clock Ram 1500 2018 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 1500, Model: Ram 1500 2018Pages: 372, PDF Size: 7.1 MB

Page 34 of 372

EXTERIOR LIGHTS

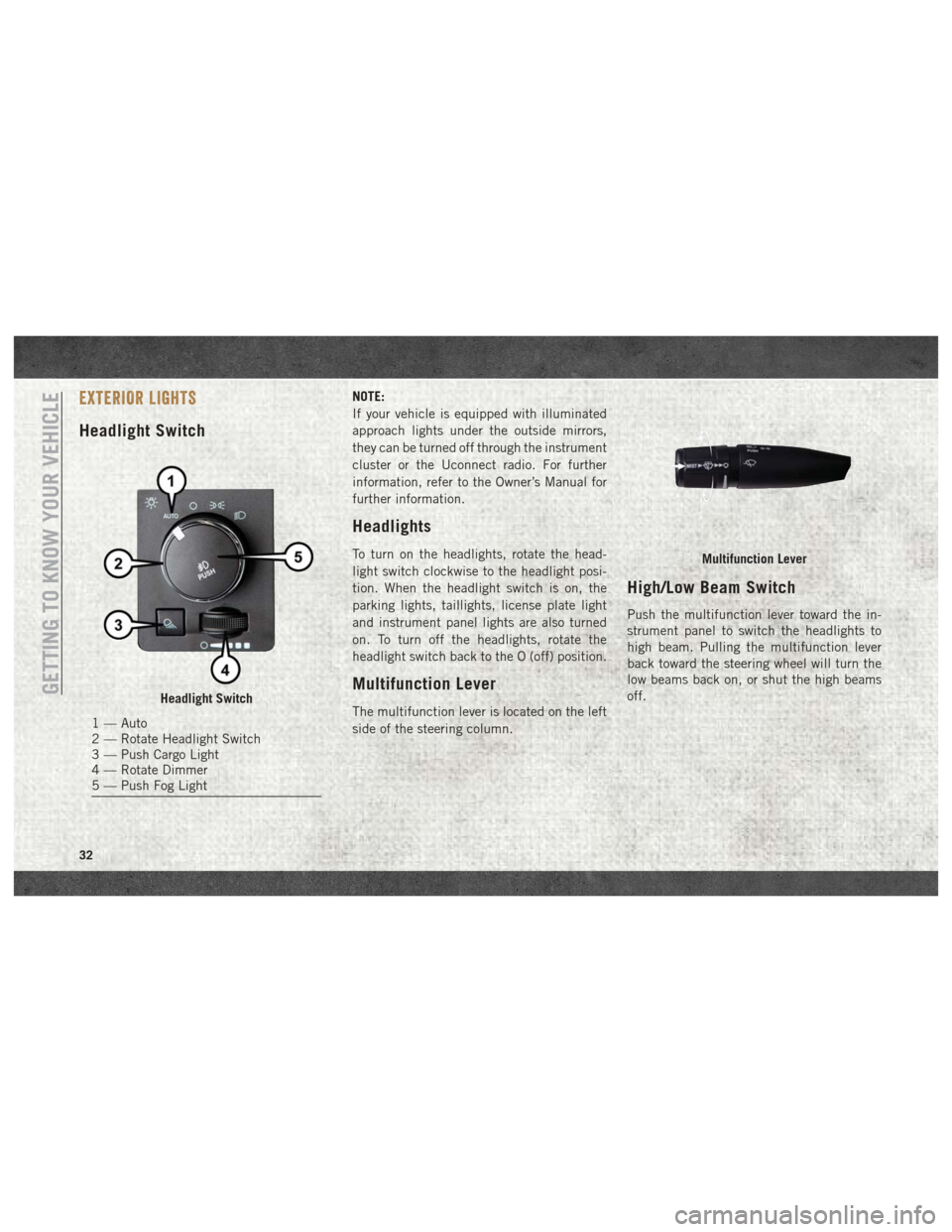

Headlight Switch

NOTE:

If your vehicle is equipped with illuminated

approach lights under the outside mirrors,

they can be turned off through the instrument

cluster or the Uconnect radio. For further

information, refer to the Owner’s Manual for

further information.

Headlights

To turn on the headlights, rotate the head-

light switch clockwise to the headlight posi-

tion. When the headlight switch is on, the

parking lights, taillights, license plate light

and instrument panel lights are also turned

on. To turn off the headlights, rotate the

headlight switch back to the O (off) position.

Multifunction Lever

The multifunction lever is located on the left

side of the steering column.

High/Low Beam Switch

Push the multifunction lever toward the in-

strument panel to switch the headlights to

high beam. Pulling the multifunction lever

back toward the steering wheel will turn the

low beams back on, or shut the high beams

off.

Headlight Switch

1 — Auto

2 — Rotate Headlight Switch

3 — Push Cargo Light

4 — Rotate Dimmer

5 — Push Fog Light

Multifunction Lever

GETTING TO KNOW YOUR VEHICLE

32

Page 35 of 372

Automatic High Beam Headlamp

Control — If Equipped

The Automatic High Beam Headlamp Control

system provides increased forward lighting at

night by automating high beam control

through the use of a digital camera mounted

on the inside rearview mirror. This camera

detects vehicle specific light and automati-

cally switches from high beams to low beams

until the approaching vehicle is out of view.

NOTE:

• The Automatic High Beam Headlamp Con-trol can be turned on or off by selecting

“ON” under “Auto High Beam” within your

Uconnect settings, as well as turning the

headlight switch to the AUTO position. Re-

fer to “Uconnect Settings” in “Multimedia”

in the Owner’s Manual for further informa-

tion.

• Broken, muddy, or obstructed headlights and taillights of vehicles in the field of view

will cause headlights to remain on longer

(closer to the vehicle). Also, dirt, film, and

other obstructions on the windshield or

camera lens will cause the system to func-

tion improperly. If the windshield or Automatic High Beam

Headlamp Control mirror is replaced, the

mirror must be re-aimed to ensure proper

performance. See a local authorized dealer.

Automatic Headlights — If

Equipped

This system automatically turns the head-

lights on or off according to ambient light

levels. To turn the system on, rotate the

headlight switch counterclockwise to the

AUTO position. When the system is on, the

headlight time delay feature is also on. This

means the headlights will stay on for up to

90 seconds after you place the ignition into

the OFF position. The headlight time delay

can be programmed 0/30/60/90 seconds.

Refer to “Uconnect Settings” in “Multime-

dia” in the Owner’s Manual for further infor-

mation.

To turn the automatic system off, move the

headlight switch out of the AUTO position.

NOTE:

The engine must be running before the head-

lights will turn on in the Automatic Mode.

Parking Lights And Panel Lights

To turn on the parking lights and instrument

panel lights, rotate the headlight switch

clockwise. To turn off the parking lights,

rotate the headlight switch back to the O (off)

position.

Turn Signals

Move the multifunction lever up or down and

the arrows on each side of the instrument

cluster display will flash to show proper op-

eration of the front and rear turn signal lights.

NOTE:

If either light remains on and does not flash,

or there is a very fast flash rate, check for a

defective outside light bulb. If an indicator

fails to light when the lever is moved, it would

suggest that the indicator bulb is defective.

33

Page 41 of 372

IconDescription

Temperature Control

Press the arrows on the touchscreen or faceplate to regulate the temperature of the air inside the passenger compart-

ment. Pressing the down arrow indicates cooler temperatures, and pressing the up arrow indicates warmer tempera-

tures.

Blower Control

There are seven blower speeds. Press the buttons to regulate the amount of air forced through the system in any mode

you select. The blower speed increases as you move the control clockwise from the off position.

Panel Mode

Panel Mode

Air comes from the outlets in the instrument panel. Each of these outlets can be individually adjusted to direct the flow

of air. The air vanes of the center outlets and outboard outlets can be moved up and down or side to side to regulate

airflow direction. There is a shut off wheel located below the air vanes to shut off or adjust the amount of airflow from

these outlets.

Bi-Level Mode

Bi-Level Mode

Air comes from the instrument panel outlets and floor outlets. A slight amount of air is directed through the defrost and

side window demister outlets.

NOTE:

Bi-Level mode is designed under comfort conditions to provide cooler air out of the panel outlets and warmer air from

the floor outlets.

Floor Mode

Floor Mode

Air comes from the floor outlets. A slight amount of air is directed through the defrost and side window demister out-

lets.

39

Page 47 of 372

IconDescription

SYNC Button — If Equipped

Press the SYNC button on the touchscreen to toggle the SYNC feature on/off. The SYNC indicator is illuminated when

this feature is enabled. SYNC is used to synchronize the passenger temperature setting with the driver temperature set-

ting. The SYNC feature also synchronizes the rear passengers’ temperature to the driver temperature setting. Changing

the passenger temperature setting while in SYNC will automatically exit this feature.

Faceplate Knob

Touchscreen Buttons

Blower Control

Blower Control is used to regulate the amount of air forced through the climate system. There are seven blower speeds

available. The speeds can be selected using either the blower control knob on the faceplate or the buttons on the touch-

screen.

• Faceplate: The blower speed increases as you turn the blower control knob clockwise from the lowest blower setting. The

blower speed decreases as you turn the blower control knob counterclockwise.

• Touchscreen:

Use the small blower icon to reduce the blower setting and the large blower icon to increase the blower

setting. Blower can also be selected by pressing the blower bar area between the icons. For Uconnect 3, press the button

to access the blower screen and control the blower.

Panel Mode

Panel Mode

Air comes from the outlets in the instrument panel. Each of these outlets can be individually adjusted to direct the flow

of air. The air vanes of the center outlets and outboard outlets can be moved up and down or side to side to regulate

airflow direction. There is a shut off wheel located below the air vanes to shut off or adjust the amount of airflow from

these outlets.

Bi-Level Mode

Bi-Level Mode

Air comes from the instrument panel outlets and floor outlets. A slight amount of air is directed through the defrost and

side window demister outlets.

NOTE:

Bi-Level mode is designed under comfort conditions to provide cooler air out of the panel outlets and warmer air from

the floor outlets.

45

Page 62 of 372

CAUTION!

Leaving the lid open for extended periods

of time could cause the vehicle battery to

discharge. If the lid is required to stay

open for extended periods of time, it is

recommended that the bin lights be

turned off manually using the on/off

switch.

The interior of the RamBox will automatically

illuminate when the lid is opened. In addition

to the automatic illumination switch, there is

a manual on/off switch located at the rear of

each storage bin. Pushing the switch once

will turn off the bin lights, pushing the switch

again will turn the lights back on.

Cargo bins feature two removable drain plugs

(to allow water to drain from bins). To remove

plug, pull up on the edge. To install push plug

downward into drain hole.

NOTE:

Provisions are provided in the bins for cargo

dividers and shelf supports. These accesso-

ries (in addition to other RamBox accesso-

ries) are available from Mopar.

Locking And Unlocking RamBox

Push and release the lock or unlock button on

the key fob to lock and unlock all doors, the

tailgate and the RamBox (if equipped). Refer

to “Keys” in “Getting To Know Your Vehicle”

in the Owner’s Manual for further details. The

RamBox storage bins can be locked using the

vehicle key. To lock and unlock the storage

bin, insert the key into the keyhole on the

push button and turn clockwise to lock or

counterclockwise to unlock. Always return

the key to the upright (vertical) position be-

fore removing the key from the push button.

CAUTION!

• Ensure cargo bin lids are closed and latched before moving or driving vehicle.

• Loads applied to the top of the bin lid

should be minimized to prevent damage

to the lid and latching/hinging mecha-

nisms.

• Damage to the RamBox bin may occur

due to heavy/sharp objects placed in bin

that shift due to vehicle motion. In order

to minimize potential for damage, se-

CAUTION!

cure all cargo to prevent movement and

protect inside surfaces of bin from

heavy/sharp objects with appropriate

padding.

RamBox Safety Warning

Carefully follow these warnings to help pre-

vent personal injury or damage to your

vehicle:

WARNING!

• Always close the storage bin coverswhen your vehicle is unattended.

• Do not allow children to have access to

the storage bins. Once in the storage

bin, young children may not be able to

escape. If trapped in the storage bin,

children can die from suffocation or heat

stroke.

• In an accident, serious injury could re-

sult if the storage bin covers are not

properly latched.

GETTING TO KNOW YOUR VEHICLE

60

Page 64 of 372

Extender Position

The extender position allows you to load the

bed of the truck beyond the tail gate. The bed

extender will add an additional 15 inches

(38 cm) in the back of the truck when addi-

tional cargo room is needed. The extender

position utilizes a locating pin and rotating

handle located on both sides of the truck bed

near the tailgate.

To install the bed extender into the extender

position, perform the following:

1. Lower the tailgate.

2. Make sure the center handle is unlockedand rotate the center handle vertically in

order to release the extender side gates.

3. Fit the end of the side gate ends onto the pin and handle.

4. Rotate the handles to the horizontal posi- tion to secure into place.WARNING!

To reduce the risk of potential injury or

property damage:

• Cargo must be secured.

• Do not exceed cargo load rating of yourvehicle.

• Secure all loads to truck utilizing cargo

tie downs.

• Extender should not be used as cargo tie

down.

• When vehicle is in motion do not exceed

150 lbs (68 kg) load on the tailgate.

• The bed extender is not intended for off

road use.

• When not in use, the extender/divider

should be in stowed or divider position

with the tailgate closed.

• When in use all handles are to be in the

locked position.

Bed Rail Tie-Down System

CAUTION!

The maximum load per cleat should not

exceed 250 lbs (113 kg) and the angle of

CAUTION!

the load on each cleat should not exceed

45 degrees above horizontal, or damage to

the cleat or cleat rail may occur.

There are two adjustable cleats on each side

of the bed that can be used to assist in

securing cargo.

Each cleat must be located and tightened

down in one of the detents, along either rail,

in order to keep cargo properly secure.

To move the cleat to any position on the rail,

turn the nut counterclockwise, approximately

three turns. Then pull out on the cleat and

slide it to the detent nearest the desired

location. Make sure the cleat is seated in the

detent and tighten the nut.

To remove the cleats from the utility rail,

remove the end cap screw located in the

center of the end cap, using a #T30 Torx

head driver. Remove the end cap and slide

the cleat off the end of the rail.

GETTING TO KNOW YOUR VEHICLE

62

Page 128 of 372

seat belts are designed to keep the lap por-

tion of the seat belt tight around the child

restraint so that it is not necessary to use a

locking clip. The ALR retractor can be

“switched” into a locked mode by pulling all

of the webbing out of the retractor and then

letting the webbing retract back into the

retractor. If it is locked, the ALR will make a

clicking noise while the webbing is pulled

back into the retractor. Refer to the “Auto-

matic Locking Mode” description in “Switch-

able Automatic Locking Retractors (ALR)”

under “Occupant Restraint Systems” for ad-

ditional information on ALR. The cinching

latch plate is designed to hold the lap portion

of the seat belt tight when webbing is pulled

tight and straight through a child restraint’s

belt path.

Please see the table below and the following

sections for more information.Lap/Shoulder Belt Systems For Installing

Child Restraints In This Vehicle

Frequently Asked Questions About Installing Child Restraints With Seat Belts

What is the weight limit (child’s weight +

weight of the child restraint) for using the

Tether Anchor with the seat belt to attach a forward facing child restraint? Weight limit of the Child RestraintAlways use the tether anchor when using the

seat belt to install a forward facing child re-

straint, up to the recommended weight limit of the child restraint.

Regular Cab Automatic Locking Retractor(ALR) Locations

ALR = Switchable Automatic Locking

Retractor

Top Tether Anchorage Symbol

Quad Cab/Mega Cab/Crew Cab AutomaticLocking Retractor (ALR) Locations

CINCH = Cinching Latchplate

ALR = Switchable Automatic Locking

Retractor

Top Tether Anchorage Symbol

SAFETY

126

Page 183 of 372

REFUELING THE VEHICLE — GAS

ENGINE

The fuel filler cap (gas cap) is located behind

the fuel filler door, on the left side of the

vehicle. Open the fuel door and remove the

fuel cap by turning it counter-clockwise.

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler

door.

WARNING!

• Never have any smoking materials lit inor near the vehicle when the gas cap is

removed or the tank is being filled.

• Never add fuel to the vehicle when the

engine is running.

• A fire may result if gasoline is pumped

into a portable container that is inside of

a vehicle. You could be burned. Always

place gas containers on the ground while

filling.

CAUTION!

• Damage to the fuel system or emissionscontrol system could result from using

an improper fuel tank filler tube cap.

• A poorly fitting fuel filler cap could let

impurities into the fuel system.

• A poorly fitting fuel filler cap may cause

the “Malfunction Indicator Light (MIL)”

to turn on.

• To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

When the fuel nozzle “clicks” or shuts

off, the fuel tank is full.

NOTE:

• When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

• Tighten the gas cap until you hear a “click- ing” sound. This is an indication that the

gas cap is tightened properly. The MIL in

the instrument cluster may turn on if the

gas cap is not secured properly. Make sure

that the gas cap is tightened each time the

vehicle is refueled.

WARNING!

Static electricity can cause an ignition of

flammable liquid, vapor or gas in any ve-

hicle or trailer. To reduce risk of serious

injury or death when filling containers:

• Always place container on the ground before filling.

• Keep the pump nozzle in contact with

the container when you are filling it.

• Use only approved containers for flam-

mable liquid.

• Do not leave container unattended while

filling.

• A static electric charge could cause a

spark and fire hazard.

181

Page 211 of 372

1500 Series Trucks

• Remove the jack and tool bag by removingthe wing bolt and sliding the jack and tool

bag from under the seat. 2500/3500 Series Trucks

• Remove the jack and tool bracket assembly

by removing the wing bolt and sliding the

jack and tool bracket assembly from under

the seat.Removing The Spare Tire

1. Remove the spare tire before attempting

to jack up the truck.

2. Attach the lug wrench to the extension tubes with the curved angle facing away

from the vehicle.

3. Insert the extension tube through the ac- cess hole between the lower tailgate and

the top of the bumper and into the winch

mechanism tube.

4. Rotate the lug wrench handle counter- clockwise until the spare tire is on the

ground with enough cable slack to allow

you to pull it out from under the vehicle.

5. When the spare is clear, tilt the retainer at the end of the cable and pull it through

the center of the wheel.

Wing Bolt Location

Jack And Tool Bracket Assembly

209

Page 213 of 372

Jacking Instructions

1. Remove the spare wheel, jack, and toolsfrom storage.

2. Using the lug wrench, loosen, but do not remove, the lug nuts by turning them

counterclockwise one turn while the

wheel is still on the ground. 3. Placement of the jack is critical:

NOTE:

Keep the jack and tools aligned while raising

the vehicle

1500 Series Trucks (4x2 And 4x4)

• When changing a front wheel, place the

scissors jack under the rear portion of the

lower control arm as shown below.

NOTE:

Access the front jacking location from behind

the front tire, and rear jacking location from

behind the rear tire. • Operate the jack using the extension with

the jack hook and the lug wrench. The

extension tubes may be used but is not

required.

Warning Label

Front 4x2 Jacking Location

Front 4x4 Jacking Location

211