for service as soon as possible.

CAUTION!

• Prolonged driving with the MIL on could

cause further damage to the emission

control system. It could also affect fuelGETTING TO KNOW YOUR INSTRUMENT PANEL

84

Page 109 of 372

Because air bag sensors measure vehicle de-

celeration over time, vehicle speed and dam-

age by themselves are not good indicators of

whether or not an air bag should have de-

ployed.

Seat belts are necessary for your protection in

all collisions, and also are needed to help

keep you in position, away from an inflating

air bag.

When the ORC detects a collision requiring

the front air bags, it signals the inflator units.

A large quantity of non-toxic gas is generated

to inflate the front air bags.

The steering wheel hub trim cover and the

upper right side of the instrument panel

separate and fold out of the way as the air

bags inflate to their full size. The front air

bags fully inflate in less time than it takes to

blink your eyes. The front air bags then

quickly deflate while helping to restrain the

driver and front passenger.Knee Impact Bolsters

The Knee Impact Bolsters help protect the

knees of the driver and front passenger, and

position the front occupants for improved

interaction with the front air bags.

WARNING!

• Do not drill, cut, or tamper with the kneeimpact bolsters in any way.

• Do not mount any accessories to the

knee impact bolsters such as alarm

lights, stereos, citizen band radios, etc.

Supplemental Side Air Bags

Ram 1500

Supplemental Seat-Mounted Side Air Bags

(SABs)

This vehicle is equipped with Supplemental

Seat-Mounted Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags

(SABs) are located in the outboard side of the

front seats. The SABs are marked with a

“SRS AIRBAG” or “AIRBAG” label sewn into

the outboard side of the seats. The SABs may help to reduce the risk of

occupant injury during certain side impacts,

in addition to the injury reduction potential

provided by the seat belts and body structure.

When the SAB deploys, it opens the seam on

the outboard side of the seatback’s trim

cover. The inflating SAB deploys through the

seat seam into the space between the occu-

pant and the door. The SAB moves at a very

high speed and with such a high force that it

could injure occupants if they are not seated

Supplemental Seat-Mounted Side Air Bag

Label

107

Page 116 of 372

have skin or eye irritation, rinse the area

with cool water. For nose or throat irritation,

move to fresh air. If the irritation continues,

see your doctor. If these particles settle on

your clothing, follow the garment manufac-

turer’s instructions for cleaning.

Do not drive your vehicle after the air bags

have deployed. If you are involved in another

collision, the air bags will not be in place to

protect you.

WARNING!

Deployed air bags and seat belt preten-

sioners cannot protect you in another col-

lision. Have the air bags, seat belt preten-

sioners, and the seat belt retractor

assemblies replaced by an authorized

dealer immediately. Also, have the Occu-

pant Restraint Controller System serviced

as well.

NOTE:

• Air bag covers may not be obvious in the interior trim, but they will open during air

bag deployment. • After any collision, the vehicle should be

taken to an authorized dealer immediately.

Enhanced Accident Response System

In the event of an impact, if the communica-

tion network remains intact, and the power

remains intact, depending on the nature of

the event, the ORC will determine whether to

have the Enhanced Accident Response Sys-

tem perform the following functions:

• Cut off fuel to the engine.

• Flash hazard lights as long as the batteryhas power or until the hazard light button is

pressed. The hazard lights can be deacti-

vated by pressing the hazard light button.

• Turn on the interior lights, which remain on as long as the battery has power.

• Unlock the power door locks.

Enhanced Accident Response System Reset

Procedure

In order to reset the Enhanced Accident Re-

sponse System functions after an event, the

ignition switch must be changed from igni-

tion START or ON/RUN to ignition OFF. Care-

fully check the vehicle for fuel leaks in the engine compartment and on the ground near

the engine compartment and fuel tank before

resetting the system and starting the engine.

Maintaining Your Air Bag System

WARNING!

• Modifications to any part of the air bag

system could cause it to fail when you

need it. You could be injured if the air

bag system is not there to protect you.

Do not modify the components or wiring,

including adding any kind of badges or

stickers to the steering wheel hub trim

cover or the upper right side of the

instrument panel. Do not modify the

front bumper, vehicle body structure, or

add aftermarket side steps or running

boards.

• It is dangerous to try to repair any part of

the air bag system yourself. Be sure to

tell anyone who works on your vehicle

that it has an air bag system.

• Do not attempt to modify any part of your

air bag system. The air bag may inflate

accidentally or may not function prop-

SAFETY

114

Page 138 of 372

WARNING!

• ONLY use the driver’s side floor mat onthe driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress

the accelerator, the brake, and the

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

•

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference with

the accelerator, brake, or clutch pedals.

WARNING!

• If the vehicle carpet has been removed

and re-installed, always properly attach

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You

Should Make Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel bolts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid

leaks. Also, if gasoline fumes are detected or

if fuel, or brake fluid leaks are suspected. The

cause should be located and corrected imme-

diately.

SAFETY

136

Page 144 of 372

STARTING THE ENGINE — 3.0L

DIESEL ENGINE

Before starting your vehicle, adjust your seat,

both inside and outside mirrors, and fasten

your seat belts.

The starter is allowed to crank for up to

30-second intervals. Waiting a few minutes

between such intervals will protect the starter

from overheating.

WARNING!

• Before exiting a vehicle, always come toa complete stop, then shift the auto-

matic transmission into PARK and apply

the parking brake. Always make sure the

keyless ignition node is in the OFF

mode, remove the key fob from the ve-

hicle and lock the vehicle.

• Never leave children alone in a vehicle,

or with access to an unlocked vehicle.

Leaving children in a vehicle unattended

is dangerous for a number of reasons. A

child or others could be seriously or

fatally injured. Children should be

WARNING!

warned not to touch the parking brake,

brake pedal or the gear selector.

• Do not leave the key fob in or near the

vehicle, or in a location accessible to

children, and do not leave the ignition of

a vehicle equipped with Keyless Enter-

N-Go in the ACC or ON/RUN mode. A

child could operate power windows,

other controls, or move the vehicle.

• Do not leave children or animals inside

parked vehicles in hot weather. Interior

heat build-up may cause serious injury

or death.

NOTE:

Engine start up in very low ambient tempera-

ture could result in evident white smoke. This

condition will disappear as the engine warms

up.

CAUTION!

• The engine is allowed to crank as long as 30 seconds. If the engine fails to start

during this period, please wait at least

CAUTION!

two minutes for the starter to cool before

repeating start procedure.

• If the “Water in Fuel Indicator Light”

remains on, DO NOT START engine be-

fore you drain the water from the fuel

filters to avoid engine damage. Refer to

“Draining Fuel/Water Separator Filter”

in “Servicing And Maintenance” in your

Diesel Supplement on www.mopar.com/

en-us/care/owners-manual.html (U.S.

Residents) or www.owners.mopar.ca

(Canadian Residents) for further infor-

mation.

Normal Starting Using ENGINE

STOP/START Button

Observe the instrument panel cluster lights

when starting the engine.

NOTE:

Normal starting of either a cold or a warm

engine is obtained without pumping or press-

ing the accelerator pedal.

STARTING AND OPERATING

142

Page 151 of 372

NOTE:

The engine block heater cord is a factory

installed option. If your vehicle is not

equipped, heater cords are available from

your authorized Mopar dealer.

• A 12 Volt heater built into the fuel filterhousings aid in preventing fuel gelling. It is

controlled by a built-in thermostat.

• A heated intake air system both improves engine starting and reduces the amount of

white smoke generated by a warming

engine.NORMAL OPERATION — 3.0L DIESEL

ENGINE

Observe the following when the diesel engine

is operating.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Engine Oil Pressure telltale is not illumi-nated.

• Voltmeter operation:

The voltmeter may show a gauge fluctuation

at various engine temperatures. This is

caused by the glow plug heating system. The

number of cycles and the length of the cy-

cling operation is controlled by the engine

control module. Glow plug heater operation

can run for several minutes, once the heater

operation is complete the voltmeter needle

will stabilize.

Cold Weather Precautions

Operation in ambient temperature below

32°F (0°C) may require special consider-

ations. The following charts suggest these

options:

Winter Front Usage

A winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi-

Winter Front Cover

149

Page 153 of 372

NORMAL OPERATION — 6.7L DIESEL

ENGINE

Observe the following when the engine is

operating.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Engine oil pressure is above 10 psi(69 kPa) at idle.

• Voltmeter operation:

The voltmeter may show a gauge fluctuation

at various engine temperatures. This cycling

operation is caused by the post-heat cycle of

the intake manifold heater system. The num-

ber of cycles and the length of the cycling

operation is controlled by the engine control

module. Post-heat operation can run for sev-

eral minutes, and then the electrical system

and voltmeter needle will stabilize.

The cycling action will cause temporary dim-

ming of the headlamps, interior lamps, and

also a noticeable reduction in blower motor

speed.

Cold Weather Precautions

Operation in ambient temperature below

32°F (0°C) may require special consider-

ations. The following charts suggest these

options:

Winter Front Cover Usage

A winter front or cold weather cover is to be

used in ambient temperatures below 32°F

(0°C), especially during extended idle condi-

tions. This cover is equipped with four flaps

for managing total grille opening in varying

ambient temperatures. If a winter front or

cold weather cover is to be used the flaps

should be left in the full open position to

allow air flow to the charge air cooler and

automatic transmission oil cooler. When am-

bient temperatures drop below 0°F (-17°C)

the four flaps need to be closed. A suitable

cold weather cover is available from your

Mopar dealer.

Engine Idling

Avoid prolonged idling, long periods of idling

may be harmful to your engine because com-

bustion chamber temperatures can drop so low that the fuel may not burn completely.

Incomplete combustion allows carbon and

varnish to form on piston rings, engine valves,

and injector nozzles. Also, the unburned fuel

can enter the crankcase, diluting the oil and

causing rapid wear to the engine.

If the engine is allowed to idle or the truck is

driven on low engine speed drive cycles for

more than 2 hours, the system will automati-

cally enter an emissions operating mode that

will increase the engine idle speed to

900 RPM (1050 RPM for Chassis Cab).

While in this mode, which is designed to help

maintain the diesel particulate filter, the en-

gine idle speed will return to normal when the

brake pedal is applied. A small change in

engine tone or a slight change in engine

performance while accelerating may also be

noticeable at speeds below 20 mph

(32 kmh). This operating mode may last for

up to an hour of idle time, or around 20 min-

utes of driving time.

Your truck may have been ordered with an

optional voltage monitoring idle up feature. If

a load is placed on the electrical system while

the truck is in park, this feature will attempt

151

Page 201 of 372

The NEUTRAL (N) indicator light will

blink while the shift is in progress. The

light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is com-

plete. After the shift is completed and

the NEUTRAL (N) light stays on, re-

lease the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal on manual transmissions) for five seconds

and ensure that there is no vehicle

movement.

9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual trans-

mission in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply the parking brake. Turn OFF

the engine. For vehicles with Keyless

Enter-N-Go, push and hold the ENGINE

START/STOP button until the engine

shuts off.

11. Shift the transmission into PARK or place manual transmission in gear (NOT in Neutral). On 8-speed transmissions

the shifter will automatically select

PARK when the engine is turned off.

12. Turn the ignition to the OFF mode, then cycle the ignition to the RUN mode and

back to the OFF mode. Remove the key

fob from the ignition.

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake.

NOTE:

With electronic shift transfer case:

• Steps 2 through 4 are requirements that must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, the NEUTRAL

(N) indicator light will flash continuously

until all requirements are met or until the

NEUTRAL (N) button is released. • The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

• If the vehicle is equipped with air suspen- sion, the engine should be started and left

running for a minimum of 60 seconds (with

all the doors closed) at least once every

24 hours. This process allows the air sus-

pension to adjust the vehicle’s ride height

to compensate for temperature effects.

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage:

1. Bring the vehicle to a complete stop, leav-

ing it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Press and hold the brake pedal.

199

Page 202 of 372

4. Start the engine. Shift the transmissioninto NEUTRAL. Depress the clutch pedal

on a manual transmission.

• With manual shift transfer case, shift the transfer case lever to the desired

position.

• With electronic shift transfer case with rotary selector switch, push and hold

the transfer case NEUTRAL (N) button

until the NEUTRAL (N) indicator light

turns off. After the NEUTRAL (N) indi-

cator light turns off, release the NEU-

TRAL (N) button. After the NEUTRAL

(N) button has been released, the

transfer case will shift to the position

indicated by the selector switch.

• With electronic shift transfer case with push-button selector switch, push and

hold the switch for the desired transfer

case position, until the NEUTRAL (N)

indicator light turns off and the desired

position indicator light turns on. NOTE:

When shifting out of transfer case NEUTRAL

(N), turning the engine OFF is not required,

but may be helpful to avoid gear clash. With

the 8-speed automatic transmission, the en-

gine must remain running, since turning the

engine OFF will shift the transmission to

PARK (and the transmission must be in NEU-

TRAL for the transfer case to shift out of

NEUTRAL).

5. Turn the engine OFF. Shift automatic

transmission into PARK. On 8-speed

transmissions the shifter will automati-

cally select PARK when the engine is

turned off.

6. Release the brake pedal (and clutch pedal on a manual transmission).

7. Disconnect vehicle from the tow vehicle.

8. Start the engine.

9. Press and hold the brake pedal.

10. Release the parking brake.

11. Shift the transmission into gear, release the brake pedal (and clutch pedal on

manual transmissions), and check that

the vehicle operates normally. NOTE:

With electronic shift transfer case:

• Steps 3 and 4 are requirements that must

be met before pushing the button to shift

out of NEUTRAL (N), and must continue to

be met until the shift has been completed.

If any of these requirements are not met

before pushing the button or are no longer

met during the shift, the NEUTRAL (N)

indicator light will flash continuously until

all requirements are met or until the button

is released.

• The ignition must be in the ON/RUN mode for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indicates that shift requirements have

not been met.

STARTING AND OPERATING

200

Page 207 of 372

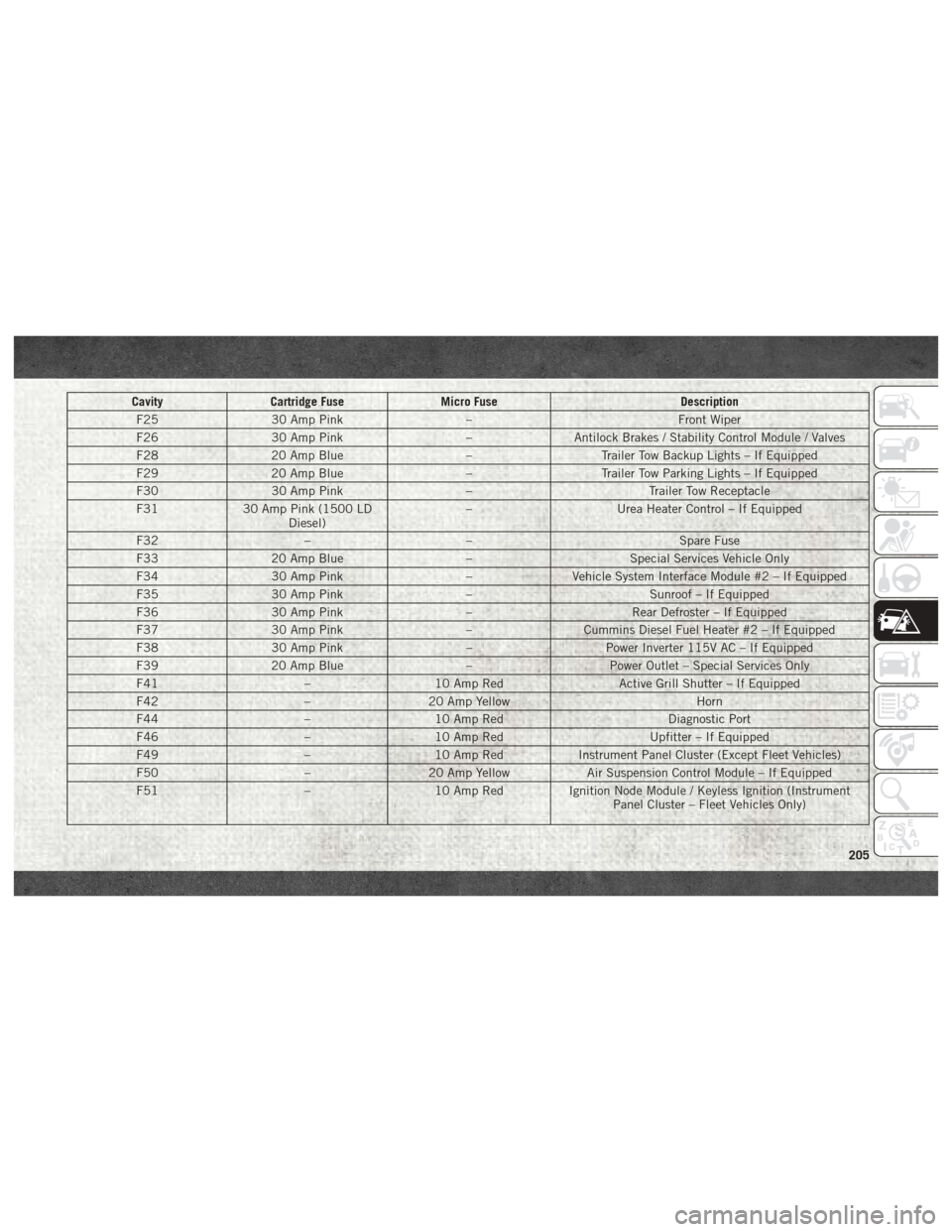

CavityCartridge Fuse Micro Fuse Description

F25 30 Amp Pink – Front Wiper

F26 30 Amp Pink –Antilock Brakes / Stability Control Module / Valves

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle

F31 30 Amp Pink (1500 LD

Diesel) –

Urea Heater Control – If Equipped

F32 –– Spare Fuse

F33 20 Amp Blue –Special Services Vehicle Only

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Rear Defroster – If Equipped

F37 30 Amp Pink –Cummins Diesel Fuel Heater #2 – If Equipped

F38 30 Amp Pink –Power Inverter 115V AC – If Equipped

F39 20 Amp Blue –Power Outlet – Special Services Only

F41 –10 Amp Red Active Grill Shutter – If Equipped

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitter – If Equipped

F49 –10 Amp Red Instrument Panel Cluster (Except Fleet Vehicles)

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp Red Ignition Node Module / Keyless Ignition (Instrument

Panel Cluster – Fleet Vehicles Only)

205