Tire Ram 1500 2020 Repair Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 1500, Model: Ram 1500 2020Pages: 674, PDF Size: 32.69 MB

Page 469 of 674

IN CASE OF EMERGENCY 467

6. Remove the lug nuts and pull the wheel off. Install thespare wheel and lug nuts with the cone shaped end of the

lug nuts toward the wheel. Hand tighten the lug nuts

with vehicle lifted. To avoid the risk of forcing the vehicle

off the jack, do not fully tighten the lug nuts until the

vehicle has been lowered.

7. Lower vehicle to ground, finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in a star

pattern until each nut has been tightened twice.

NOTE:

For the correct lug nut torque refer to “Technical Specifica -

tions” in “Torque Specifications.” If in doubt about the

correct tightness, have them checked with a torque wrench

by an authorized dealer or service station. 8. If your vehicle is equipped with a wheel center cap, install

the cap and remove the wheel blocks. Do not install

chrome or aluminum wheel center caps on the spare

wheel. This may result in cap damage.

9. Lower the jack to its fully closed position. Stow the replaced tire, and secure the jack and tools in the proper

location.

10. Adjust the tire pressure when possible.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

6

2020_DT_1500_OM_US.book Page 467

Page 470 of 674

468 IN CASE OF EMERGENCY

To Stow The Flat Or Spare

1. Turn the wheel so that the valve stem is facing upwardand toward the rear of the vehicle for convenience in

checking the spare tire inflation. Slide the wheel retainer

through the center of the wheel. Reinstalling The Retainer

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

2020_DT_1500_OM_US.book Page 468

Page 471 of 674

IN CASE OF EMERGENCY 469

2. Lift the spare tire with one hand to give clearance to tiltthe retainer at the end of the cable and position it properly

across the wheel opening.

Pushing The Retainer Through The Center Of The Wheel And Positioning It 3. Remove the extension with the hook and reattach the

short extension 5. Attach the lug wrench to the extension

tubes with the curved angle facing away from the vehicle.

Insert the extension tubes through the access hole

between the lower tailgate and the top of the bumper and

into the winch mechanism tube.

Lug Wrench And Extension Tubes Assembled And In Position

6

2020_DT_1500_OM_US.book Page 469

Page 472 of 674

470 IN CASE OF EMERGENCY

4. Rotate the lug wrench handle clockwise until the wheel isdrawn into place against the underside of the vehicle.

Continue to rotate until you feel the winch mechanism

slip, or click three or four times. It cannot be overtight -

ened. Push against the tire several times to ensure it is

firmly in place.

Rotating The Lug Wrench Handle

NOTE:

The winch mechanism is designed for use with the extension

tube only. Use of an air wrench or other power tools is not

recommended and can damage the winch.Reinstalling The Jack And Tools

1. Tighten the jack all the way down by turning the jack turn-screw counterclockwise until the jack is snug.

2. Position the jack and tool bag. Make sure the lug wrench is under the jack near the jack turn-screw.

Jack And Tool Bag

2020_DT_1500_OM_US.book Page 470

Page 480 of 674

478 IN CASE OF EMERGENCY

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial towing service.

If the transmission and drivetrain are operable, disabled

vehicles may also be towed as described under “Recreational

Towing (Behind Motorhome, Etc.)” in the “Starting And

Operating” section.

NOTE:

Vehicles equipped with the Active-Level Four Corner Air

Suspension System must be placed in Transport mode,

before tying them down (from the body) on a trailer or

flatbed truck. If the vehicle cannot be placed in Transport

mode (for example, engine will not run), tie-downs must be

fastened to the axles (not to the body). Failure to follow these

instructions may cause fault codes to be set and/or cause loss

of proper tie-down tension.

Refer to "Active-Level Four Corner Air Suspension System

— If Equipped" in "Starting And Operating" for more infor-

mation.

WARNING!

Fast spinning tires can be dangerous. Forces generated by

excessive wheel speeds may cause damage, or even failure, of

the axle and tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than 30 mph (48 km/ h) or for longer than 30 seconds continuously without

stopping when you are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the engine to

idle with the transmission in NEUTRAL for at least one

minute after every five rocking-motion cycles. This will

minimize overheating and reduce the risk of transmission

failure during prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shifting between DRIVE and REVERSE, do not spin the wheels faster than

15 mph (24 km/h), or drivetrain damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission overheating and failure. It can also

damage the tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission shifting occur-

ring).

2020_DT_1500_OM_US.book Page 478

Page 485 of 674

SERVICING AND MAINTENANCE 483

Once A Month Or Before A Long Trip:

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual wear or damage.Rotate tires at the first sign of irregular wear, even if it

occurs before the oil indicator system turns on.

• Check the fluid levels of the coolant reservoir, brake master cylinder, and fill as needed.

• Check function of all interior and exterior lights.Maintenance Plan

Required Maintenance

Refer to the Maintenance Plan on the following pages for

required maintenance.

NOTE:

Using white lithium grease, lubricate the door hinge roller pivot joints twice a year to prevent premature wear. At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change the oil and filter.

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

• Inspect the battery and clean and tighten terminals as required.

• Inspect the CV/Universal joints.

• Inspect the brake pads, shoes, rotors, drums, and hoses.

• Inspect the engine cooling system protection and hoses.

• Inspect the exhaust system.

• Inspect the engine air cleaner if using in dusty or off-road conditions.

7

2020_DT_1500_OM_US.book Page 483

Page 509 of 674

SERVICING AND MAINTENANCE 507

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every

12 months (before the onset of freezing weather, where

applicable). If the engine coolant (antifreeze) is dirty or rusty

in appearance, the system should be drained, flushed and

refilled with fresh coolant. Check the front of the A/C

condenser (if equipped) or radiator for any accumulation of

bugs, leaves, etc. If dirty, clean by gently spraying water

from a garden hose vertically down the face of the A/C

condenser (if equipped) or the back of the radiator core.

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks.

DO NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT. Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add coolant properly.

Failure to fill these systems properly could lead to severe

internal engine damage. If any coolant is needed to be added

to the system please contact an authorized dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

OAT coolant (antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section for the proper

maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical Specifica

-

tions” for further information.

NOTE:

• Mixing of engine coolant (antifreeze) other than specified Organic Additive Technology (OAT) engine coolant (anti -

freeze), may result in engine damage and may decrease

corrosion protection. Organic Additive Technology (OAT)

engine coolant is different and should not be mixed with

Hybrid Organic Additive Technology (HOAT) engine

coolant (antifreeze) or any “globally compatible” coolant

• When working near the radiator cooling fan, discon

-

nect the fan motor lead or turn the ignition to the OFF

mode. The fan is temperature controlled and can start at

any time the ignition is in the ON mode.

WARNING! (Continued)

7

2020_DT_1500_OM_US.book Page 507

Page 518 of 674

516 SERVICING AND MAINTENANCE

Fluid Level Check

This fluid level can be checked by removing the filler plug. The

fluid level should be to the bottom edge of the filler plug hole (or

within 1/8 inch of the bottom) with the vehicle in a level position.

Drain And Refill

Refer to the “Maintenance Plan” in this section for the proper

maintenance intervals.

HOISTING

A conventional floor jack may be used at the jacking loca-

tions. Refer to the graphics that show jacking locations.

However, a floor jack or frame hoist must never be used on

any other parts of the underbody.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the following infor -

mation: Tire Markings, Tire Identification Numbers, Tire Termi -

nology and Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire MarkingsCAUTION!

Never use a floor jack directly under the differential housing

of a loaded truck or damage to your vehicle may result.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Temperature Grades

2020_DT_1500_OM_US.book Page 516

Page 519 of 674

SERVICING AND MAINTENANCE 517

NOTE:

• P (Passenger) — Metric tire sizing is based on US designstandards. P-Metric tires have the letter “P” molded into

the sidewall preceding the size designation. Example:

P215/65R15 95H.

• European — Metric tire sizing is based on European design standards. Tires designed to this standard have the

tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

• LT (Light Truck) — Metric tire sizing is based on US design standards. The size designation for LT-Metric tires is the same as for P-Metric tires except for the letters “LT” that

are molded into the sidewall preceding the size designa

-

tion. Example: LT235/85R16.

• Temporary spare tires are designed for temporary emer -

gency use only. Temporary high pressure compact spare

tires have the letter “T” or “S” molded into the sidewall

preceding the size designation. Example: T145/80D18

103M.

• High flotation tire sizing is based on US design standards and it begins with the tire diameter molded into the side -

wall. Example: 31x10.5 R15 LT.

Tire Sizing Chart EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

7

2020_DT_1500_OM_US.book Page 517

Page 520 of 674

518 SERVICING AND MAINTENANCE

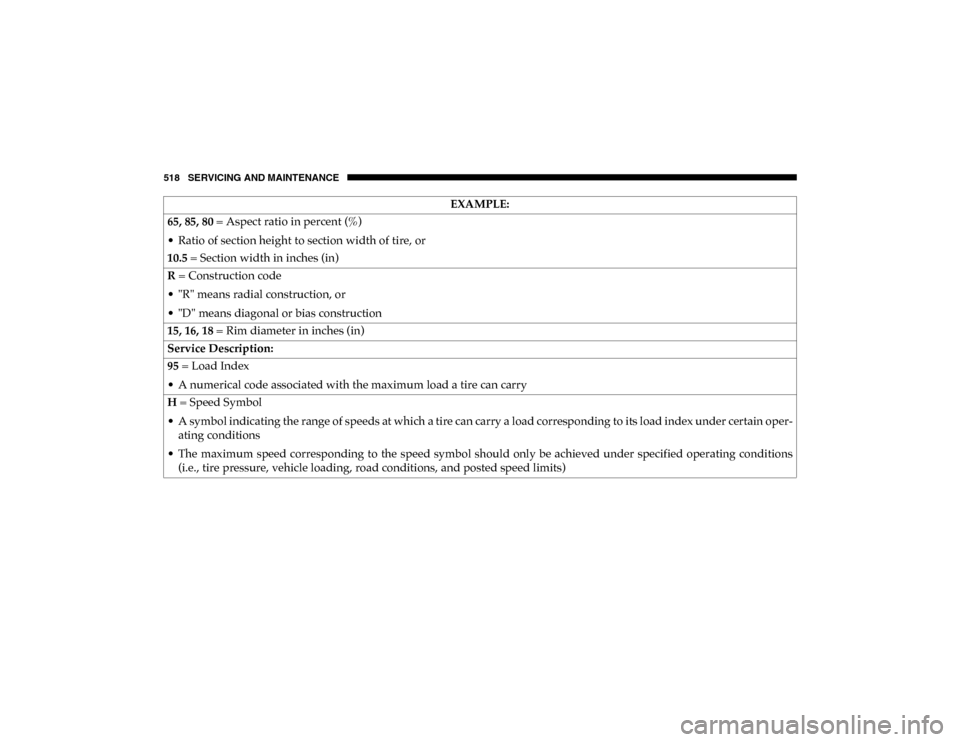

65, 85, 80 = Aspect ratio in percent (%)

• Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

• "R" means radial construction, or

• "D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

• A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

• A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain oper -

ating conditions

• The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and posted speed limits) EXAMPLE:

2020_DT_1500_OM_US.book Page 518