fuel filter Ram 2500 2016 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 2500, Model: Ram 2500 2016Pages: 406, PDF Size: 1.84 MB

Page 137 of 406

3. Open the water drain valve, and let any accumulatedwater drain.

4. Close the water drain valve.

5. Remove bottom cover using a strap wrench. Rotate counterclockwise for removal. Remove the used o-ring

and discard it.

6. Remove the used filter cartridge from the housing and dispose of it according to your local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install a new o-ring into the ring groove on the filter housing and lubricate with clean engine oil.

NOTE: WIF (Water In Fuel) sensor is re-usable. Service

kit comes with new o-ring for filter canister and WIF

sensor.Priming If The Engine Has Run Out Of Fuel

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

1. Add a substantial amount of fuel to the tank, approxi- mately 2 to 5 gal (8L to 19L).

2. Press ignition switch twice without your foot on brake to put vehicle in Run position. This will activate the in

tank fuel pump for approximately 30 seconds. Repeat

this process twice.

3. Start the engine using the “Normal Starting” proce- dure. Refer to “Starting Procedures” in “Starting and

Operating” for further information.

5

MAINTAINING YOUR VEHICLE 135

Page 138 of 406

CAUTION!

The starter motor will engage for approximately 30

seconds at a time. Allow two minutes between crank-

ing intervals.

NOTE: The engine may run rough until the air is forced

from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel blending

agent. They can be unstable under certain conditions

and be hazardous or explosive when mixed with

diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or gasoline, the

use of these fuels can cause damage to the fuel

system.

NOTE:

• We recommend you use a blend of up to 5% biodiesel,

that meets ASTM specification D-975 with your diesel

engine. Use of biodiesel mixture in excess of 20% can

negatively impact the fuel filter’s ability to separate

water from the fuel, resulting in high pressure fuel

system corrosion or damage.

• In addition, commercially available fuel additives are

not necessary for the proper operation of your diesel

engine.

136 MAINTAINING YOUR VEHICLE

Page 148 of 406

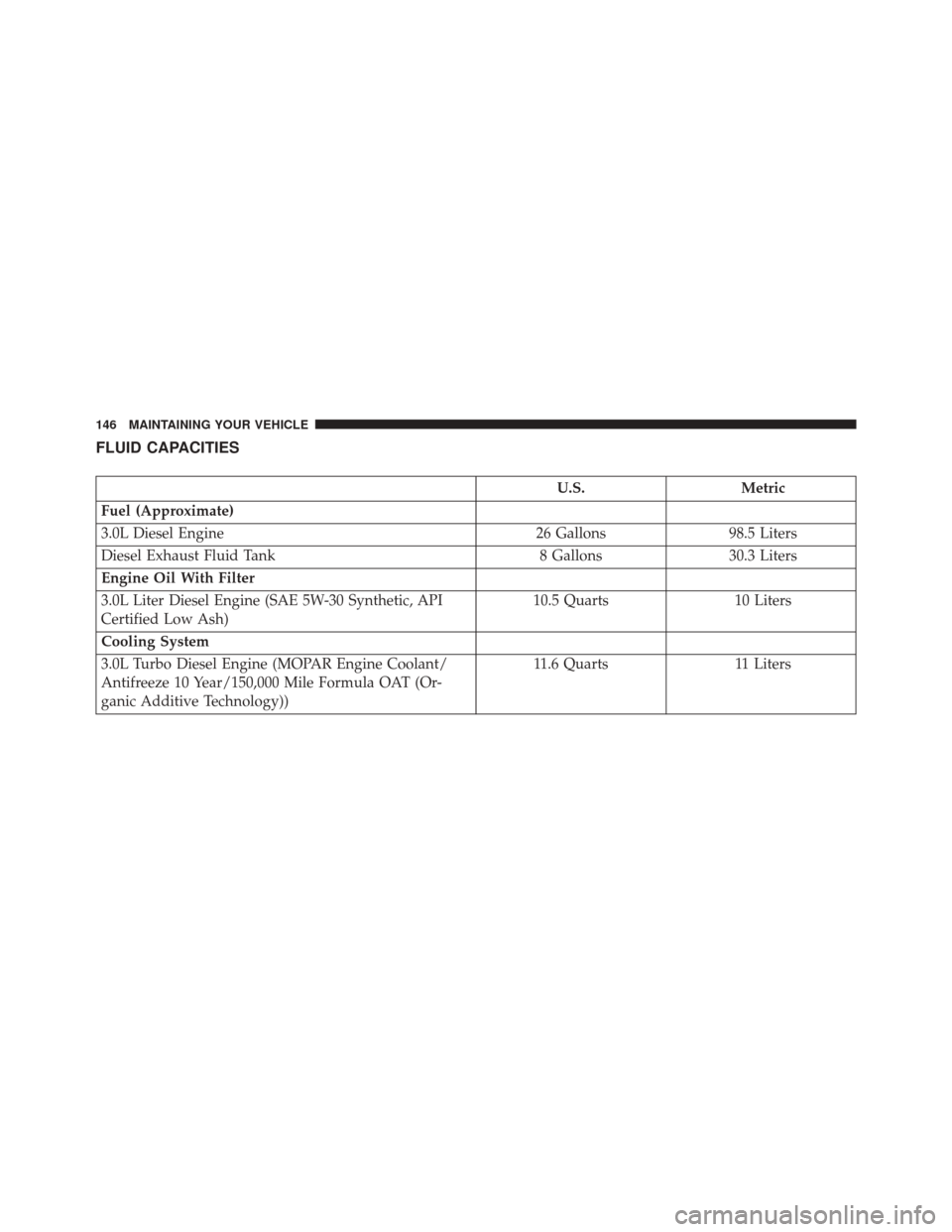

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

3.0L Diesel Engine 26 Gallons98.5 Liters

Diesel Exhaust Fluid Tank 8 Gallons30.3 Liters

Engine Oil With Filter

3.0L Liter Diesel Engine (SAE 5W-30 Synthetic, API

Certified Low Ash) 10.5 Quarts

10 Liters

Cooling System

3.0L Turbo Diesel Engine (MOPAR Engine Coolant/

Antifreeze 10 Year/150,000 Mile Formula OAT (Or-

ganic Additive Technology)) 11.6 Quarts

11 Liters

146 MAINTAINING YOUR VEHICLE

Page 149 of 406

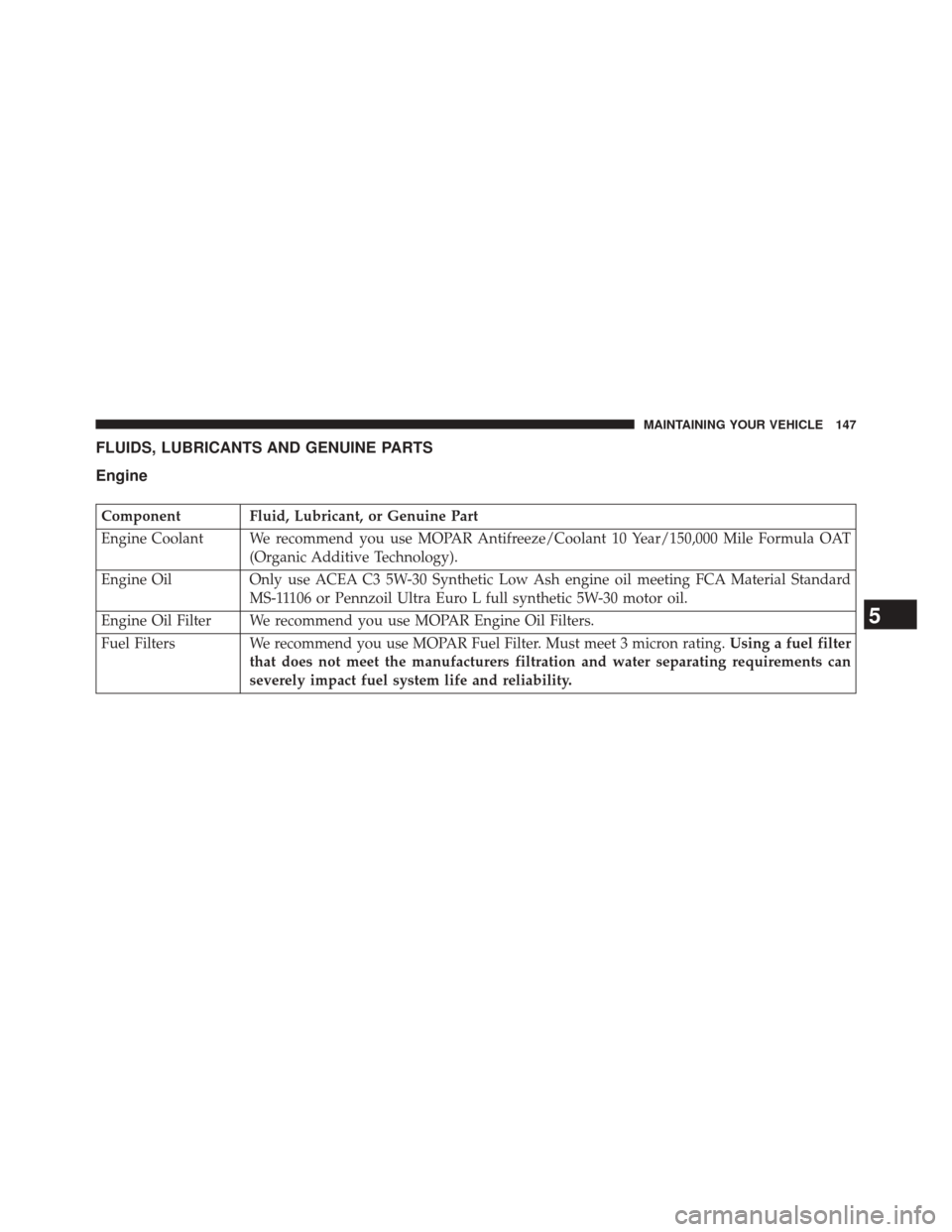

FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use MOPAR Antifreeze/Coolant 10 Year/150,000 Mile Formula OAT(Organic Additive Technology).

Engine Oil Only use ACEA C3 5W-30 Synthetic Low Ash engine oil meeting FCA Material Standard

MS-11106 or Pennzoil Ultra Euro L full synthetic 5W-30 motor oil.

Engine Oil Filter We recommend you use MOPAR Engine Oil Filters.

Fuel Filters We recommend you use MOPAR Fuel Filter. Must meet 3 micron rating. Using a fuel filter

that does not meet the manufacturers filtration and water separating requirements can

severely impact fuel system life and reliability.

5

MAINTAINING YOUR VEHICLE 147

Page 150 of 406

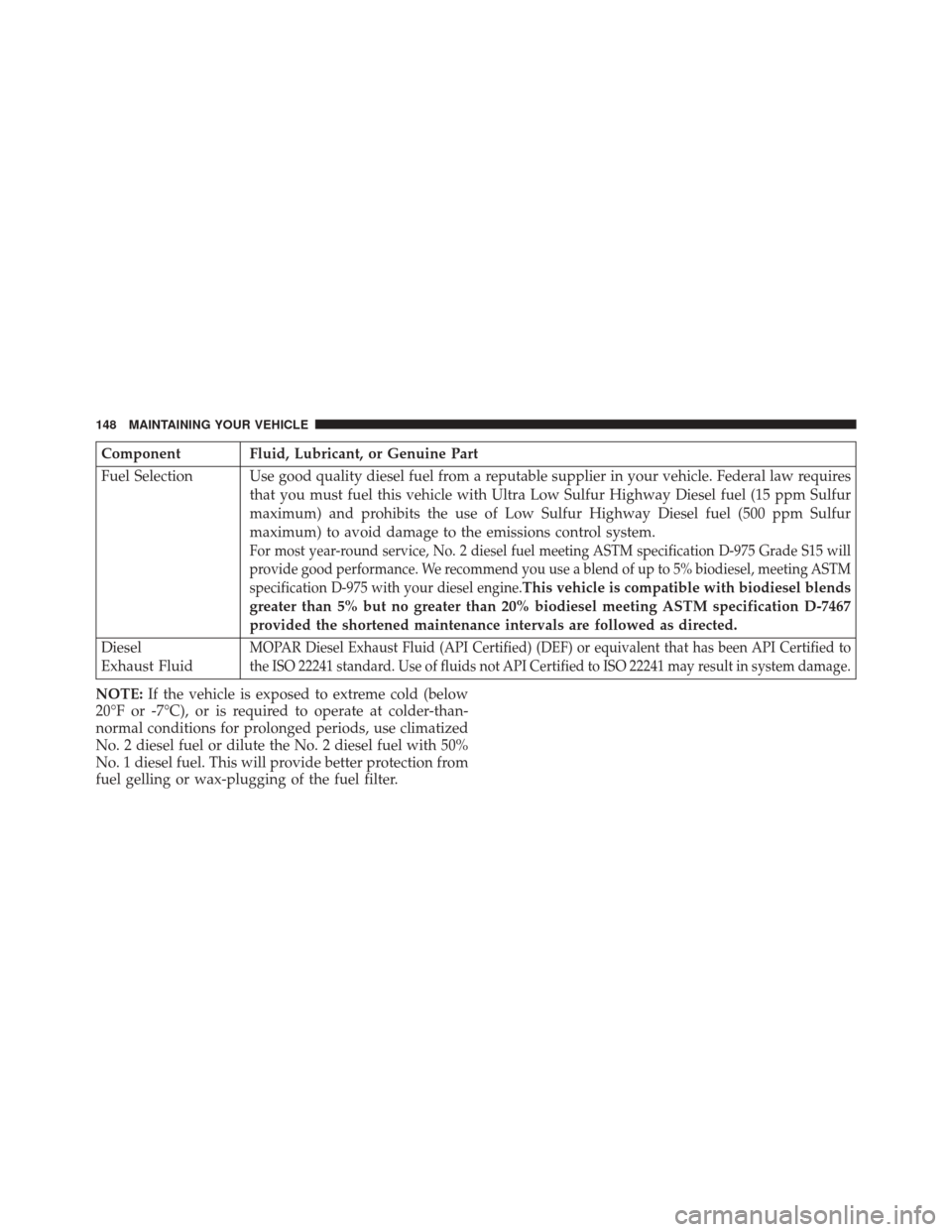

Component Fluid, Lubricant, or Genuine Part

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requiresthat you must fuel this vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur

maximum) and prohibits the use of Low Sulfur Highway Diesel fuel (500 ppm Sulfur

maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will

provide good performance. We recommend you use a blend of up to 5% biodiesel, meeting ASTM

specification D-975 with your diesel engine.

This vehicle is compatible with biodiesel blends

greater than 5% but no greater than 20% biodiesel meeting ASTM specification D-7467

provided the shortened maintenance intervals are followed as directed.

Diesel

Exhaust Fluid

MOPAR Diesel Exhaust Fluid (API Certified) (DEF) or equivalent that has been API Certified to

the ISO 22241 standard. Use of fluids not API Certified to ISO 22241 may result in system damage.

NOTE: If the vehicle is exposed to extreme cold (below

20°F or -7°C), or is required to operate at colder-than-

normal conditions for prolonged periods, use climatized

No. 2 diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection from

fuel gelling or wax-plugging of the fuel filter.

148 MAINTAINING YOUR VEHICLE

Page 155 of 406

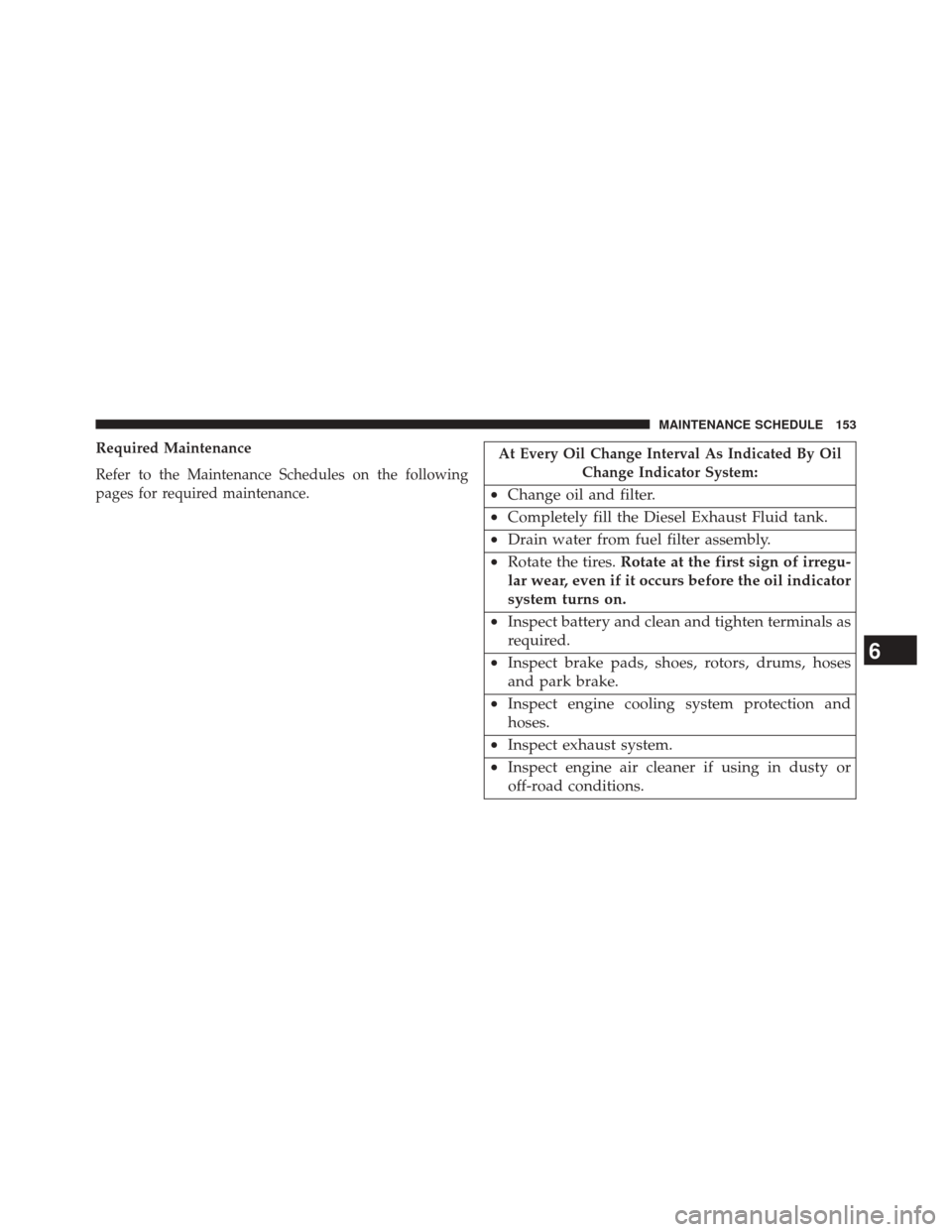

Required Maintenance

Refer to the Maintenance Schedules on the following

pages for required maintenance.At Every Oil Change Interval As Indicated By OilChange Indicator System:

•Change oil and filter.

• Completely fill the Diesel Exhaust Fluid tank.

• Drain water from fuel filter assembly.

• Rotate the tires. Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

• Inspect battery and clean and tighten terminals as

required.

• Inspect brake pads, shoes, rotors, drums, hoses

and park brake.

• Inspect engine cooling system protection and

hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or

off-road conditions.

6

MAINTENANCE SCHEDULE 153

Page 157 of 406

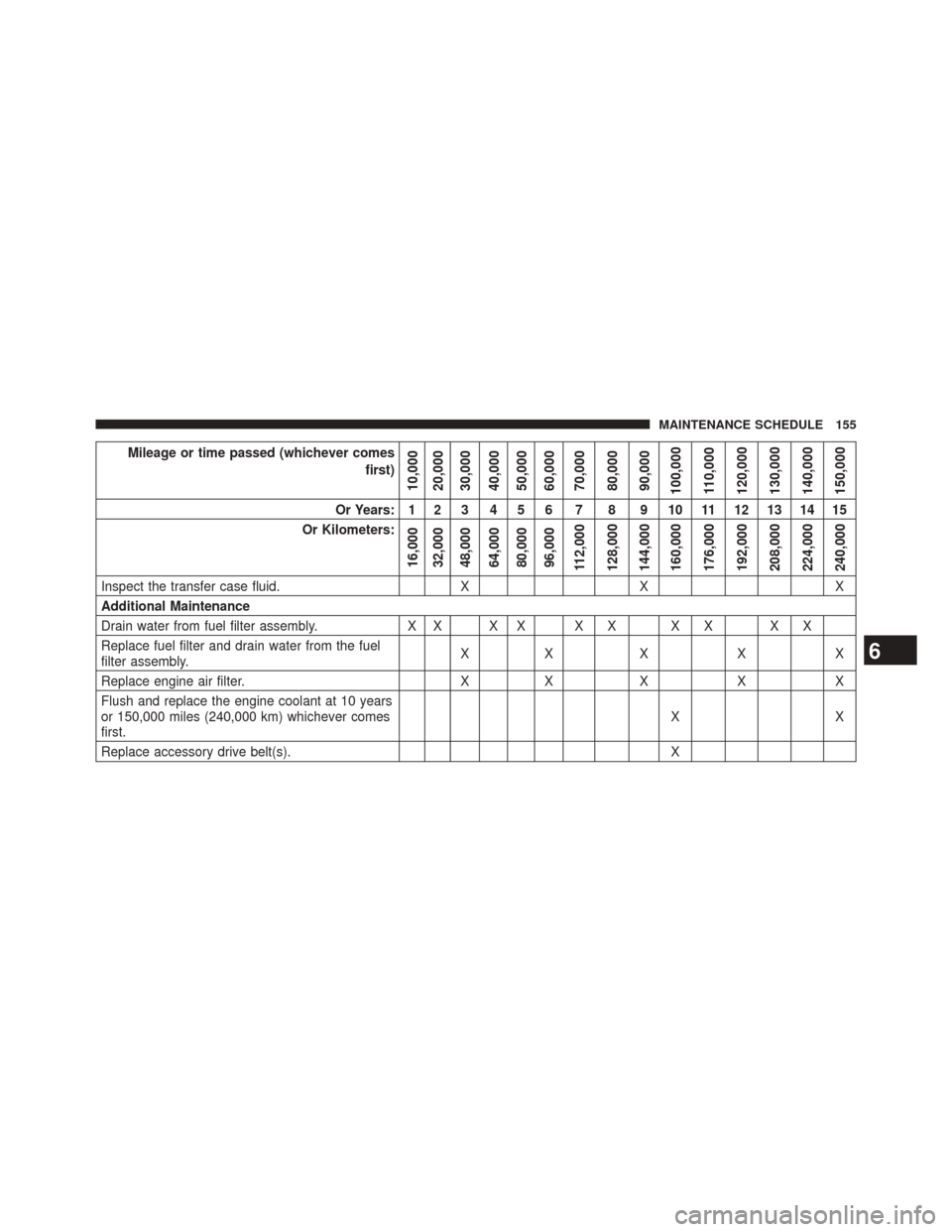

Mileage or time passed (whichever comesfirst)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Inspect the transfer case fluid. XX X

Additional Maintenance

Drain water from fuel filter assembly. X X X X X X X X X X

Replace fuel filter and drain water from the fuel

filter assembly. XX X X X

Replace engine air filter. XX X X X

Flush and replace the engine coolant at 10 years

or 150,000 miles (240,000 km) whichever comes

first. XX

Replace accessory drive belt(s). X

6

MAINTENANCE SCHEDULE 155

Page 160 of 406

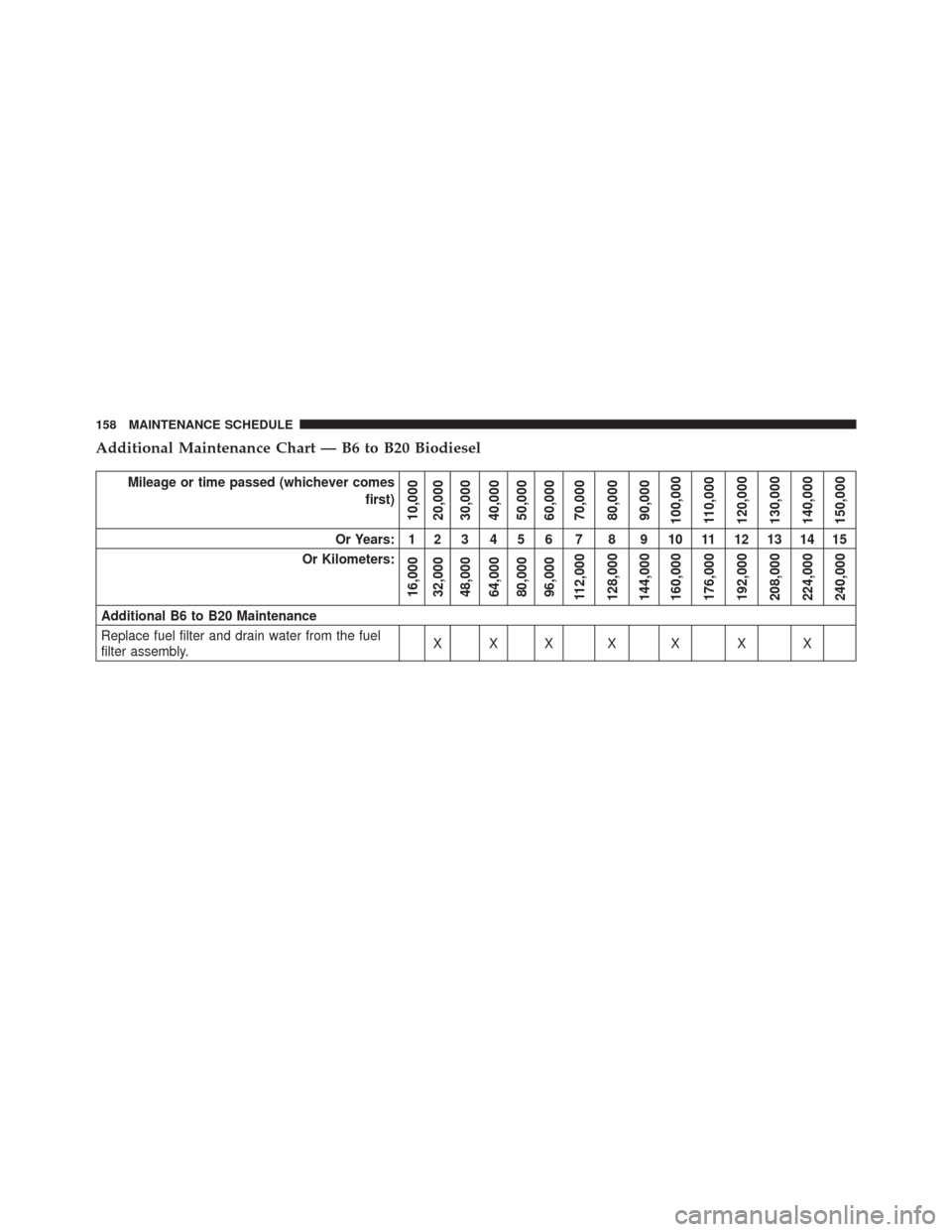

Additional Maintenance Chart — B6 to B20 Biodiesel

Mileage or time passed (whichever comesfirst)

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

16,000

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional B6 to B20 Maintenance

Replace fuel filter and drain water from the fuel

filter assembly. XXX X X X X

158 MAINTENANCE SCHEDULE

Page 184 of 406

▫Diesel Exhaust Fluid (DEF) Fault Warning

Messages .......................... .250

▫ RAM Active Air System .................252 ▫

Fuel Filter Life Reset ...................252

▫ Oil Life Reset ....................... .254

182 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 222 of 406

Water in Fuel Indicator Light — If Equipped

Yellow TelltaleLight What It Means

Water in Fuel Indicator Light

The “Water In Fuel Indicator Light” will illuminate when there is water detected in the fuel

filters. If this light remains on, DO NOT start the vehicle before you drain the water from

the fuel filters to prevent engine damage. Refer to “Maintenance Procedures” in “Maintain-

ing Your Vehicle” for further information.

Low Diesel Exhaust Fluid (DEF) Indicator Light — If Equipped

Yellow Telltale

Light What It Means

Low Diesel Exhaust Fluid (DEF) Indicator Light

The Low Diesel Exhaust Fluid (DEF) Indicator will illuminate if the vehicle is low on Diesel

Exhaust Fluid (DEF). Refer to “Starting And Operating” for further information.

220 UNDERSTANDING YOUR INSTRUMENT PANEL