sensor RAM 1500 2021 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 326 of 496

324SAFETY

Trailer length between 30 ft and 39.5 ft (9 m

to 12 m) — Blind spot zone will be adjusted to

Max distance .

NOTE:

Trailer length is determined within +/- 3 ft (1 m)

of actual length. Trailers that are the same size

as the category limit, 10/20/30 ft (3/6/9 m),

could be subject to being placed in the category

above or below the correct one.

Trailer Merge Warning

Trailer Merge Warning is the extension of the

blind spot function to cover the length of the

trailer, plus a safety margin, to warn the driver

when there is a vehicle in the adjacent lane. The

driver is alerted by the illumination of the BSM

warning light located in the outside mirror on

the side the other vehicle is detected on. In

addition, an audible (chime) alert will be heard

and radio volume will be reduced Ú page 322.

NOTE:

The Trailer Merge Alert system DOES NOT

alert the driver about rapidly approaching

vehicles that are outside the detection zones.

The Blind Spot Monitoring (BSM) system may

experience drop outs (blinking on and off) of the side mirror warning indicator lamps when

a motorcycle or any small object remains at

the side of the vehicle for extended periods of

time (more than a couple of seconds).

Crowded areas such as parking lots, neigh

-

borhoods, etc. may lead to an increased

amount of false alerts. This is normal opera -

tion.

FORWARD COLLISION WARNING (FCW)

W

ITH MITIGATION — IF EQUIPPED

FCW with Mitigation provides the driver with

audible warnings, visual warnings (within the

instrument cluster display), and may apply a

brake jerk to warn the driver when it detects a potential frontal collision. The warnings and

limited braking are intended to provide the

driver with enough time to react, avoid or

mitigate the potential collision.

NOTE:

FCW monitors the information from the forward

looking sensors as well as the Electronic Brake

Controller (EBC), to calculate the probability of a

forward collision. When the system determines

that a forward collision is probable, the driver

will be provided with audible and visual warn-

ings as well as a possible brake jerk warning.

If the driver does not take action based upon

these progressive warnings, then the system

will provide a limited level of active braking to

help slow the vehicle and mitigate the potential

forward collision. If the driver reacts to the warn

-

ings by braking and the system determines that

the driver intends to avoid the collision by

braking but has not applied sufficient brake

force, the system will compensate and provide

additional brake force as required.

If a FCW with Mitigation event begins at a speed

below 32 mph (52 km/h), the system may

provide the maximum braking possible to miti -

gate the potential forward collision. If the

WARNING!

The Blind Spot Monitoring system is only an

aid to help detect objects in the blind spot

zones. The BSM system is not designed to

detect pedestrians, bicyclists, or animals.

Even if your vehicle is equipped with the BSM

system, always check your vehicle’s mirrors,

glance over your shoulder, and use your turn

signal before changing lanes. Failure to do so

can result in serious injury or death.

21_DT_OM_EN_USC_t.book Page 324

Page 330 of 496

328SAFETY

pressure should always be set based on cold

inflation tire pressure. This is defined as the tire

pressure after the vehicle has not been driven

for at least three hours, or driven less than

1 mile (1.6 km) after a three hour period. The

cold tire inflation pressure must not exceed the

maximum inflation pressure molded into the

tire sidewall. The tire pressure will also increase

as the vehicle is driven — this is normal and

there should be no adjustment for this

increased pressure.

See Úpage 443 on how to properly inflate the

vehicle’s tires.

The TPMS will warn the driver of a low tire

pressure if the tire pressure falls below the

low-pressure warning limit for any reason,

including low temperature effects and natural

pressure loss through the tire Ú page 482.

The TPMS will continue to warn the driver of low

tire pressure as long as the condition exists,

and will not turn off until the tire pressure is at

or above the recommended cold placard

pressure. Once the low TPMS Warning Light

illuminates, increase the tire pressure to the

recommended cold placard pressure in order

for the TPMS Warning Light to turn off. The

system will automatically update and the TPMS Warning Light will turn off once the system

receives the updated tire pressures. The vehicle

may need to be driven for up to 20 minutes

above 15 mph (24 km/h) in order for the TPMS

to receive this information.

NOTE:

When filling warm tires, the tire pressure may

need to be increased up to an additional 4 psi

(28 kPa) above the recommended cold placard

pressure in order to turn the TPMS Warning

Light off.

For example, your vehicle may have a

recommended cold (parked for more than three

hours) placard pressure of 30 psi (207 kPa). If

the ambient temperature is 68°F (20°C) and

the measured tire pressure is 27 psi (186 kPa),

a temperature drop to 20°F (-7°C) will

decrease the tire pressure to approximately

23 psi (158 kPa). This tire pressure is

sufficiently low enough to turn on the TPMS

Warning Light. Driving the vehicle may cause

the tire pressure to rise to approximately 27 psi

(186 kPa), but the TPMS Warning Light will still

be on. In this situation, the TPMS Warning Light

will turn off only after the tires are inflated to the

vehicle’s recommended cold placard pressure

value.CAUTION!

The TPMS has been optimized for the orig -

inal equipment tires and wheels. TPMS

pressures and warning have been estab -

lished for the tire size equipped on your

vehicle. Undesirable system operation or

sensor damage may result when using

replacement equipment that is not of the

same size, type, and/or style. Aftermarket

wheels can cause sensor damage.

Using aftermarket tire sealants may cause

the Tire Pressure Monitoring System

(TPMS) sensor to become inoperable. After

using an aftermarket tire sealant it is

recommended that you take your vehicle to

an authorized dealership to have your

sensor function checked.

After inspecting or adjusting the tire pres -

sure always reinstall the valve stem cap.

This will prevent moisture and dirt from

entering the valve stem, which could

damage the TPMS sensor.

21_DT_OM_EN_USC_t.book Page 328

Page 331 of 496

SAFETY329

NOTE:

The TPMS is not intended to replace normal

tire care and maintenance or to provide

warning of a tire failure or condition.

The TPMS should not be used as a tire pres -

sure gauge while adjusting your tire pressure,

unless your vehicle is equipped with a Tire Fill

Alert (TFA) system.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to

tire failure. Underinflation also reduces fuel

efficiency and tire tread life, and may affect

the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsi -

bility to maintain correct tire pressure using

an accurate tire pressure gauge, even if

underinflation has not reached the level to

trigger illumination of the TPMS Warning

Light.

Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor the

actual tire pressure in the tire.

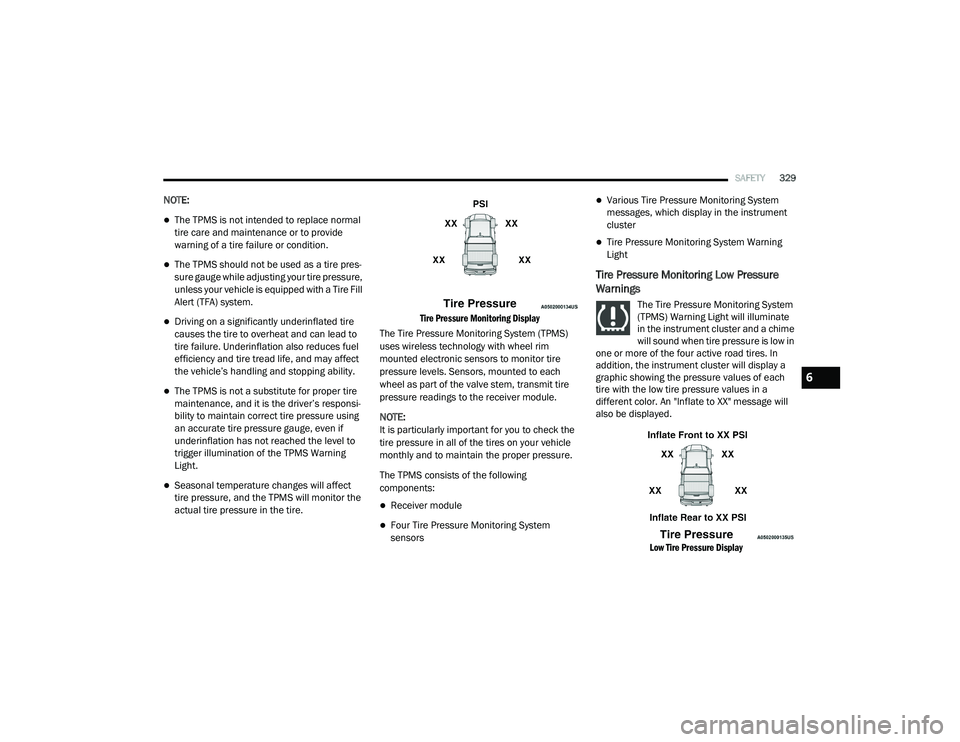

Tire Pressure Monitoring Display

The Tire Pressure Monitoring System (TPMS)

uses wireless technology with wheel rim

mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the receiver module.

NOTE:

It is particularly important for you to check the

tire pressure in all of the tires on your vehicle

monthly and to maintain the proper pressure.

The TPMS consists of the following

components:

Receiver module

Four Tire Pressure Monitoring System

sensors

Various Tire Pressure Monitoring System

messages, which display in the instrument

cluster

Tire Pressure Monitoring System Warning

Light

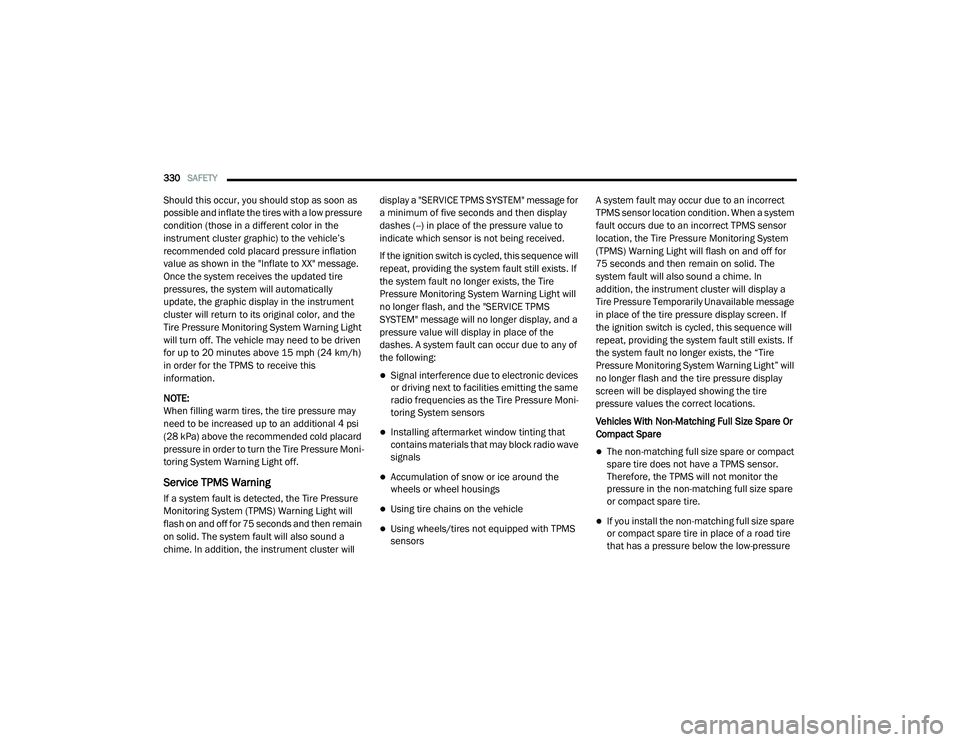

Tire Pressure Monitoring Low Pressure

Warnings

The Tire Pressure Monitoring System

(TPMS) Warning Light will illuminate

in the instrument cluster and a chime

will sound when tire pressure is low in

one or more of the four active road tires. In

addition, the instrument cluster will display a

graphic showing the pressure values of each

tire with the low tire pressure values in a

different color. An "Inflate to XX" message will

also be displayed.

Low Tire Pressure Display

6

21_DT_OM_EN_USC_t.book Page 329

Page 332 of 496

330SAFETY

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure

condition (those in a different color in the

instrument cluster graphic) to the vehicle’s

recommended cold placard pressure inflation

value as shown in the "Inflate to XX" message.

Once the system receives the updated tire

pressures, the system will automatically

update, the graphic display in the instrument

cluster will return to its original color, and the

Tire Pressure Monitoring System Warning Light

will turn off. The vehicle may need to be driven

for up to 20 minutes above 15 mph (24 km/h)

in order for the TPMS to receive this

information.

NOTE:

When filling warm tires, the tire pressure may

need to be increased up to an additional 4 psi

(28 kPa) above the recommended cold placard

pressure in order to turn the Tire Pressure Moni -

toring System Warning Light off.

Service TPMS Warning

If a system fault is detected, the Tire Pressure

Monitoring System (TPMS) Warning Light will

flash on and off for 75 seconds and then remain

on solid. The system fault will also sound a

chime. In addition, the instrument cluster will display a "SERVICE TPMS SYSTEM" message for

a minimum of five seconds and then display

dashes (--) in place of the pressure value to

indicate which sensor is not being received.

If the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If

the system fault no longer exists, the Tire

Pressure Monitoring System Warning Light will

no longer flash, and the "SERVICE TPMS

SYSTEM" message will no longer display, and a

pressure value will display in place of the

dashes. A system fault can occur due to any of

the following:

Signal interference due to electronic devices

or driving next to facilities emitting the same

radio frequencies as the Tire Pressure Moni

-

toring System sensors

Installing aftermarket window tinting that

contains materials that may block radio wave

signals

Accumulation of snow or ice around the

wheels or wheel housings

Using tire chains on the vehicle

Using wheels/tires not equipped with TPMS

sensors A system fault may occur due to an incorrect

TPMS sensor location condition. When a system

fault occurs due to an incorrect TPMS sensor

location, the Tire Pressure Monitoring System

(TPMS) Warning Light will flash on and off for

75 seconds and then remain on solid. The

system fault will also sound a chime. In

addition, the instrument cluster will display a

Tire Pressure Temporarily Unavailable message

in place of the tire pressure display screen. If

the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If

the system fault no longer exists, the “Tire

Pressure Monitoring System Warning Light” will

no longer flash and the tire pressure display

screen will be displayed showing the tire

pressure values the correct locations.

Vehicles With Non-Matching Full Size Spare Or

Compact Spare

The non-matching full size spare or compact

spare tire does not have a TPMS sensor.

Therefore, the TPMS will not monitor the

pressure in the non-matching full size spare

or compact spare tire.

If you install the non-matching full size spare

or compact spare tire in place of a road tire

that has a pressure below the low-pressure

21_DT_OM_EN_USC_t.book Page 330

Page 333 of 496

SAFETY331

warning limit, upon the next ignition switch

cycle, the Tire Pressure Monitoring System

(TPMS) Warning Light and a “LOW TIRE”

message will remain on and a chime will

sound. In addition, the graphic in the instru -

ment cluster will still display a pressure value

in a different color and an “Inflate to XX”

message.

After driving the vehicle for up to 20 minutes

above 15 mph (24 km/h), the Tire Pressure

Monitoring System (TPMS) Warning Light will

flash on and off for 75 seconds and then

remain on solid. In addition, the instrument

cluster will display a "SERVICE TPMS

SYSTEM" message for a minimum of five

seconds and then display dashes (--) in place

of the pressure value.

For each subsequent ignition switch cycle, a

chime will sound, the Tire Pressure Moni -

toring System (TPMS) Warning Light will flash

on and off for 75 seconds and then remain

on solid, and the instrument cluster will

display a "SERVICE TPMS SYSTEM" message

for a minimum of five seconds and then

display dashes (--) in place of the pressure

value.

Once you repair or replace the original road

tire and reinstall it on the vehicle in place of

the non-matching full size spare or compact

spare, the TPMS will update automatically. In

addition, the Tire Pressure Monitoring

System (TPMS) Warning Light will turn off and

the graphic in the instrument cluster will

display a new pressure value instead of

dashes (--), as long as no tire pressure is

below the low-pressure warning limit in any of

the four active road tires. The vehicle may

need to be driven for up to 20 minutes above

15 mph (24 km/h) in order for the TPMS to

receive this information.

Tire Fill Alert

This feature notifies the user when the placard

tire pressure is attained while inflating or

deflating the tire.

You may choose to disable or enable the Tire Fill

Alert feature through use of the Uconnect

Settings in the radio.

NOTE:

Only one tire can be filled at a time when

using the Tire Fill Alert system.

The Tire Fill Alert feature cannot be entered if

an existing TPMS fault is set to “active” or if

the system is in deactivation mode (if

equipped).

The system will be activated when a positive

increase in tire pressure is detected by the

TPMS while inflating the tire. The ignition must

be in the RUN mode, with the transmission in

PARK.

NOTE:

It is not required to have the engine running to

enter Tire Fill Alert mode.

The hazard lamps will come on to confirm the

vehicle is in Tire Fill Alert mode.

When Tire Fill Alert mode is entered, the tire

pressure display screen will be displayed in the

instrument cluster.

If the hazard lamps do not come on while

inflating the tire, the TPMS sensor may be out of

range preventing the TPMS sensor signal from

being received. In this case, the vehicle may

need to be moved either forward or backward

slightly to exit the null spot.

6

21_DT_OM_EN_USC_t.book Page 331

Page 334 of 496

332SAFETY

Operation:

The horn will sound once to let the user know

when to stop filling the tire, when it reaches

recommended pressure.

The horn will sound three times if the tire is

overfilled and will continue to sound every

five seconds if the user continues to inflate

the tire.

The horn will sound once again when enough

air is let out to reach proper inflation level.

The horn will also sound three times if the tire

is then underinflated and will continue to

sound every five seconds if the user

continues to deflate the tire.

Trailer Tire Pressure Monitoring System

(TTPMS) — If Equipped

The Trailer Tire Pressure Monitoring System

(TTPMS) is a feature that displays the trailer tire

pressure values and warns the driver of a low

tire pressure event based on the drivers set

target tire pressure value, through TTPMS

settings found in the radio.

The TTPMS monitors the pressure of each tire

and warns the driver through the instrument

cluster, when either a low tire pressure condition falls below 25% of the drivers set

pressure or if a system malfunction occurs. The

instrument cluster will display the actual tire

pressure or dashes for each of the trailer tires in

the correct trailer position, based on trailer

configuration. The TTPMS can support up to

12 trailer tires per configured trailer on up to

four configurable trailers Ú

page 237.

Trailer Tire Pressure Monitoring System

Trailer Tire Pressure Sensor Pairing

In order use this feature, the provided tire

pressure sensors must be installed in the

desired trailer tires and the sensors must be

paired to the truck. If the target trailer requires

more than the provided four sensors, additional

sensors can be purchased at an authorized

Ram dealership. With the sensors installed and the trailer near

or connected to your Ram truck, initiate the

pairing process by entering the settings menu in

the radio and selecting trailer. Select the

desired trailer profile to pair to, open the “Tire

Pressure” menu, and hit “Setup All Tires”

Ú

page 237.

NOTE:

The vehicle may not be driven until the pairing

process is complete.

Trailer Tire Pressure Settings

21_DT_OM_EN_USC_t.book Page 332

Page 335 of 496

SAFETY333

Trailer Tire Pressure Pairing

Follow the on screen prompts to select the

number of axles (1 - 3), the number of trailer

tires (2, 4, 6, 8, or 12), and the set trailer tire

pressure. The range is selectable anywhere

between 25-125 PSI (172-862 kPa).

Once PSI (kPa) is programmed, the pairing

screen appears. Tire sensors must be paired in

order shown. Starting with Tire 1, deflate tire by

5 PSI (34 kPa) and wait for a horn chirp. It may

take up to three minutes for the chirp to occur,

indicating that the sensor has paired. Repeat

process on each tire, in order, until complete.

Do not exit the pairing screen until process is

complete. If pairing was unsuccessful, a double

horn chirp will sound, and a prompt on the

touchscreen will allow you to retry the

procedure; “Retry” will only appear when setup fails. Each tire must be successfully paired

during a single pairing process to receive the

success screen.

NOTE:

If the pairing process times out after three

minutes of no communication with a sensor, a

double horn chip will occur indicating the

pairing has failed and a message will display on

the radio indicating the process was unsuc

-

cessful. Under certain circumstances, the

double horn chirp may continue to happen

every three minutes indicating the failed

pairing. If this happens, the horn chirping may

be canceled by cycling the ignition button OFF

and then back to RUN position.

Tire Pressure Monitoring Low Pressure

Warnings

When a tire pressure low in one or more of the

active road tires is detected, the instrument

cluster will display a message stating “Trailer

Tire Pressure Low”. The instrument cluster will

then display the TTPMS graphic showing the

pressure values of each tire with the low tire

pressure values in a different color.

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure condition (those in a different color in the

instrument cluster graphic) to the customer

programmed target tire pressure value as

shown at the top of the TTPMS instrument

cluster graphic. Once the tire(s) are inflated, the

system will automatically update the graphic

display in the instrument cluster, returning to its

original color. The vehicle may need to be driven

for up to 10 minutes above 15 mph (24 km/h)

in order for the TTPMS to receive the updated

information.

Service TTPMS Warning

If a system fault is detected, the instrument

cluster will display a “Trailer Tire Pressure

System Service Required” message for a

minimum of five seconds.

Once the system fault is corrected the "Trailer

Tire Pressure System Service Required"

message will no longer be displayed. The

vehicle may need to be driven for up to

10 minutes above 15 mph (24 km/h) in order

for the TTPMS to receive the trailer tire pressure

information.

6

21_DT_OM_EN_USC_t.book Page 333

Page 336 of 496

334SAFETY

Trailer Tire Pres sure System Not Configured

A “Trailer Tire Pressure System Not Configured”

message will be displayed in the instrument

cluster on the TTPMS instrument cluster

graphic when a trailer number is selected that

has not had trailer tire pressure sensors paired.

To correct this condition, see Ú page 237.

Trailer Sensors Detected Do Not Match Active

Trailer

The “Trailer Sensors Detected Do Not Match

Active Trailer” message will be displayed in the

instrument cluster when the trailer sensors

being received by the TTPMS module do not

match the trailer sensors paired to the current

trailer number selected. This message will be

displayed when the sensors being received

completely match the sensors paired to another

trailer number configured in the TTPMS module.

To correct this condition, the correct trailer

number must be selected in the radio

Ú page 237.OCCUPANT RESTRAINT SYSTEMS

Some of the most important safety features in

your vehicle are the restraint systems:

OCCUPANT RESTRAINT SYSTEMS

F

EATURES

Seat Belt Systems

Supplemental Restraint Systems (SRS) Air

Bags

Child Restraints

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

IMPORTANT SAFETY PRECAUTIONS

Please pay close attention to the information in

this section. It tells you how to use your restraint

system properly, to keep you and your

passengers as safe as possible.

Here are some simple steps you can take to

minimize the risk of harm from a deploying air

bag:

1. Children 12 years old and under should

always ride buckled up in the rear seat of a

vehicle with a rear seat.

2. A child who is not big enough to wear the vehicle seat belt properly must be secured

in the appropriate child restraint or

belt-positioning booster seat in a rear

seating position Ú page 355.

3. If a child from 2 to 12 years old (not in a rear-facing child restraint) must ride in the

front passenger seat, move the seat as far

back as possible and use the proper child

restraint Ú page 355.

4. Never allow children to slide the shoulder belt behind them or under their arm.

5. You should read the instructions provided with your child restraint to make sure that

you are using it properly.

6. All occupants should always wear their lap and shoulder belts properly.

7. The driver and front passenger seats should be moved back as far as practical to allow

the front air bags room to inflate.

21_DT_OM_EN_USC_t.book Page 334

Page 344 of 496

342SAFETY

SUPPLEMENTAL RESTRAINT SYSTEMS

(SRS)

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you

in a collision. The Occupant Restraint Controller

(ORC) monitors the internal circuits and

interconnecting wiring associated with the

electrical Air Bag System Components. Your

vehicle may be equipped with the following Air

Bag System Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

Air Bag Warning Light

The Occupant Restraint Controller

(ORC) monitors the readiness of the

electronic parts of the air bag system

whenever the ignition switch is in the

START or ON/RUN position. If the ignition switch

is in the OFF position or in the ACC position, the

air bag system is not on and the air bags will not

inflate. The ORC contains a backup power supply

system that may deploy the air bag system even

if the battery loses power or it becomes

disconnected prior to deployment.

The ORC turns on the Air Bag Warning Light in

the instrument panel for approximately four to

eight seconds for a self-check when the ignition

switch is first in the ON/RUN position. After the

self-check, the Air Bag Warning Light will turn

off. If the ORC detects a malfunction in any part

of the system, it turns on the Air Bag Warning

Light, either momentarily or continuously. A

single chime will sound to alert you if the light

comes on again after initial startup.

The ORC also includes diagnostics that will

illuminate the instrument panel Air Bag Warning

Light if a malfunction is detected that could

affect the air bag system. The diagnostics also

record the nature of the malfunction. While the

air bag system is designed to be maintenance

free, if any of the following occurs, have an

authorized dealer service the air bag system

immediately.

Failure to replace the seat belt assembly

could increase the risk of injury in colli

-

sions.

Do not use the Automatic Locking Mode to

restrain occupants who are wearing the

seat belt or children who are using booster

seats. The locked mode is only used to

install rear-facing or forward-facing child

restraints that have a harness for

restraining the child.

WARNING! (Continued)

21_DT_OM_EN_USC_t.book Page 342

Page 346 of 496

344SAFETY

(Continued)

Driver And Passenger Front Air Bag

Features

The Advanced Front Air Bag system has

multistage driver and front passenger air bags.

This system provides output appropriate to the

severity and type of collision as determined by

the Occupant Restraint Controller (ORC), which

may receive information from the front impact

sensors (if equipped) or other system

components.

The first stage inflator is triggered immediately

during an impact that requires air bag

deployment. A low energy output is used in less severe collisions. A higher energy output is used

for more severe collisions.

This vehicle may be equipped with a driver and/

or front passenger seat belt buckle switch that

detects whether the driver or front passenger

seat belt is buckled. The seat belt buckle switch

may adjust the inflation rate of the Advanced

Front Air Bags.

This vehicle may be equipped with driver and/or

front passenger seat track position sensors that

may adjust the inflation rate of the Advanced

Front Air Bags based upon seat position.

This vehicle is equipped with a right front

passenger Occupant Classification System

(“OCS”) that is designed to provide Passenger

Advanced Front Air Bag output appropriate to

the occupant’s seated weight input, as

determined by the OCS.Front Air Bag Operation

Front Air Bags are designed to provide

additional protection by supplementing the seat

belts. Front air bags are not expected to reduce

the risk of injury in rear, side, or rollover

collisions. The front air bags will not deploy in all

frontal collisions, including some that may

produce substantial vehicle damage — for

example, some pole collisions, truck

underrides, and angle offset collisions.

Never place a rear-facing child restraint in

front of an air bag. A deploying passenger

front air bag can cause death or serious

injury to a child 12 years or younger,

including a child in a rear-facing child

restraint.

Never install a rear-facing child restraint in

the front seat of a vehicle. Only use a

rear-facing child restraint in the rear seat. If

the vehicle does not have a rear seat, do

not transport a rear-facing child restraint in

that vehicle.

WARNING!

(Continued)

WARNING!

No objects should be placed over or near

the air bag on the instrument panel or

steering wheel because any such objects

could cause harm if the vehicle is in a colli -

sion severe enough to cause the air bag to

inflate.

Do not put anything on or around the air

bag covers or attempt to open them manu -

ally. You may damage the air bags and you

could be injured because the air bags may

no longer be functional. The protective

covers for the air bag cushions are

designed to open only when the air bags

are inflating.

Relying on the air bags alone could lead to

more severe injuries in a collision. The air

bags work with your seat belt to restrain you

properly. In some collisions, air bags won’t

deploy at all. Always wear your seat belts

even though you have air bags.

WARNING! (Continued)

21_DT_OM_EN_USC_t.book Page 344