RAM 1500 2022 Owners Manual

Manufacturer: RAM, Model Year: 2022, Model line: 1500, Model: RAM 1500 2022Pages: 496, PDF Size: 18.03 MB

Page 211 of 496

STARTING AND OPERATING209

BULK FUEL STORAGE — DIESEL FUEL

If you store quantities of fuel, good maintenance of

the stored fuel is also essential. Fuel contaminated

with water will promote the growth of “microbes.”

These microbes form “slime” that will clog the fuel

filtration system and lines. Drain condensation

from the supply tank and change the line filter on

a regular basis.

NOTE:When a diesel engine is allowed to run out of fuel,

air is pulled into the fuel system.

If the vehicle will not start Úpage 414.

DIESEL EXHAUST FLUID

Your vehicle is equipped with a Selective Catalytic

Reduction (SCR) system to meet diesel emissions

standards required by the Environmental

Protection Agency. The purpose of the SCR system is to reduce levels

of oxides of nitrogen (NO

x) emitted from engines

that are harmful to our health and the environment

to a near-zero level. A small quantity of Diesel

Exhaust Fluid (DEF) is injected into the exhaust

upstream of a catalyst where, when vaporized,

converts smog-forming NO

x into harmless

nitrogen (N

2) and water vapor (H2O), two natural

components of the air we breathe.

DIESEL EXHAUST FLUID STORAGE

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is kept

in temperatures between 10° and 90°F (-12° and

32°C), it will last a minimum of one year.

DEF may freeze at temperatures at or below 12°F

(-11°C). The system has been designed to operate

in this environment.

NOTE:When working with DEF, it is important to know

that:

Any containers or parts that come into contact

with DEF must be DEF compatible (plastic or

stainless steel). Copper, brass, aluminum, iron

or non-stainless steel should be avoided as they

are subject to corrosion by DEF.

If DEF is spilled, it should be wiped up

completely.

ADDING DIESEL EXHAUST FLUID

The Diesel Exhaust Fluid (DEF) gauge (located on

the instrument cluster) will display the level of DEF

remaining in the tank Ú page 110.

NOTE:

Driving conditions (altitude, vehicle speed, load,

etc.) will effect the amount of DEF that is used in

your vehicle.

Outside temperature can affect DEF consump -

tion. In cold conditions, 12°F (-11°C) and

below, the DEF gauge may take longer to

operate as intended. This is a normal function of

the system.

There is an electric heater inside the DEF tank

that automatically works when necessary. If the

DEF supply does freeze, the truck will operate

normally until it thaws.WARNING!

Do not open the high pressure fuel system with

the engine running. Engine operation causes

high fuel pressure. High pressure fuel spray can

cause serious injury or death.

4

22_DT_OM_EN_USC_t.book Page 209

Page 212 of 496

210STARTING AND OPERATING

(Continued)

Diesel Exhaust Fluid (DEF) Fill Procedure

NOTE:

For the correct fluid type Úpage 473.

1. Remove cap from Diesel Exhaust Fluid (DEF) tank which is located next to the diesel fuel

filler.

DEF Filler Cap And Fuel Fill

2. Insert DEF fill adapter/nozzle into DEF tank

filler neck.NOTE:

The DEF gauge may take up to five seconds

to update after adding a gallon or more of

(DEF) to the DEF tank. If you have a fault

related to the DEF system, the gauge may

not update to the new level. See an autho -

rized dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of the

DEF fluid is below 12°F (-11°C). The DEF

line heater will possibly warm up the DEF

fluid and allow the gauge to update after a

period of run time. Under very cold condi -

tions, it is possible that the gauge may not

reflect the new fill level for several drives.

Refilling With Nozzles

You can fill up at any DEF distributor.

Proceed as follows:

Insert the DEF nozzle in the filler, start

refilling and stop refilling at the first shut-off

(the shut-off indicates that the DEF tank is

full). Do not proceed with the refilling, to

prevent spillage of DEF.

Extract the nozzle.

Refilling With Containers

Proceed as follows:

Check the expiration date.

Read the advice for use on the label before

pouring the content of the bottle into the

DEF tank.

If systems which cannot be screwed in

(e.g. tanks) are used for refilling, after the

indication appears on the instrument panel

display Úpage 114 fill the DEF tank with no

more than 2 gallons (8 liters).

If containers which can be screwed to the

filler are used, the reservoir is full when the

DEF level in the container stops pouring out.

Do not proceed further.

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

CAUTION!

To avoid DEF spillage, and possible damage to

the DEF tank from overfilling, do not “top off”

the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below 12ºF

(-11ºC). The DEF system is designed to work in

temperatures below the DEF freezing point,

however, if the tank is overfilled and freezes,

the system could be damaged.

22_DT_OM_EN_USC_t.book Page 210

Page 213 of 496

STARTING AND OPERATING211

3. Stop filling the DEF tank immediately when any of the following happen: DEF stops flowing

from the fill bottle into the DEF tank, DEF

splashes out the filler neck, or a DEF pump

nozzle automatically shuts off.

4. Reinstall cap onto DEF tank.

Filling The Def Tank In Cold Climates

Your vehicle is equipped with an automatic DEF

heating system. This allows the DEF injection

system to operate properly at temperatures below

12°F (-11°C). If your vehicle is not in operation for

an extended period of time with temperatures

below 12°F (-11°C), the DEF in the tank may

freeze. Do not overfill the DEF tank. If the tank is

overfilled and freezes, it could be damaged.

Extra care should be taken when filling with

portable containers to avoid overfilling. Keep an

eye on the DEF gauge in your instrument cluster.

You may safely add a maximum of 2 gallons

(7.6 Liters) when your DEF gauge is reading at

the half mark.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear Gross Axle

Weight Rating (GAWR). Total load must be limited

so GVWR and front and rear GAWR are not

exceeded.

PAYLOAD

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

When DEF is spilled, clean the area immedi -

ately with water and use an absorbent mate -

rial to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank as it

can result in severe damage to your engine,

including but not limited to failure of the fuel

pump and injectors.

Never add anything other than DEF to the tank

– especially any form of hydrocarbon such as

diesel fuel, fuel system additives, gasoline, or

any other petroleum-based product. Even a

very small amount of these, less than

100 parts per million or less than 1 oz. per

78 gallons (295 liters) will contaminate the

entire DEF system and will require replace -

ment. If owners use a container, funnel or

nozzle when refilling the tank, it should either

be new or one that has only been used for

adding DEF. Mopar® provides an attachable

nozzle with its DEF for this purpose.

CAUTION!

4

22_DT_OM_EN_USC_t.book Page 211

Page 214 of 496

212STARTING AND OPERATING

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full Gross

Axle Weight Rating (GAWR).

CURB WEIGHT

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

LOADING

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to insure that the Gross Vehicle

Weight Rating (GVWR) has not been exceeded. The

weight on the front and rear of the vehicle should

then be determined separately to be sure that the

load is properly distributed over the front and rear

axle. Weighing the vehicle may show that the Gross

Axle Weight Rating (GAWR) of either the front or

rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be

shifted from front to rear or rear to front as

appropriate until the specified weight limitations

are met. Store the heavier items down low and be

sure that the weight is distributed equally. Stow all

loose items securely before driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow your

load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Also, overloading can

shorten the life of your vehicle.

22_DT_OM_EN_USC_t.book Page 212

Page 215 of 496

STARTING AND OPERATING213

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will

assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be limited

so that you do not exceed the GVWR Ú page 211.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight

of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the

trailer in its “loaded and ready for operation”

condition.

The recommended way to measure GTW is to put

your fully loaded trailer on a vehicle scale. The

entire weight of the trailer must be supported by

the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Úpage 211.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

The electronic TSC (If equipped) recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

WARNING!

If the gross trailer weight is 5,000 lb (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

4

22_DT_OM_EN_USC_t.book Page 213

Page 216 of 496

214STARTING AND OPERATING

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and

the trailer axle(s). When used in accordance with

the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control, thereby enhancing towing

safety. The addition of a friction/hydraulic sway

control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer Sway Control

and a weight-distributing (load equalizing) hitch

are recommended for heavier Tongue Weights

(TW) and may be required depending on vehicle

and trailer configuration/loading to comply with

GAWR requirements.

Without Weight-Distributing Hitch (Incorrect)With Weight-Distributing Hitch (Correct)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability

and braking performance and could result in a

collision.

Weight-distributing systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

22_DT_OM_EN_USC_t.book Page 214

Page 217 of 496

STARTING AND OPERATING215

RECOMMENDED DISTRIBUTION HITCH

ADJUSTMENT

Towing With Air Suspension — If Equipped

1. Verify that the vehicle is at the normal ride

height.

NOTE:The vehicle must remain in the engine run position

with all doors closed while attaching a trailer for

proper leveling of the air suspension system.

2. Position the truck to be ready to connect to the trailer (do not connect the trailer).

3. Enable tire jack mode through the instrument cluster or touchscreen radio settings. Tire jack

mode will be canceled and the procedure must

be restarted if the vehicle is driven at speeds

above 5 mph (8 km/h).

4. Measure the height from the top of the front wheel opening on the fender to ground; this is

height H1.

Measuring Height (H)

5. Attach the trailer to the vehicle without the weight-distributing bars connected.

6. Measure the height from the top of the front wheel opening on the fender to the ground;

this is height H2.

7. Install and adjust the tension in the weight-distributing bars per the

manufacturer’s recommendations so that the

height of the front fender is approximately

(H2-H1)/3+H1 (about 1/3 the difference

between H2 and H1 above normal ride height

[H1]). 8. Use the instrument cluster or touchscreen

radio settings and switch off tire jack mode.

Make sure the truck returns to normal ride

height. Perform a visual inspection of the

trailer and weight-distributing hitch to confirm

the manufacturer’s recommendations have

been met.

9. The truck can now be driven.

NOTE:For all towing conditions, we recommend towing

with Tow/Haul mode engaged.

Measurement Example Example Height (mm)

H1

925

H2 946

H2-H1 21

(H2-H1)/3 7

(H2-H1)/3 + H1 932

4

22_DT_OM_EN_USC_t.book Page 215

Page 218 of 496

216STARTING AND OPERATING

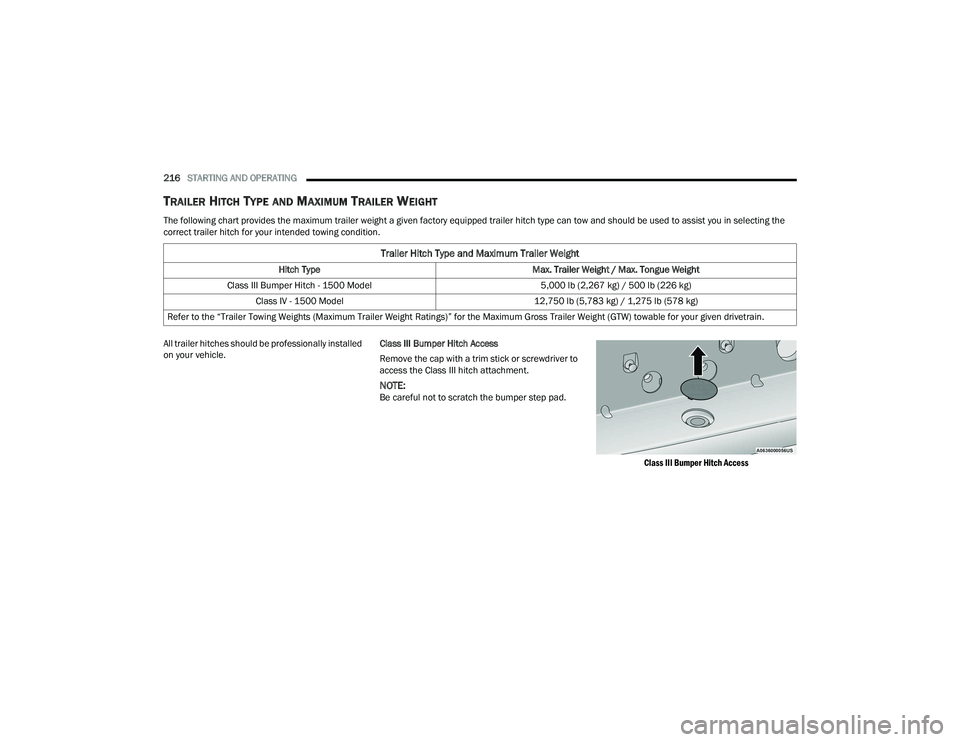

TRAILER HITCH TYPE AND MAXIMUM TRAILER WEIGHT

The following chart provides the maximum trailer weight a given factory equipped trailer hitch type can tow and should be used to assist you in selecting the

correct trailer hitch for your intended towing condition.

All trailer hitches should be professionally installed

on your vehicle. Class III Bumper Hitch Access

Remove the cap with a trim stick or screwdriver to

access the Class III hitch attachment.

NOTE:Be careful not to scratch the bumper step pad.

Class III Bumper Hitch Access

Trailer Hitch Type and Maximum Trailer Weight

Hitch TypeMax. Trailer Weight / Max. Tongue Weight

Class III Bumper Hitch - 1500 Model 5,000 lb (2,267 kg) / 500 lb (226 kg)

Class IV - 1500 Model 12,750 lb (5,783 kg) / 1,275 lb (578 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

22_DT_OM_EN_USC_t.book Page 216

Page 219 of 496

STARTING AND OPERATING217

TRAILER TOWING WEIGHTS (MAXIMUM

T

RAILER WEIGHT RATINGS)

NOTE:For trailer towing information (maximum trailer

weight ratings) refer to the following website

addresses:

ramtrucks.com/en/towing_guide/

ramtruck.ca (Canada)

rambodybuilder.com

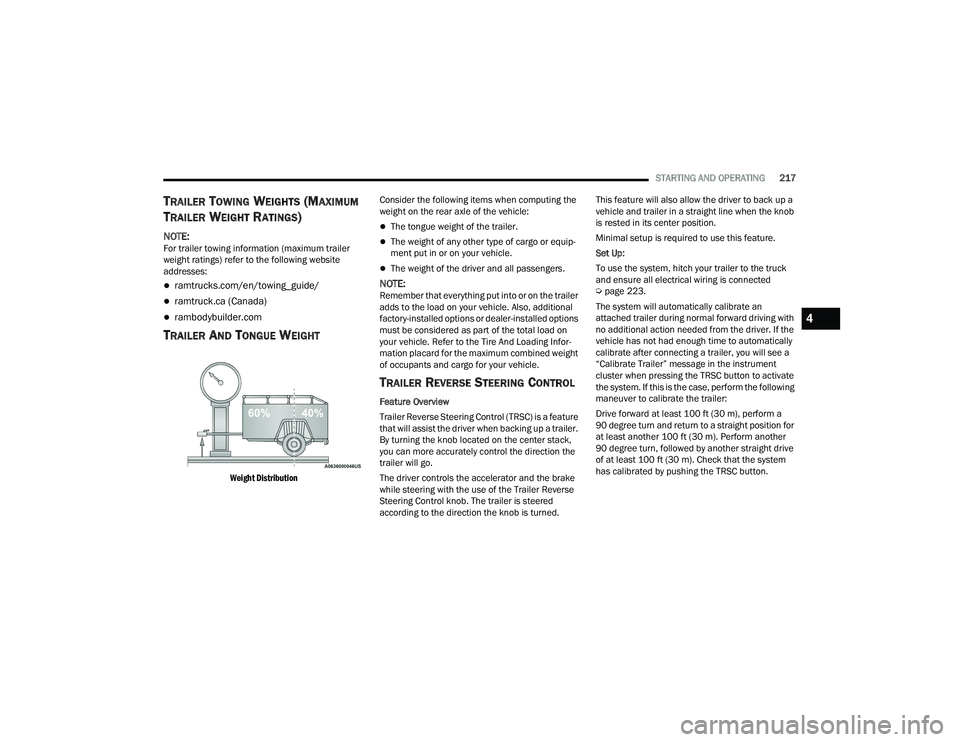

TRAILER AND TONGUE WEIGHT

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or equip

-

ment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options

must be considered as part of the total load on

your vehicle. Refer to the Tire And Loading Infor -

mation placard for the maximum combined weight

of occupants and cargo for your vehicle.

TRAILER REVERSE STEERING CONTROL

Feature Overview

Trailer Reverse Steering Control (TRSC) is a feature

that will assist the driver when backing up a trailer.

By turning the knob located on the center stack,

you can more accurately control the direction the

trailer will go.

The driver controls the accelerator and the brake

while steering with the use of the Trailer Reverse

Steering Control knob. The trailer is steered

according to the direction the knob is turned. This feature will also allow the driver to back up a

vehicle and trailer in a straight line when the knob

is rested in its center position.

Minimal setup is required to use this feature.

Set Up:

To use the system, hitch your trailer to the truck

and ensure all electrical wiring is connected

Ú

page 223.

The system will automatically calibrate an

attached trailer during normal forward driving with

no additional action needed from the driver. If the

vehicle has not had enough time to automatically

calibrate after connecting a trailer, you will see a

“Calibrate Trailer” message in the instrument

cluster when pressing the TRSC button to activate

the system. If this is the case, perform the following

maneuver to calibrate the trailer:

Drive forward at least 100 ft (30 m), perform a

90 degree turn and return to a straight position for

at least another 100 ft (30 m). Perform another 90 degree turn, followed by another straight drive

of at least 100 ft (30 m). Check that the system has calibrated by pushing the TRSC button.

4

22_DT_OM_EN_USC_t.book Page 217

Page 220 of 496

218STARTING AND OPERATING

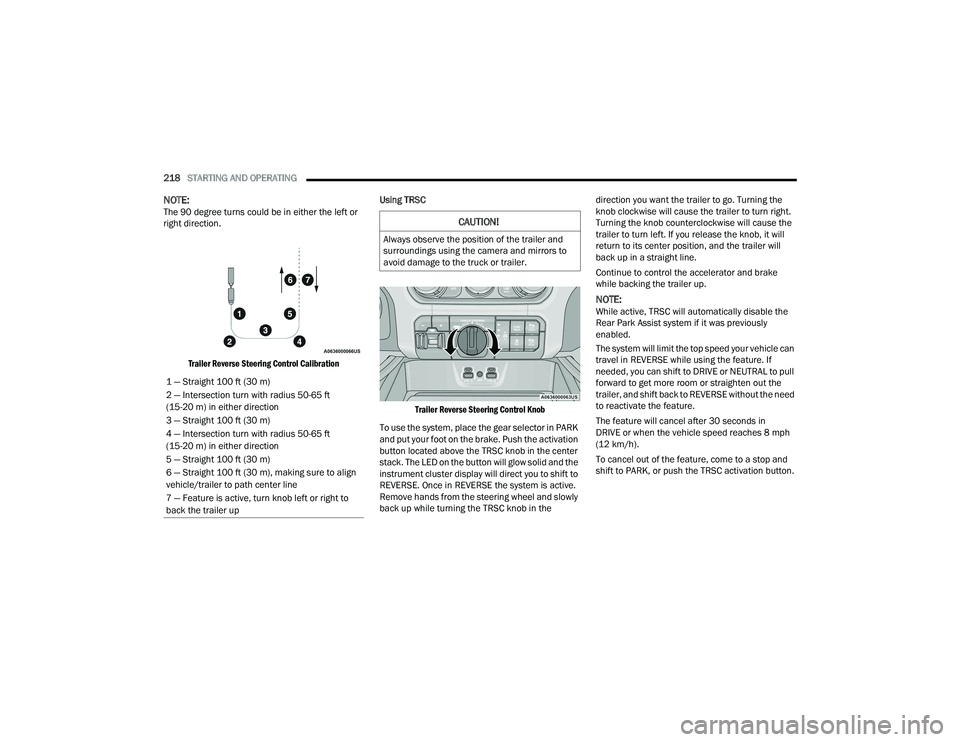

NOTE:The 90 degree turns could be in either the left or

right direction.

Trailer Reverse Steering Control Calibration

Using TRSC

Trailer Reverse Steering Control Knob

To use the system, place the gear selector in PARK

and put your foot on the brake. Push the activation

button located above the TRSC knob in the center

stack. The LED on the button will glow solid and the

instrument cluster display will direct you to shift to

REVERSE. Once in REVERSE the system is active.

Remove hands from the steering wheel and slowly

back up while turning the TRSC knob in the direction you want the trailer to go. Turning the

knob clockwise will cause the trailer to turn right.

Turning the knob counterclockwise will cause the

trailer to turn left. If you release the knob, it will

return to its center position, and the trailer will

back up in a straight line.

Continue to control the accelerator and brake

while backing the trailer up.

NOTE:While active, TRSC will automatically disable the

Rear Park Assist system if it was previously

enabled.

The system will limit the top speed your vehicle can

travel in REVERSE while using the feature. If

needed, you can shift to DRIVE or NEUTRAL to pull

forward to get more room or straighten out the

trailer, and shift back to REVERSE without the need

to reactivate the feature.

The feature will cancel after 30 seconds in

DRIVE or when the vehicle speed reaches 8 mph

(12 km/h).

To cancel out of the feature, come to a stop and

shift to PARK, or push the TRSC activation button.

1 — Straight 100 ft (30 m)

2 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

3 — Straight 100 ft (30 m)

4 — Intersection turn with radius 50-65 ft

(15-20 m) in either direction

5 — Straight 100 ft (30 m)

6 — Straight 100 ft (30 m), making sure to align

vehicle/trailer to path center line

7 — Feature is active, turn knob left or right to

back the trailer up

CAUTION!

Always observe the position of the trailer and

surroundings using the camera and mirrors to

avoid damage to the truck or trailer.

22_DT_OM_EN_USC_t.book Page 218