technical specifications Ram 1500 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: 1500, Model: Ram 1500 2020Pages: 674, PDF Size: 32.69 MB

Page 3 of 674

TABLE OF CONTENTS

20_DT_OM_EN_USC

1

2

3

4

5

6

7

8

9

10

11

1 INTRODUCTION ................................................................................................................................................................................. 132 GETTING TO KNOW YOUR VEHICLE ......................................................................................................................................... 16

3 GETTING TO KNOW YOUR INSTRUMENT PANEL .............................................................................................................. 161

4 SAFETY ................................................................................................................................................................................................. 198

5 STARTING AND OPERATING ...................................................................................................................................................... 290

6 IN CASE OF EMERGENCY .............................................................................................................................................................. 431

7 SERVICING AND MAINTENANCE ............................................................................................................................................. 482

8 TECHNICAL SPECIFICATIONS .................................................................................................................................................... 546

9 MULTIMEDIA .................................................................................................................................................................................... 557

10 CUSTOMER ASSISTANCE ............................................................................................................................................................. 652

11 INDEX .................................................................................................................................................................................................... 657

2020_DT_1500_OM_US.book Page 1

Page 12 of 674

10

Brake System ............................................................... 512

Automatic Transmission ........................................... 513

Rear Axle And 4x4 Front Driving Axle Fluid

Level ............................................................................. 515

Transfer Case ............................................................... 515

HOISTING ......................................................................... 516

TIRES................................................................................... 516

Tire Safety Information............................................... 516

Tires — General Information .................................... 525

Tire Types ..................................................................... 531

Spare Tires — If Equipped ......................................... 532

Wheel And Wheel Trim Care .................................... 535

Tire Chains (Traction Devices) .................................. 536

Tire Rotation Recommendations .............................. 537

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES ............................................... 538

Treadwear..................................................................... 538

Traction Grades ........................................................... 538

Temperature Grades ................................................... 538

STORING THE VEHICLE................................................ 539

BODYWORK...................................................................... 539

Protection From Atmospheric Agents ...................... 539

Body And Underbody Maintenance......................... 540

Preserving The Bodywork.......................................... 540

INTERIORS .......................................................................543

Seats And Fabric Parts ................................................543

Plastic And Coated Parts ............................................544

Leather Parts.................................................................545

Glass Surfaces ..............................................................545

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA ...............................................546

Vehicle Identification Number ................................. 546

BRAKE SYSTEM ...............................................................546

WHEEL AND TIRE TORQUE SPECIFICATIONS ....... 546

Torque Specifications ..................................................547

FUEL REQUIREMENTS ..................................................548

3.6L Engine ..................................................................548

5.7L Engine ...................................................................549

Reformulated Gasoline ...............................................549

Materials Added To Fuel ............................................550

Gasoline/Oxygenate Blends ......................................550

Do Not Use E-85 In Non-Flex Fuel Vehicles ............551

CNG And LP Fuel System Modifications ................ 551

MMT In Gasoline .........................................................551

Fuel System Cautions ..................................................551

Carbon Monoxide Warnings......................................552

2020_DT_1500_OM_US.book Page 10

Page 17 of 674

INTRODUCTION 15

Operating instructions for the special equipment installed by

the conversion/camper manufacturer should also be

supplied with your vehicle. If these instructions are missing,

please contact your authorized dealer for assistance in

obtaining replacement documents from the applicable

manufacturer.

For information on the Body Builder’s Guide refer to

www.rambodybuilder.com. This website contains dimen -

sional and technical specifications for your vehicle. It is

intended for Second Stage Manufacturer's technical support.

For service issues, contact your authorized dealer.VEHICLE MODIFICATIONS/ALTERATIONS

WARNING!

Any modifications or alterations to this vehicle could

seriously affect its roadworthiness and safety and may

lead to a collision resulting in serious injury or death.1

2020_DT_1500_OM_US.book Page 15

Page 299 of 674

STARTING AND OPERATING 297

ENGINE BREAK-IN RECOMMENDATIONS

A long break-in period is not required for the engine and

drivetrain (transmission and axle) in your vehicle.

Drive moderately during the first 300 miles (500 km). After

the initial 60 miles (100 km), speeds up to 50 or 55 mph (80 or

90 km/h) are desirable.

While cruising, brief full-throttle acceleration within the

limits of local traffic laws contributes to a good break-in.

Wide-open throttle acceleration in low gear can be detri-

mental and should be avoided.

The engine oil installed in the engine at the factory is a

high-quality energy conserving type lubricant. Oil changes

should be consistent with anticipated climate conditions

under which vehicle operations will occur. For the recom -

mended viscosity and quality grades, refer to “Fluids And

Lubricants” in “Technical Specifications”. NOTE:

A new engine may consume some oil during its first few

thousand miles (kilometers) of operation. This should be

considered a normal part of the break-in and not interpreted

as a problem. Please check your oil level with the engine oil

indicator often during the break in period. Add oil as

required.

PARKING BRAKE

Electric Park Brake (EPB)

Your vehicle is equipped with an Electric Park Brake System

(EPB) that offers simple operation, and some additional

features that make the parking brake more convenient and

useful.

The parking brake is primarily intended to prevent the

vehicle from rolling while parked. Before leaving the vehicle,

make sure that the park brake is applied. Also, be certain to

leave the transmission in PARK.

You can engage the park brake in two ways:

• Manually, by applying the park brake switch.

• Automatically, by enabling the Auto Park Brake feature in

the customer programmable features section of the Ucon -

nect settings.

CAUTION!

Never use Non-Detergent Oil or Straight Mineral Oil in

the engine or damage may result.5

2020_DT_1500_OM_US.book Page 297

Page 469 of 674

IN CASE OF EMERGENCY 467

6. Remove the lug nuts and pull the wheel off. Install thespare wheel and lug nuts with the cone shaped end of the

lug nuts toward the wheel. Hand tighten the lug nuts

with vehicle lifted. To avoid the risk of forcing the vehicle

off the jack, do not fully tighten the lug nuts until the

vehicle has been lowered.

7. Lower vehicle to ground, finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts in a star

pattern until each nut has been tightened twice.

NOTE:

For the correct lug nut torque refer to “Technical Specifica -

tions” in “Torque Specifications.” If in doubt about the

correct tightness, have them checked with a torque wrench

by an authorized dealer or service station. 8. If your vehicle is equipped with a wheel center cap, install

the cap and remove the wheel blocks. Do not install

chrome or aluminum wheel center caps on the spare

wheel. This may result in cap damage.

9. Lower the jack to its fully closed position. Stow the replaced tire, and secure the jack and tools in the proper

location.

10. Adjust the tire pressure when possible.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.WARNING!

A loose tire or jack thrown forward in a collision or hard

stop, could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided.

6

2020_DT_1500_OM_US.book Page 467

Page 515 of 674

SERVICING AND MAINTENANCE 513

(Continued)

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission fluid to ensure

optimum transmission performance and life. Use only the

manufacturer’s specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifications”. It is

important to maintain the transmission fluid at the correct

level using the recommended fluid. No chemical flushes

should be used in any transmission; only the approved lubri-

cant should be used.

WARNING!

• Use only manufacturer's recommended brake fluid. Refer to “Fluids And Lubricants” in “Technical Speci -

fications” for further information. Using the wrong

type of brake fluid can severely damage your brake

system and/or impair its performance. The proper type

of brake fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

• To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been in

a tightly closed container. Keep the master cylinder

reservoir cap secured at all times. Brake fluid in a open

container absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil unexpect -

edly during hard or prolonged braking, resulting in

sudden brake failure. This could result in a collision.

• Overfilling the brake fluid reservoir can result in spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate thebrake fluid. Brake seal components could be damaged,

causing partial or complete brake failure. This could

result in a collision.

CAUTION!

Using a transmission fluid other than the manufacturer’s

recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

WARNING! (Continued)

7

2020_DT_1500_OM_US.book Page 513

Page 517 of 674

SERVICING AND MAINTENANCE 515

Rear Axle And 4x4 Front Driving Axle Fluid Level

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons the

exterior surfaces of the axle assembly should be inspected. If

gear oil leakage is suspected inspect the fluid level. Refer to

“Fluids And Lubricants” in “Technical Specifications” for

further information. This inspection should be made with

the vehicle in a level position.

The fluid level should be even with the bottom of the fill hole

(within 1/4 in (6.4 mm) of edge of hole) for the front axle and

rear axle.

Lubricant Selection

Refer to “Fluids And Lubricants” in “Technical Specifica-

tion” for further information.

NOTE:

The presence of water in the gear lubricant will result in

corrosion and possible failure of differential components.

Operation of the vehicle in water, as may be encountered in

some off-highway types of service, will require draining and

refilling the axle to avoid damage. Limited-Slip Differentials

Rear axles equipped with a Limited Slip Differential require

that 5 oz. (148 ml) Mopar Limited Slip Additive be added to

the gear lubricant. Refer to “Fluids And Lubricants” in

“Technical Specification” for further information. The

Mopar Limited Slip Additive should be added to the gear

lubricant whenever a fluid change is made to an axle

equipped with a Limited Slip Differential.

NOTE:

When refilling a limited slip differential axle which requires

a friction modification additive, the additive should be

added before the gear lubricant to ensure proper additive

fill.

Drain And Refill

Refer to the “Maintenance Plan” for the proper maintenance

intervals.

Transfer Case

Selection Of Lubricant

Use only the manufacturer's recommended fluid. Refer to

“Fluids And Lubricants” in “Technical Specifications” for

further information.

7

2020_DT_1500_OM_US.book Page 515

Page 548 of 674

546

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

Vehicle Identification Number

The Vehicle Identification Number (VIN) is found on the left

front corner of the instrument panel, visible through the

windshield. This number also appears on the vehicle frame

etched on right hand center rail, as well as the Automobile

Information Disclosure Label affixed to a window on your

vehicle, the vehicle registration and title.Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example, repeated

brake applications with the engine off), the brakes will still

function. However, you will experience a substantial

increase in braking effort to stop the vehicle.

If either the front or rear hydraulic system loses normal

braking capability, the remaining system will still function

with some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application, greater

pedal force required to slow or stop, and activation of the

“Brake Warning Light” and the “ABS Warning Light” (if

equipped) during brake use.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle, the

lug nuts/bolts should be torqued using a properly calibrated

torque wrench using a high quality six sided (hex) deep wall

socket.

2020_DT_1500_OM_US.book Page 546

Page 549 of 674

TECHNICAL SPECIFICATIONS 547

Torque Specifications

**Use only your authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

NOTE:

Do not oil wheel studs. For chrome wheels, do not substitute

with chrome plated wheel nuts.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.Wheel Mounting Surface

Lug Nut/Bolt

Torque Lug Nut/Bolt

Type **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

130 Ft-Lbs (176 N·m) Cone M14 x 1.50 22 mm

8

2020_DT_1500_OM_US.book Page 547

Page 550 of 674

548 TECHNICAL SPECIFICATIONS

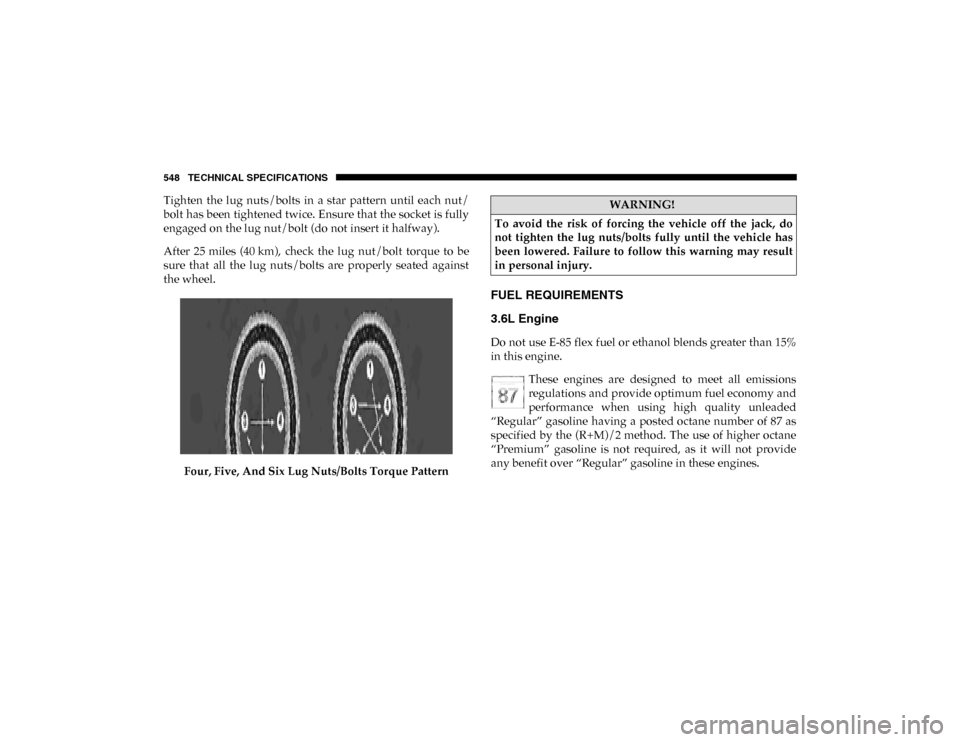

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is fully

engaged on the lug nut/bolt (do not insert it halfway).

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated against

the wheel.Four, Five, And Six Lug Nuts/Bolts Torque Pattern

FUEL REQUIREMENTS

3.6L Engine

Do not use E-85 flex fuel or ethanol blends greater than 15%

in this engine. These engines are designed to meet all emissions

regulations and provide optimum fuel economy and

performance when using high quality unleaded

“Regular” gasoline having a posted octane number of 87 as

specified by the (R+M)/2 method. The use of higher octane

“Premium” gasoline is not required, as it will not provide

any benefit over “Regular” gasoline in these engines.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts/bolts fully until the vehicle has

been lowered. Failure to follow this warning may result

in personal injury.

2020_DT_1500_OM_US.book Page 548