fuel filter Ram 2500 2016 Diesel Supplement

[x] Cancel search | Manufacturer: RAM, Model Year: 2016, Model line: 2500, Model: Ram 2500 2016Pages: 406, PDF Size: 1.84 MB

Page 348 of 406

NOTE:Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately dis-

carded, can present a problem to the environment. Con-

tact an authorized dealer, service station, or government

agency for advice on recycling programs and for where

used fluids and filters can be properly disposed of in

your area.

Drain the fuel/water separator filters when the “Water In

Fuel Indicator Light” is ON. Within 10 minutes of vehicle

shutdown, turn the engine mounted filter drain valve

(located on the side of the filter assembly) counterclock-

wise 1/4 turn, and turn the under body mounted filter

drain valve (located on the bottom of the filter assembly)

counterclock wise 1 full turn. Then turn the ignition

switch to the ON position, and allow any accumulated

water to drain. Leave the drain valve open until all water

and contaminants have been removed. When clean fuel is

visible, close the drain valves by turning them fully

clockwise, and turn the ignition switch to OFF. If more than a couple ounces/milliliters of fuel have been

drained, follow the directions for “Priming If The Engine

Has Run Out Of Fuel.”

Engine Mounted Fuel Filter Replacement

NOTE:

•

Using a fuel filter that does not meet the manufactur-

er’s filtration and water separating requirements can

severely impact fuel system life and reliability.

• The engine mounted filter housing is equipped with a

No-Filter-No-Run (NFNR) feature. Engine will not run

if:

1. No filter is installed.

2. Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle will run.

346 MAINTAINING YOUR VEHICLE

Page 349 of 406

CAUTION!

•Diesel fuel will damage blacktop paving surfaces.

Drain the filter into an appropriate container.

• Do not prefill the fuel filter when installing a new

fuel filter. There is a possibility debris could be

introduced into the fuel filter during this action. It

is best to install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve 1/4 turn counterclockwise and completely drain fuel and water into the ap-

proved container.

4. Close the water drain valve.

Engine Mounted Fuel Filter Assembly

1 — Drain Valve7

MAINTAINING YOUR VEHICLE 347

Page 350 of 406

5. Remove lid using a socket or strap wrench. Rotatecounterclockwise for removal. Remove used o-ring

and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE: Do not remove cartridge from bag until you reach

this step in order to keep cartridge clean. 10. Push down on the cartridge to ensure it is properly

seated. Do not pre-fill the filter housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not overtighten the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of Fuel.” Then start the

engine and confirm there are no leaks.

Underbody Mounted Fuel Filter Replacement

NOTE:

•Using a fuel filter that does not meet the manufactur-

er’s filtration and water separating requirements can

severely impact fuel system life and reliability.

348 MAINTAINING YOUR VEHICLE

Page 351 of 406

•The underbody mounted filter housing will cause the

engine not to run if:

1. No filter is installed.CAUTION!

• Diesel fuel will damage blacktop paving surfaces.

Drain the filter into an appropriate container.

• Do not prefill the fuel filter when installing a new

fuel filter. There is a possibility debris could be

introduced into the fuel filter during this action. It

is best to install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve 1 full turn counterclock- wise and completely drain fuel and water into the

approved container.

4. Close the water drain valve.

Underbody Mounted Fuel Filter Assembly

1 — Drain Valve 2 — WIF Sensor

7

MAINTAINING YOUR VEHICLE 349

Page 352 of 406

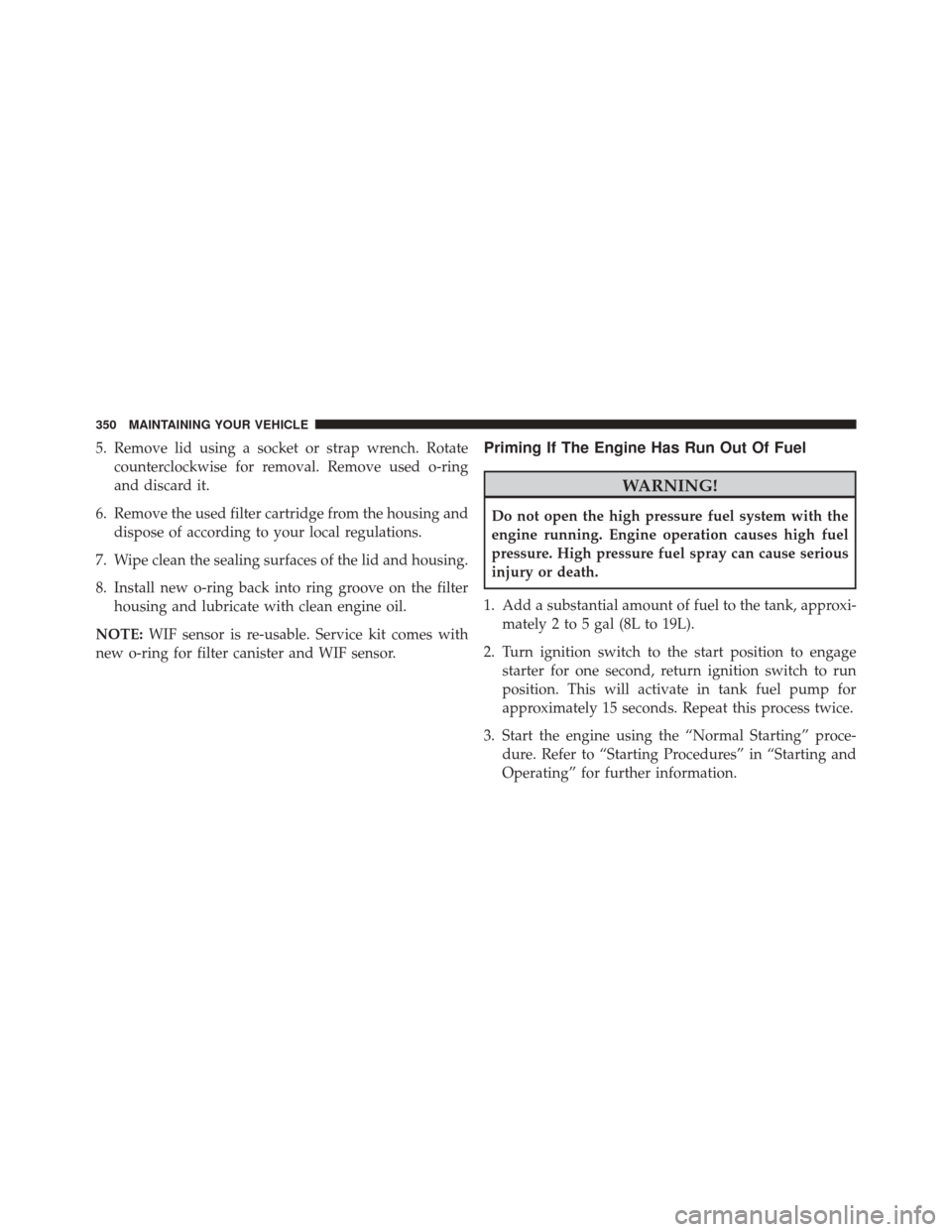

5. Remove lid using a socket or strap wrench. Rotatecounterclockwise for removal. Remove used o-ring

and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine oil.

NOTE: WIF sensor is re-usable. Service kit comes with

new o-ring for filter canister and WIF sensor.Priming If The Engine Has Run Out Of Fuel

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

1. Add a substantial amount of fuel to the tank, approxi- mately 2 to 5 gal (8L to 19L).

2. Turn ignition switch to the start position to engage starter for one second, return ignition switch to run

position. This will activate in tank fuel pump for

approximately 15 seconds. Repeat this process twice.

3. Start the engine using the “Normal Starting” proce- dure. Refer to “Starting Procedures” in “Starting and

Operating” for further information.

350 MAINTAINING YOUR VEHICLE

Page 354 of 406

•Use of biodiesel mixture in excess of 20% can nega-

tively impact the fuel filter’s ability to separate water

from the fuel, resulting in high pressure fuel system

corrosion or damage.

• Ethanol blends are not recommended or approved for

use with your Cummins diesel engine.

• In addition, commercially available fuel additives are

not necessary for the proper operation of your Cum-

mins diesel engine.

Intervention Regeneration Strategy — Message

Process Flow

The Cummins diesel engine meets all EPA Heavy Duty

Diesel Engine Emissions Standards, resulting in one of

the lowest emitting diesel engines ever produced.

To achieve these emissions standards, your vehicle is

equipped with a state-of-the-art engine and exhaust

system. The engine and exhaust after-treatment system work together to achieve the EPA Heavy Duty Diesel

Engine Emissions Standards. These systems are seam-

lessly integrated into your vehicle and managed by the

Cummins Powertrain Control Module (PCM). The PCM

manages engine combustion to allow the exhaust sys-

tem’s catalyst to trap and burn Particulate Matter (PM)

pollutants, with no input or interaction on your part.

Additionally, your vehicle has the ability to alert you to

additional maintenance required on your truck or engine.

Refer to “Electronic Vehicle Information Center (EVIC)”

or “Driver Information Display (DID)” in “Understand-

ing Your Instrument Panel” for further information.

WARNING!

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

(Continued)

352 MAINTAINING YOUR VEHICLE

Page 375 of 406

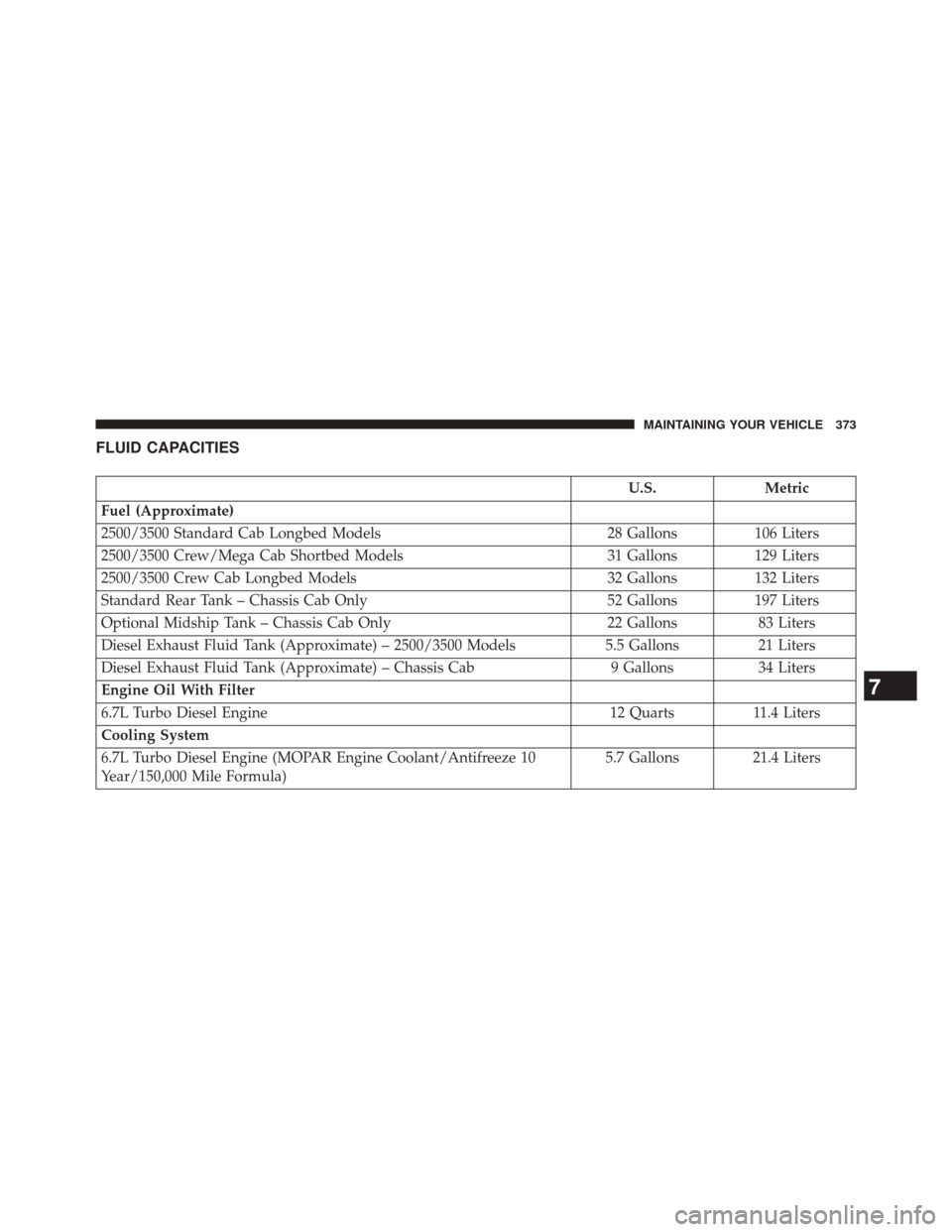

FLUID CAPACITIES

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons83 Liters

Diesel Exhaust Fluid Tank (Approximate) – 2500/3500 Models 5.5 Gallons21 Liters

Diesel Exhaust Fluid Tank (Approximate) – Chassis Cab 9 Gallons34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts11.4 Liters

Cooling System

6.7L Turbo Diesel Engine (MOPAR Engine Coolant/Antifreeze 10

Year/150,000 Mile Formula) 5.7 Gallons

21.4 Liters

7

MAINTAINING YOUR VEHICLE 373

Page 377 of 406

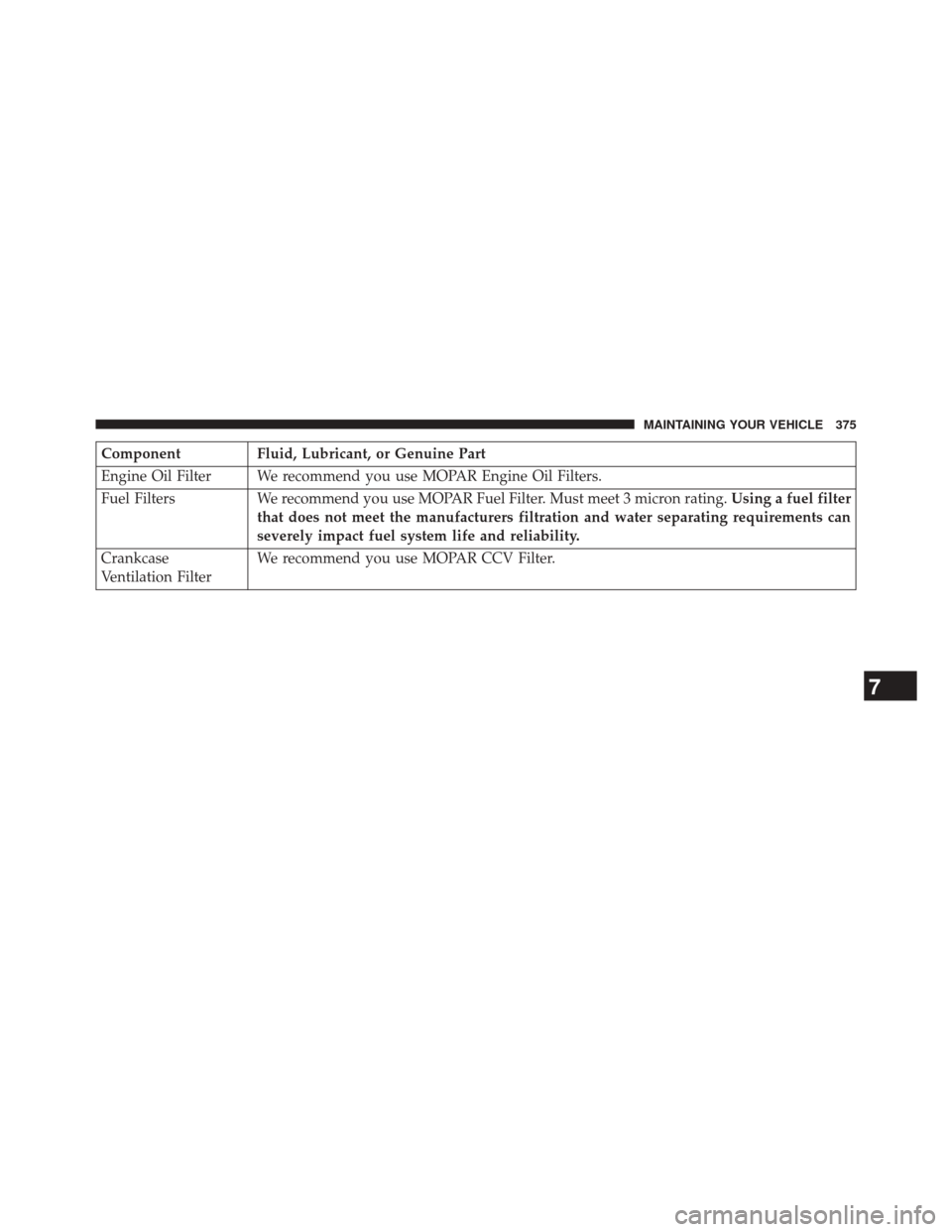

ComponentFluid, Lubricant, or Genuine Part

Engine Oil Filter We recommend you use MOPAR Engine Oil Filters.

Fuel Filters We recommend you use MOPAR Fuel Filter. Must meet 3 micron rating. Using a fuel filter

that does not meet the manufacturers filtration and water separating requirements can

severely impact fuel system life and reliability.

Crankcase

Ventilation Filter We recommend you use MOPAR CCV Filter.

7

MAINTAINING YOUR VEHICLE 375

Page 378 of 406

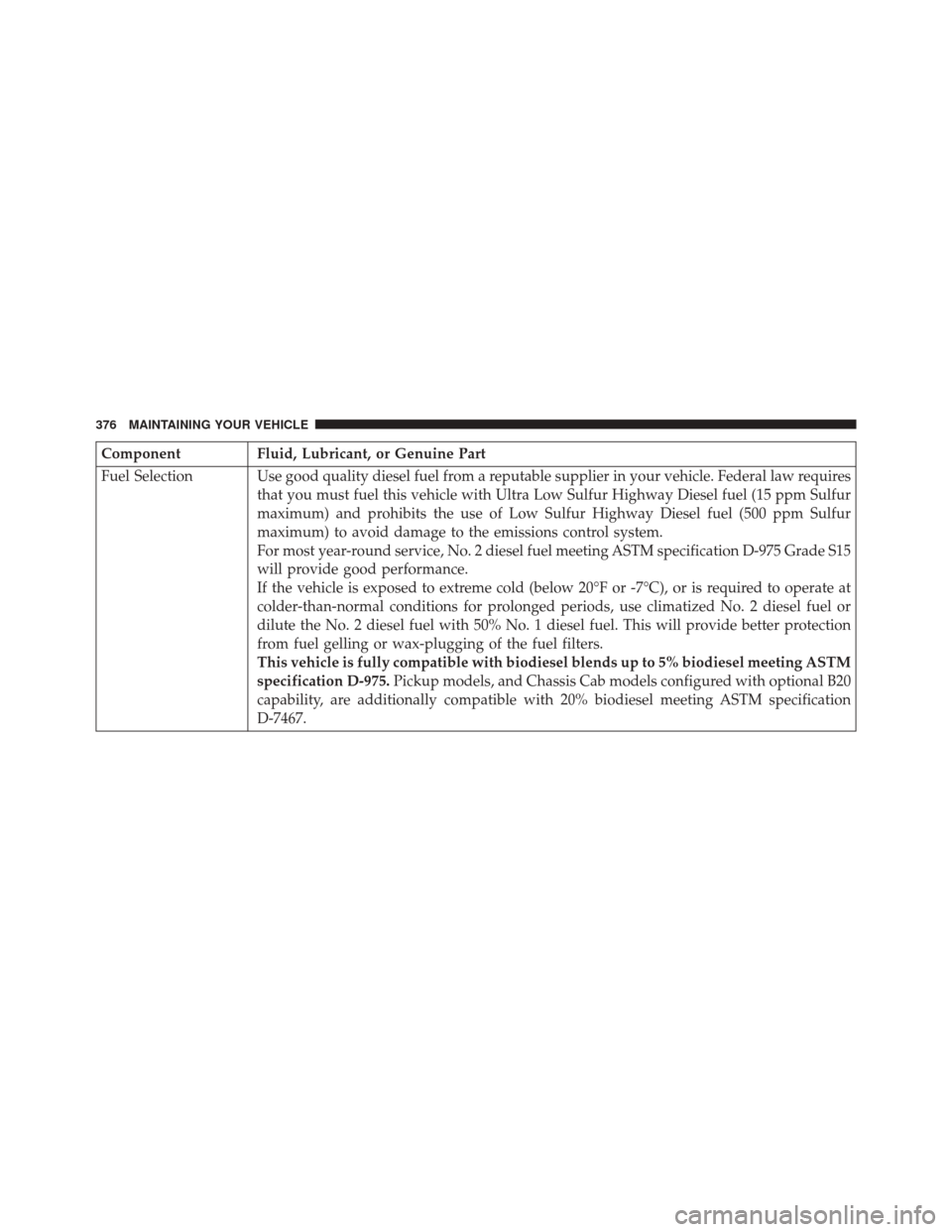

ComponentFluid, Lubricant, or Genuine Part

Fuel Selection Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur

maximum) and prohibits the use of Low Sulfur Highway Diesel fuel (500 ppm Sulfur

maximum) to avoid damage to the emissions control system.

For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15

will provide good performance.

If the vehicle is exposed to extreme cold (below 20°F or -7°C), or is required to operate at

colder-than-normal conditions for prolonged periods, use climatized No. 2 diesel fuel or

dilute the No. 2 diesel fuel with 50% No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

This vehicle is fully compatible with biodiesel blends up to 5% biodiesel meeting ASTM

specification D-975.Pickup models, and Chassis Cab models configured with optional B20

capability, are additionally compatible with 20% biodiesel meeting ASTM specification

D-7467.

376 MAINTAINING YOUR VEHICLE

Page 382 of 406

MAINTENANCE SCHEDULE — DIESEL ENGINE

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accuracy

of the oil level reading. Add oil only when the level is at

or below the ADD or MIN mark.

Once A Month

• Inspect the batteries, and clean and tighten the termi-

nals as required. •

Check the fluid levels of the coolant reservoir, brake

master cylinder, and automatic transmission (if

equipped), and add as needed.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect engine air filter.

• Check the coolant level, hoses, and clamps.

• Lubricate outer tie rod ends.

Inspection and service should also be performed anytime

a malfunction is observed or suspected. Retain all re-

ceipts.

380 MAINTENANCE SCHEDULE