spare wheel Ram 2500 2011 User Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2011, Model line: 2500, Model: Ram 2500 2011Pages: 622

Page 489 of 622

Removing The Spare Tire

Remove the spare tire before attempting to jack up the

truck. Attach the wheel wrench to the jack extension tube.

Insert the tube through the access hole between the lower

tailgate and the top of the bumper and into the winchmechanism tube. Rotate the wheel wrench handle coun-

terclockwise until the spare tire is on the ground with

enough cable slack to allow you to pull it out from under

the vehicle. When the spare is clear, tilt the retainer at the

end of the cable and pull it through the center of the

wheel.

NOTE:Always stow the spare tire with the valve stem

facing the ground.

Jack and Tools (2500/3500 Series)

488 WHAT TO DO IN EMERGENCIES

Page 490 of 622

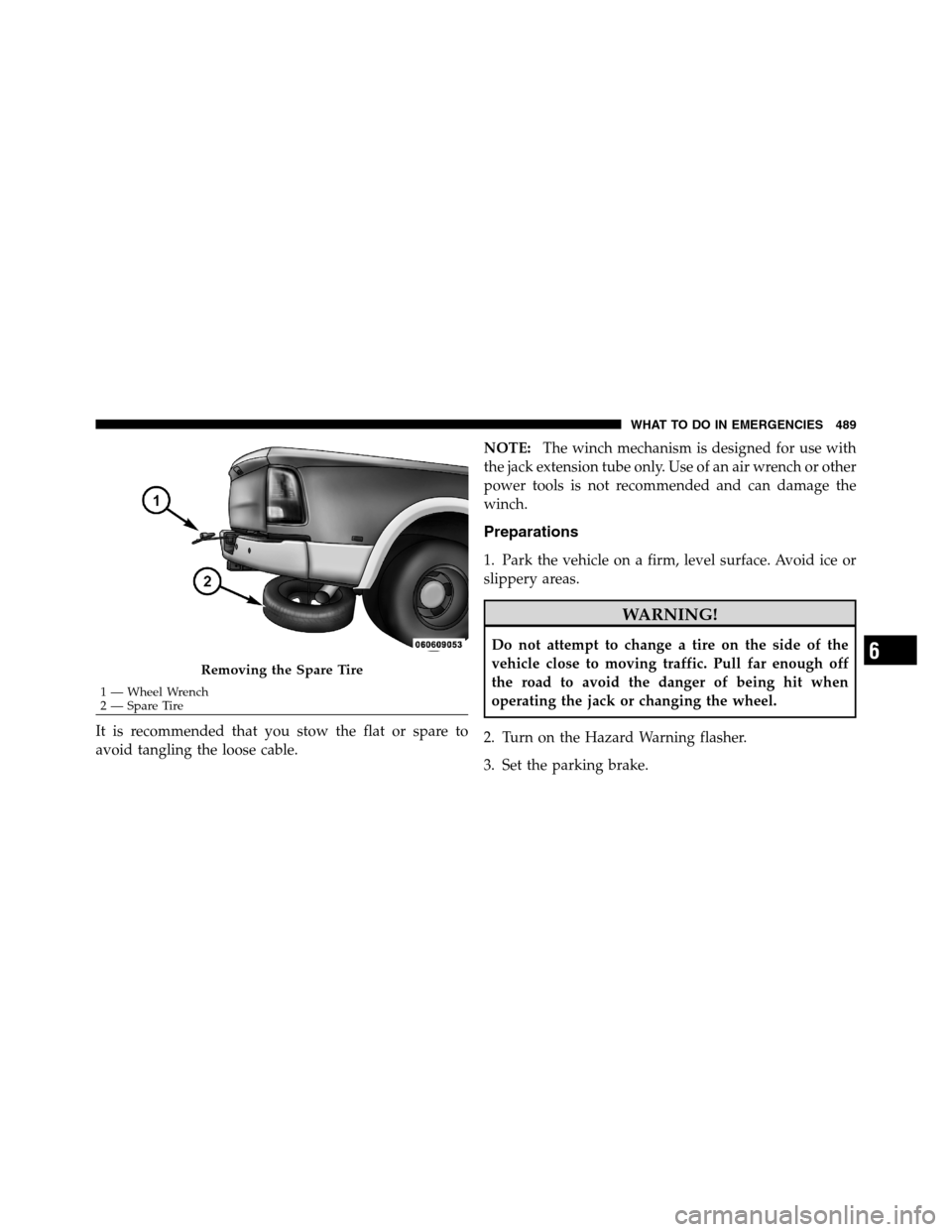

It is recommended that you stow the flat or spare to

avoid tangling the loose cable.NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Preparations

1. Park the vehicle on a firm, level surface. Avoid ice or

slippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

Removing the Spare Tire

1 — Wheel Wrench

2 — Spare Tire

6

WHAT TO DO IN EMERGENCIES 489

Page 492 of 622

WARNING! (Continued)

•Do not let anyone sit in the vehicle when it is on a

jack.

•Do not get under the vehicle when it is on a jack.

•Only use the jack in the positions indicated and

for lifting this vehicle during a tire change.

•If working on or near a roadway, be extremely

careful of motor traffic.

•To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

3. Placement of the jack:

•1500 Series Trucks

When changing a front wheel, place the scissors jack

under the rear portion of the lower control arm as shown

below.

Jack Warning Label

6

WHAT TO DO IN EMERGENCIES 491

Page 497 of 622

5. Remove the wheel nuts and pull the wheel off. On

single rear-wheel (SRW) trucks, install the spare wheel

and wheel nuts with the cone shaped end of the wheel

nuts toward the wheel. On 3500 dual rear-wheel models

(DRW) the wheel nuts are a two-piece assembly with a

flat face. Lightly tighten the wheel nuts. To avoid the risk

of forcing the vehicle off the jack, do not fully tighten the

wheel nuts until the vehicle has been lowered.

6. Using the wheel wrench, finish tightening the wheel

nuts using a crisscross pattern. The correct wheel nut

tightness is 130 ft lbs (177 N·m) torque (1500 Series), 135 ft

lbs (183 N·m) torque for 2500/3500 single-rear wheel

(SRW) models, and 145 ft lbs (197 N·m) for 3500 dual

rear-wheel models. If in doubt about the correct tight-

ness, have them checked with a torque wrench by your

authorized dealer or at a service station.WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install the wheel center cap and remove the wheel

blocks. Do not install chrome or aluminum wheel center

caps on the spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the bottle

jack will not lower by turning the dial (thumbwheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

496 WHAT TO DO IN EMERGENCIES

Page 500 of 622

Slots in the wheels will assist in properly orienting the

inner and outer wheels. Align these slots when assem-

bling the wheels for best access to the tire valve on the

inner wheel. The tires of both dual wheels must be

completely off the ground when tightening, to ensure

wheel centering and maximum wheel clamping.Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to cor-

rectly tighten the lug nuts. Also, when it is necessary to

remove and install dual rear wheels, use a proper vehicle

lifting device.

NOTE:When installing a spare tire as part of a dual rear

wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front

location. The correct direction of rotation for dual tire

installations must also be observed.

Oiling Location6

WHAT TO DO IN EMERGENCIES 499

Page 501 of 622

These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the numbered sequence to a

snug fit.

2. Retighten the wheel nuts in the same sequence to the

torques listed in the table. Go through the sequence asecond time to verify that specific torque has been

achieved. Retighten to specifications at 100 miles

(160 km) and after 500 miles (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

To Stow The Flat Or Spare

NOTE:Vehicles equipped with aluminum wheels can-

not be stored under the vehicle because the wheel

retainer will not fit through the wheel pilot hole. Secure

the flat tire in the bed of the truck.Have the flat tire

repaired or replaced immediately.

Tightening Pattern

500 WHAT TO DO IN EMERGENCIES

Page 502 of 622

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced immedi-

ately.

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or click three or

four times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improperly

so please follow the procedures in this section carefully.

6

WHAT TO DO IN EMERGENCIES 501

Page 557 of 622

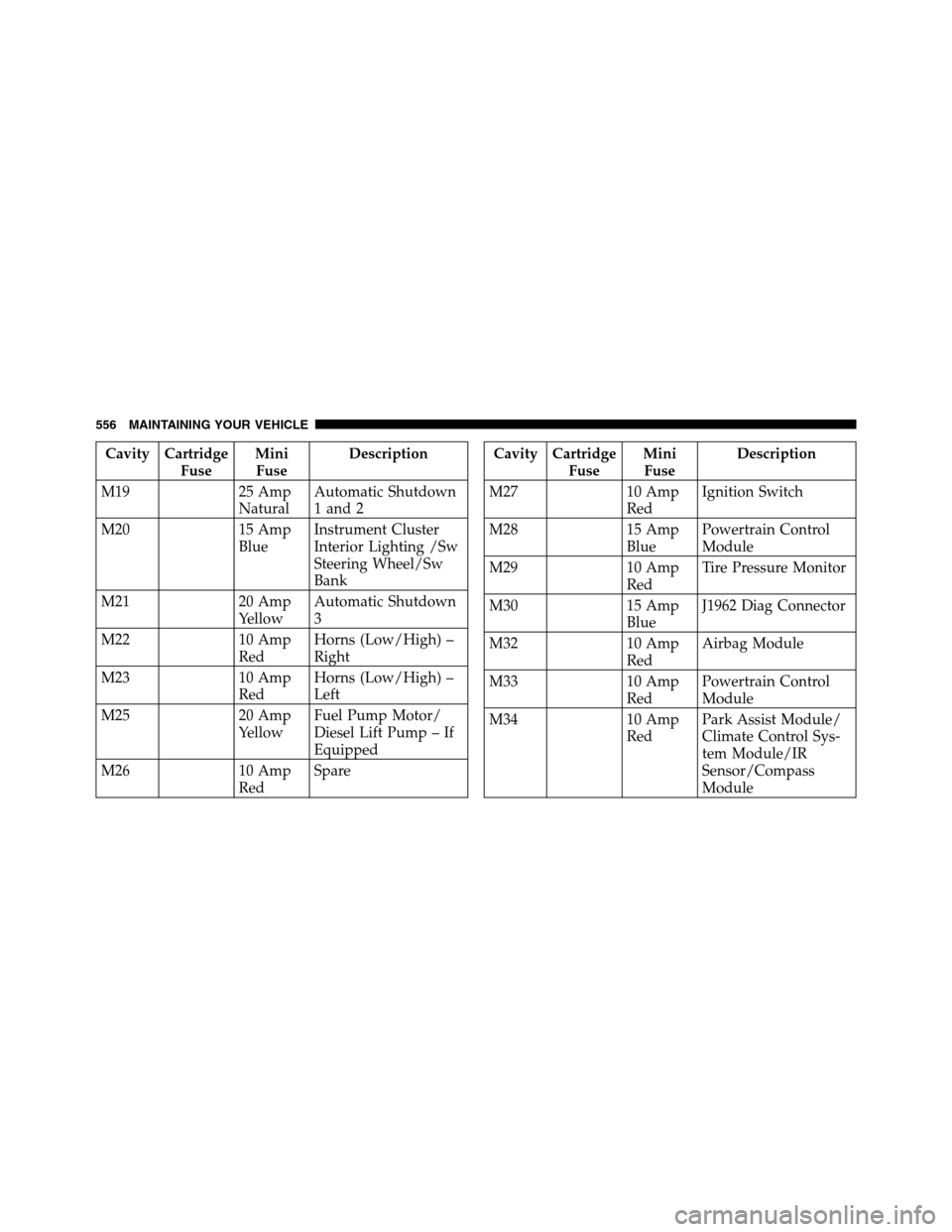

Cavity Cartridge

FuseMini

FuseDescription

M19 25 Amp

NaturalAutomatic Shutdown

1 and 2

M20 15 Amp

BlueInstrument Cluster

Interior Lighting /Sw

Steering Wheel/Sw

Bank

M21 20 Amp

YellowAutomatic Shutdown

3

M22 10 Amp

RedHorns (Low/High) –

Right

M23 10 Amp

RedHorns (Low/High) –

Left

M25 20 Amp

YellowFuel Pump Motor/

Diesel Lift Pump – If

Equipped

M26 10 Amp

RedSpareCavity Cartridge

FuseMini

FuseDescription

M27 10 Amp

RedIgnition Switch

M28 15 Amp

BluePowertrain Control

Module

M29 10 Amp

RedTire Pressure Monitor

M30 15 Amp

BlueJ1962 Diag Connector

M32 10 Amp

RedAirbag Module

M33 10 Amp

RedPowertrain Control

Module

M34 10 Amp

RedPark Assist Module/

Climate Control Sys-

tem Module/IR

Sensor/Compass

Module

556 MAINTAINING YOUR VEHICLE