sensor RAM 1500 2021 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 347 of 496

SAFETY345

On the other hand, depending on the type and

location of impact, front air bags may deploy in

crashes with little vehicle front-end damage but

that produce a severe initial deceleration.

Because air bag sensors measure vehicle

deceleration over time, vehicle speed and

damage by themselves are not good indicators

of whether or not an air bag should have

deployed.

Seat belts are necessary for your protection in

all collisions, and also are needed to help keep

you in position, away from an inflating air bag.

When the Occupant Restraint Controller (ORC)

detects a collision requiring the front air bags, it

signals the inflator units. A large quantity of

non-toxic gas is generated to inflate the front air

bags.

The steering wheel hub trim cover and the

upper passenger side of the instrument panel

separate and fold out of the way as the air bags

inflate to their full size. The front air bags fully

inflate in less time than it takes to blink your

eyes. The front air bags then quickly deflate

while helping to restrain the driver and front

passenger.Occupant Classification System (OCS) —

Front Passenger Seat

The OCS is part of a Federally regulated safety

system for this vehicle. It is designed to provide

Passenger Advanced Front Air Bag output

appropriate to the occupant’s seated weight, as

determined by the OCS.

The Occupant Classification System (OCS)

consists of the following:

Occupant Restraint Controller (ORC)

Occupant Classification Module (OCM) and

Sensor located in the front passenger seat

Air Bag Warning Light

Occupant Classification Module (OCM) And

Sensor

The Occupant Classification Module (OCM) is

located underneath the front passenger seat.

The Sensor is located beneath the passenger

seat cushion foam. Any weight on the seat will

be sensed by the Sensor. The OCM uses input

from the Sensor to determine the front

passenger’s most probable classification. The

OCM communicates this information to the ORC. The ORC may reduce the inflation rate of

the Passenger Advanced Front Air Bag

deployment based on occupant classification.

In order for the OCS to operate as designed, it is

important for the front passenger to be seated

properly and properly wearing the seat belt.

The OCS will NOT prevent deployment of the

Passenger Advanced Front Air Bag. The OCS

may reduce the inflation rate of the Passenger

Advanced Front Air Bag if the OCS estimates

that:

The front passenger seat is unoccupied or

has very light objects on it; or

The front passenger seat is occupied by a

small passenger, including a child; or

The front passenger seat is occupied by a

rear-facing child restraint; or

The front passenger is not properly seated or

his or her weight is taken off of the seat for a

period of time.

6

21_DT_OM_EN_USC_t.book Page 345

Page 353 of 496

SAFETY351

Side Impacts

The Side Air Bags are designed to activate in

certain side impacts. The Occupant Restraint

Controller (ORC) determines whether the

deployment of the Side Air Bags in a particular

impact event is appropriate, based on the

severity and type of collision. The side impact

sensors aid the ORC in determining the

appropriate response to impact events. The

system is calibrated to deploy the Side Air Bags

on the impact side of the vehicle during impacts

that require Side Air Bag occupant protection. In

side impacts, the Side Air Bags deploy

independently; a left side impact deploys the

left Side Air Bags only and a right-side impact

deploys the right Side Air Bags only. Vehicle

damage by itself is not a good indicator of

whether or not Side Air Bags should have

deployed.

The Side Air Bags will not deploy in all side

collisions, including some collisions at certain

angles, or some side collisions that do not

impact the area of the passenger compartment.

The Side Air Bags may deploy during angled or

offset frontal collisions where the front air bags

deploy. Side Air Bags are a supplement to the seat belt

restraint system. Side Air Bags deploy in less

time than it takes to blink your eyes.

NOTE:

Air bag covers may not be obvious in the interior

trim, but they will open during air bag deploy-

ment.

WARNING!

Occupants, including children, who are up

against or very close to Side Air Bags can be

seriously injured or killed. Occupants,

including children, should never lean on or

sleep against the door, side windows, or

area where the side air bags inflate, even if

they are in an infant or child restraint.

Seat belts (and child restraints where

appropriate) are necessary for your protec -

tion in all collisions. They also help keep

you in position, away from an inflating Side

Air Bag. To get the best protection from the

Side Air Bags, occupants must wear their

seat belts properly and sit upright with their

backs against the seats. Children must be

properly restrained in a child restraint or

booster seat that is appropriate for the size

of the child.

WARNING!

Side Air Bags need room to inflate. Do not

lean against the door or window. Sit upright

in the center of the seat.

Being too close to the Side Air Bags during

deployment could cause you to be severely

injured or killed.

Relying on the Side Air Bags alone could

lead to more severe injuries in a collision.

The Side Air Bags work with your seat belt

to restrain you properly. In some collisions,

Side Air Bags won’t deploy at all. Always

wear your seat belt even though you have

Side Air Bags.

6

21_DT_OM_EN_USC_t.book Page 351

Page 354 of 496

352SAFETY

Rollover Events

Side Air Bags and seat belt pretensioners are

designed to activate in certain rollover events.

The Occupant Restraint Controller (ORC)

determines whether deployment in a particular

rollover event is appropriate, based on the

severity and type of collision. Vehicle damage by

itself is not a good indicator of whether or not

Side Air Bags and seat belt pretensioners

should have deployed.

The Side Air Bags and seat belt pretensioners

will not deploy in all rollover events. The rollover

sensing system determines if a rollover event

may be in progress and whether deployment is

appropriate. In the event the vehicle

experiences a rollover or near rollover event,

and deployment is appropriate, the rollover

sensing system will deploy the side air bags and

seat belt pretensioners on both sides of the

vehicle.

The SABICs may help reduce the risk of partial

or complete ejection of vehicle occupants

through side windows in certain rollover or side

impact events.Air Bag System Components

NOTE:

The Occupant Restraint Controller (ORC) moni -

tors the internal circuits and interconnecting

wiring associated with electrical Air Bag System

Components listed below:

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

If A Deployment Occurs

The front air bags are designed to deflate

immediately after deployment.

NOTE:

Front and/or side air bags will not deploy in all

collisions. This does not mean something is

wrong with the air bag system.

If you do have a collision which deploys the air

bags, any or all of the following may occur:

The air bag material may sometimes cause

abrasions and/or skin reddening to the occu -

pants as the air bags deploy and unfold. The

abrasions are similar to friction rope burns or

those you might get sliding along a carpet or

gymnasium floor. They are not caused by

contact with chemicals. They are not perma -

nent and normally heal quickly. However, if

you haven’t healed significantly within a few

days, or if you have any blistering, see your

doctor immediately.

As the air bags deflate, you may see some

smoke-like particles. The particles are a

normal by-product of the process that gener -

ates the non-toxic gas used for air bag infla -

tion. These airborne particles may irritate the

skin, eyes, nose, or throat. If you have skin or

21_DT_OM_EN_USC_t.book Page 352

Page 414 of 496

412SERVICING AND MAINTENANCE

(Continued)

Engine Air Cleaner Filter Installation

NOTE:

Inspect and clean the housing if dirt or debris is

present before replacing the engine air cleaner

filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air

cleaner filter inspection surface facing

downward.

2. Install the engine air cleaner filter cover onto the housing assembly.

3. Tighten the fasteners (six) on the engine air cleaner filter assembly.

DRAINING FUEL/WATER SEPARATOR

F

ILTER — DIESEL ENGINE

The fuel/water separator filter housing is

located inside the frame rail, behind the left

front wheel. The best access to this water drain

valve is from under the vehicle. If water is detected in the water separator while

the engine is running, or while the ignition

switch is in the ON/RUN position, the “Water In

Fuel Indicator Light” will illuminate and an

audible chime will be heard. At this point, you

should stop the engine and drain the water from

the filter housing.

Fuel Filter Assembly

If the “Water In Fuel Indicator Light” comes on

and a single chime is heard while you are

driving, or with the ignition in the ON position,

there may be a problem with your water

separator wiring or sensor. See an authorized

dealer for service.

Upon proper draining of the water from the fuel

filter, the “Water In Fuel Indicator Light” will

remain illuminated for approximately 10

seconds. If the water was drained while the

engine was running, the “Water In Fuel Indicator

Light” may remain on for approximately three

minutes.

NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

station, or government agency for advice on

recycling programs and for where used fluids

and filters can be properly disposed of in your

area.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

1 — Water In Fuel Drain Valve

CAUTION! (Continued)CAUTION!

If the “Water In Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain water from the fuel filter to avoid engine

damage.

21_DT_OM_EN_USC_t.book Page 412

Page 431 of 496

SERVICING AND MAINTENANCE429

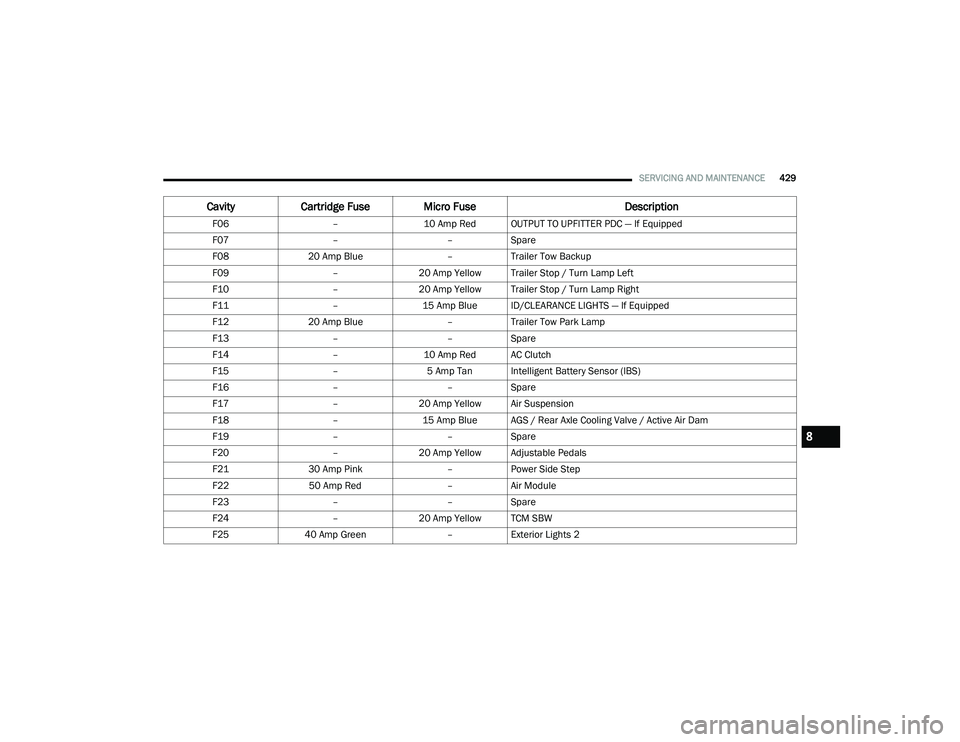

F06–10 Amp Red OUTPUT TO UPFITTER PDC — If Equipped

F07 ––Spare

F08 20 Amp Blue –Trailer Tow Backup

F09 –20 Amp Yellow Trailer Stop / Turn Lamp Left

F10 –20 Amp Yellow Trailer Stop / Turn Lamp Right

F11 –15 Amp Blue ID/CLEARANCE LIGHTS — If Equipped

F12 20 Amp Blue –Trailer Tow Park Lamp

F13 ––Spare

F14 –10 Amp Red AC Clutch

F15 –5 Amp Tan Intelligent Battery Sensor (IBS)

F16 ––Spare

F17 –20 Amp Yellow Air Suspension

F18 –15 Amp Blue AGS / Rear Axle Cooling Valve / Active Air Dam

F19 ––Spare

F20 –20 Amp Yellow Adjustable Pedals

F21 30 Amp Pink –Power Side Step

F22 50 Amp Red –Air Module

F23 ––Spare

F24 –20 Amp Yellow TCM SBW

F25 40 Amp Green –Exterior Lights 2

Cavity Cartridge Fuse Micro Fuse Description

8

21_DT_OM_EN_USC_t.book Page 429

Page 433 of 496

SERVICING AND MAINTENANCE431

F4630 Amp Pink –Fuel Heater

F47 30 Amp Pink –Rear Defroster

F48 ––Spare

F49 30 Amp Pink –Htr Ctrl (Diesel Only)

F50 20 Amp Blue –AUX SWITCH #6 — If Equipped

F51 25 Amp White –FUEL PUMP MOTOR #1 — If Equipped

F52 ––Spare

F53 –10 Amp Red Supply / Purging Pump – If Equipped

F54 –15 Amp Blue PCM

F55 –15 Amp Blue Right HID Headlamp

F56 ––Spare

F57 –20 Amp Yellow Horn

F58 25 Amp White –FUEL PUMP MOTOR #2 — If Equipped

F59 –25 Amp Clear Injectors / IGN Coil / Glow Plug Module

F60 –20 Amp Yellow ECM / PCM / ACT Short Running Valve

F61 –15 Amp Blue Left HID Headlamp / Spare

F62 60 Amp Blue

40 Amp Green –

Glow Plug (DSL) / LTR Coolant Pump (TRX)

F63 20 Amp Blue –NOx Sensor

F64 –10 Amp Red PM Sensor – If Equipped

CavityCartridge Fuse Micro Fuse Description

8

21_DT_OM_EN_USC_t.book Page 431

Page 437 of 496

SERVICING AND MAINTENANCE435

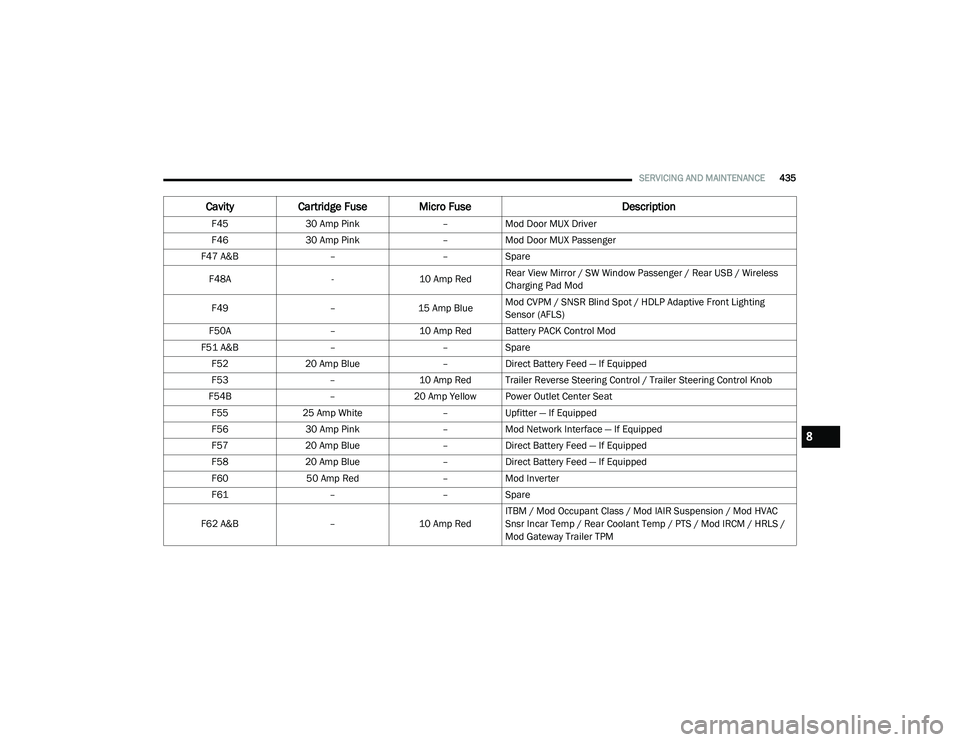

F4530 Amp Pink –Mod Door MUX Driver

F46 30 Amp Pink –Mod Door MUX Passenger

F47 A&B ––Spare

F48A -10 Amp RedRear View Mirror / SW Window Passenger / Rear USB / Wireless

Charging Pad Mod

F49 –15 Amp BlueMod CVPM / SNSR Blind Spot / HDLP Adaptive Front Lighting

Sensor (AFLS)

F50A –10 Amp Red Battery PACK Control Mod

F51 A&B ––Spare

F52 20 Amp Blue –Direct Battery Feed — If Equipped

F53 –10 Amp Red Trailer Reverse Steering Control / Trailer Steering Control Knob

F54B –20 Amp Yellow Power Outlet Center Seat

F55 25 Amp White –Upfitter — If Equipped

F56 30 Amp Pink –Mod Network Interface — If Equipped

F57 20 Amp Blue –Direct Battery Feed — If Equipped

F58 20 Amp Blue –Direct Battery Feed — If Equipped

F60 50 Amp Red –Mod Inverter

F61 ––Spare

F62 A&B –10 Amp RedITBM / Mod Occupant Class / Mod IAIR Suspension / Mod HVAC

Snsr Incar Temp / Rear Coolant Temp / PTS / Mod IRCM / HRLS /

Mod Gateway Trailer TPM

Cavity

Cartridge Fuse Micro Fuse Description

8

21_DT_OM_EN_USC_t.book Page 435

Page 453 of 496

SERVICING AND MAINTENANCE451

cold tire inflation pressure must not exceed the

maximum inflation pressure molded into the

tire sidewall.

Check tire pressures more often if subject to a

wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature

change. Keep this in mind when checking tire

pressure inside a garage, especially in the

Winter.

Example: If garage temperature = 68°F (20°C)

and the outside temperature = 32°F (0°C) then

the cold tire inflation pressure should be

increased by 3 psi (21 kPa), which equals 1 psi

(7 kPa) for every 12°F (7°C) for this outside

temperature condition.

Tire pressure may increase from 2 to 6 psi

(13 to 40 kPa) during operation. DO NOT reduce

this normal pressure build up or your tire

pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe

speeds and within posted speed limits. Where

speed limits or conditions are such that the

vehicle can be driven at high speeds, maintaining correct tire inflation pressure is

very important. Increased tire pressure and

reduced vehicle loading may be required for

high-speed vehicle operation. Refer to an

authorized tire dealer or original equipment

vehicle dealer for recommended safe operating

speeds, loading and cold tire inflation

pressures.

Radial Ply Tires

Tire Repair

If your tire becomes damaged, it may be

repaired if it meets the following criteria:

The tire has not been driven on when flat

The damage is only on the tread section of

your tire (sidewall damage is not repairable)

The puncture is no greater than a ¼ of an

inch (6 mm)

Consult an authorized tire dealer for tire repairs

and additional information.

Damaged Run Flat tires, or Run Flat tires that

have experienced a loss of pressure should be

replaced immediately with another Run Flat tire

of identical size and service description (Load

Index and Speed Symbol). Replace the tire

pressure sensor as well as it is not designed to

be reused.

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive

50 miles (80 km) at 50 mph (80 km/h) after a

rapid loss of inflation pressure. This rapid loss

of inflation is referred to as the Run Flat mode.

A Run Flat mode occurs when the tire inflation

pressure is of/or below 14 psi (96 kPa). Once a

Run Flat tire reaches the Run Flat mode it has

WARNING!

High speed driving with your vehicle under

maximum load is dangerous. The added

strain on your tires could cause them to fail.

You could have a serious collision. Do not

drive a vehicle loaded to the maximum

capacity at continuous speeds above 75 mph

(120 km/h).

WARNING!

Combining radial ply tires with other types of

tires on your vehicle will cause your vehicle to

handle poorly. The instability could cause a

collision. Always use radial ply tires in sets of

four. Never combine them with other types of

tires.

8

21_DT_OM_EN_USC_t.book Page 451

Page 454 of 496

452SERVICING AND MAINTENANCE

limited driving capabilities and needs to be

replaced immediately. A Run Flat tire is not

repairable. When a Run Flat tire is changed

after driving with underinflated tire condition,

please replace the TPM sensor as it is not

designed to be reused when driven under Run

Flat mode 14 psi (96 kPa) condition.

NOTE:

TPM Sensor must be replaced after driving the

vehicle on a flat tire condition.

It is not recommended driving a vehicle loaded

at full capacity or to tow a trailer while a tire is in

the Run Flat mode.

For more information Úpage 327.

Tire Spinning

When stuck in mud, sand, snow, or ice

conditions, do not spin your vehicle's wheels

above 30 mph (48 km/h) or for longer than

30 seconds continuously without stopping.

For further information Ú page 391.

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

Tire Tread

These indicators are molded into the bottom of

the tread grooves. They will appear as bands

when the tread depth becomes a 1/16 of an

inch (1.6 mm). When the tread is worn to the

tread wear indicators, the tire should be

replaced.

For further information Ú

page 453.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These

abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replace -

ment

Distance driven

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have

a reduced tread life. Rotation of these tires

per the vehicle scheduled maintenance is

highly recommended

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause tire damage or failure. A tire could

explode and injure someone. Do not spin your

vehicle's wheels faster than 30 mph (48 km/h)

for more than 30 seconds continuously when

you are stuck, and do not let anyone near a

spinning wheel, no matter what the speed.

1 — Worn Tire

2 — New Tire

21_DT_OM_EN_USC_t.book Page 452

Page 489 of 496

487

J

Jack Location

................................................. 377Jump Starting................................................ 386

K

Key Fob Programming Additional Key Fobs

.............. 20Key Fob Battery Service (Remote Keyless

Entry)............................................................... 18Key Fob Programming (Remote Keyless

Entry)............................................................... 20Keyless Enter-N-Go................................. 28, 143Passive Entry............................................... 28Keys................................................................. 17

L

Lane Change And Turn Signals........................ 55Lane Change Assist......................................... 55LaneSense.................................................... 199Lap/Shoulder Belts....................................... 336Latches.......................................................... 371Hood........................................................... 84Lead Free Gasoline........................................ 468Leaks, Fluid................................................... 371Life Of Tires................................................... 452Light Bulbs........................................... 371, 437

Lights............................................................ 371Air Bag.................................... 126, 342, 369Brake Assist Warning............................... 314Brake Warning.......................................... 126Bulb Replacement.................................... 437Cargo........................................................... 56Center Mounted Stop............................... 442Courtesy/Reading....................................... 57Cruise....................................................... 136Daytime Running......................................... 53Electronic Stability Program (ESP)Indicator............................................... 128Exterior...............................................52, 371Fog........................................................... 441Hazard Warning Flasher........................... 373Headlights............................................ 52, 54High Beam................................................... 53High Beam/Low Beam Select...................... 53Hill Descent Control Indicator................... 315Illuminated Entry......................................... 58Interior......................................................... 57Lights On Reminder..................................... 55Low Fuel................................................... 131Malfunction Indicator (Check Engine)....... 130Park.......................................................... 135Passing........................................................ 54

Seat Belt Reminder.................................. 126Security Alarm.......................................... 127Service...................................................... 437Traction Control........................................ 314Turn Signals............55, 136, 371, 439, 441Warning Instrument ClusterDescriptions................................ 128, 136Limited-Slip Differential....................... 174, 427Load Shed Battery Saver Mode..................... 125Load Shed Battery Saver On......................... 125Load Shed Electrical Load Reduction........... 125Load Shed Intelligent Battery Sensor............ 125Loading Vehicle............................................. 213Tires.......................................................... 447LocksAutomatic Door............................................30Child Protection...........................................31Power Door..................................................28Low Tire Pressure System............................. 327Lubrication, Body.......................................... 418Lug Nuts........................................................ 467Lug Nuts/Bolts.............................................. 467

M

Maintenance.............................................81, 84Maintenance Free Battery............................ 409Maintenance Schedule............... 395, 399, 40011

21_DT_OM_EN_USC_t.book Page 487