lock RAM 1500 2023 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: 1500, Model: RAM 1500 2023Pages: 416, PDF Size: 20.59 MB

Page 349 of 416

SERVICING AND MAINTENANCE347

Any belt with cracks running along a rib must be replaced.

Also have the belt replaced if it has excessive wear, frayed

cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated from

belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

Groove jumping (belt does not maintain correct posi -

tion on pulley)

Belt broken

Noise (objectionable squeal, squeak, or rumble is

heard or felt while drive belt is in operation)

NOTE:Identify and correct problem before new belt is installed.

NOTE:If your vehicle is equipped with a Stop/Start, belt must be

replaced with an OEM grade Mopar® belt.

Some conditions can be caused by a faulty component

such as a belt pulley. Belt pulleys should be carefully

inspected for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically. Use a lithium-based grease, such

as Mopar® Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned should

be wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch release

mechanism, and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Autumn and Spring. Apply a small

amount of a high quality lubricant, such as Mopar® Lock

Cylinder Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending on

geographical area and frequency of use. If chattering,

marks, water lines or wet spots are present, clean the

wiper blades or replace as necessary.

The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the

following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

8

23_DT_OM_EN_USC_t.book Page 347

Page 350 of 416

348SERVICING AND MAINTENANCE

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the

glass, until the wiper arm is in the full up position.

Wiper Blade With Release Tab In Locked Position

2. To disengage the wiper blade from the wiper arm, press the release tab on the wiper blade and while

holding the wiper arm with one hand, slide the wiper

blade down towards the base of the wiper arm.

Wiper Blade With Release Tab In Unlocked Position

3. With the wiper blade disengaged, remove the wiper blade from the wiper arm.

4. Gently lower the wiper arm onto the glass.

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm.

3. Slide the wiper blade up into the hook on the wiper arm, latch engagement will be accompanied by an

audible click.

4. Gently lower the wiper blade onto the glass.

EXHAUST SYSTEM

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system;

or if the exhaust fumes can be detected inside the vehicle;

or when the underside or rear of the vehicle is damaged;

have an authorized technician inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition, have

the exhaust system inspected each time the vehicle is

raised for lubrication or oil change. Replace as required.CAUTION!

Do not allow the wiper arm to spring back against the

glass without the wiper blade in place or the glass may

be damaged.

1 — Wiper Blade

2 — Wiper Arm

3 — Release Tab

1 — Wiper Blade

2 — Wiper Arm J Hook

3 — J Hook Retainer

WARNING!

Exhaust gases can injure or kill. They contain Carbon

Monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO see

Úpage 311.

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

grass or leaves coming into contact with your

exhaust system. Do not park or operate your vehicle

in areas where your exhaust system can contact

anything that can burn.

23_DT_OM_EN_USC_t.book Page 348

Page 361 of 416

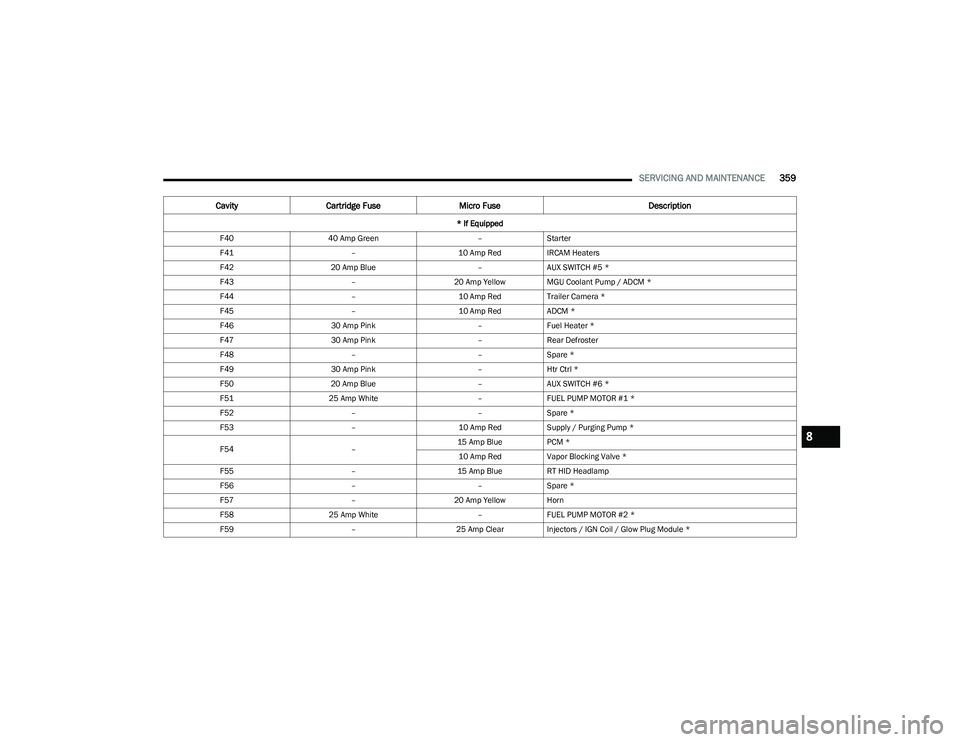

SERVICING AND MAINTENANCE359

F4040 Amp Green –Starter

F41 –10 Amp RedIRCAM Heaters

F42 20 Amp Blue –AUX SWITCH #5 *

F43 –20 Amp Yellow MGU Coolant Pump / ADCM *

F44 –10 Amp RedTrailer Camera *

F45 –10 Amp RedADCM *

F46 30 Amp Pink –Fuel Heater *

F47 30 Amp Pink –Rear Defroster

F48 ––Spare *

F49 30 Amp Pink –Htr Ctrl *

F50 20 Amp Blue –AUX SWITCH #6 *

F51 25 Amp White –FUEL PUMP MOTOR #1 *

F52 ––Spare *

F53 –10 Amp RedSupply / Purging Pump *

F54 –15 Amp Blue

PCM *

10 Amp Red Vapor Blocking Valve *

F55 –15 Amp BlueRT HID Headlamp

F56 ––Spare *

F57 –20 Amp Yellow Horn

F58 25 Amp White –FUEL PUMP MOTOR #2 *

F59 –25 Amp ClearInjectors / IGN Coil / Glow Plug Module *

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_DT_OM_EN_USC_t.book Page 359

Page 363 of 416

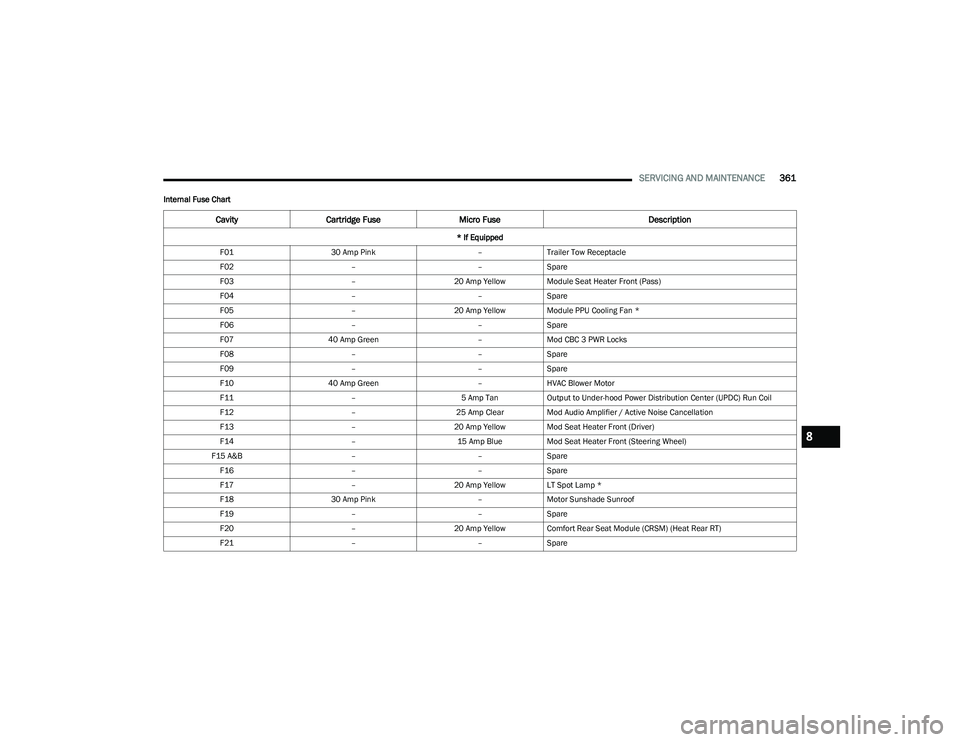

SERVICING AND MAINTENANCE361

Internal Fuse Chart

CavityCartridge Fuse Micro Fuse Description

* If Equipped

F01 30 Amp Pink –Trailer Tow Receptacle

F02 ––Spare

F03 –20 Amp Yellow Module Seat Heater Front (Pass)

F04 ––Spare

F05 –20 Amp Yellow Module PPU Cooling Fan *

F06 ––Spare

F07 40 Amp Green –Mod CBC 3 PWR Locks

F08 ––Spare

F09 ––Spare

F10 40 Amp Green –HVAC Blower Motor

F11 –5 Amp TanOutput to Under-hood Power Distribution Center (UPDC) Run Coil

F12 –25 Amp ClearMod Audio Amplifier / Active Noise Cancellation

F13 –20 Amp Yellow Mod Seat Heater Front (Driver)

F14 –15 Amp BlueMod Seat Heater Front (Steering Wheel)

F15 A&B ––Spare

F16 ––Spare

F17 –20 Amp Yellow LT Spot Lamp *

F18 30 Amp Pink –Motor Sunshade Sunroof

F19 ––Spare

F20 –20 Amp Yellow Comfort Rear Seat Module (CRSM) (Heat Rear RT)

F21 ––Spare

8

23_DT_OM_EN_USC_t.book Page 361

Page 368 of 416

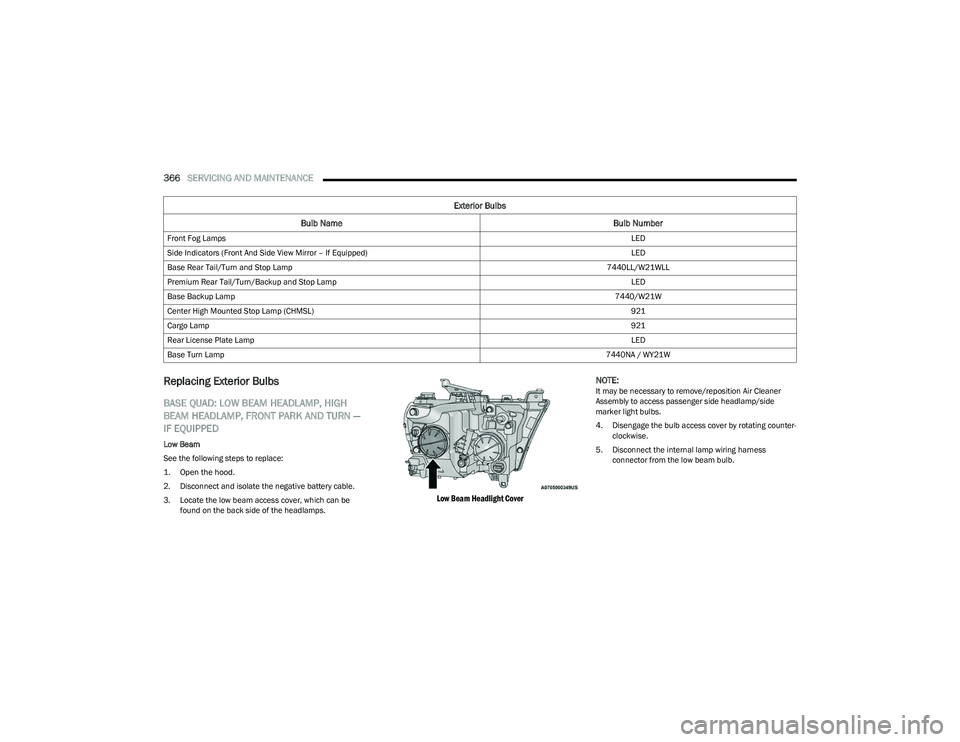

366SERVICING AND MAINTENANCE

Replacing Exterior Bulbs

BASE QUAD: LOW BEAM HEADLAMP, HIGH

BEAM HEADLAMP, FRONT PARK AND TURN —

IF EQUIPPED

Low Beam

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the low beam access cover, which can be

found on the back side of the headlamps.

Low Beam Headlight Cover

NOTE:

It may be necessary to remove/reposition Air Cleaner

Assembly to access passenger side headlamp/side

marker light bulbs.

4. Disengage the bulb access cover by rotating counter

-

clockwise.

5. Disconnect the internal lamp wiring harness connector from the low beam bulb.

Front Fog Lamps

LED

Side Indicators (Front And Side View Mirror – If Equipped) LED

Base Rear Tail/Turn and Stop Lamp 7440LL/W21WLL

Premium Rear Tail/Turn/Backup and Stop Lamp LED

Base Backup Lamp 7440/W21W

Center High Mounted Stop Lamp (CHMSL) 921

Cargo Lamp 921

Rear License Plate Lamp LED

Base Turn Lamp 7440NA / WY21W

Exterior Bulbs

Bulb Name Bulb Number

23_DT_OM_EN_USC_t.book Page 366

Page 369 of 416

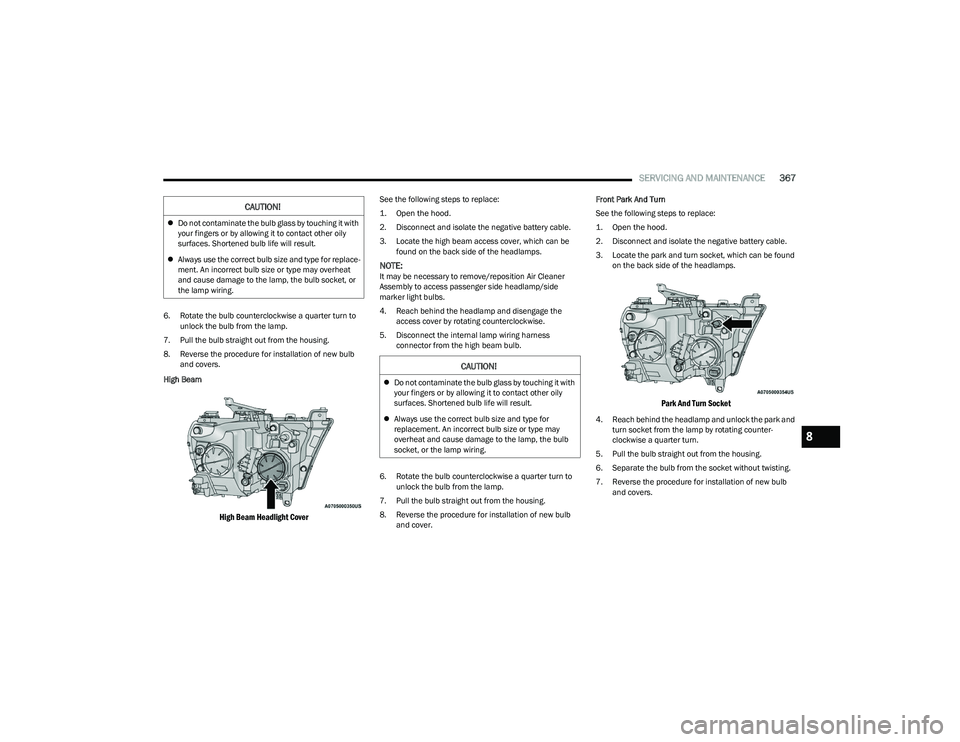

SERVICING AND MAINTENANCE367

6. Rotate the bulb counterclockwise a quarter turn to

unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and covers.

High Beam

High Beam Headlight Cover

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the high beam access cover, which can be found on the back side of the headlamps.

NOTE:It may be necessary to remove/reposition Air Cleaner

Assembly to access passenger side headlamp/side

marker light bulbs.

4. Reach behind the headlamp and disengage the access cover by rotating counterclockwise.

5. Disconnect the internal lamp wiring harness connector from the high beam bulb.

6. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the lamp.

7. Pull the bulb straight out from the housing.

8. Reverse the procedure for installation of new bulb and cover. Front Park And Turn

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the park and turn socket, which can be found

on the back side of the headlamps.

Park And Turn Socket

4. Reach behind the headlamp and unlock the park and turn socket from the lamp by rotating counter -

clockwise a quarter turn.

5. Pull the bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

Always use the correct bulb size and type for replace -

ment. An incorrect bulb size or type may overheat

and cause damage to the lamp, the bulb socket, or

the lamp wiring.

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

Always use the correct bulb size and type for

replacement. An incorrect bulb size or type may

overheat and cause damage to the lamp, the bulb

socket, or the lamp wiring.

8

23_DT_OM_EN_USC_t.book Page 367

Page 370 of 416

368SERVICING AND MAINTENANCE

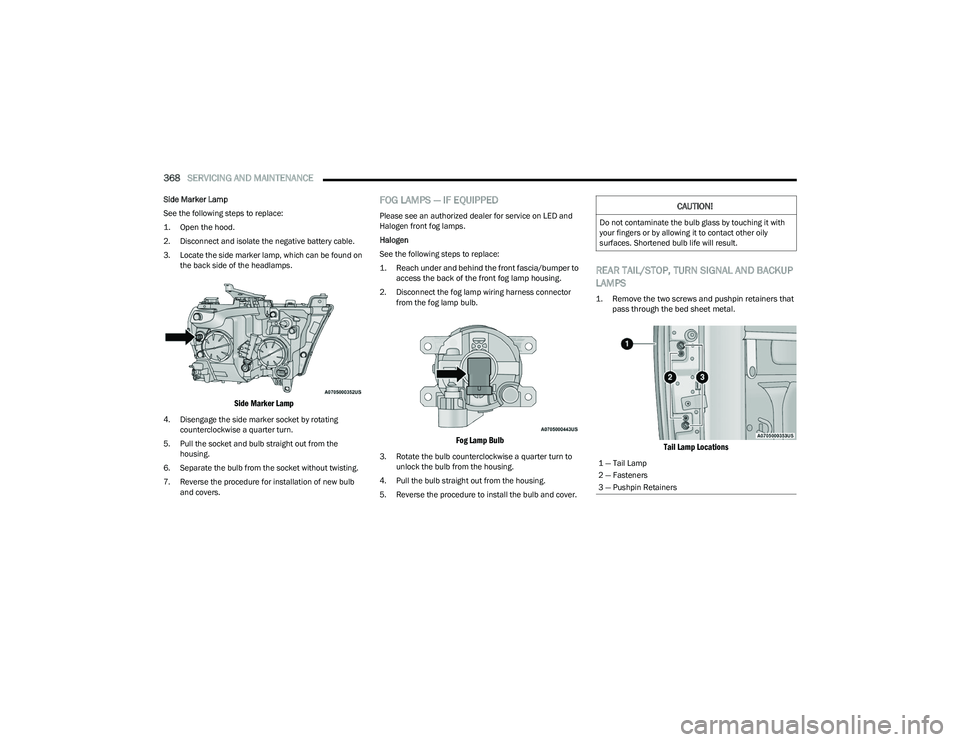

Side Marker Lamp

See the following steps to replace:

1. Open the hood.

2. Disconnect and isolate the negative battery cable.

3. Locate the side marker lamp, which can be found on

the back side of the headlamps.

Side Marker Lamp

4. Disengage the side marker socket by rotating counterclockwise a quarter turn.

5. Pull the socket and bulb straight out from the housing.

6. Separate the bulb from the socket without twisting.

7. Reverse the procedure for installation of new bulb and covers.

FOG LAMPS — IF EQUIPPED

Please see an authorized dealer for service on LED and

Halogen front fog lamps.

Halogen

See the following steps to replace:

1. Reach under and behind the front fascia/bumper to access the back of the front fog lamp housing.

2. Disconnect the fog lamp wiring harness connector from the fog lamp bulb.

Fog Lamp Bulb

3. Rotate the bulb counterclockwise a quarter turn to unlock the bulb from the housing.

4. Pull the bulb straight out from the housing.

5. Reverse the procedure to install the bulb and cover.

REAR TAIL/STOP, TURN SIGNAL AND BACKUP

LAMPS

1. Remove the two screws and pushpin retainers that pass through the bed sheet metal.

Tail Lamp Locations

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

1 — Tail Lamp

2 — Fasteners

3 — Pushpin Retainers

23_DT_OM_EN_USC_t.book Page 368

Page 371 of 416

SERVICING AND MAINTENANCE369

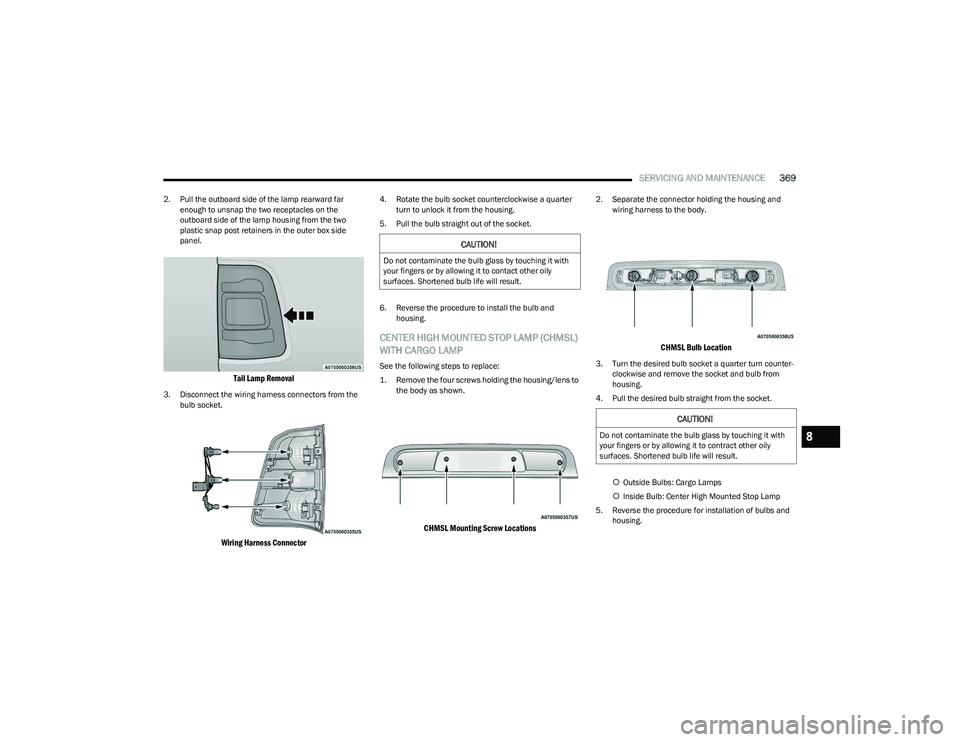

2. Pull the outboard side of the lamp rearward far

enough to unsnap the two receptacles on the

outboard side of the lamp housing from the two

plastic snap post retainers in the outer box side

panel.

Tail Lamp Removal

3. Disconnect the wiring harness connectors from the bulb socket.

Wiring Harness Connector

4. Rotate the bulb socket counterclockwise a quarter turn to unlock it from the housing.

5. Pull the bulb straight out of the socket.

6. Reverse the procedure to install the bulb and housing.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

WITH CARGO LAMP

See the following steps to replace:

1. Remove the four screws holding the housing/lens to the body as shown.

CHMSL Mounting Screw Locations

2. Separate the connector holding the housing and wiring harness to the body.

CHMSL Bulb Location

3. Turn the desired bulb socket a quarter turn counter -

clockwise and remove the socket and bulb from

housing.

4. Pull the desired bulb straight from the socket.

Outside Bulbs: Cargo Lamps

Inside Bulb: Center High Mounted Stop Lamp

5. Reverse the procedure for installation of bulbs and housing.

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contact other oily

surfaces. Shortened bulb life will result.

CAUTION!

Do not contaminate the bulb glass by touching it with

your fingers or by allowing it to contract other oily

surfaces. Shortened bulb life will result.8

23_DT_OM_EN_USC_t.book Page 369

Page 394 of 416

392

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the instrument

panel, visible through the windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off), the

brakes will still function. However, you will experience a

substantial increase in braking effort to stop the vehicle. If either the front or rear hydraulic systems lose normal

braking capability, the remaining system will still function

with some loss of overall braking effectiveness. This will

be evident by increased pedal travel during application,

greater pedal force required to slow or stop, and the Brake

Warning Light and the Anti-Lock Brake System (ABS)

Warning Light will activate during brake use.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil before

tightening.

NOTE:Do not oil wheel studs. For chrome wheels, do not

substitute with chrome plated wheel nuts.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it halfway).

Lug Nut/

Bolt Torque Lug Nut/

Bolt Type **Lug Nut/

Bolt Size Lug Nut/

Bolt Socket Size

130 ft-lb

(176 N·m) Cone M14 x 1.50 22 mm

23_DT_OM_EN_USC_t.book Page 392

Page 400 of 416

398

CUSTOMER ASSISTANCE

SUGGESTIONS FOR OBTAINING SERVICE

FOR YOUR VEHICLE

PREPARE FOR THE APPOINTMENT

All work to be performed may not be covered by the

warranty. Discuss additional charges with the service

manager. Keep a maintenance log of your vehicle's

service history. This can often provide a clue to the current

problem.

PREPARE A LIST

Make a written list of your vehicle's problems or the

specific work you want done. If you've had an accident or

work done that is not on your maintenance log, let the

service advisor know.

BE REASONABLE WITH REQUESTS

If you list a number of items and you must have your

vehicle by the end of the day, discuss the situation with the

service advisor and list the items in order of priority.

At many authorized dealers, you may obtain a rental

vehicle (additional charges may apply). If you need a

rental, it is advisable to make these arrangements when

you call for an appointment.

IF YOU NEED ASSISTANCE

FCA US LLC and its authorized dealers are vitally

interested in your satisfaction. We want you to be happy

with our products and services.

Warranty service must be done by an authorized dealer.

We strongly recommend that you take the vehicle to an

authorized dealer. They know your vehicle the best, and

are most concerned that you get prompt and high quality

service. FCA US LLC's authorized dealers have the

facilities, factory-trained technicians, special tools, and

the latest information to ensure the vehicle is repaired

correctly and in a timely manner.

This is why you should always talk to an authorized

dealer’s service manager first. If for some reason you are

still not satisfied, talk to the general manager or owner of

the authorized dealer. They want to know if you need

assistance. If an authorized dealer is unable to resolve the

concern, you may contact FCA US LLC's Customer

Assistance center.

Any communication to FCA US LLC's customer center

should include the following information:

Owner's name and address

Owner's telephone number (home, mobile, and office)

Authorized dealer name

Vehicle Identification Number (VIN)

Vehicle delivery date and mileage

ROADSIDE ASSISTANCE

Available 24 hours, 7 days a week.

Call 1-800-521-2779 or visit chrysler.rsahelp.com(USA)

Call 1-800-363-4869 or visit fca.roadsideaid.com

(Canada)

Who is Covered

You are covered by Roadside Assistance services if you

are a purchaser for use of the vehicle. Roadside

Assistance services last for five years or 60,000 miles on

the odometer, whichever occurs first, calculated from the

start date of the Basic Limited Warranty, as set forth in

your Warranty Information book.

1

1. Towing services provided through Cross Country Motor Club, Inc.

Medford, MA 02155, except in AK,CA, HI, OR, WI, and WY, where services

are provided by Cross Country Motor Club of California, Inc., Thousand

Oaks, CA 91360.

What to Do

If your vehicle requires jump start assistance, out of gas/

fuel delivery, tire service, lockout service or towing as a

result of a mechanical breakdown, dial toll-free: USA:

1-800-521-2779/Canada: 1-800-363-4869. Provide your

name, Vehicle Identification Number (VIN) required for

covered services, license plate number, and your location,

including the telephone number from which you are

calling. Briefly describe the nature of the problem and

answer a few simple questions.

23_DT_OM_EN_USC_t.book Page 398