weight RAM 1500 2023 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2023, Model line: 1500, Model: RAM 1500 2023Pages: 416, PDF Size: 20.59 MB

Page 176 of 416

174STARTING AND OPERATING

Weight-Distributing Hitch

A weight-distributing system works by applying leverage

through spring (load) bars. They are typically used for

heavier loads to distribute trailer tongue weight to the tow

vehicle's front axle and the trailer axle(s). When used in

accordance with the manufacturer's directions, it provides

for a more level ride, offering more consistent steering and

brake control, thereby enhancing towing safety. The

addition of a friction/hydraulic sway control also dampens

sway caused by traffic and crosswinds and contributes

positively to tow vehicle and trailer stability. Trailer Sway

Control and a weight-distributing (load equalizing) hitch

are recommended for heavier Tongue Weights (TW) and

may be required depending on vehicle and trailer

configuration/loading to comply with GAWR requirements.

Without Weight-Distributing Hitch (Incorrect) With Weight-Distributing Hitch (Correct)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

WARNING!

An improperly adjusted weight-distributing hitch

system may reduce handling, stability and braking

performance and could result in a collision.

Weight-distributing systems may not be compatible

with surge brake couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

23_DT_OM_EN_USC_t.book Page 174

Page 177 of 416

STARTING AND OPERATING175

RECOMMENDED DISTRIBUTION HITCH

ADJUSTMENT

Towing With Air Suspension — If Equipped

1. Verify that the vehicle is at the normal ride height.

NOTE:The vehicle must remain in the engine run position with all

doors closed while attaching a trailer for proper leveling of

the air suspension system.

2. Position the truck to be ready to connect to the trailer

(do not connect the trailer).

3. Enable tire jack mode through the instrument cluster or touchscreen radio settings. Tire jack mode will be

canceled and the procedure must be restarted if the

vehicle is driven at speeds above 5 mph (8 km/h).

4. Measure the height from the top of the front wheel opening on the fender to ground; this is height H1.

Measuring Height (H)

5. Attach the trailer to the vehicle without the weight-distributing bars connected.

6. Measure the height from the top of the front wheel opening on the fender to the ground; this is height H2.

7. Install and adjust the tension in the weight-distributing bars per the manufacturer’s

recommendations so that the height of the front

fender is approximately (H2-H1)/3+H1

(about 1/3 the difference between H2 and H1 above

normal ride height [H1]). 8. Use the instrument cluster or touchscreen radio

settings and switch off tire jack mode. Make sure the

truck returns to normal ride height. Perform a visual

inspection of the trailer and weight-distributing hitch

to confirm the manufacturer’s recommendations

have been met.

9. The truck can now be driven.

NOTE:For all towing conditions, we recommend towing with

Tow/Haul mode engaged.

Measurement Example Example Height (mm)

H1 925

H2 946

H2-H1 21

(H2-H1)/3 7

(H2-H1)/3 + H1 932

4

23_DT_OM_EN_USC_t.book Page 175

Page 178 of 416

176STARTING AND OPERATING

TRAILER HITCH TYPE AND MAXIMUM TRAILER WEIGHT

The following chart provides the maximum trailer weight a given factory equipped trailer hitch type can tow and should be used to assist you in selecting the correct trailer hitch for your

intended towing condition.

All trailer hitches should be professionally installed on

your vehicle.

Class III Bumper Hitch Access

Remove the cap with a trim stick or screwdriver to access

the Class III hitch attachment.

NOTE:Be careful not to scratch the bumper step pad.

Class III Bumper Hitch Access

TRAILER TOWING WEIGHTS

(M

AXIMUM TRAILER WEIGHT RATINGS)

NOTE:For trailer towing information (maximum trailer weight

ratings) refer to the following website addresses:

ramtrucks.com/towing/towing-guide

ramtruck.ca (Canada)

rambodybuilder.com

TRAILER AND TONGUE WEIGHT

Weight Distribution

Trailer Hitch Type and Maximum Trailer Weight

Hitch Type Max. Trailer Weight / Max. Tongue Weight

Class III Bumper Hitch - 1500 Model 5,000 lb (2,267 kg) / 500 lb (226 kg)

Class IV - 1500 Model 12,750 lb (5,783 kg) / 1,275 lb (578 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

23_DT_OM_EN_USC_t.book Page 176

Page 179 of 416

STARTING AND OPERATING177

Consider the following items when computing the weight

on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or equipment put

in or on your vehicle.

The weight of the driver and all passengers.

NOTE:Remember that everything put into or on the trailer adds

to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options must

be considered as part of the total load on your vehicle.

Refer to the Tire And Loading Information Placard for the

maximum combined weight of occupants and cargo for

your vehicle.

TRAILER REVERSE STEERING

C

ONTROL — IF EQUIPPED

Feature Overview

Trailer Reverse Steering Control (TRSC) is a feature that

will assist the driver when backing up a trailer. By turning

the knob located on the center stack, you can more

accurately control the direction the trailer will go. The driver controls the accelerator and the brake while

steering with the use of the Trailer Reverse Steering

Control knob. The trailer is steered according to the

direction the knob is turned.

This feature will also allow the driver to back up a vehicle

and trailer in a straight line when the knob is rested in its

center position.

Minimal setup is required to use this feature.

Set Up:

To use the system, hitch your trailer to the truck and

ensure all electrical wiring is connected

Úpage 182.

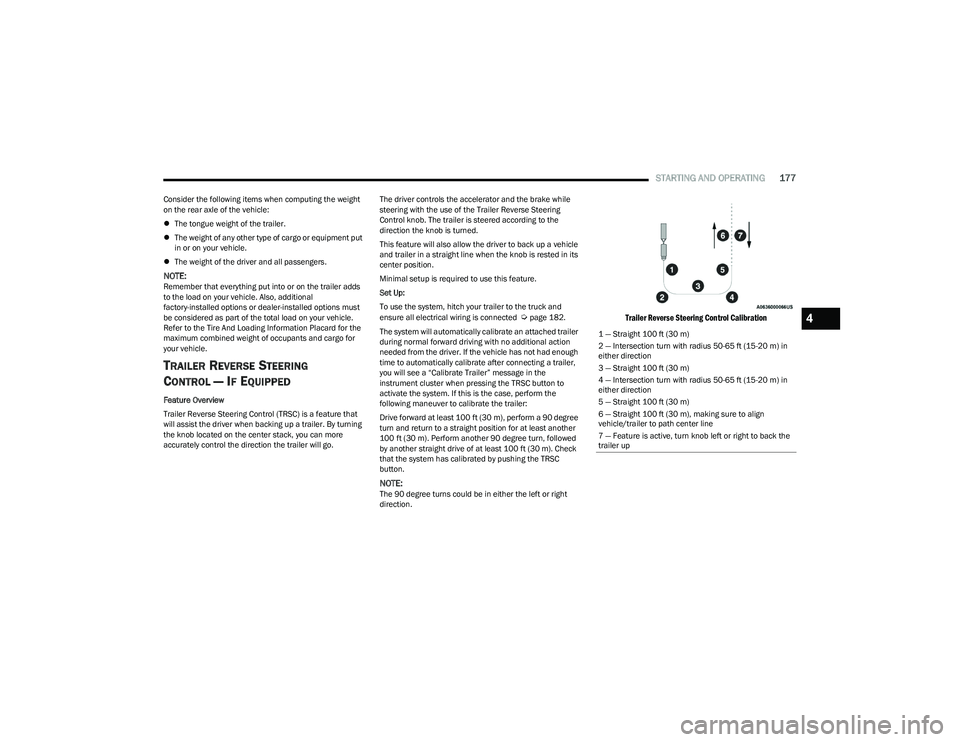

The system will automatically calibrate an attached trailer

during normal forward driving with no additional action

needed from the driver. If the vehicle has not had enough

time to automatically calibrate after connecting a trailer,

you will see a “Calibrate Trailer” message in the

instrument cluster when pressing the TRSC button to

activate the system. If this is the case, perform the

following maneuver to calibrate the trailer:

Drive forward at least 100 ft (30 m), perform a 90 degree

turn and return to a straight position for at least another

100 ft (30 m). Perform another 90 degree turn, followed

by another straight drive of at least 100 ft (30 m). Check

that the system has calibrated by pushing the TRSC

button.

NOTE:The 90 degree turns could be in either the left or right

direction.

Trailer Reverse Steering Control Calibration

1 — Straight 100 ft (30 m) 2 — Intersection turn with radius 50-65 ft (15-20 m) in

either direction

3 — Straight 100 ft (30 m)4 — Intersection turn with radius 50-65 ft (15-20 m) in

either direction

5 — Straight 100 ft (30 m)6 — Straight 100 ft (30 m), making sure to align vehicle/trailer to path center line

7 — Feature is active, turn knob left or right to back the

trailer up

4

23_DT_OM_EN_USC_t.book Page 177

Page 181 of 416

STARTING AND OPERATING179

(Continued)

Some trailers (such as boat trailers) will need to

recalibrate while loaded and unloaded.

NOTE:

The system may not detect a trailer in low light condi -

tions. In sunny conditions, the performance may be

degraded as shadows pass over the trailer.

The driver is always responsible for safe operation of

truck and trailer.

The driver is always in control of the truck as well as the

trailer and is responsible for controlling the throttle and

brakes.

The system may not function when the camera lens is

blocked, blurred (covered with water, snow, ice, dirt,

etc) and will not work unless the tailgate is upright and

fully latched.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle drivetrain

components, the following guidelines are recommended. Perform the maintenance listed in the Scheduled

Servicing section for the proper maintenance intervals

Úpage 333. When towing a trailer, never exceed the

GAWR or GCWR ratings.

Towing Requirements — Tires

Do not attempt to tow a trailer while using a compact

spare tire.

Do not drive more than 50 mph (80 km/h) when towing

while using a full size spare tire.

Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle.

Check the trailer tires for proper tire inflation pressures

before trailer usage.

Check for signs of tire wear or visible tire damage

before towing a trailer.

Replacing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

For further information

Úpage 370.

CAUTION!

Do not tow a trailer at all during the first 500 miles

(805 km) the new vehicle is driven. The engine, axle

or other parts could be damaged.

Then, during the first 500 miles (805 km) that a

trailer is towed, do not drive over 50 mph (80 km/h)

and do not make starts at full throttle. This helps the

engine and other parts of the vehicle wear in at the

heavier loads.

WARNING!

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering cargo

that is not fully secured, dynamic load shifts can

occur that may be difficult for the driver to control.

You could lose control of your vehicle and have a

collision.

When hauling cargo or towing a trailer, do not over -

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to

brakes, axle, engine, transmission, steering, suspen -

sion, chassis structure or tires.

Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

hook retainers of the vehicle hitch. Cross the chains

under the trailer tongue and allow enough slack for

turning corners.

Vehicles with trailers should not be parked on a

grade. When parking, apply the parking brake on the

tow vehicle. Put the tow vehicle transmission in

PARK. For four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL. Always, block or

"chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch utilized

WARNING!

4

23_DT_OM_EN_USC_t.book Page 179

Page 186 of 416

184STARTING AND OPERATING

TOWING TIPS

Before towing, practice turning, stopping, and backing up

the trailer in an area located away from heavy traffic.

Automatic Transmission

The DRIVE range can be selected when towing. The

transmission controls include a drive strategy to avoid

frequent shifting when towing. However, if frequent

shifting does occur while in DRIVE, select TOW/HAUL

mode or select a lower gear range (using the Electronic

Range Select (ERS) shift control).

NOTE:Using TOW/HAUL mode or selecting a lower gear range

(using the ERS shift control) while operating the vehicle

under heavy loading conditions will improve performance

and extend transmission life by reducing excessive

shifting and heat build up. This action will also provide

better engine braking.

Tow/Haul Mode

To reduce potential for automatic transmission

overheating, activate TOW/HAUL mode when driving in

hilly areas, or select a lower gear range (using the (ERS)

shift control) on more severe grades.

Cruise Control — If Equipped

Do not use on hilly terrain or with heavy loads.

When using the Cruise Control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

Use Cruise Control in flat terrain and with light loads to

maximize fuel efficiency.

Air Suspension System

To aid in attaching/detaching the trailer from the vehicle,

the air suspension system can be used Úpage 134.

Selecting Tow/Haul or connecting a trailer with an

Integrated Trailer Brake Module (ITBM) will disable

Automatic Aero mode to avoid height changes while

towing and shifting loads or tongue weights.

NOTE:The vehicle must remain in the engine running position

while attaching a trailer for proper leveling of the air

suspension system.

SNOWPLOW

Snowplow Prep Packages are available as a factory

installed option. These packages include components

necessary to equip your vehicle with a snowplow.

NOTE:Before installation of a snowplow it is highly recom -

mended that the owner/installer obtain and follow the

recommendations contained within the current Body

Builder’s Guide. See an authorized dealer, installer or

snowplow manufacturer for this information. There are

unique electrical systems that must be connected to

properly ensure operator safety and prevent overloading

vehicle systems.

WARNING!

Attaching a snowplow to this vehicle could adversely

affect performance of the airbag system in a collision.

Do not expect that the airbag will perform as described

earlier in this manual.

CAUTION!

The “Lamp Out” indicator could illuminate if exterior

lamps are not properly installed.

23_DT_OM_EN_USC_t.book Page 184

Page 187 of 416

STARTING AND OPERATING185

BEFORE PLOWING

Check the hydraulic system for leaks and proper fluid

level.

Check the mounting bolts and nuts for proper tight -

ness.

Check the runners and cutting edge for excessive wear.

The cutting edge should be ¼ to ½ inches

(6 cm to 1.2 cm) above ground in snow plowing

position.

Check that snowplow lighting is connected and

functioning properly.

SNOWPLOW PREP PACKAGE MODEL

A

VAILABILITY

For Information about snowplow applications visit

www.ramtrucks.com or refer to the current Body Builder’s

Guide.

1. The maximum number of occupants in the truck

should not exceed one.

2. The total GVWR, Front GAWR or the Rear GAWR should never be exceeded.

3. Cargo capacity will be reduced by the addition of options or passengers, etc.

The loaded vehicle weight, including the snowplow

system, all aftermarket accessories, driver, passengers,

options, and cargo, must not exceed either the Gross

Vehicle Weight (GVWR) or Gross Axle Weight (GAWR)

ratings. These weights are specified on the Safety Compliance Certification Label on the driver's side door

opening.

NOTE:Detach the snowplow when transporting passengers.

Vehicle front end wheel alignment was set to

specifications at the factory without consideration for the

weight of the plow. Front end toe-in should be checked

and reset if necessary at the beginning and end of the

snowplow season. This will help prevent uneven tire wear.

The blade should be lowered whenever the vehicle is

parked.

Maintain and operate your vehicle and snowplow

equipment following the recommendations provided by

the specific snowplow manufacturer.

OVER THE ROAD OPERATION WITH

S

NOWPLOW ATTACHED

The blade restricts air flow to the radiator and causes the

engine to operate at higher than normal temperatures.

Therefore, when transporting the plow, angle the blade

completely and position it as low as road or surface

conditions permit. Do not exceed 40 mph (64 km/h). The

operator should always maintain a safe stopping distance

and allow adequate passing clearance.

NOTE:Lane Departure Warning / Lane Keep Assist is not

available when a snow plow is attached.

OPERATING TIPS

Under ideal snow plowing conditions, 20 mph (32 km/h)

should be maximum operating speed. The operator should

be familiar with the area and surface to be cleaned.

Reduce speed and use extreme caution when plowing

unfamiliar areas or under poor visibility.

GENERAL MAINTENANCE

Snowplows should be maintained in accordance with the

plow manufacturer's instructions.

Keep all snowplow electrical connections and battery

terminals clean and free of corrosion.

When plowing snow, to avoid transmission and drivetrain

damage, the following precautions should be observed:

Operate with transfer case in 4WD LOW when plowing

small or congested areas where speeds are not likely to

exceed 15 mph (24 km/h). At higher speeds operate in

4WD HIGH.

Vehicles with automatic transmissions should use

4WD LOW when plowing deep or heavy snow for

extended periods of time to avoid transmission over -

heating.

Do not shift the transmission unless the engine has

returned to idle and wheels have stopped. Make a

practice of stepping on the brake pedal while shifting

the transmission.

4

23_DT_OM_EN_USC_t.book Page 185

Page 270 of 416

268SAFETY

Driver Override

The driver may override SSC activation with throttle or

brake application at any time.

Deactivating SSC

SSC will be deactivated but remain available if any of the

following conditions occur:

The driver overrides SSC set speed with throttle or

brake application.

The vehicle speed exceeds 20 mph (32 km/h) but

remains below 40 mph (64 km/h).

The vehicle is shifted into PARK.

Disabling SSC

SSC will deactivate and be disabled if any of the following

conditions occur:

The driver pushes the SSC switch.

The driveline is shifted out of the 4WD Low.

The parking brake is applied.

The driver door opens.

The vehicle is driven greater than 20 mph (32 km/h)

for greater than 70 seconds.

The vehicle is driven greater than 40 mph (64 km/h).

SSC will exist immediately. Feedback To The Driver

The instrument cluster has an SSC icon and the SSC

switch has a lamp which offers feedback to the driver

about the state SSC is in.

The cluster icon and switch lamp will illuminate and

remain on solid when SSC is enabled or activated.

These are the normal operating conditions for SSC.

The cluster icon and switch lamp will flash for several

seconds then extinguish when the driver pushes the

SSC switch but enabled conditions are not met.

The cluster icon and switch lamp will flash for several

seconds then extinguish when SSC disables due to

excess speed.

The cluster icon and switch lamp will flash then extin -

guish when SSC deactivates due to overheated brakes.

Traction Control System (TCS)

The TCS monitors the amount of wheel spin of each of the

driven wheels. If wheel spin is detected, the TCS may apply

brake pressure to the spinning wheel(s) and/or reduce

engine power to provide enhanced acceleration and

stability. A feature of the TCS, Brake Limited Differential (BLD)

functions similarly to a limited slip differential and controls

the wheel spin across a driven axle. If one wheel on a

driven axle is spinning faster than the other, the system

will apply the brake of the spinning wheel. This will allow

more engine torque to be applied to the wheel that is not

spinning. BLD may remain enabled even if TCS and

Electronic Stability Control (ESC) are in reduced modes.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the appropriate

actions to attempt to stop the sway.

NOTE:TSC cannot stop all trailers from swaying. Always use

caution when towing a trailer and follow the trailer tongue

weight recommendations

Úpage 173.

When TSC is functioning, the ESC Activation/Malfunction

Indicator Light will flash, the engine power may be reduced

and you may feel the brakes being applied to individual

wheels to attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial Off” or

“Full Off” modes.

WARNING!

SSC is only intended to assist the driver in controlling

vehicle speed when driving in off road conditions. The

driver must remain attentive to the driving conditions

and is responsible for maintaining a safe vehicle speed.

WARNING!

If TSC activates while driving, slow the vehicle down,

stop at the nearest safe location, and adjust the trailer

load to eliminate trailer sway.

23_DT_OM_EN_USC_t.book Page 268

Page 292 of 416

290SAFETY

Driver And Passenger Front Air Bag

Features

The Advanced Front Air Bag system has multistage driver

and front passenger air bags. This system provides output

appropriate to the severity and type of collision as

determined by the Occupant Restraint Controller (ORC),

which may receive information from the front impact

sensors (if equipped) or other system components.

The first stage inflator is triggered immediately during an

impact that requires air bag deployment. A low energy

output is used in less severe collisions. A higher energy

output is used for more severe collisions. This vehicle may be equipped with a driver and/or front

passenger seat belt buckle switch that detects whether

the driver or front passenger seat belt is buckled. The seat

belt buckle switch may adjust the inflation rate of the

Advanced Front Air Bags.

This vehicle may be equipped with driver and/or front

passenger seat track position sensors that may adjust the

inflation rate of the Advanced Front Air Bags based upon

seat position.

This vehicle is equipped with a right front passenger

Occupant Classification System (“OCS”) that is designed

to provide Passenger Advanced Front Air Bag output

appropriate to the occupant’s seated weight input, as

determined by the OCS.

Front Air Bag Operation

Front Air Bags are designed to provide additional

protection by supplementing the seat belts. Front air bags

are not expected to reduce the risk of injury in rear, side,

or rollover collisions. The front air bags will not deploy in all

frontal collisions, including some that may produce

substantial vehicle damage — for example, some pole

collisions, truck underrides, and angle offset collisions.

On the other hand, depending on the type and location of

impact, front air bags may deploy in crashes with little

vehicle front-end damage but that produce a severe initial

deceleration.

Because air bag sensors measure vehicle deceleration

over time, vehicle speed and damage by themselves are

not good indicators of whether or not an air bag should

have deployed.

Seat belts are necessary for your protection in all

collisions, and also are needed to help keep you in

position, away from an inflating air bag.

When the Occupant Restraint Controller (ORC) detects a

collision requiring the front air bags, it signals the inflator

units. A large quantity of non-toxic gas is generated to

inflate the front air bags.

The steering wheel hub trim cover and the upper

passenger side of the instrument panel separate and fold

out of the way as the air bags inflate to their full size. The

front air bags fully inflate in less time than it takes to blink

your eyes. The front air bags then quickly deflate while

helping to restrain the driver and front passenger.WARNING!

Being too close to the steering wheel or instrument

panel during front air bag deployment could cause

serious injury, including death. Air bags need room to

inflate. Sit back, comfortably extending your arms to

reach the steering wheel or instrument panel.

Never place a rear-facing child restraint in front of an

air bag. A deploying passenger front air bag can

cause death or serious injury to a child 12 years or

younger, including a child in a rear-facing child

restraint.

Never install a rear-facing child restraint in the front

seat of a vehicle. Only use a rear-facing child

restraint in the rear seat. If the vehicle does not have

a rear seat, do not transport a rear-facing child

restraint in that vehicle.

WARNING!

No objects should be placed over or near the air bag

on the instrument panel or steering wheel because

any such objects could cause harm if the vehicle is in

a collision severe enough to cause the air bag to

inflate.

Do not put anything on or around the air bag covers

or attempt to open them manually. You may damage

the air bags and you could be injured because the air

bags may no longer be functional. The protective

covers for the air bag cushions are designed to open

only when the air bags are inflating.

Relying on the air bags alone could lead to more

severe injuries in a collision. The air bags work with

your seat belt to restrain you properly. In some colli -

sions, air bags won’t deploy at all. Always wear your

seat belts even though you have air bags.

23_DT_OM_EN_USC_t.book Page 290

Page 293 of 416

SAFETY291

Occupant Classification System (OCS) —

Front Passenger Seat

The Occupant Classification System (OCS) is part of a

Federally regulated safety system for this vehicle. It is

designed to provide Passenger Advanced Front Air Bag

output appropriate to the occupant’s seated weight, as

determined by the OCS.

The Occupant Classification System (OCS) consists of the

following:

Occupant Restraint Controller (ORC)

Occupant Classification Module (OCM) and Sensor

located in the front passenger seat

Air Bag Warning Light Occupant Classification Module (OCM) And Sensor

The Occupant Classification Module (OCM) is located

underneath the front passenger seat. The Sensor is

located beneath the passenger seat cushion foam.

Any weight on the seat will be sensed by the Sensor.

The OCM uses input from the Sensor to determine the

front passenger’s most probable classification. The OCM

communicates this information to the ORC. The ORC may

reduce the inflation rate of the Passenger Advanced Front

Air Bag deployment based on occupant classification. In

order for the OCS to operate as designed, it is important

for the front passenger to be seated properly and properly

wearing the seat belt.

The OCS will NOT prevent deployment of the Passenger

Advanced Front Air Bag. The OCS may reduce the inflation

rate of the Passenger Advanced Front Air Bag if the OCS

estimates that:

The front passenger seat is unoccupied or has very

light objects on it; or

The front passenger seat is occupied by a small

passenger, including a child; or

The front passenger seat is occupied by a rear-facing

child restraint; or

The front passenger is not properly seated or his or her

weight is taken off of the seat for a period of time.

* It is possible for a child to be classified as an adult, allowing a full-power Passenger Advanced Front Air Bag deployment. Never allow children to ride in the front passenger seat and

never install a child restraint system, including a rear-facing child restraint, in the front passenger seat.

Front Passenger Seat Occupant Status Front Passenger Air Bag Output

Rear-facing child restraint Reduced-power deployment

Child, including a child in a forward-facing child restraint or booster seat* Reduced-power deployment OR full-power deployment

Properly seated adult Full-power deployment OR reduced-power deployment

Unoccupied seat Reduced-power deployment6

23_DT_OM_EN_USC_t.book Page 291