brake RAM 1500 2023 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: 1500, Model: RAM 1500 2023Pages: 416, PDF Size: 20.59 MB

Page 337 of 416

SERVICING AND MAINTENANCE335

Mileage Or Time Passed (Whichever Comes

First)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, tie rod ends, and

replace if necessary. X

X X XX XX

Inspect the front and rear axle surfaces. If gear

oil leakage is suspected, check the fluid level.

If using your vehicle for police, taxi, fleet,

off-road or frequent trailer towing, change

axle fluid. X

X XXX

Inspect the brake linings, replace as necessary. X XX XX XX

Inspect transfer case fluid. X

Additional Maintenance

Replace cabin air filter. To be replaced every 12,000 miles (19,000 km).

For severe dusty driving conditions, inspect and

replace the Evaporative System Fresh Air Filter

as necessary; replacement may be more

frequent depending on conditions. X X X X X X X X X X X X X X

Replace engine air cleaner filter. XX XXX

If equipped with Stop/Start, replace accessory

drive belt with OEM grade Mopar® belt. X

8

23_DT_OM_EN_USC_t.book Page 335

Page 339 of 416

SERVICING AND MAINTENANCE337

ENGINE COMPARTMENT

3.6L ENGINE WITH STOP/START

1 — Motor Generator Unit Coolant Reservoir Pressure Cap 6 — Battery

2 — Engine Coolant Reservoir Pressure Cap 7 — Engine Air Cleaner Filter

3 — Engine Oil Dipstick 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Fill 9 — Power Distribution Center (Fuses)

5 — Brake Fluid Reservoir

8

23_DT_OM_EN_USC_t.book Page 337

Page 340 of 416

338SERVICING AND MAINTENANCE

5.7L ENGINE WITHOUT STOP/START

1 — Engine Air Cleaner Filter 6 — Battery

2 — Engine Coolant Pressure Cap 7 — Engine Coolant Reservoir Cap

3 — Engine Oil Fill 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Power Distribution Center (Fuses)

5 — Brake Fluid Reservoir Cap

23_DT_OM_EN_USC_t.book Page 338

Page 341 of 416

SERVICING AND MAINTENANCE339

5.7L ENGINE WITH STOP/START

1 — Engine Air Cleaner Filter 6 — Battery

2 — Engine Coolant Pressure Cap 7 — Engine Coolant Reservoir Cap

3 — Engine Oil Fill 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Power Distribution Center (Fuses)

5 — Brake Fluid Reservoir Cap

8

23_DT_OM_EN_USC_t.book Page 339

Page 354 of 416

352SERVICING AND MAINTENANCE

(Continued)

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilometers

of operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulating

on the radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to enter

the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant needs

to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

If frequent engine coolant additions are required, the

cooling system should be pressure tested for leaks.

Maintain engine coolant concentration at a minimum

of 50% OAT coolant (conforming to MS.90032) and

distilled water for proper corrosion protection of your

engine which contains aluminum components.

Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine cooling performance,

poor gas mileage, and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all brake

system components should be inspected periodically

Úpage 334.

Fluid Level Check — Brake Master Cylinder

The fluid level of the brake master cylinder should be

checked whenever the vehicle is serviced, or immediately

if the Brake System Warning Light is on. If necessary, add

fluid to bring level within the designated marks on the side

of the reservoir of the brake master cylinder. Be sure to

clean the top of the master cylinder area before removing

cap. With disc brakes, fluid level can be expected to fall as

the brake pads wear. Brake fluid level should be checked

when pads are replaced. If the brake fluid is abnormally

low, check the system for leaks

Úpage 397.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on the

brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

Use only manufacturer's recommended brake fluid Úpage 397. Using the wrong type of brake fluid can

severely damage your brake system and/or impair its

performance. The proper type of brake fluid for your

vehicle is also identified on the original factory

installed hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that has

been in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in an open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

23_DT_OM_EN_USC_t.book Page 352

Page 355 of 416

SERVICING AND MAINTENANCE353

AUTOMATIC TRANSMISSION

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic

Transmission Fluid (ATF) is an engineered product and its

performance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. Avoid using transmission sealers as they

may adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required, therefore the

transmission has no dipstick. An authorized dealer can

check your transmission fluid level using special

service tools.

If you notice fluid leakage or transmission malfunction,

visit an authorized dealer immediately to have the

transmission fluid level checked. Operating the vehicle

with an improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer recommended transmission fluid

Úpage 397. It is important to maintain the transmission

fluid at the correct level using the recommended fluid. No

chemical flushes should be used in any transmission; only

the approved lubricant should be used.

REAR AXLE AND 4X4 FRONT DRIVING

A

XLE FLUID LEVEL

For normal service, periodic fluid level checks are not

required. When the vehicle is serviced for other reasons

the exterior surfaces of the axle assembly should be

inspected. If gear oil leakage is suspected inspect the fluid

level

Úpage 397. This inspection should be made with

the vehicle in a level position.

The fluid level should be even with the bottom of the fill

hole (within 1/4 in (6.4 mm) of edge of hole) for the front

axle and rear axle.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

WARNING!

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to

adjust the fluid level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or torque

converter shudder

Úpage 397.

8

23_DT_OM_EN_USC_t.book Page 353

Page 360 of 416

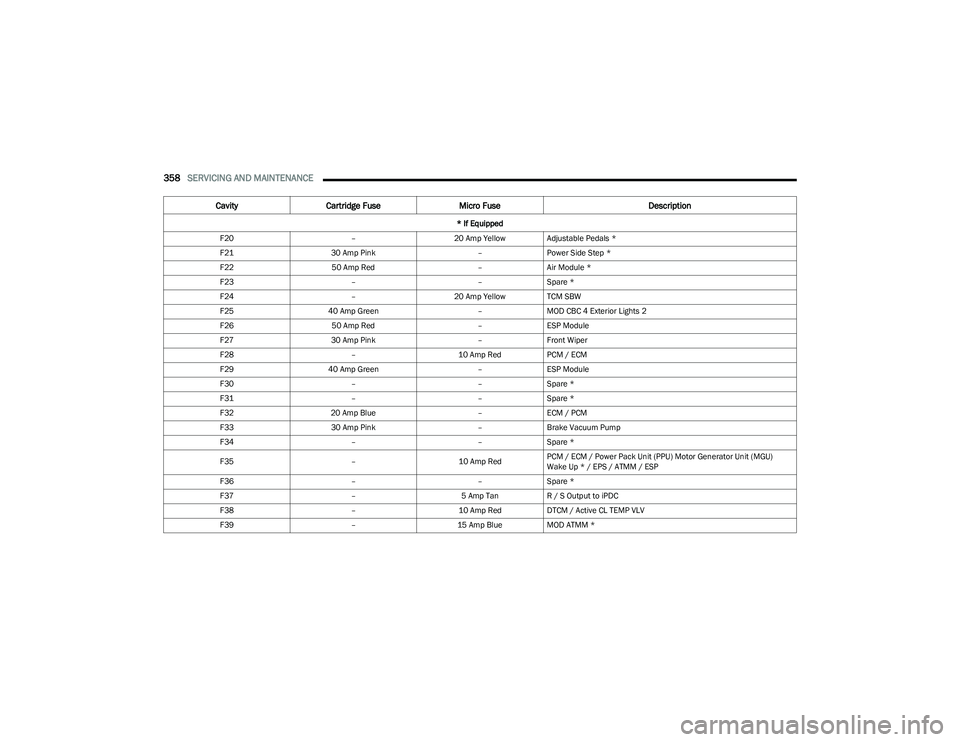

358SERVICING AND MAINTENANCE

F20 –20 Amp Yellow Adjustable Pedals *

F21 30 Amp Pink –Power Side Step *

F22 50 Amp Red –Air Module *

F23 ––Spare *

F24 –20 Amp Yellow TCM SBW

F25 40 Amp Green –MOD CBC 4 Exterior Lights 2

F26 50 Amp Red –ESP Module

F27 30 Amp Pink –Front Wiper

F28 –10 Amp RedPCM / ECM

F29 40 Amp Green –ESP Module

F30 ––Spare *

F31 ––Spare *

F32 20 Amp Blue –ECM / PCM

F33 30 Amp Pink –Brake Vacuum Pump

F34 ––Spare *

F35 –10 Amp RedPCM / ECM / Power Pack Unit (PPU) Motor Generator Unit (MGU)

Wake Up * / EPS / ATMM / ESP

F36 ––Spare *

F37 –5 Amp TanR / S Output to iPDC

F38 –10 Amp RedDTCM / Active CL TEMP VLV

F39 –15 Amp BlueMOD ATMM *

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

23_DT_OM_EN_USC_t.book Page 358

Page 364 of 416

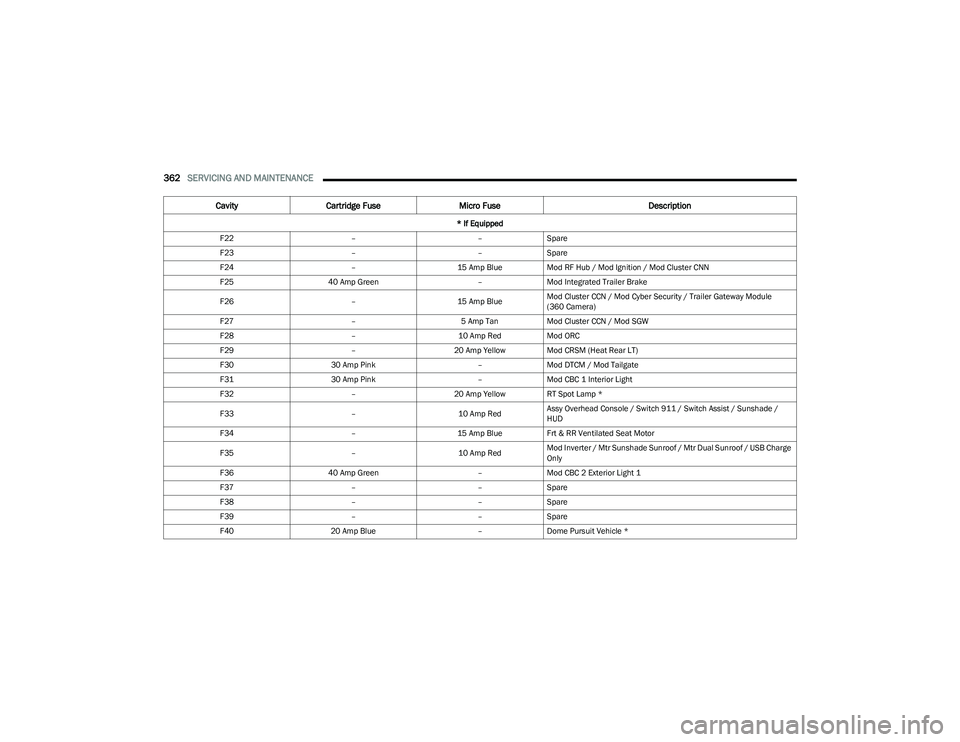

362SERVICING AND MAINTENANCE

F22 ––Spare

F23 ––Spare

F24 –15 Amp BlueMod RF Hub / Mod Ignition / Mod Cluster CNN

F25 40 Amp Green –Mod Integrated Trailer Brake

F26 –15 Amp BlueMod Cluster CCN / Mod Cyber Security / Trailer Gateway Module

(360 Camera)

F27 –5 Amp TanMod Cluster CCN / Mod SGW

F28 –10 Amp RedMod ORC

F29 –20 Amp Yellow Mod CRSM (Heat Rear LT)

F30 30 Amp Pink –Mod DTCM / Mod Tailgate

F31 30 Amp Pink –Mod CBC 1 Interior Light

F32 –20 Amp Yellow RT Spot Lamp *

F33 –10 Amp RedAssy Overhead Console / Switch 911 / Switch Assist / Sunshade /

HUD

F34 –15 Amp BlueFrt & RR Ventilated Seat Motor

F35 –10 Amp RedMod Inverter / Mtr Sunshade Sunroof / Mtr Dual Sunroof / USB Charge

Only

F36 40 Amp Green –Mod CBC 2 Exterior Light 1

F37 ––Spare

F38 ––Spare

F39 ––Spare

F40 20 Amp Blue –Dome Pursuit Vehicle *

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

23_DT_OM_EN_USC_t.book Page 362

Page 365 of 416

SERVICING AND MAINTENANCE363

F41 A&B –15 Amp BlueLumbar Support & Pass SW / Steering Column Control Module / HVAC

Control Module / ICS Switch Bank / Upper Switch Bank

F42 A&B –10 Amp RedMod Transfer Case Switch Module (TCSM) / SBW / Electric Park Brake

SW / Module TPM Trailer / Module Gateway Can-C Trailer TPM / Seat

LT & RT Vent

F43 A&B –10 Amp RedPort Diagnostics / Front & Rear USB

F44 –20 Amp Yellow Radio / DCSD / Telematics Box Mod / Trailer Gateway Module (360)

F45 30 Amp Pink –Mod Door MUX Driver

F46 30 Amp Pink –Mod Door MUX Passenger

F47 ––Spare

F48A –10 Amp RedRear View Mirror / SW Window Passenger / Rear USB / Wireless

Charging Pad Mod

F49 –15 Amp BlueMod CVPM / SNSR Blind Spot / HDLP Adaptive Front Lighting Sensor

(AFLS)

F50A –10 Amp RedBattery PACK Control Mod (BPCM) *

F51 A&B ––Spare

F52 20 Amp Blue –Direct Battery Feed *

F53 –10 Amp RedTrailer Reverse Steering Control / Trailer Steering Control Knob

F54 A&B –20 Amp YellowPower Outlet Center Seat Battery Feed Position

Power Outlet Center Seat Ignition Feed Position

F55 25 Amp White –Upfitter *

F56 30 Amp Pink –Mod Network Interface *

F57 20 Amp Blue –Direct Battery Feed *

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_DT_OM_EN_USC_t.book Page 363

Page 385 of 416

SERVICING AND MAINTENANCE383

WHEEL AND WHEEL TRIM CARE

All wheels and wheel trim, especially aluminum and

chrome plated wheels, should be cleaned regularly using

mild (neutral Ph) soap and water to maintain their luster

and to prevent corrosion. Wash wheels with the same

soap solution recommended for the body of the vehicle

and remember to always wash when the surfaces are not

hot to the touch.

Your wheels are susceptible to deterioration caused by

salt, sodium chloride, magnesium chloride, calcium

chloride, etc., and other road chemicals used to melt ice

or control dust on dirt roads. Use a soft cloth or sponge

and mild soap to wipe away promptly. Do not use harsh

chemicals or a stiff brush. They can damage the wheel’s

protective coating that helps keep them from corroding

and tarnishing. When cleaning extremely dirty wheels including excessive

brake dust, care must be taken in the selection of tire and

wheel cleaning chemicals and equipment to prevent

damage to the wheels. Mopar® Wheel Treatment or

Mopar® Chrome Cleaner or their equivalent is

recommended or select a non-abrasive, non-acidic

cleaner for aluminum or chrome wheels.

NOTE:If you intend parking or storing your vehicle for an

extended period after cleaning the wheels with wheel

cleaner, drive your vehicle and apply the brakes to remove

the water droplets from the brake components. This

activity will remove the red rust on the brake rotors and

prevent vehicle vibration when braking.

Dark Vapor Chrome, Black Satin Chrome, or Low Gloss

Clear Coat WheelsCAUTION!

Avoid products or automatic car washes that use acidic

solutions or strong alkaline additives or harsh brushes.

Many aftermarket wheel cleaners and automatic car

washes may damage the wheel's protective finish. Such

damage is not covered by the New Vehicle Limited

Warranty. Only car wash soap, Mopar® Wheel Cleaner

or equivalent is recommended.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush,

metal polishes or oven cleaner. These products may

damage the wheel's protective finish. Such damage is

not covered by the New Vehicle Limited Warranty. Only

car wash soap, Mopar® Wheel Cleaner or equivalent is

recommended.

CAUTION!

If your vehicle is equipped with these specialty wheels,

DO NOT USE wheel cleaners, abrasives, or polishing

compounds. They will permanently damage this finish

and such damage is not covered by the New Vehicle

Limited Warranty. HAND WASH ONLY USING MILD SOAP

AND WATER WITH A SOFT CLOTH. Used on a regular

basis; this is all that is required to maintain this finish.

8

23_DT_OM_EN_USC_t.book Page 383