air filter RAM 1500 2021 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 406 of 496

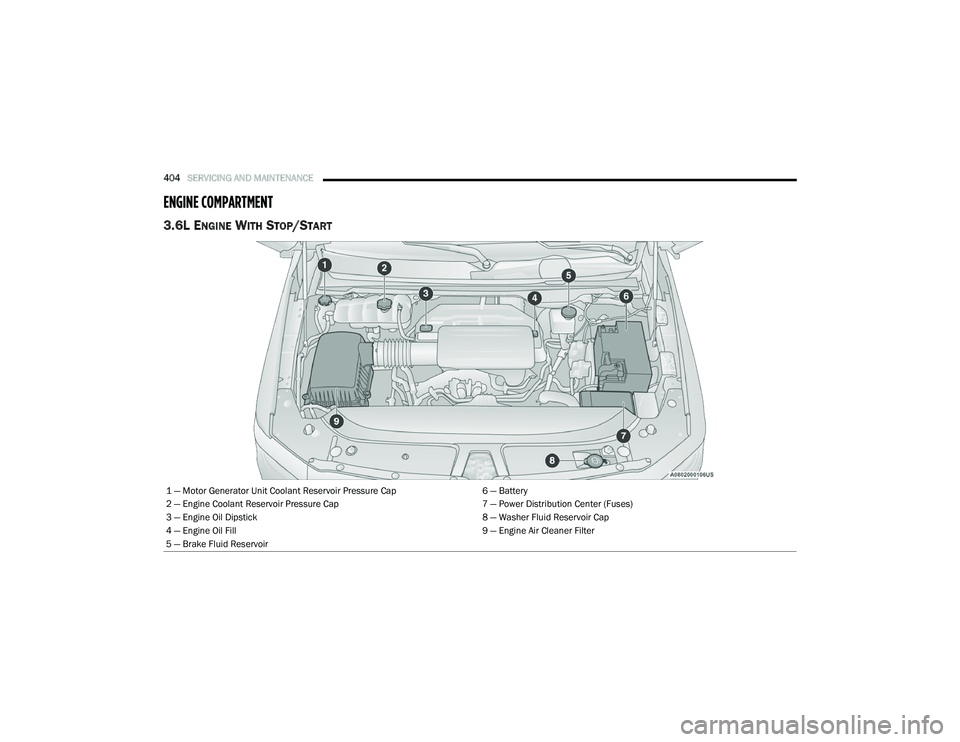

404SERVICING AND MAINTENANCE

ENGINE COMPARTMENT

3.6L ENGINE WITH STOP/START

1 — Motor Generator Unit Coolant Reservoir Pressure Cap 6 — Battery

2 — Engine Coolant Reservoir Pressure Cap 7 — Power Distribution Center (Fuses)

3 — Engine Oil Dipstick 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Fill 9 — Engine Air Cleaner Filter

5 — Brake Fluid Reservoir

21_DT_OM_EN_USC_t.book Page 404

Page 407 of 496

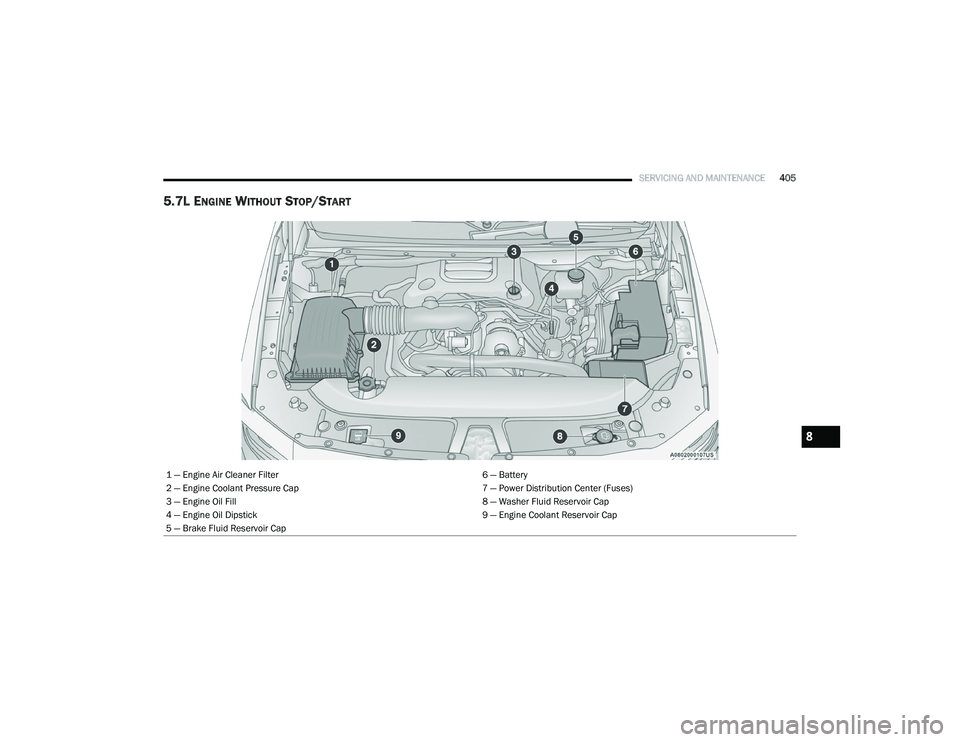

SERVICING AND MAINTENANCE405

5.7L ENGINE WITHOUT STOP/START

1 — Engine Air Cleaner Filter 6 — Battery

2 — Engine Coolant Pressure Cap 7 — Power Distribution Center (Fuses)

3 — Engine Oil Fill 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Engine Coolant Reservoir Cap

5 — Brake Fluid Reservoir Cap

8

21_DT_OM_EN_USC_t.book Page 405

Page 408 of 496

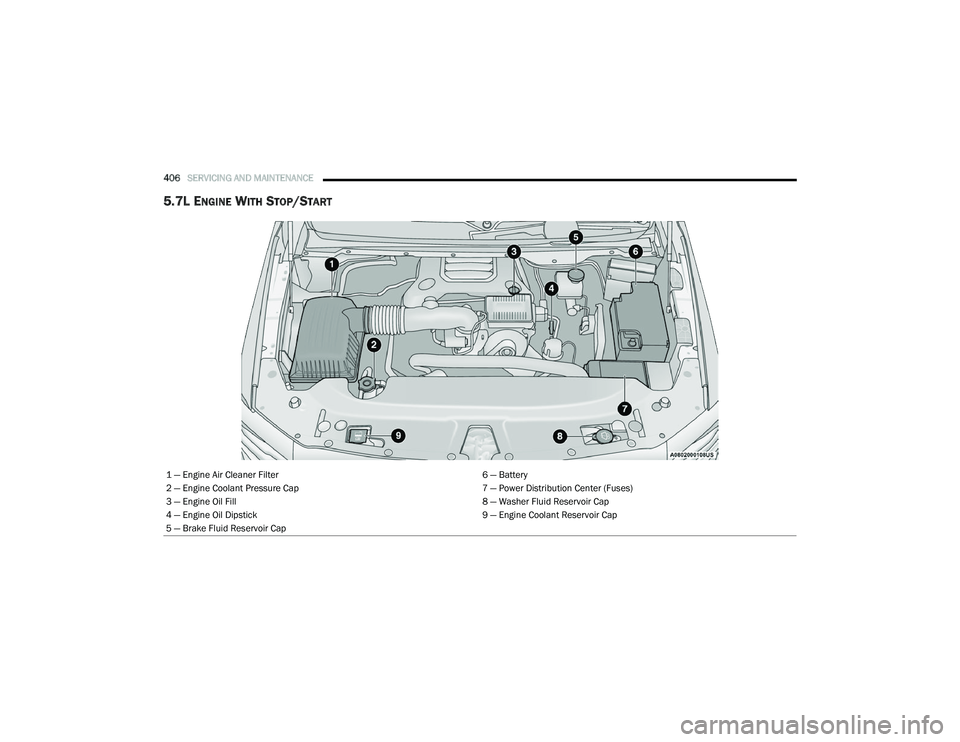

406SERVICING AND MAINTENANCE

5.7L ENGINE WITH STOP/START

1 — Engine Air Cleaner Filter 6 — Battery

2 — Engine Coolant Pressure Cap 7 — Power Distribution Center (Fuses)

3 — Engine Oil Fill 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Engine Coolant Reservoir Cap

5 — Brake Fluid Reservoir Cap

21_DT_OM_EN_USC_t.book Page 406

Page 409 of 496

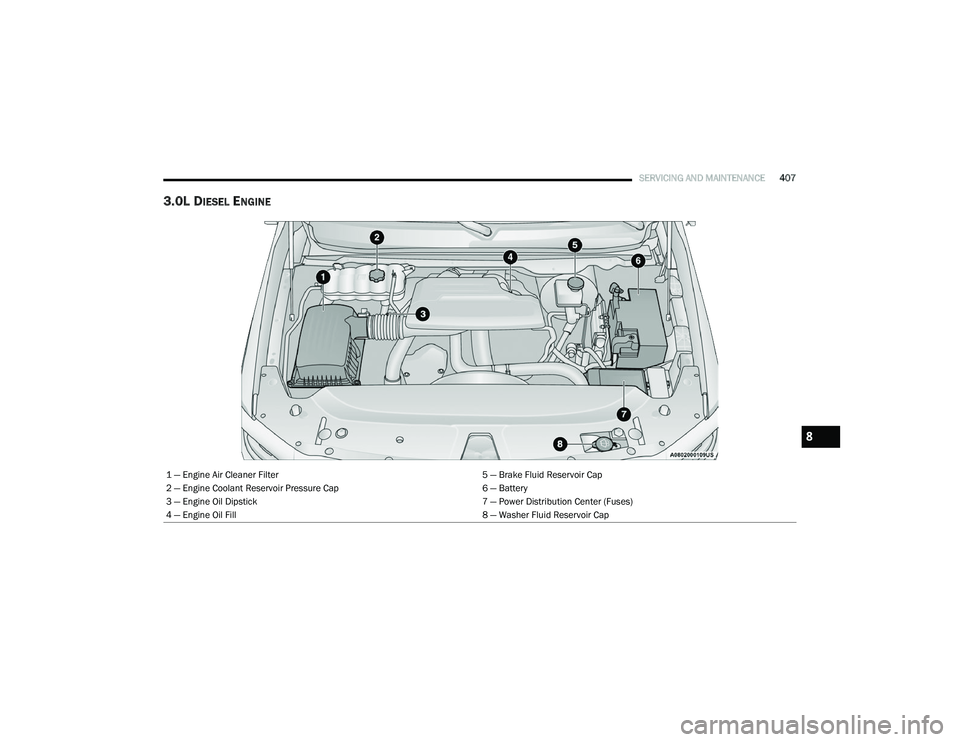

SERVICING AND MAINTENANCE407

3.0L DIESEL ENGINE

1 — Engine Air Cleaner Filter 5 — Brake Fluid Reservoir Cap

2 — Engine Coolant Reservoir Pressure Cap 6 — Battery

3 — Engine Oil Dipstick 7 — Power Distribution Center (Fuses)

4 — Engine Oil Fill 8 — Washer Fluid Reservoir Cap

8

21_DT_OM_EN_USC_t.book Page 407

Page 412 of 496

410SERVICING AND MAINTENANCE

ENGINE OIL — GAS ENGINE

Engine Oil Selection — Gasoline Engine

For best performance and maximum protection

under all types of operating conditions, FCA only

recommends engine oils that are API Certified

and meet the requirements of FCA Material

Standard MS-6395.

NOTE:

Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approxi -

mately 30 seconds. This is normal and will not

harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experi -

ence a ticking sound. Other causes could be if

the vehicle is unused for an extended period of

time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick

or if the Malfunction Indicator Light (MIL) comes

on, see the nearest authorized dealer.

Engine Oil Selection — Diesel Engine

For best performance and maximum protection

under all types of operating conditions, FCA

recommends engine oils that meet the

requirements of FCA Material Standard MS-12991, and that are API SN certified and

meet the requirements of FCA LLC.

American Petroleum Institute (API) Engine

Oil Identification Symbol

This symbol means that the oil has

been certified by the American

Petroleum Institute (API). The

manufacturer only recommends API

Certified engine oils.

This symbol certifies 0W-20, 5W-20, 0W-30,

5W-30 and 10W-30 engine oils.

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

FCA strongly recommends against the addition

of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered

product and its performance may be impaired

by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle. Used

oil and oil filters, indiscriminately discarded, can

present a problem to the environment. Contact

an authorized dealer, service station or

governmental agency for advice on how and

where used oil and oil filters can be safely

discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be

used for replacement. The quality of

replacement filters varies considerably. Only

high quality Mopar certified filters should be

used.

CAUTION!

Do not use chemical flushes in your engine oil

as the chemicals can damage your engine.

Such damage is not covered by the New

Vehicle Limited Warranty.

21_DT_OM_EN_USC_t.book Page 410

Page 413 of 496

SERVICING AND MAINTENANCE411

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals

Úpage 395.

NOTE:

Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable.

Engine Air Cleaner Filter Selection

The quality of replacement filters varies

considerably. Only high quality Mopar certified

filters should be used.

Engine Air Cleaner Filter Inspection And

Replacement

Inspect engine air cleaner filter for dirt and or

debris, if you find evidence of either dirt or

debris you should change your engine air

cleaner filter.

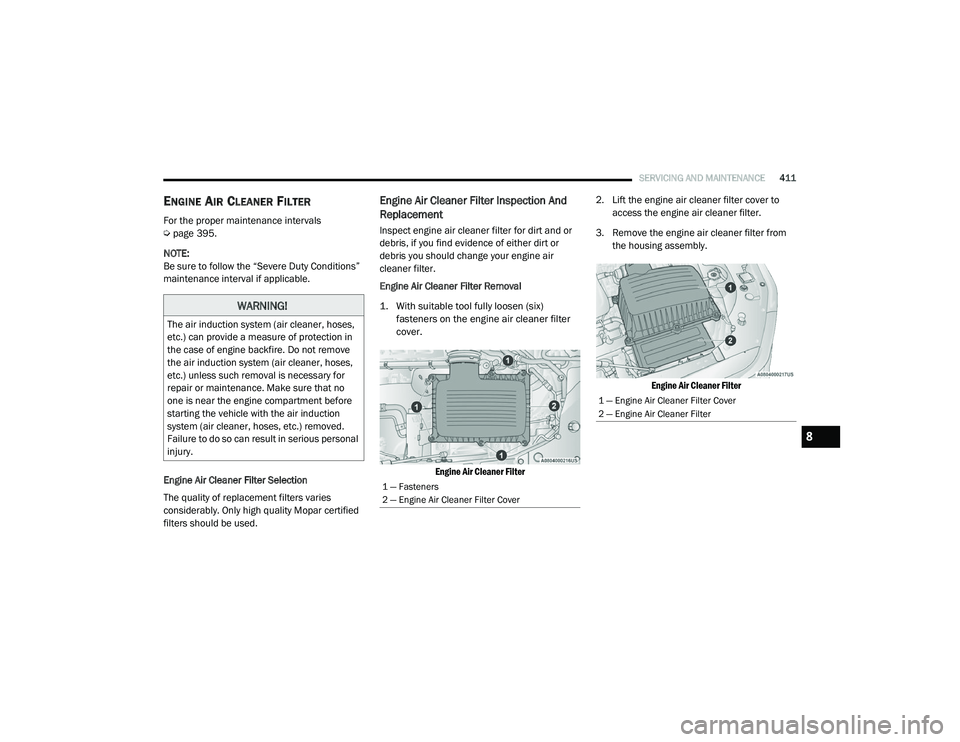

Engine Air Cleaner Filter Removal

1. With suitable tool fully loosen (six) fasteners on the engine air cleaner filter

cover.

Engine Air Cleaner Filter

2. Lift the engine air cleaner filter cover to

access the engine air cleaner filter.

3. Remove the engine air cleaner filter from the housing assembly.

Engine Air Cleaner Filter

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in

the case of engine backfire. Do not remove

the air induction system (air cleaner, hoses,

etc.) unless such removal is necessary for

repair or maintenance. Make sure that no

one is near the engine compartment before

starting the vehicle with the air induction

system (air cleaner, hoses, etc.) removed.

Failure to do so can result in serious personal

injury.

1 — Fasteners

2 — Engine Air Cleaner Filter Cover

1 — Engine Air Cleaner Filter Cover

2 — Engine Air Cleaner Filter

8

21_DT_OM_EN_USC_t.book Page 411

Page 414 of 496

412SERVICING AND MAINTENANCE

(Continued)

Engine Air Cleaner Filter Installation

NOTE:

Inspect and clean the housing if dirt or debris is

present before replacing the engine air cleaner

filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air

cleaner filter inspection surface facing

downward.

2. Install the engine air cleaner filter cover onto the housing assembly.

3. Tighten the fasteners (six) on the engine air cleaner filter assembly.

DRAINING FUEL/WATER SEPARATOR

F

ILTER — DIESEL ENGINE

The fuel/water separator filter housing is

located inside the frame rail, behind the left

front wheel. The best access to this water drain

valve is from under the vehicle. If water is detected in the water separator while

the engine is running, or while the ignition

switch is in the ON/RUN position, the “Water In

Fuel Indicator Light” will illuminate and an

audible chime will be heard. At this point, you

should stop the engine and drain the water from

the filter housing.

Fuel Filter Assembly

If the “Water In Fuel Indicator Light” comes on

and a single chime is heard while you are

driving, or with the ignition in the ON position,

there may be a problem with your water

separator wiring or sensor. See an authorized

dealer for service.

Upon proper draining of the water from the fuel

filter, the “Water In Fuel Indicator Light” will

remain illuminated for approximately 10

seconds. If the water was drained while the

engine was running, the “Water In Fuel Indicator

Light” may remain on for approximately three

minutes.

NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

station, or government agency for advice on

recycling programs and for where used fluids

and filters can be properly disposed of in your

area.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

1 — Water In Fuel Drain Valve

CAUTION! (Continued)CAUTION!

If the “Water In Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain water from the fuel filter to avoid engine

damage.

21_DT_OM_EN_USC_t.book Page 412

Page 416 of 496

414SERVICING AND MAINTENANCE

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL — DIESEL ENGINE

1. Add a substantial amount of fuel to the

tank, approximately 2 to 5 gal (8 L to 19 L).

2. Press ignition switch twice without your foot on brake to put vehicle in ON/RUN position.

This will activate the in tank fuel pump for

approximately 30 seconds. Repeat this

process twice.

3. Start the engine using the “Normal Starting” procedure Ú page 144.

NOTE:

The engine may run rough until the air is forced

from all the fuel lines. NOTE:

Use of biodiesel mixture in excess of 20% can

negatively impact the fuel filter's ability to

separate water from the fuel, resulting in

high pressure fuel system corrosion or

damage.

In addition, commercially available fuel addi

-

tives are not necessary for the proper opera -

tion of your diesel engine.

For extreme cold conditions, "Mopar

Premium Diesel Fuel Treatment" is recom -

mended to assist with cold starting.

INTERVENTION REGENERATION

S

TRATEGY — MESSAGE PROCESS FLOW

(D

IESEL ENGINE)

This engine meets all required diesel engine

emissions standards. To achieve these

emissions standards, your vehicle is equipped

with a state-of-the-art engine and exhaust

system. These systems are seamlessly

integrated into your vehicle and managed by

the Powertrain Control Module (PCM). The PCM

manages engine combustion to allow the

exhaust system’s catalyst to trap and burn

Particulate Matter (PM) pollutants, with no input

or interaction on your part.

Additionally, your vehicle has the ability to alert

you to additional maintenance required on your

vehicle or engine Ú page 114.WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure fuel

spray can cause serious injury or death.

CAUTION!

The starter motor will engage for

approximately 30 seconds at a time. Allow

two minutes between cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

WARNING!

A hot exhaust system can start a fire if you

park over materials that can burn, such as

grass or leaves, and those items that come

into contact with your exhaust system. Do not

park or operate your vehicle in areas where

your exhaust system can contact anything

that can burn.

21_DT_OM_EN_USC_t.book Page 414

Page 417 of 496

SERVICING AND MAINTENANCE415

DIESEL EXHAUST FLUID

Diesel Exhaust Fluid (DEF) sometimes known

simply by the name of its active component,

UREA—is a key component of Selective Catalytic

Reduction (SCR) systems, which help diesel

vehicles meet stringent emission regulations.

DEF is a liquid reducing agent that reacts with

engine exhaust in the presence of a catalyst to

convert smog-forming nitrogen oxides (NOx)

into harmless nitrogen and water vapor.

Refer to Engine Fluids And Lubricants

Úpage 475 for further information.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air

conditioner should be checked and serviced by

an authorized dealer at the start of each warm

season. This service should include cleaning of

the condenser fins and a performance test.

Drive belt tension should also be checked at

this time.

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. It is recommended

that air conditioning service be performed by an

authorized dealer using recovery and recycling

equipment.

NOTE:

Use only FCA approved A/C system PAG

compressor oil, and refrigerants.

Cabin Filter Replacement (A/C Air Filter)

For the proper maintenance intervals

Úpage 395.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by FCA for your air condi -

tioning system. Some unapproved

refrigerants are flammable and can

explode, injuring you. Other unapproved

refrigerants or lubricants can cause the

system to fail, requiring costly repairs.

Refer to Warranty Information Book, for

further warranty information.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring

lines to be disconnected should be done by

an experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components.

Such damage is not covered by the New

Vehicle Limited Warranty.

WARNING!

Do not remove the cabin air filter while the

vehicle is running, or while the ignition is in

the ACC or ON/RUN mode. With the cabin air

filter removed and the blower operating, the

blower can contact hands and may propel dirt

and debris into your eyes, resulting in

personal injury.

8

21_DT_OM_EN_USC_t.book Page 415

Page 418 of 496

416SERVICING AND MAINTENANCE

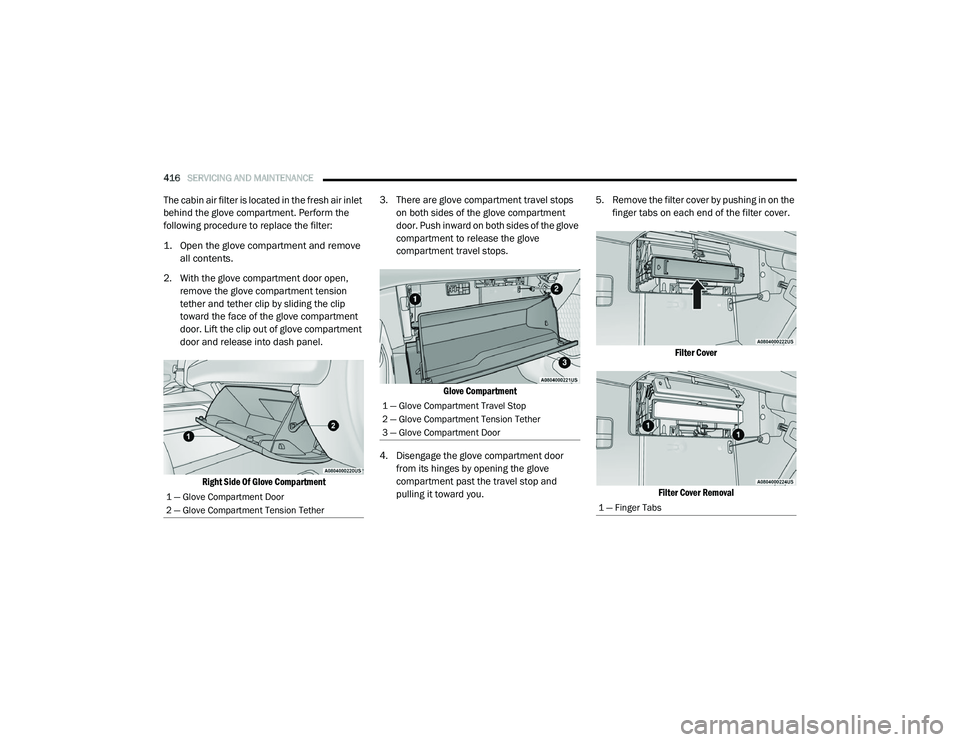

The cabin air filter is located in the fresh air inlet

behind the glove compartment. Perform the

following procedure to replace the filter:

1. Open the glove compartment and remove

all contents.

2. With the glove compartment door open, remove the glove compartment tension

tether and tether clip by sliding the clip

toward the face of the glove compartment

door. Lift the clip out of glove compartment

door and release into dash panel.

Right Side Of Glove Compartment

3. There are glove compartment travel stops

on both sides of the glove compartment

door. Push inward on both sides of the glove

compartment to release the glove

compartment travel stops.

Glove Compartment

4. Disengage the glove compartment door from its hinges by opening the glove

compartment past the travel stop and

pulling it toward you. 5. Remove the filter cover by pushing in on the

finger tabs on each end of the filter cover.

Filter Cover

Filter Cover Removal

1 — Glove Compartment Door

2 — Glove Compartment Tension Tether

1 — Glove Compartment Travel Stop

2 — Glove Compartment Tension Tether

3 — Glove Compartment Door

1 — Finger Tabs

21_DT_OM_EN_USC_t.book Page 416