gas type RAM 1500 2021 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: 1500, Model: RAM 1500 2021Pages: 496, PDF Size: 20.89 MB

Page 10 of 496

8

VEHICLE MAINTENANCE .................................. 409 Engine Oil — Gas Engine ...........................410

Engine Oil Filter ..........................................410Engine Air Cleaner Filter ............................411

Draining Fuel/Water Separator Filter —

Diesel Engine ............................................412 Underbody Mounted Fuel Filter

Replacement — Diesel Engine ..................413 Priming If The Engine Has Run Out Of

Fuel — Diesel Engine .................................414 Intervention Regeneration Strategy —

Message Process Flow (Diesel Engine) ....414 Diesel Exhaust Fluid ..................................415Air Conditioner Maintenance ....................415

Accessory Drive Belt Inspection................417Body Lubrication ........................................418

Windshield Wiper Blades ..........................418

Exhaust System ........................................420

Cooling System .........................................421

Charge Air Cooler — Inter-Cooler (Diesel

Engine)........................................................ 424 Brake System ............................................425

Automatic Transmission ...........................426

Rear Axle And 4x4 Front Driving Axle

Fluid Level .................................................426 Transfer Case ............................................427

FUSES .........................................................427

BULB REPLACEMENT ................................437 TIRES....................................................................443

Tire Safety Information .............................. 443

Tires — General Information ..................... 449Tire Types ................................................... 454

Spare Tires — If Equipped ......................... 455

Wheel And Wheel Trim Care ..................... 456Snow Traction Devices .............................. 458

Tire Rotation Recommendations ............. 460

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................. 460

Treadwear .................................................. 460

Traction Grades ......................................... 461

Temperature Grades ................................. 461

STORING THE VEHICLE ......................................461

BODYWORK ........................................................ 461

Protection From Atmospheric Agents....... 461

Body And Underbody Maintenance .......... 462Preserving The Bodywork .......................... 462

INTERIORS ......................................................... 464

Seats And Fabric Parts .............................. 464

Plastic And Coated Parts ........................... 465

Leather Surfaces ....................................... 465Glass Surfaces .......................................... 466

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER ................ 467

BRAKE SYSTEM ................................................ 467

WHEEL AND TIRE TORQUE

SPECIFICATIONS ................................................ 467

Torque Specifications ............................... 467

FUEL REQUIREMENTS — GASOLINE

ENGINE ............................................................... 468

3.6L Engine ............................................... 468

5.7L Engine ................................................ 469

Reformulated Gasoline ............................. 469

Materials Added To Fuel ........................... 469

Gasoline/Oxygenate Blends ..................... 469

Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 470 CNG And LP Fuel System Modifications .. 470Methylcyclopentadienyl Manganese

Tricarbonyl (MMT) In Gasoline .................. 470 Fuel System Cautions................................ 470

FUEL REQUIREMENTS – DIESEL ENGINE ....... 471

Diesel Fuel Specifications......................... 471

Biodiesel Fuel Requirements.................... 472

FLUID CAPACITIES ............................................ 474

ENGINE FLUIDS AND LUBRICANTS ................ 475

CHASSIS FLUIDS AND LUBRICANTS ............... 478

21_DT_OM_EN_USC_t.book Page 8

Page 152 of 496

150STARTING AND OPERATING

ENGINE BLOCK HEATER — IF EQUIPPED

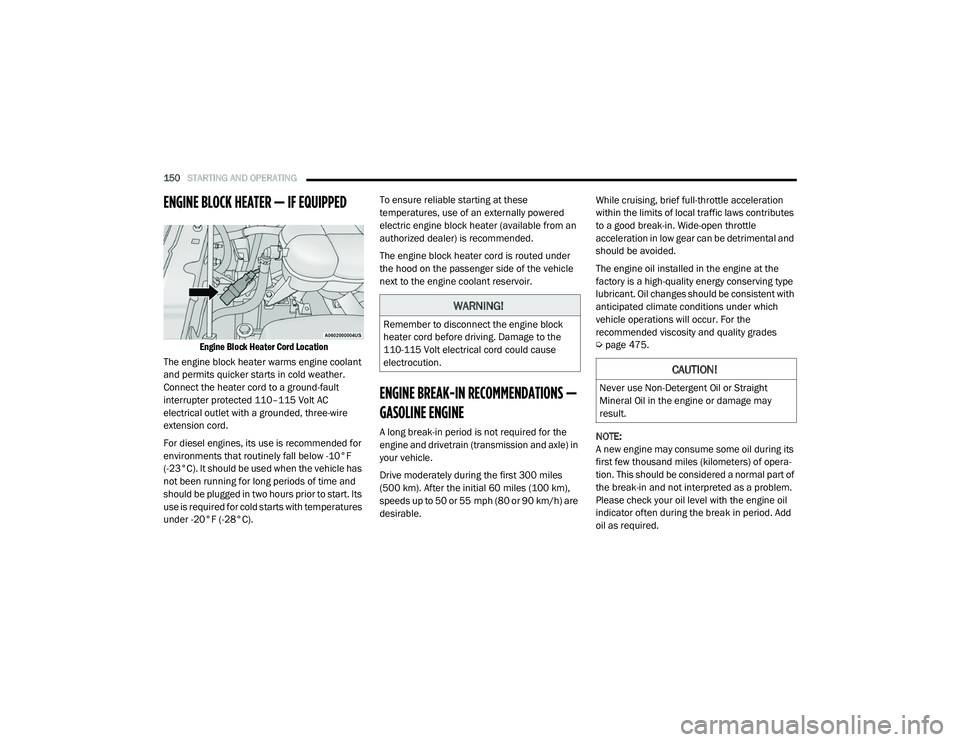

Engine Block Heater Cord Location

The engine block heater warms engine coolant

and permits quicker starts in cold weather.

Connect the heater cord to a ground-fault

interrupter protected 110–115 Volt AC

electrical outlet with a grounded, three-wire

extension cord.

For diesel engines, its use is recommended for

environments that routinely fall below -10°F

(-23°C). It should be used when the vehicle has

not been running for long periods of time and

should be plugged in two hours prior to start. Its

use is required for cold starts with temperatures

under -20°F (-28°C). To ensure reliable starting at these

temperatures, use of an externally powered

electric engine block heater (available from an

authorized dealer) is recommended.

The engine block heater cord is routed under

the hood on the passenger side of the vehicle

next to the engine coolant reservoir.

ENGINE BREAK-IN RECOMMENDATIONS —

GASOLINE ENGINE

A long break-in period is not required for the

engine and drivetrain (transmission and axle) in

your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles (100 km),

speeds up to 50 or 55 mph (80 or 90 km/h) are

desirable.

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contributes

to a good break-in. Wide-open throttle

acceleration in low gear can be detrimental and

should be avoided.

The engine oil installed in the engine at the

factory is a high-quality energy conserving type

lubricant. Oil changes should be consistent with

anticipated climate conditions under which

vehicle operations will occur. For the

recommended viscosity and quality grades

Ú

page 475.

NOTE:

A new engine may consume some oil during its

first few thousand miles (kilometers) of opera -

tion. This should be considered a normal part of

the break-in and not interpreted as a problem.

Please check your oil level with the engine oil

indicator often during the break in period. Add

oil as required.

WARNING!

Remember to disconnect the engine block

heater cord before driving. Damage to the

110-115 Volt electrical cord could cause

electrocution.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

21_DT_OM_EN_USC_t.book Page 150

Page 347 of 496

SAFETY345

On the other hand, depending on the type and

location of impact, front air bags may deploy in

crashes with little vehicle front-end damage but

that produce a severe initial deceleration.

Because air bag sensors measure vehicle

deceleration over time, vehicle speed and

damage by themselves are not good indicators

of whether or not an air bag should have

deployed.

Seat belts are necessary for your protection in

all collisions, and also are needed to help keep

you in position, away from an inflating air bag.

When the Occupant Restraint Controller (ORC)

detects a collision requiring the front air bags, it

signals the inflator units. A large quantity of

non-toxic gas is generated to inflate the front air

bags.

The steering wheel hub trim cover and the

upper passenger side of the instrument panel

separate and fold out of the way as the air bags

inflate to their full size. The front air bags fully

inflate in less time than it takes to blink your

eyes. The front air bags then quickly deflate

while helping to restrain the driver and front

passenger.Occupant Classification System (OCS) —

Front Passenger Seat

The OCS is part of a Federally regulated safety

system for this vehicle. It is designed to provide

Passenger Advanced Front Air Bag output

appropriate to the occupant’s seated weight, as

determined by the OCS.

The Occupant Classification System (OCS)

consists of the following:

Occupant Restraint Controller (ORC)

Occupant Classification Module (OCM) and

Sensor located in the front passenger seat

Air Bag Warning Light

Occupant Classification Module (OCM) And

Sensor

The Occupant Classification Module (OCM) is

located underneath the front passenger seat.

The Sensor is located beneath the passenger

seat cushion foam. Any weight on the seat will

be sensed by the Sensor. The OCM uses input

from the Sensor to determine the front

passenger’s most probable classification. The

OCM communicates this information to the ORC. The ORC may reduce the inflation rate of

the Passenger Advanced Front Air Bag

deployment based on occupant classification.

In order for the OCS to operate as designed, it is

important for the front passenger to be seated

properly and properly wearing the seat belt.

The OCS will NOT prevent deployment of the

Passenger Advanced Front Air Bag. The OCS

may reduce the inflation rate of the Passenger

Advanced Front Air Bag if the OCS estimates

that:

The front passenger seat is unoccupied or

has very light objects on it; or

The front passenger seat is occupied by a

small passenger, including a child; or

The front passenger seat is occupied by a

rear-facing child restraint; or

The front passenger is not properly seated or

his or her weight is taken off of the seat for a

period of time.

6

21_DT_OM_EN_USC_t.book Page 345

Page 354 of 496

352SAFETY

Rollover Events

Side Air Bags and seat belt pretensioners are

designed to activate in certain rollover events.

The Occupant Restraint Controller (ORC)

determines whether deployment in a particular

rollover event is appropriate, based on the

severity and type of collision. Vehicle damage by

itself is not a good indicator of whether or not

Side Air Bags and seat belt pretensioners

should have deployed.

The Side Air Bags and seat belt pretensioners

will not deploy in all rollover events. The rollover

sensing system determines if a rollover event

may be in progress and whether deployment is

appropriate. In the event the vehicle

experiences a rollover or near rollover event,

and deployment is appropriate, the rollover

sensing system will deploy the side air bags and

seat belt pretensioners on both sides of the

vehicle.

The SABICs may help reduce the risk of partial

or complete ejection of vehicle occupants

through side windows in certain rollover or side

impact events.Air Bag System Components

NOTE:

The Occupant Restraint Controller (ORC) moni -

tors the internal circuits and interconnecting

wiring associated with electrical Air Bag System

Components listed below:

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

If A Deployment Occurs

The front air bags are designed to deflate

immediately after deployment.

NOTE:

Front and/or side air bags will not deploy in all

collisions. This does not mean something is

wrong with the air bag system.

If you do have a collision which deploys the air

bags, any or all of the following may occur:

The air bag material may sometimes cause

abrasions and/or skin reddening to the occu -

pants as the air bags deploy and unfold. The

abrasions are similar to friction rope burns or

those you might get sliding along a carpet or

gymnasium floor. They are not caused by

contact with chemicals. They are not perma -

nent and normally heal quickly. However, if

you haven’t healed significantly within a few

days, or if you have any blistering, see your

doctor immediately.

As the air bags deflate, you may see some

smoke-like particles. The particles are a

normal by-product of the process that gener -

ates the non-toxic gas used for air bag infla -

tion. These airborne particles may irritate the

skin, eyes, nose, or throat. If you have skin or

21_DT_OM_EN_USC_t.book Page 352

Page 412 of 496

410SERVICING AND MAINTENANCE

ENGINE OIL — GAS ENGINE

Engine Oil Selection — Gasoline Engine

For best performance and maximum protection

under all types of operating conditions, FCA only

recommends engine oils that are API Certified

and meet the requirements of FCA Material

Standard MS-6395.

NOTE:

Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approxi -

mately 30 seconds. This is normal and will not

harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experi -

ence a ticking sound. Other causes could be if

the vehicle is unused for an extended period of

time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick

or if the Malfunction Indicator Light (MIL) comes

on, see the nearest authorized dealer.

Engine Oil Selection — Diesel Engine

For best performance and maximum protection

under all types of operating conditions, FCA

recommends engine oils that meet the

requirements of FCA Material Standard MS-12991, and that are API SN certified and

meet the requirements of FCA LLC.

American Petroleum Institute (API) Engine

Oil Identification Symbol

This symbol means that the oil has

been certified by the American

Petroleum Institute (API). The

manufacturer only recommends API

Certified engine oils.

This symbol certifies 0W-20, 5W-20, 0W-30,

5W-30 and 10W-30 engine oils.

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

FCA strongly recommends against the addition

of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered

product and its performance may be impaired

by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle. Used

oil and oil filters, indiscriminately discarded, can

present a problem to the environment. Contact

an authorized dealer, service station or

governmental agency for advice on how and

where used oil and oil filters can be safely

discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be

used for replacement. The quality of

replacement filters varies considerably. Only

high quality Mopar certified filters should be

used.

CAUTION!

Do not use chemical flushes in your engine oil

as the chemicals can damage your engine.

Such damage is not covered by the New

Vehicle Limited Warranty.

21_DT_OM_EN_USC_t.book Page 410

Page 426 of 496

424SERVICING AND MAINTENANCE

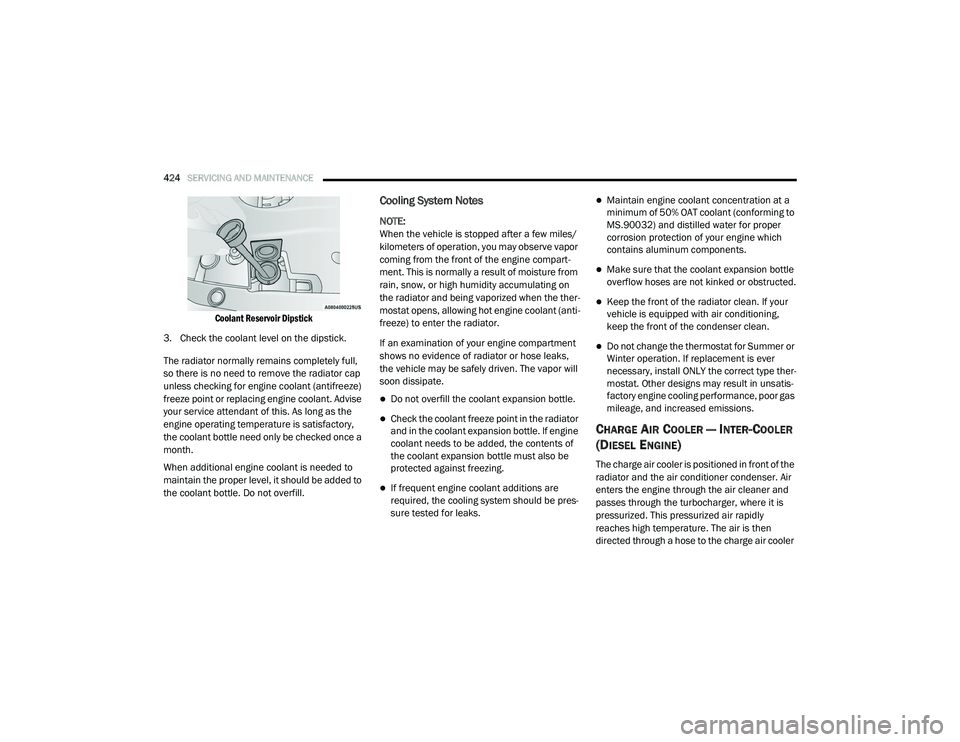

Coolant Reservoir Dipstick

3. Check the coolant level on the dipstick.

The radiator normally remains completely full,

so there is no need to remove the radiator cap

unless checking for engine coolant (antifreeze)

freeze point or replacing engine coolant. Advise

your service attendant of this. As long as the

engine operating temperature is satisfactory,

the coolant bottle need only be checked once a

month.

When additional engine coolant is needed to

maintain the proper level, it should be added to

the coolant bottle. Do not overfill.

Cooling System Notes

NOTE:

When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor

coming from the front of the engine compart -

ment. This is normally a result of moisture from

rain, snow, or high humidity accumulating on

the radiator and being vaporized when the ther -

mostat opens, allowing hot engine coolant (anti -

freeze) to enter the radiator.

If an examination of your engine compartment

shows no evidence of radiator or hose leaks,

the vehicle may be safely driven. The vapor will

soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of

the coolant expansion bottle must also be

protected against freezing.

If frequent engine coolant additions are

required, the cooling system should be pres -

sure tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper

corrosion protection of your engine which

contains aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine cooling performance, poor gas

mileage, and increased emissions.

CHARGE AIR COOLER — INTER-COOLER

(D

IESEL ENGINE)

The charge air cooler is positioned in front of the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly

reaches high temperature. The air is then

directed through a hose to the charge air cooler

21_DT_OM_EN_USC_t.book Page 424

Page 466 of 496

464SERVICING AND MAINTENANCE

To Help Maintain The Appearance Of Your

Spray-On Bedliner, Follow The Steps Below:

1. Rinse your truck bed out with water to remove any loose dirt and debris.

2. Mix a mild soap or detergent with water. Then apply solution with a soft cloth or

brush.

3. Rinse bedliner with water.

4. Once dry, apply a small amount of Mopar Spray-On Bedliner Conditioner to a moist

towel or sponge and wipe over the entire

surface of the truck bedliner.

Spray-On Bedliners are chemically-resistant to

many different types of chemicals (including

gasoline, oil, hydraulic fluids) for short periods

of time. If a spill occurs on your Spray-On

Bedliner, rinse the truck out as soon as possible

to avoid permanent damage. Repairing The Spray-On Bedliner

While extremely tough, it is possible to damage

a Spray-On Bedliner. One common condition is

when loading a heavy pallet and dragging that

pallet across the floor of the bed. If a nail or

sharp point is exposed under the weight of the

pallet a scratch or tear is possible. While not

covered by your new vehicle warranty, a

cosmetic fix to cover the metal exposed by the

scratch is required. To repair a tear or gouge,

follow the directions provided in the Mopar

Quick Repair Kit.

INTERIORS

SEATS AND FABRIC PARTS

Use Mopar Total Clean to clean fabric

upholstery and carpeting.

Stain Repel Fabric Cleaning Procedure — If

Equipped

Stain Repel seats may be cleaned in the

following manner:

Remove as much of the stain as possible by

blotting with a clean, dry towel.

Blot any remaining stain with a clean, damp

towel.

For tough stains, apply Mopar Total Clean, or

a mild soap solution to a clean, damp cloth

and remove stain. Use a fresh, damp towel to

remove soap residue.

For grease stains, apply Mopar Multi-Purpose

Cleaner to a clean, damp cloth and remove

stain. Use a fresh, damp towel to remove

soap residue.

Do not use any harsh solvents or any other

form of protectants on Stain Repel products.

WARNING!

Do not use silicon-based protection products

to clean your bedliner. Silicon-based products

can become slippery and may result in

personal injury.

WARNING!

Do not use volatile solvents for cleaning

purposes. Many are potentially flammable,

and if used in closed areas they may cause

respiratory harm.

21_DT_OM_EN_USC_t.book Page 464